3 minute read

Shinglu and shakes enjoy nohile hone narket

I'IOUR years ago iI you suggested I to a shingle mill operator that his product would be gracing the walls of some of the country's most innovative new mobile homes in 1971, he would have tossed you back down the log chute.

However, the mobile home market is in fact presenting the red cedar shingle and handsplit shake industry with one of several exciting new marketing opportunities.

The Bureau has followed this trend with fascination, because the basic technology of the mobile home and that of modular unit construction are greatly similar, offering the industry a two-for-one inroad into the growing low-cost market. Although long associated with the premium end of the single family residential housing market, both shingles and shakes offer numerous practical and'ocosmetic" advantages to the low cost mobile or modular

By Morshqll Ritchie merchqndising monoger Red Cedor Shingle & Hond Split Shoke Bureou

Sfory q] s Glqnce

Shingles and shakes find a big new market in manufactured housing but worry that it may eventually hurt the products' present image of quality.

unit. developer. Chief among them, of course, is the ability to dress up the unit, give it a respectable degree of warmth and just generally upgrade its appearance with a touch of quality.

The move into the low cost housirg end of the market is being watched carefully by the Bureau and the industry generally. The quality image secured by shingles and shakes in their close association with guality design is not something to be bartered lightly. These two products have a major service to render in providing an attractive, environ. mentally palatable caste to what could otherwise become a strictly utilitarian and unpleasing blight on the land.

The Bureau is today actively engaged with designers, architects and mobile home manufacturers in developing new, practical product approaches to this engaging new market. With volume predictions running well over a half million units annually, there is no question that the mobile home represents a significant marketing opportunity. The obvious charge to the industry is to make its products widely available while maintaining the quality image and thus assuring a continued acceptance in the traditional residential, apartment and light commercial fields.

Buildingmoteriol Disfribulors

"ll Wos o Very Good Yeor. ."

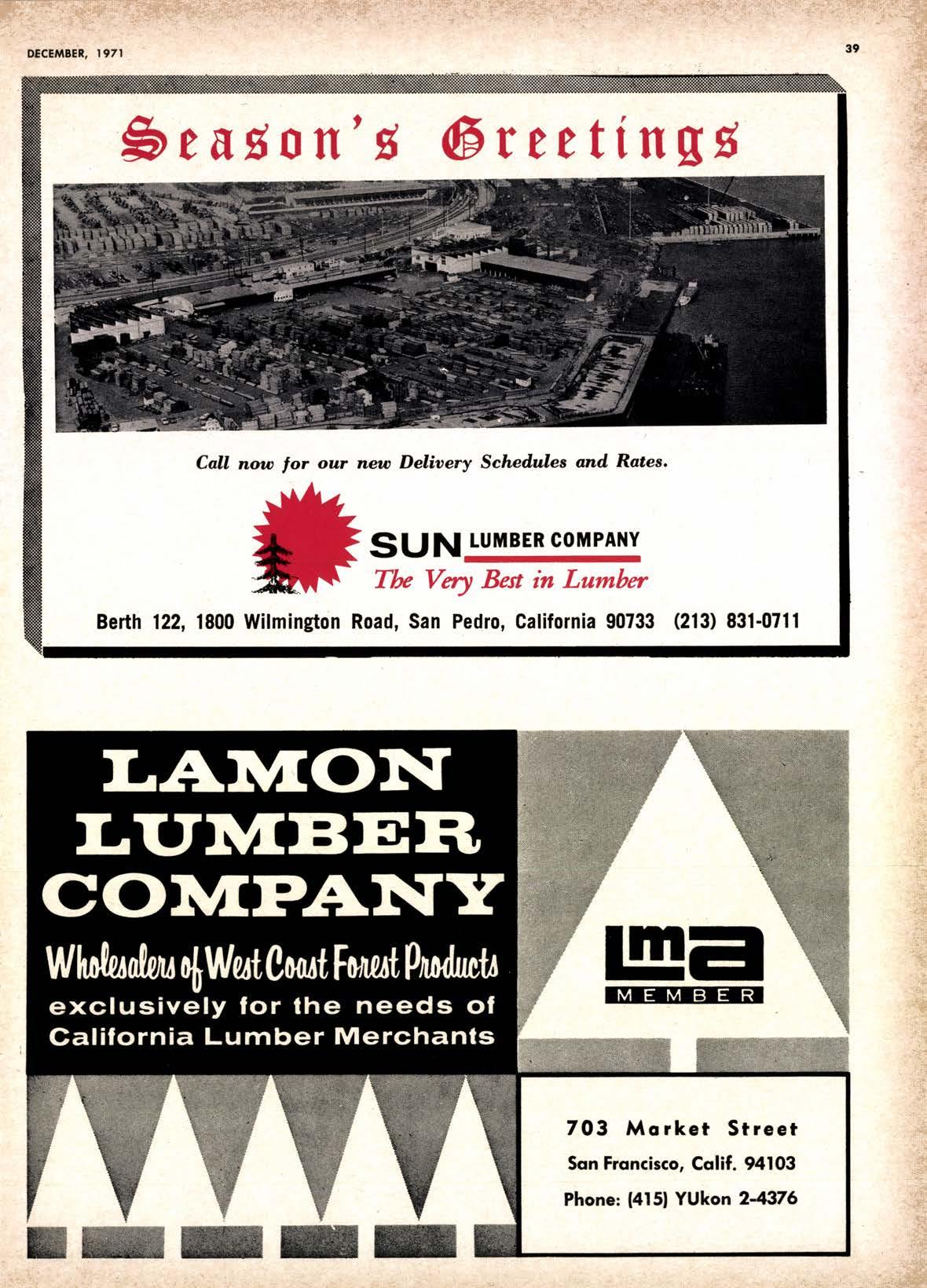

Successfully wrapping up their first year of service in California's booming Orange County is Oliver Lumber Co. and Cal Custom Mill, both of Santa Ana.

Maintaining an inventory of milled and rough lcl redwood and rough western red cedar, Oliver completes its services by furnishing a complete milling service through Cal Custom Mill.

Affable Bud Oliver is compliment. ed by having the services of Freeman Campbell, a well-known lumberman throughout the coastal area, riding "shot-gun" in both operations. Inez Deming is in charge'of telephone inquiries and clerical.

New So-Col Soles Monoger

So-Cal Commercial, an old-line southern California distributor of building materials, has appointed Richard Ferrell sales manager.

Ferrell has been with the firm since 1967 and has previously operated as merchandise manager.

Price Freeze Hurts Lumbermen

The wage-price freeze has resulted in inequities for lumbermen, according to John Hampton, president of the Western lVood Products Assn. and president of the Willamina Lumber'Co., Portland.

"Probably the most serious inequity," Hampton noted, "is a price freeze with no concurrent [rw,e on the cost of government timber. As a consequence, many mills dependent on federal timber are finding that they rnust sell their lumber at a loes. Others cannot afiord to cut timber purchased at public auction and sell manufactured products at price levels established under the presidential freeze order.

o'When the freeze was announce{," Hampton said, towe assumed lumber prices would be established on the basis of sales we had made during the base period. Lumber sales are completed at the time the order is accepted and shipments may lag by as many as 12 weeks," he said. "Rail car availability, long order files, lumber inventories and other factors afiect the time interval between an order and a shipment.t'

Hampton said the Cost of Living Council has rejected pleas by lumbermen for relief. "Basing prices on shipments," he explained, "has resulted in establishing any number of different price ceilings for identical products. Obviously the mill which ships late will have a comparatively low product price and mills with short order files which ship quickly will have a higher price more in line with the current market."