4 minute read

GRADE STAMPS

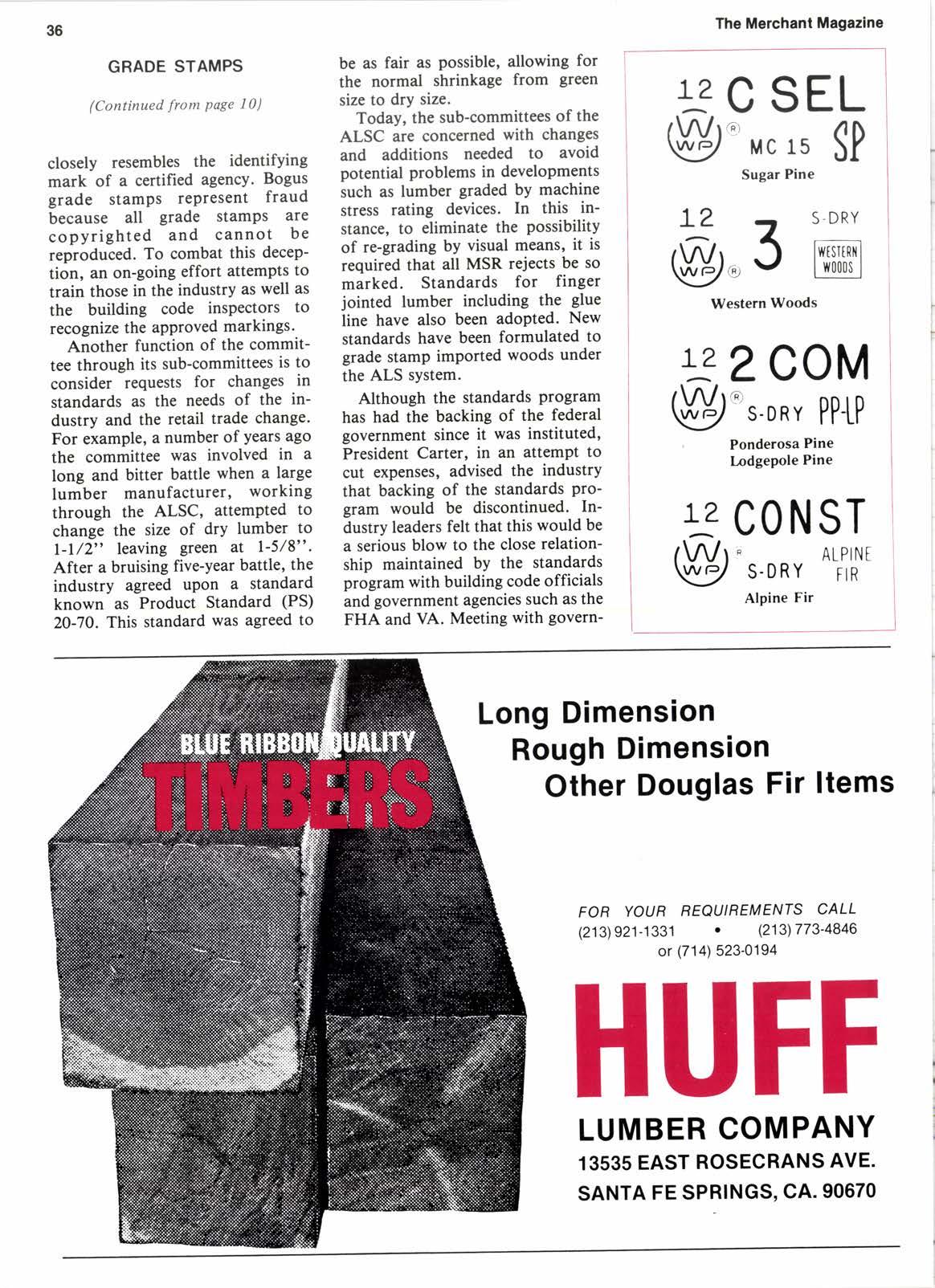

(Continued from Page l0) closely resembles the identifying mark of a certified agency. Bogus grade stamps represent fraud because all grade stamps are copyrighted and cannot be reproduced. To combat this decePtion, an on-going effort attempts to train those in the industry as well as the building code insPectors to recognize the aPProved markings. Another function of the committee through its sub-committees is to consider requests for changes in standards as the needs of the industry and the retail trade change. For example, a number of Years ago the committee was involved in a long and bitter battle when a large lumber manufacturer, working through the ALSC, attempted to change the size of drY lumber to l-l/2" leaving green at l-5/8". After a bruising five-year battle, the industry agreed upon a standard known as Product Standard (PS) 20-70. This standard was agreed to be as fair as possible, allowing for the normal shrinkage from green size to dry size.

