3 minute read

New Concrete Form Ponels Cut Costs, Speed Job

filler panels by buying lr/g-inch fir plywood from thcir regular source and purchasing the panel hardware from their FormCo jobber. Since no walers or nails are needed and there is no protruding surface hardware, the materials require about 75/o less storage and truck space than average forms.

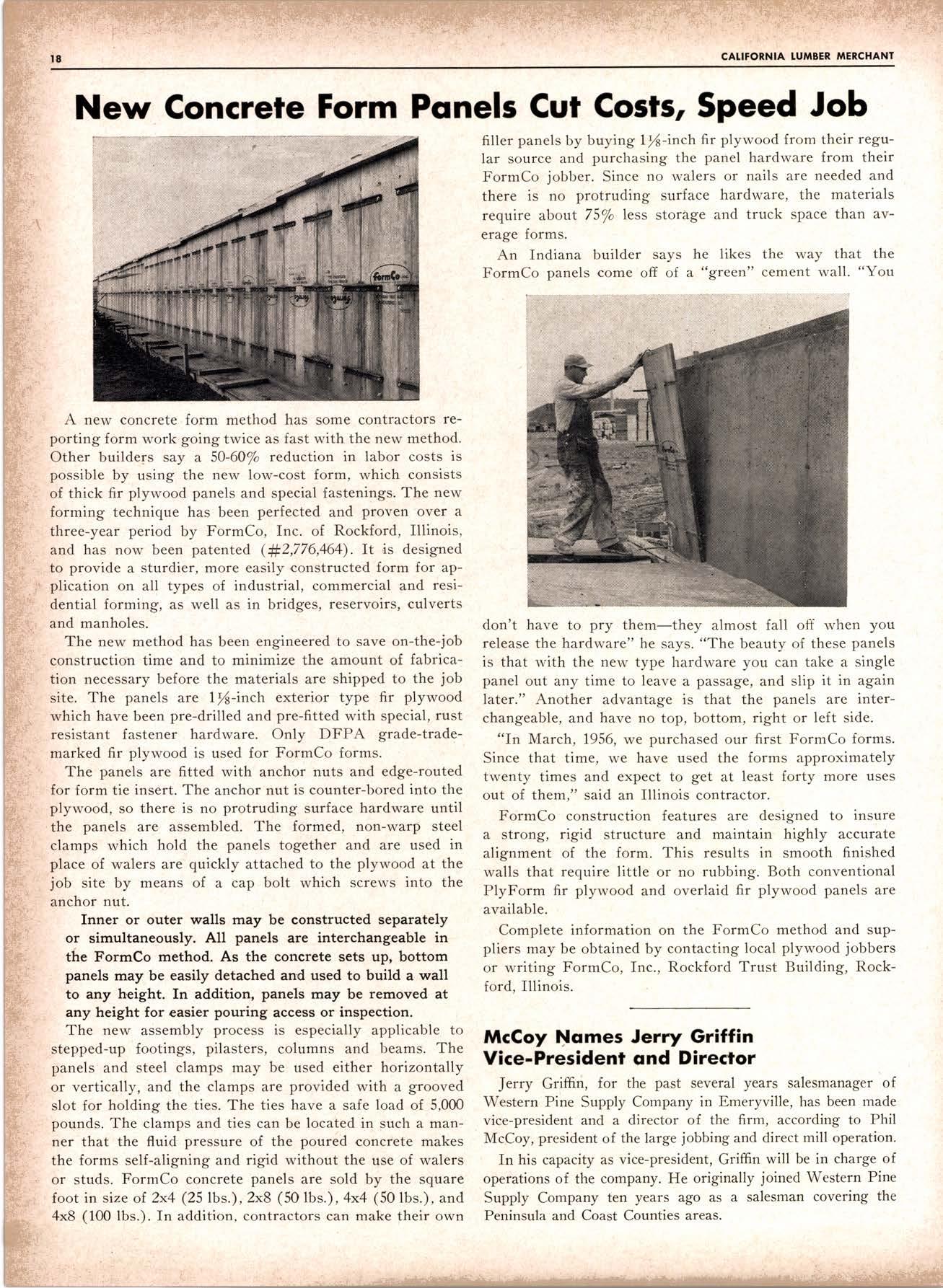

An Indiana builder says he likes the way that the FormCo panels come off of a "green" cement wall. "You fnner or outer walls may be constructed separately or simultaneously. All panels are interchangeable in the FormCo method. As the concrete sets up, bottom panels may be easily detached and used to build a wall to any height. In addition, panels may be removed at any height for easier pouring access or inspection.

