3 minute read

Roof failure cause identified

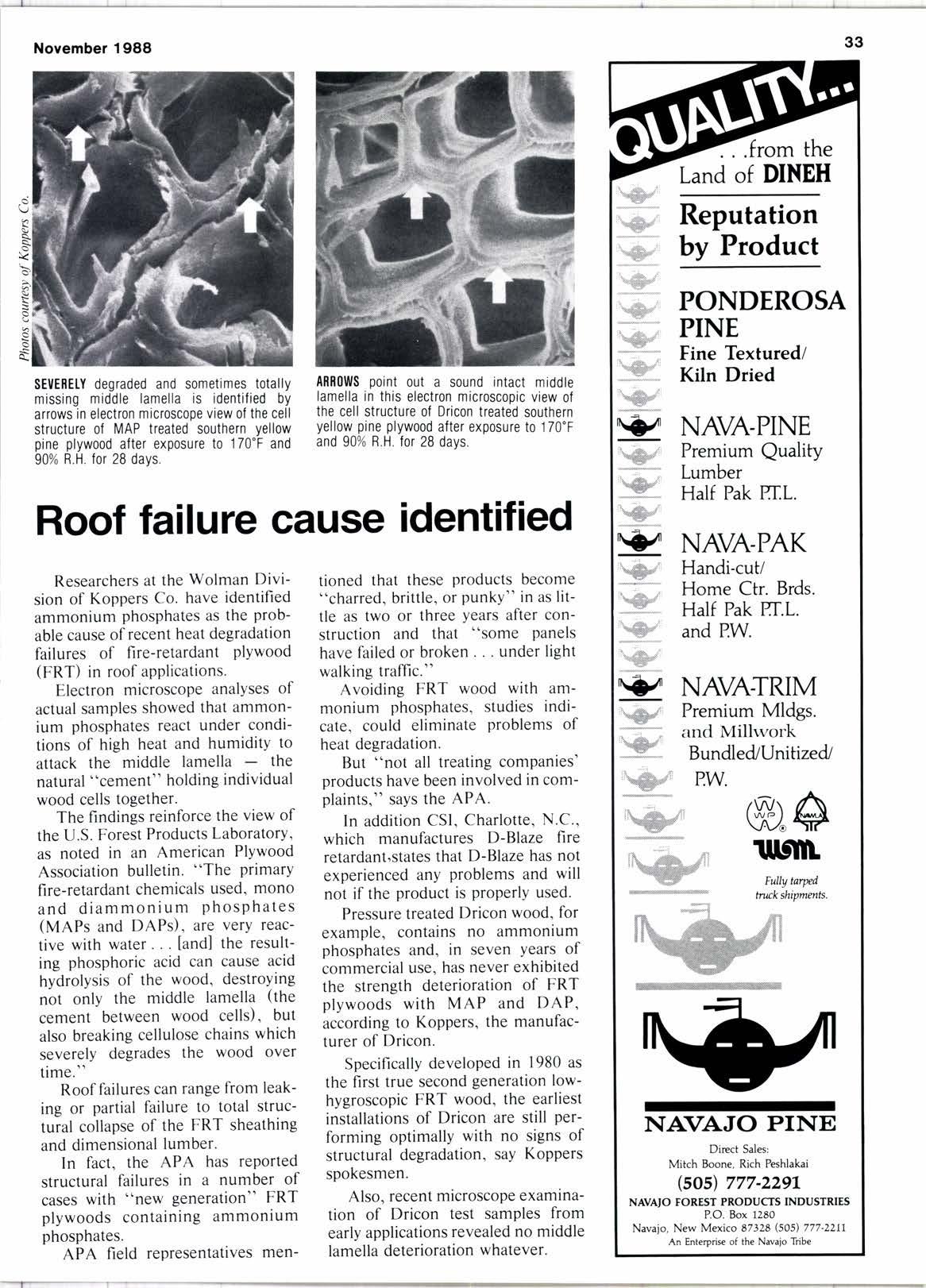

Researchers at the Wolman Division of Koppers Co. have identified ammonium phosPhates as the Probable cause ofrecent heat degradation failures of fire-retardant plywood (FRT) in roof applications.

Electron microscoPe analYses of actual samples showed that ammonium phosphates react under conditions of high heat and humiditY to attack the middle lamellathe natural "cement" holding individual wood cells together.

The findings reinforce the view of the U.S. Forest Products Laboratory, as noted in an American PlYwood Association bulletin. "The primary fire-retardant chemicals used, mono and diammonium PhosPhates (MRPs and DAPs), are very reactive with water [and] the resulting phosphoric acid can cause acid hydrolysis of the wood, destroying not only the middle lamella (the cement between wood cells), but also breaking cellulose chains which severely degrades the wood over time."

