1 minute read

Gompanies Produce "Certified Sustainable" Lumber Products

Ecologically corect "green" products now include lumber certified as being logged using susrainable forestry methods. Rogue Institute for Ecology and Economy, Ashland, Or., is directing the harvest of 140 zrres a few miles westof Eugene, Or.

Trees are on land owned by Beaver Valley Lane & Timber Co., Eugene.

Trus Joist MacMillan will make composite l-beams and laminated veneer lumber. Springfield Forest Products Co., Springfield, and Lane Plywood Co., Eugene, will make plywood and veneer. Products are destined for EcoMart, a Wal-Mart prototype store in Kansas.

Fonned more than two years ago by a coalition of tinber workers, environmentalists, wood products companies and southern Oregon businessmen, the Rogue Institute has evolved into a non-profit group promoting sustainable foresfty rather than largescale clear cutting of both public and private forests. "Our guiding philosophy from the beginning has been that there were approaches to forest management which could sustain the ecological integrity of our forests and provide stable, living wage jobs," said Brett KenCairn, director.

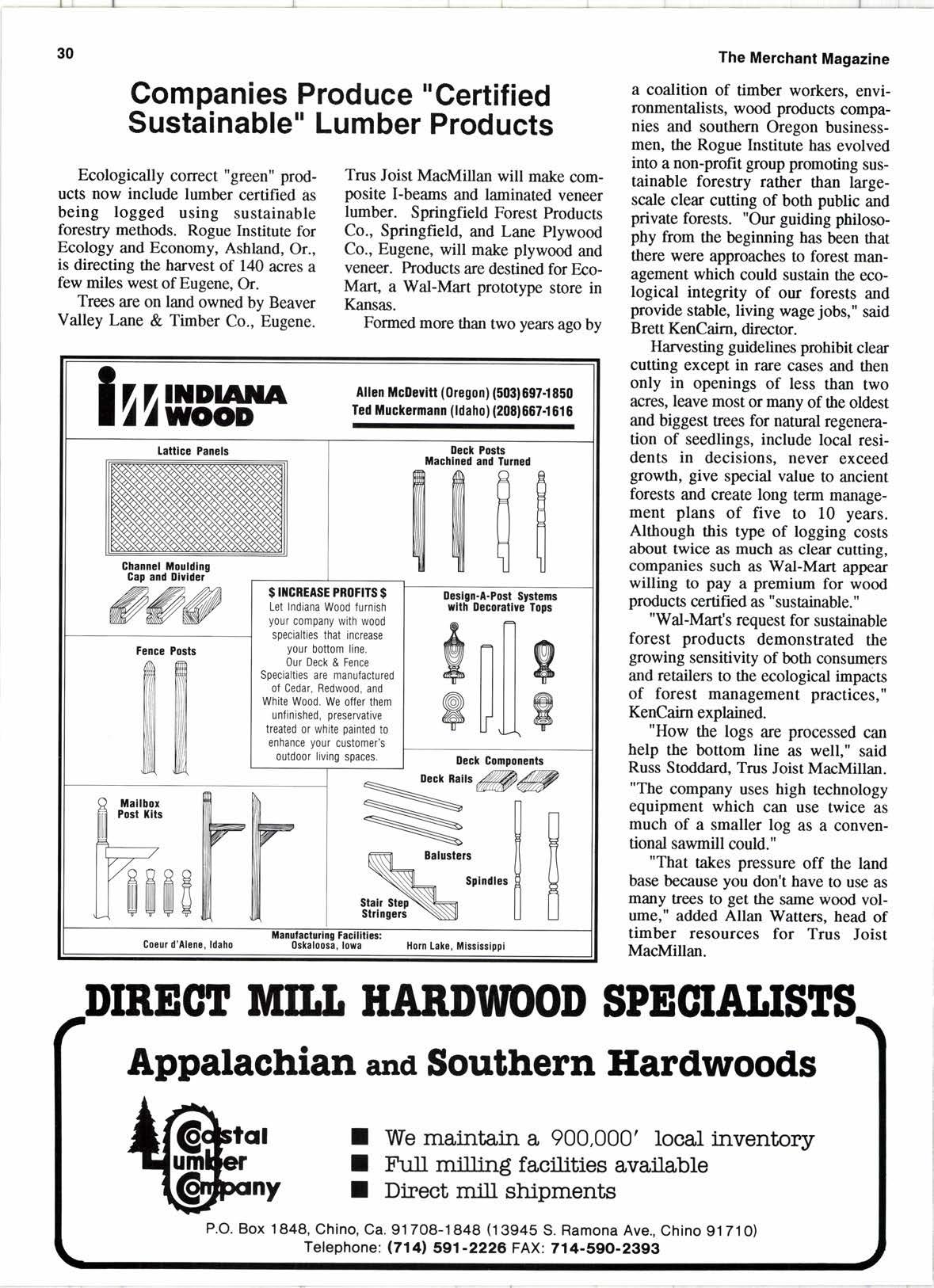

$ ITGREASE PROFITS $ Let Indiana Wood furnish your company with wood specialties that increase your bottom line. our Deck & Fence Specialties are manufactured of Cedar. Redwood. and White Wood. We otfer them unfinished, preservative treated or white oainted to enhance your customer's outdoor living spaces.

Hanresting guidelines prohibit clear cutting except in rare cases and then only in openings of less than two acres, leave most or many of the oldest and biggest trees for natual regeneration of seedlings, include local residents in decisions, never exceed growth, give special value to ancient forests and create long terrr management plans of five to l0 years. Although this type of logging costs about twice as much as clear cutting, companies such as Wd-Mart appear willing to pay a premium for wood products certified as "sustainable. "

"Wal-Mart's fequest for sustainable forest products demonstrated the growing sensitivity of both consumers and retailers to the ecological impacts of forest management practices," KenCairn explained.

"How the logs are processed can help the bottom line as well," said Russ Stoddard, Trus Joist MacMillan. "The company uses high technology equipment which can use twice as much of a smaller log as a conventional sawmill could."

"That takes pressure off the land base because you don't have to use as many trees to get the sane wood volume," added Allan Watters, head of timber resources for Trus Joist MacMillan.