7 minute read

Lucky 13th for millwork, moulding producers

At their annual meeting Aug. 79, the Western Wood Moulding and Millwork Producers declared their 13th year as an association as marketing year number one, "the year of the jobber."

The new promotion theme reflects the Portland, Or., headquartered association's 1975 promotion and marketing philosophy, one of building closer marketing alliances with sash and door jobbers and wholesale building materials distributors nationwide.

Included in the program are a detailed "Salesn'Lan's Guide to Wood Mouldings and Jan1,bs", a new display for distributor trade shows, increased emphasis on marketing at association meetings and development of a film cassette for a new distributor training and communicating network.

The sales guide is a first for the industry. Covering all aspects of wood mouldings and jambs from history and definitions to proper measurement, useage and merchandising ideas, the manual will be geared toward retail sales training and product familiarization. The guide also will be a working tool from which customers can be given moulding ideas and do-ityourself instructions. The manual will be distributed through the millwork jobbers and building material distributors.

A full convention program included an eight-man machinery panel moderated by Wesley Shoup, publishing director, "Wood and Wood Products" magazine, and industry experts.

Addressing the timber supply situation, William Hagenstein, exec. v.p., Industrial Forestry Association, Portland, said, "To lick inflation in the forest economy requires management of federal forest lands for full production. Federal schizophrenia resulting from conflicts between statutory goals has resulted in a steady erosion of the allowable harvest from the National Forests. Congress must direct and monitor the Forest Service and BLM so that the agencies adopt a timber production goal and stick with it."

B. Andrew Kugler, Bolt, Beranek and Newman, Los Angeles, briefed the moulding producers on the proposed new noise control standard which would lower allowable sound levels from 90 dBA to 85 dBA.

According to Kugler, the association's "Noise Control Design Guide", besides providing engineering capability for sound reduction to 90 dBA, proves the economic unfeasibility of reengineering to 85 in existing plants. Such a requirement would require rebuilding entire plants to accommodate the necessary controls. Under the provisions of OSHA, this certainly is not feasible from an economic standpoint."

A new slate of officers and several new directors were elected during the WWMMP meeting.

New president is T.S. "Stu" Turner, Clear Pine Mouldings Div. of Contact Lumber Co., Portland. Clear Pine is located in Prineville.

Vice-president is Sterling Mentink, Challenge Lumber Products, Inc., Marysville, Ca., and treasurer is Don Crane, Feather River Moulding Co., Inc., Oroville, Ca.

New directors are: William Berry, Kimberly-Clark Corp.; William Gazeley, Columbia Hardwood and Moulding Co.;Don Fink, Kaibab Industries; W.W. Dodson, Forest Products Co.; and Bernie Sloop, American Forest Products.

T.S. "Stu" Turner. the new president, has spent his working career in the forest products industry, starting in 1947 at Kinzua Pine Mills Co. In 1953 he became superintendent and sales manager of a planing mill in Spokane, Wa., Ieaving there in 1955 to become assistant sales manager and, later, sales manager of the Diamond National millwork operations at Chico, Ca. He has been with Clear Pine Mouldings since 1960.

New Plywood Standard

The Department of Commerce has officially approved the new Plywood Standard, PS 1-74.

It offers many refinements that serve the consumer better and assist the plywood industry to broaden its product lines.

From the manufacturers' standpoint, one of the principal advantages ofPS 1-74 is its recognition of the greater manufacturing versatility conferred by parallel laminated veneers. The new stan- dard includes changes that build further on the use of parallel lamination in grades other than sheathing, but at the same time preserve the traditional strength and dimensional properties that plywood users expect.

One of the principal benefits is in the reduced number of gluelines that some of the layup variations permit.

Parallel laminating also offers great production efficiency. As an example, a straight sheathing mill peeling only 1/8" thick veneer, can produce panel thicknesses ranging from 3/8" to in excess of I" in ll8" increments simply by adding one veneer for each increase in thickness.

Other important features of PS l-7 4 include recognition of chemical patching, or synthetic repairs; changes in panel identification for certain sanded and decorative panels; changes in length and width tolerance; a change in the definition of "Standard" sheathing; and a new section on reinspection which should help buyers and specifiers in streamlining the handling of complaints.

Truck drivers know all the best soots . . and that's where Kimberly-Clark ranks. Our loading crews are on hand from 7:00 a.m. to midnight five days a week, with a big supply of strapped and wrapped lumber, and a deft wav with a lift truck. You pull into KimberlyClark, and in no time you're on your way with a warm heart and a glow of satisfaction.

We're big on mixed loads and overnight service. In fact, if your destination's within a radius of 500 miles and you can get your truck here before 5:00 p.m., we can practically promise you its unloading will be the first order of the day.

Kimberlq'Clark

(Forest Products Division)

ANOERSON, CALIFORNIA 96007

PHONE: (LUMBER SALES MANAGER) (e16) 36s-7661

P.O. BOX 697

RHINOHIDE SALES . PHONE: (916) 246-4988

MOULDING & MILLWORK . PHONE: (916) 365-2910

PONDEROSA PINE SUGAR PINE WHITE FIR DOUGLAS FIR.INCENSE CEDAR. MOULDINGS. JAI,,4BS. DOOR FFAN4ES CUT STOCK PROVIDED SOLID AND FINGER

JOINTED, NATUFAL, t\,,llLL-PRlt\4ED, VINYL OVERLAy

Next time you have a yen to get into fast company, remember Kimberly-Clark. MARENfSCO, MICHIGAN PHONE: (906) 787-2239

MAPLE. SOFT N4APLE. BIRCH. SOFT GRAY ELM

ASH. BEECH. NORTHERN HEI\,4LOCK

WHITE PINE DFY KILNS . PLANING MILL AND DIN4ENSION CUT STOCK.