Today, the sub-committees of the ALSC are concerned with changes and additions needed to avoid potential problems in developments such as lumber graded bY machine stress rating devices. In this instance, to eliminate the possibility of re-grading by visual means, it is required that all MSR rejects be so marked. Standards for finger jointed lumber including the glue line have also been adoPted. New standards have been formulated to grade stamp imported woods under the ALS system.

Although the standards Program has had the backing of the federal government since it was instituted, President Carter, in an attempt to cut expenses, advised the industrY that backing of the standards Program would be discontinued. Industry leaders felt that this would be a serious blow to the close relationship maintained bY the standards program with building code officials and government agencies such as the FHA and VA. Meeting with govern- ment representatives, the ALSC representatives protested, citing problems which they felt would result. To solve the problem, a compromise was finally reached with the lumber industry (through the ALSC) paying the government for the administrative processes involving the Commerce Department.

As a result, the lumber industry standards program is now selffunded. Although the process protects both retailer and consumer, it does not cost either one cent. Grading agencies collect, along with their inspection fee, a mill assessment per one thousand board feet of lumber produced. These collected fees are then paid quarterly to the ALSC.

Members of the committee and their alternates are appointed by the Secretary of Commerce for terms of not less than two years and not more than five years under Department of Commerce procedures allowing industries to set standards for their products. Twenty-three representatives from all over the country are selected from softwood lumber associations, agencies, wholesalers, retailers, architects, builders, contractors, engineers, consumers and wood using industries. Five nonvoting government officials represent the departments of Agriculture, Commerce (National Bureau of Standards), Defense, Interior and Federal Housing Authority.

In addition, a Board of Review composed of three members is nominated and elected by the ALSC with the concurrence of the Department of .Commerce. To be eligible for election to this board, a person cannot be a member of the committee or be affiliated with a grading agency. Members must divest themselves of any lumber industry interests upon appointment. An elaborate nomination process is designed to avoid conflict of interest.

The American Lumber Standards Committee also is responsible for the National Grading Rules Committee composed of representatives from organizations represented on the ALSC, representatives from grading agencies in Canada, and others competent in this field. Although autonomous, this com- mittee functions under by-laws approved by the ALSC and is responsible for conforming to American Lumber Standards for grading.

Canada is not represented on the ALS committee although the Board of Review has approved l0 agencies in Canada and Canadian sawmills through these agencies contribute their share of financial support as do those in the United States. For the past 9 years both ALS inspectors and the committee, through special arrangements, have monitored Canadian lumber to be imported to the U.S., thus offering greater protection to both retailers and consumers.

Basically, all sizes for all softwood lumber are controlled by this committee with any changes in size or grades subject to its approval. The first American Lumber Standards Committee was formed in 1919 with the first standards announced in 1971. The committee is a quasi-governmental body, which functions under procedures published by the Department of Com-

(Please turn to page 62)

TOP STUDENT Julie Kelley, St Regis Paper Co., Rock lsland, ll., and Jennifer Hallock, Hallock Lumber Co., Ardsley, N.Y., were among the 40 young salespersons c0mpleting the North American Wholesale Lumber Association Wood Marketing Seminar held in Corvallis, 0r. The 250 ft. Douglas f ir was felled as part of a Willamette Industries logging demonstration at Snow Peak.

NAWLA

"Graduates" 40

Forty of North American Wholesale Lumber Association young salespeople members completed the first annual Wood Marketing Seminar conducted by the association to provide a basic foundation in the business, from logging to the marketplace.

Oregon State UniversitY at Corvallis was the location for the intensive weeklong course taught bY an instruction team made uP of NAWLA members and staff assisted by OSU professors.

NAWLA instructors were Glenn Banks, C.E. Klumb, W.W.Wood, Carleton Knight, Jr., T.C. Bloch, Eric Canton, Bill Sheathelm, Dave Benson and Pete Niebling, NAWLA exec. v.p.

Field trips took the students to Willamette Industries' Snow Peak logging operation, the Bauman salvage mill at Lebanon, and the Willamette mill at Dallas. These tours were organized bY Paul McCracken and Dick Davis of Willamette Industries.

NAWLA has contracted with OSU for the same time slot in 1982. Members will be advised later this vear when student reservations will be accepted with sixteen slots already filled by those who could not be accommodated at the first seminar due to oversubscription.

Dwelling Code Review

Of special importance to the wood product industry is the assignment to the Council of American Building officials of secretariat responsibilities for the One and Two FamilY Dwelling Code, which is part of the three model code groups rePresented bY CABO.

With a recently passed resolution, all action and communication of national significance for the Building Officials and Code Administrators, the International Conference of Building Officials, and the Southern Building Code Congress International will be cleared through CABO.

The council is reviewing the compatibility of the dwelling code with ihe Department of Housing and Urban Development's Minimum Property Standards with a goal of preparing the One and Two FamilY Dwelling Code for use as federal standards are phased out of use as recommended by the National Institute of Building Sciences.