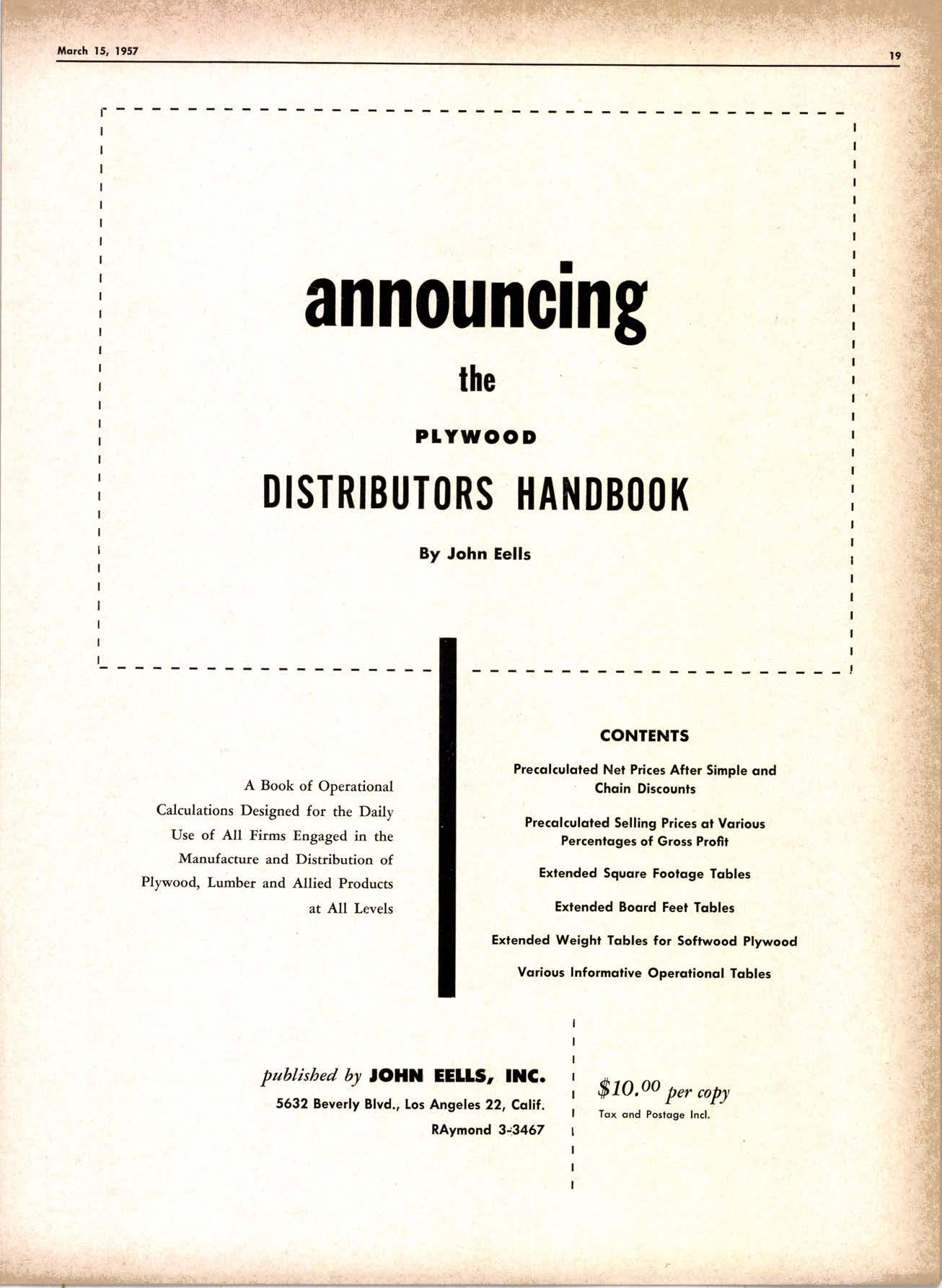

A new concrete form method has some contractors reporting form work going twice as fast with the new method. Other builders say a 50-6A% reduction in labor costs is possible by using the new low-cost form, which consists of thick fir plywood panels and special fastenings. The new forming technique has been perfected and proven over a three-year period by FormCo, Inc. of Rockford, Illinois, and has now been patented (#2,776,464). It is designed to provide a sturdier, more easily constructed form for application on all types of industrial, commercial and residential forming, as well as in bridges, reservoirs, culverts and manholes.

The new method has been engineered to save on-the-job construction time and to minimize the amount of fabrication necessary before the materials are shipped to the job site. The panels are |r/s-inch exterior type fir plywood which have been pre-drilled and pre-fitted with special, rust resistant fastener hardware. Only DFPA grade-trademarked fir plywood is used for FormCo forms.

The panels are fitted with anchor nuts and edge-routed for form tie insert. The an,chor nut is counter-bored into the plywood, so there is no protruding surface hardware until the panels are assembled. The formed, non-warp steel clamps which hold the panels together and are used in place of walers are quickly attached to the plywood at the job site by means of a cap bolt which screws into the anchor nut.

The new assembly process is especially applicable to stepped-up footings, pilasters, columns and beams. The panels and steel clamps may be used either horizontally or vertically, and the clamps are provided with a grooved slot for holding the ties. The ties have a safe load of 5,000 pounds. The clamps and ties can be located in such a manner that the fluid pressure of the poured concrete makes the forms self-aligning and rigid without the use of walers or studs. FormCo concrete panels are sold