1 minute read

Computer controlled inventory

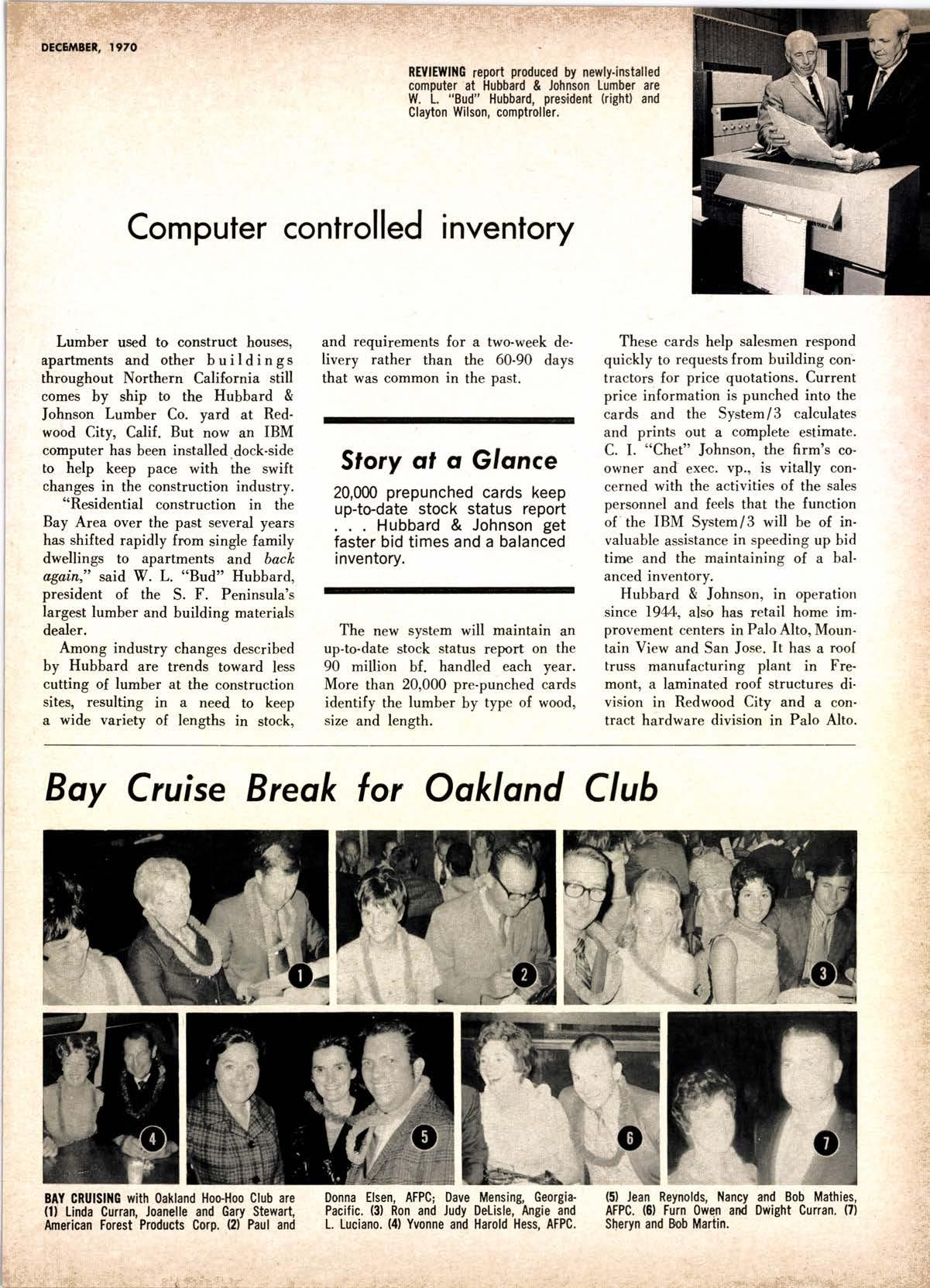

Lumber used to construct houses, apartments and other buildings throughout Northern California still comes by ship to the Hubbard & Johnson Lumber Co. yard at Redwood City, Calif. But now an IBM computer has been installed.dock-side to help keep pace with the swift changes in the construction industry.

"Residential construction in the Bay Area over the past several years has shifted rapidly from single family dwellings to apartments and back a,ga.in," said W. L. "Bud" Hubbard, president of the S. F. Peninsula's largest lumber and building materials dealer.

Among industry changes described by Hubbard are trends toward less cutting of lumber at the construction sites, resulting ina need to keep a wide variety of lengths in stock, and requirements for a two-week delivery rather than the 60-90 days that was common in the past.

Story dl a Glonce

20,000 prepunched cards keep up-to-date stock status report . Hubbard & Johnson get faster bid times and a balanced inventory.

These cards help salesmen respond quickly to requestsfrom building contractors for price quotations. Current price information is punched into the cards and the System/3 calculates and prints out a complete estimate.

C. I. "Chet" Johnson, the firm's coowner and exec. vp., is vitally concerned with the activities of the sales personnel and feels that the function of the IBM System/3 will be of invaluable assistance in speeding up bid time and the maintaining of a balanced inventory,

The new system will maintain an up-to-date stock status report on the 90 million bf. handled each year. More than 20,000 pre-punched cards identify the lumber by type of wood, size and leneth.

Hubbard & Johnson, in operation since 1944, also has retail home improvement centers in Palo Alto, Mountain View and San Jose. It has a rool truss manufacturing plant in Fremont, a laminated roof structures di vision in Redwood City and a contract hardware division in Palo Alto.