2 minute read

Modernized milt benefits certifi d forest

II IITH Collins Pine Co. primarily V Y utilizing logs from environmentally certified forests, gleaning maximum recovery from each log just made sense.

As a result, Collins has just unveiled a completely rebuilt, $20 million sawmill in Chester, Ca.

Now inefficient and labor intensive, the previous wooden frame structure, built in 1943, was demolished in December 2001. Wood from the old building was reused to power its concrete-and-steel replacement. Steel from the prior structure was later melted down and recycled.

Most of the machinery inside is new, as well. The system of saws and trimmer blades that transform logs into lumber has been completely automated.

The new equipment uses laser camera technology and provides climate-controlled cabs and digital message boards for the operators.

The improvements will nearly double the plant's efficiency. Annual production capacity of 75 million bd. ft. should eventually climb to 120 million bd. ft. a year by the time the facility is at full production in 2003.

"The new mill will have much higher recovery rates and provide more consistent quality," said plant manager Mike Zojonc. "We will get more out of the same logs."

This also will allow Collins to use more of its own smaller logs, which it had been forced to sell because they were inefficient to process through the old mill.

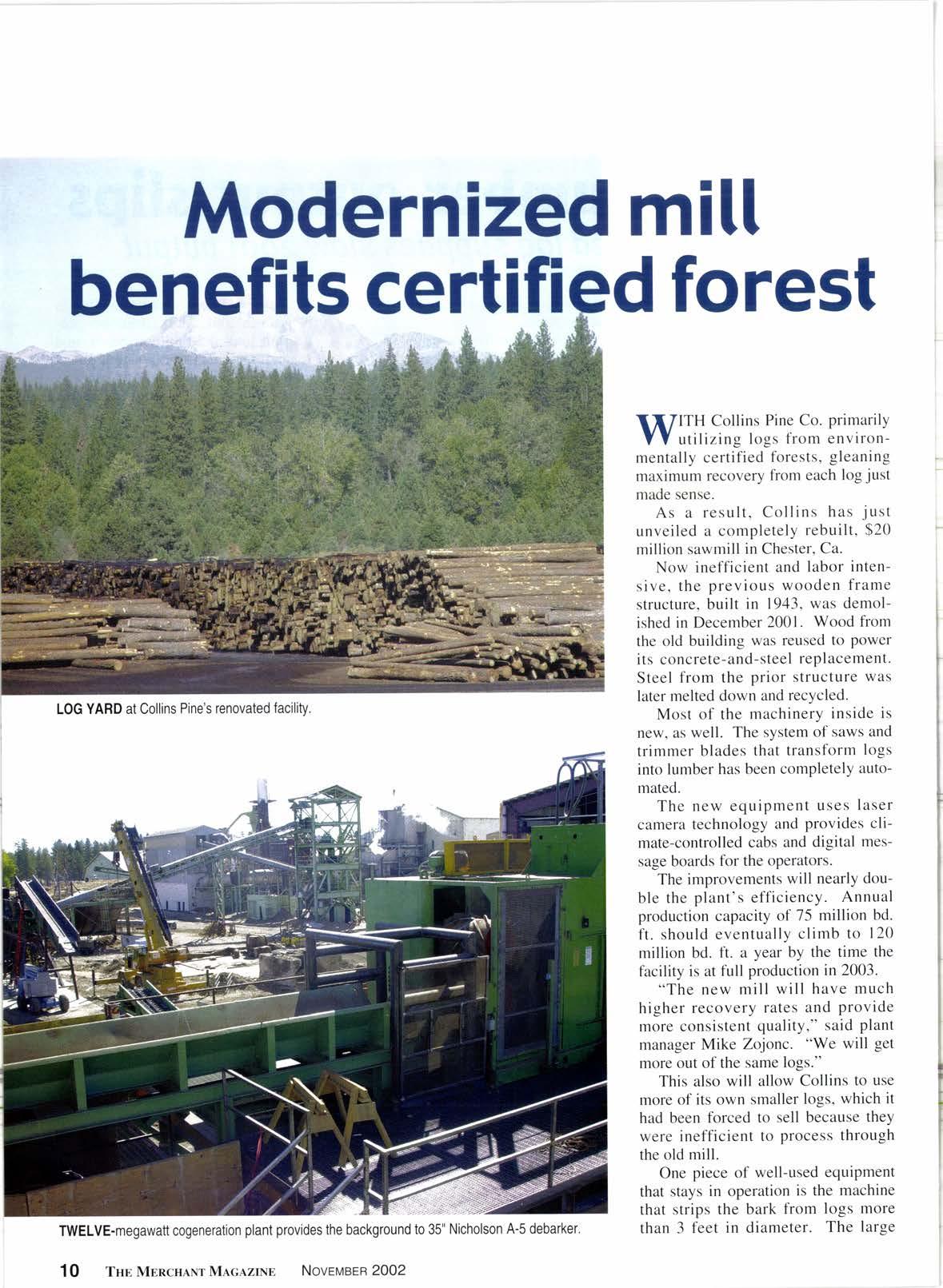

One piece of well-used equiPment that stays in operation is the machine that strips the bark from logs more than 3 feet in diameter. The large

Ioss erttre lront (-Lrllins .\lntanor'

Folcst. rr 9-1.(XX)-rLclc ntircd coniler' stanrl rre c;uir.crl br ('rrllins in 1901. Sltce ics inclLrrle rr hite f ir'. ponclcroslL pine. sttulrr pine. inecnsc ectlur. lrrrl l)oullus lir'.

Thc lirrc:1. one ol tltc lirst in llrc nlti()n t() bc ecr-tilictl lLs :trstllrrttrblc