Roof failures can range from leaking or partial failure to total structural collapse of the FRT sheathing and dimensional lumber.

In fact, the APA has rePorted structural failures in a number of cases with "new generation" FRT plywoods containing ammonium phosphates.

tioned that these products become "charred, brittle, or punky" in as little as two or three years after construction and that "some Panels have failed or broken under light walking traffic."

Avoiding FRT wood with ammonium phosphates, studies indicate, could eliminate Problems of heat degradation.

But "not all treating comPanies' products have been involved in complaints," says the APA.

In addition CSI, Charlotte, N.C., which manufactures D-Blaze fire retardant'states that D-Blaze has not experienced any problems and will not if the product is properly used.

Pressure treated Dricon wood, for example. contains no ammonium phosphates and, in seven Years of commercial use, has never exhibited the strength deterioration of FRT plywoods with MAPand DAP, according to Koppers, the manufacturer of Dricon.

Specifically developed in 1980 as the first true second generation lowhygroscopic FRT wood, the earliest installations of Dricon are still performing optimally with no signs of structural degradation, say Koppers spokesmen.

Also, recent microscope examination of Dricon test samples from early applications revealed no middle lamella deterioration whatever.

Fine Textured/ Kiln Dried

NAVA.PINE

Premium Quality

Lumber

Half Pak PIL.

NAVA.PAK

Handicut/ Home Ctr. Brds. Half Pak Pf.L. and PW.

Premium Mldgs. and Millwork

Bundled/Unitized/

Simpson's Redwood Strategy

In a move to focus its marketing and production efforts on young growth redwood, Simpson Redwood Co., an operating division of Simpson Timber Co., plans to close its Arcata, Ca., remanufacturing plant in mid-1989. The office will remain open for the present, although it is expected that it will move to the young growth redwood facility Simpson operates at Korbel, Ca., in about two years.

Two other Simpson facilities involved in old growth redwood will continue to operate at current levels: Orick, Ca., and the Brainard mill between Arcata and Eureka, Ca.

Old growth redwood operations will be handled solely by Arcata Redwood Co., which Simpson acquired in June. It will cut all of Simpson's old growth logs and is expected to continue doing so for approximately seven or eight years.

In old growth, Simpson competes with the Pacific Lumber Co.. which is expected to be a dominant player well into the next century. Industry sources say Miller Redwood's old growth redwood supply is not expect- ed to last beyond the late 1990s.

Major Simpson competitors in the young growth redwood market are Georgia-Pacific and Louisiana-Pacific. Smaller competitors include Eel River Sawmills, Redwood Empire and Harwood.

By dividing its efforts, Simpson says it can best direct its efforts to longer term operations in young growth redwood, which it anticipates to increase 300% in the next 10-15 years.

Weyerhaeuser Renews PBS TV

Weyerhaeuser Co., Tacoma, Wa., will continue to underwrite the Emmy-Award-winning public television program This Old House for a second year.

Weyerhaeuser decided to renew its backing based on the show's 130/o ratings rise last year and a survey of remodeling contractors conducted by an independent research firm.

The survey revealed most contractors consider This Old House to be a valuable application and product information source. Over half the respondents said they watch the program regularly.

Sponsorship of the l0-year-old show parallels other Weyerhaeuser efforts to focus on the growing repair and remodeling market, joining the introduction of new residential products such as Stronglam headers and Structurwood oriented strand board.

Announcing Sturdi-Wood

If vouVeever out in a subfloor vou know exactlvwhatwe mean aboutthe thrill of pfuobd. Iusthow much of this o<citement vou cantake is certainlvup tovou "

But i6 nice to know thereis a soothing possibly even boring alternative waiting at vour buildins supplv center "

Whenpbpefu"installedaSturdi-Wood floorwontwalp floorwontwarp orbuckle. And under anycon-

Tongueandgrowesmadetomeetevactly. OntOpOf that, Sturdi-Wood is 1000/o ongade,panel afterpanel,so vou setallof whatvou pav for without knothoEs and corevciids. '

'liv Sturdi-Wood on vow next iob. As with afl Weyerhaeuser pioducts wb absolutely guarantee your s atisfaction.

"F6r the disuibutor nearest you, call 800-328- 4646 ext 520.

Or writeWeverhaeuser Sturdi-Wood, PO. Box 822l debt. 520, Bumsville, MN 55337.Find out what life is like without all the excitement.

Sturdi-Wood.Tfw mare u 0u use it, the betteritlooks.