1 minute read

Fingerioint Studs Gaining Popularity

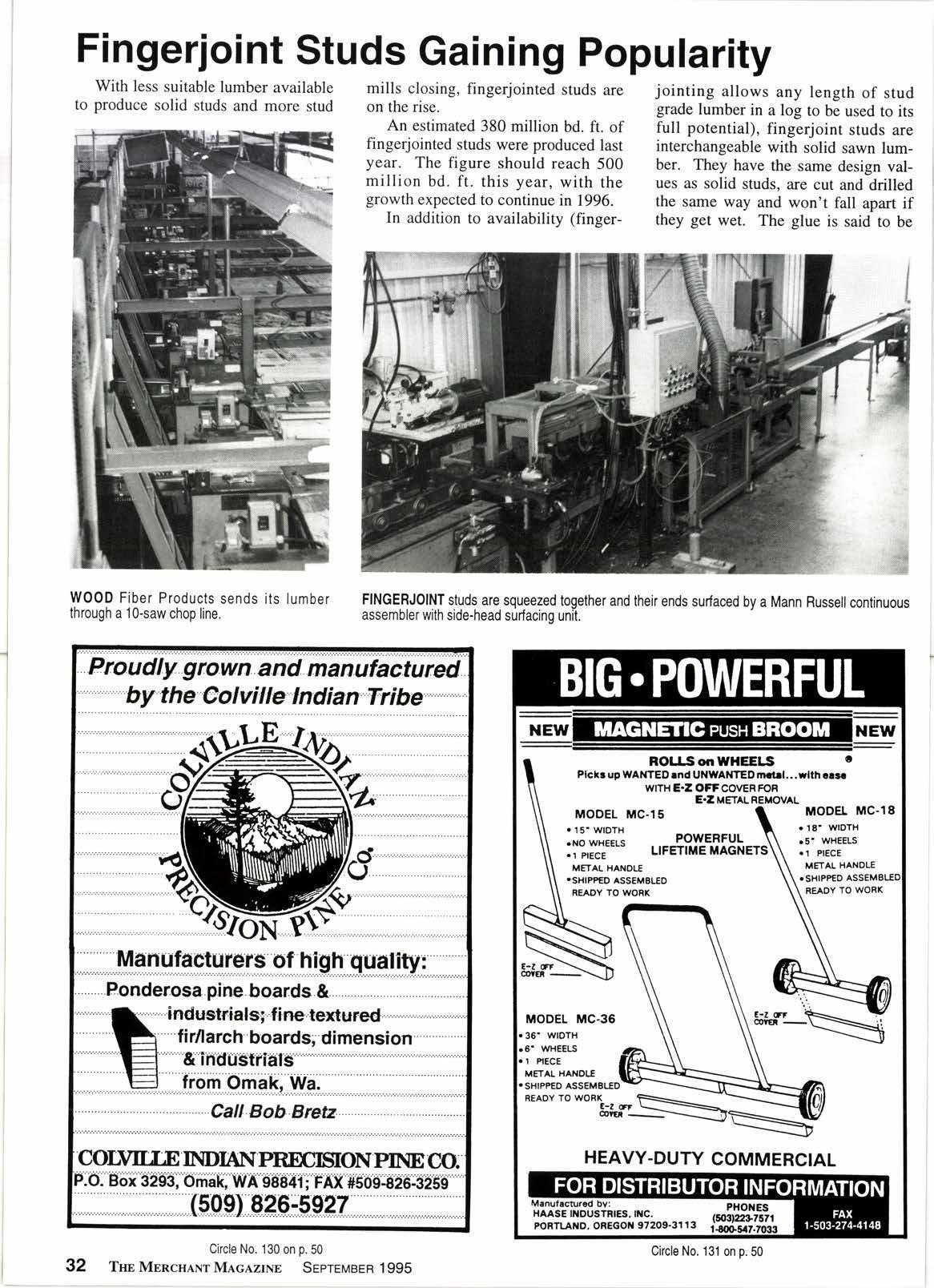

With less suitable lumber available to produce solid studs and more stud mills closing, fingerjointed studs are on the rise.

An estimated 380 million bd. fr. of fingerjointed studs were produced last year. The figure should reach 500 million bd. ft. this year, with the growth expected to continue in 1996.

In addition to availability (finger- jointing allows any length of stud grade lumber in a log to be used to its full potential), fingerjoint studs are interchangeable with solid sawn lumber. They have the same design values as solid studs, are cut and drilled the same way and won't fall apart if they get wet. The glue is said to be stronger than the wood.

Designed for stud-vertical use applications only, fingerjointed studs are not made from scrap or junk lumber. They are manufactured from short pieces of stud-grade lumber cut specifically for fingerjoint use.

Moreover, fingerjointing reportedly produces straighter walls, since the process mixes grain patterns and knot structures, minimizing the chance of bow and crook. Callbacks for stud replacement are reduced by 5O-75Vo.

Its drawback isits newness. "There are still a lot of builders who think, 'If it's not green Douglas fir, you can't build a house with it.' You have to get by that mentality, and it just takes a while," says Gus Prouty, Wood Fiber Products Inc., Lockeford, Ca..45 miles south of Sacramento.

Prouty has also encountered resistance to fingerjointed studs from county building departments. "Some county building inspectors, especially in the Southwest, just haven't seen them before, so they're not allowing them," he explains. Again, time and experience should remove any doubts.

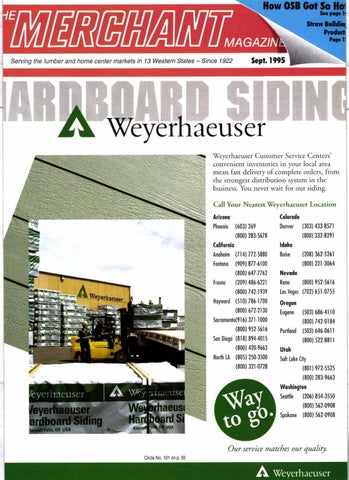

Wood Fiber Products was started in 1981 by Prouty's father, Bob, and two partners, cutting particleboard for the agricultural industry. The company gradually expanded into pallets, wooden box shook, fingerjoint blanks and, about three years ago, fingerjoint studs. Studs now account for nearly 2OVo of its business.

They are most in demand in extremely hot areas, such as Phoenix, Az., Las Vegas, Nv., and the inland California vallev.