Lrrtrlcr- llrc stlie 1 [:or-cst Stcn lrltlsltilr ('ourtcil r-c(luircnrcnl\. lrtr: bccn nlln lrgcrl on ln Llnc\ clr ilgc. str stlrrnctl l,icltl blrsis lirr 100 r crrr.s. Thc \\ \tcnt rcnr()\ cs Irigh ri:k unrl poor- tlccs lnrl lcar cs thc hcrrlthr oncs in lhc ri ootls. liourtrlcrl in IE.i-5. I'lrc C'ollins ('os. ittclLrrlcs lirnbcrlunil antl rrillinu opcrlrtions ('ollins Pinc ('ontparrr I K;rrrc I Iut'rln ooil. Klrnc. Pa.. ancl Fre rnont Slu rnill. I-akcr icu. Or'.: siclin:t. tlint lund pafticlch()irlrl ntltnLr l'uctLr lcr (lollins I)rtrtlucts. KlrLnttth Full:. Or.. ancl thlcc Builder': SLrpplr rctlil r arcls in Noltheln Calilirrnil.

Thc corrprrrtr r icn s thc ccrtil'ictl lolcst as i1: crlqc in u contpclitirc nlllke t. "lt is oLrr sulr ir ul lol tl'rc Ion.rI rult." sairl \\'atle \'losbr ir \cnior \'.p. bascd ilt c()fpol'trtc Itcatlquarters in PortlantL. Or'.

The ncu flcilitr. nhich scts 60q,i of its logs l'r'om the Collins Alnlrnor Forest. fLlns t\\o entifel\ \el)lifittc invcntories. ccltilicrl antl non cc'rtilicd. AboLrl 80'i o1'tltc logs t-t\L'(l iu.e ccrlilicd.

('ttt'rcntlr. ntolc thlrn .50 crrrplor ee s ltr-c brtek lrt tor-k conipulcrl 1o 180 prcr iorrslt . Aclrlitiorrltl t orkcls rr ill bc utltlcrl rrs. u illrin the nc\t lc\\ wccks. ('ollins rc\tilt't\ tlrc ;tllrncl ntill. corttplctcs constrrrelion ol l-1 tlr-r kilrrs. bcsins shippirrg linishcrl plotl tuct. ltrttl inerelscs thc trLr rlbcl ol' sh i l'ts.

Zojonc slirl tlrere rr ill be .jobs for all returnin-g u olkels rr ho uttcntlcrl tht'ee-cllrl olicntlrtion session: in etrrlt Scpte rrrbcr-. Positiorr rcrluetions rr ill be ltbsot'bctl br t olkcls rr ho Ilrr e r-e tile(l ()r lirLrrtti jobs e lscri ltcrc.

Slirl (iur \lc\e tt. u slri lilcr t ith ('ollins lor rtcltllr -10 r curs u lro relttfnc(l Scl)tcnlbe | 9 to ntrrr cl ut lris nrotlcrrr nc\\ \\ orkpllLcc: "-f hi: rs u u'rtt'lrl cllrss slru ntill ri or'llrr ol orrr u'or'ltl cluss liri-cst."