by the square foot in size of 2x4 (25lbs.),2x8 (50lbs.),4x4 (50lbs.), and 4x8 (100 lbs.). In addition, contractors can make their own don't have to pry them-they almost fall off when you release the hardware" he says. "The beauty of these panels is that with the new type hardware you can take a single panel out any time to leave a passage, and slip it in again later." Another advantage is that the panels are interchangeable, and have no top, bottom, right or left side.

"In March, 1956, we purchased our first FormCo forms. Since that time, we have used the forms approximately twenty times and expect to get at least forty more uses out of them," said an Illinois contractor.

FormCo construction features are designed to insure a strong, rigid structure and maintain highly accurate alignment of the form. This results in smooth finished walls that require little or no rubbing. Both conventional PlyForm fir plywood and overlaid fir plywood panels are available.

Complete information on the FormCo method and suppliers may be obtained by contacting local plywood jobbers or writing FormCo, fnc., Rockford Trust Building, Rockford, Illinois.

McGoy $omes terry Griffin Vice-President ond Director

Jerry Griffin, for the past several years salesmanager of Western Pine Supply Company in Emeryville, has been made vice-president and a director of the firm, according to Phil McCoy, president of the large jobbing and direct mill operation.

In his capacity as vice-president, Griffin will be in charge of operations of the company. He originally joined Western Pine Supply Company ten years ago as a salesman covering the Peninsula and Coast Counties areas.

By John Eells

CONTENTg

Precolculqted Net Prices Afier Simple ond Chqin Discounts

Precqlculoled Selling Prices qt Vqrious Percenloges of Gross Profit

Extended Squore Foologe Tqbles

Extended Boord Feel Tqbles

Extended Weighr Tobles for Softrrood Plywood

Vqrious Informqtive Operotionol Tobles

$7o,oo