ALABAMA

(205) 839-6368

PINE. SOUTHERN YELLOW PINE

(Continued from page 1l) some indoor operation is required) or diesel. Diesel is preferred if the duty cycle is heavy. Some larger pneumatic-tired models are available only with diesel power.

Capacity: Lifting capacity is determined by size of load, lift height required and terrain. As with frontloader lift trucks, sideloader capacity is de-rated above certain lift heights.

There are some other special considerations. The rated load center of sideloaders is approximately half the width of the deck. Capacity for carrying is usually equal to the lifting capacity.

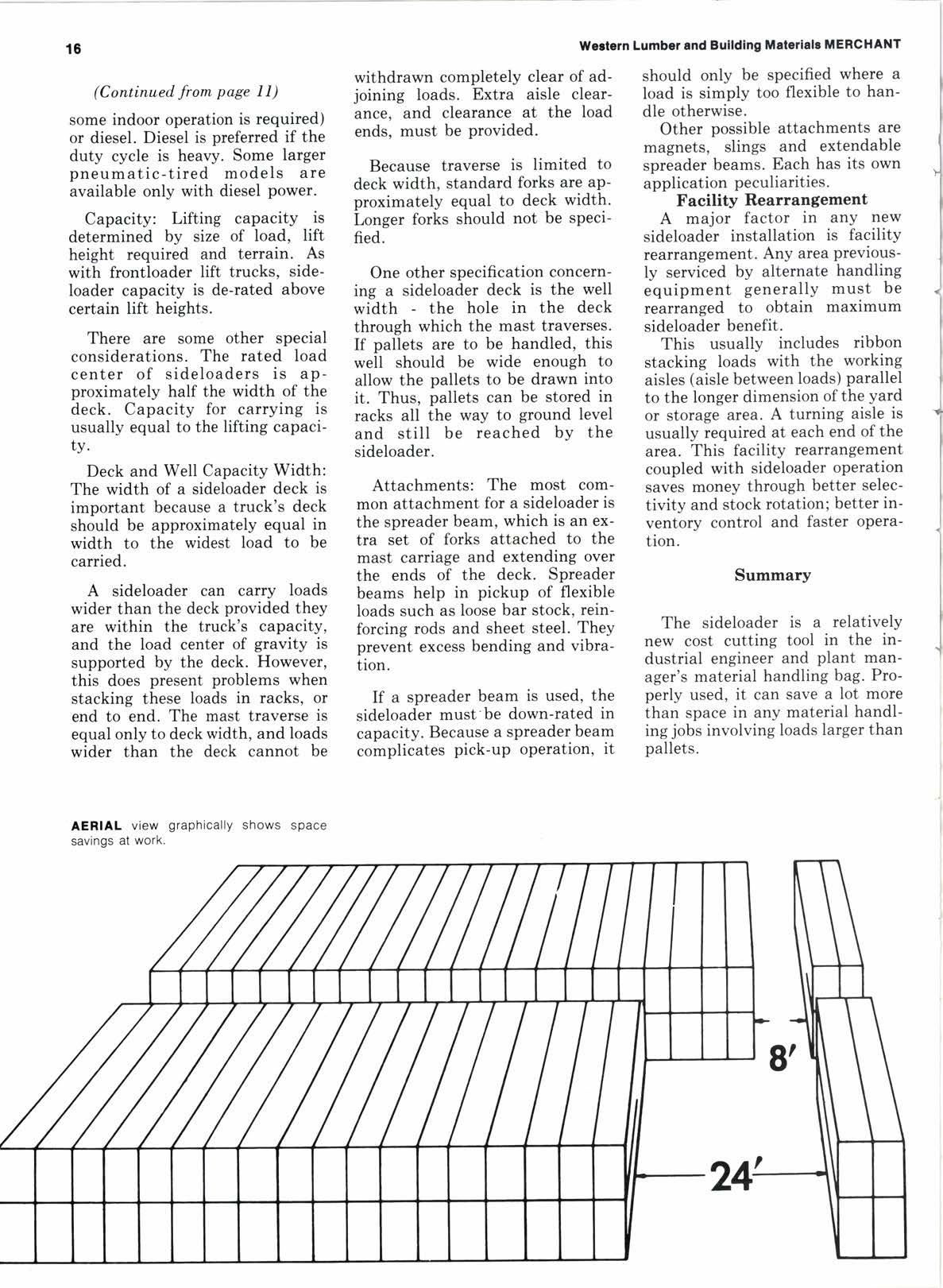

Deck and Well Capacity Width: The width of a sideloader deck is important because a truck's deck should be approximately equal in width to the widest load to be carried.

A sideloader can carry loads wider than the deck provided they are within the truck's capacity, and the load center of gravity is supported by the deck. However, this does present problems when stacking these loads in racks, or end to end. The mast traverse is equal only to deck width, and loads wider than the deck cannot be withdrawn completely clear of adjoining loads. Extra aisle clearance, and clearance at the load ends, must be provided.

We.torn Lumber and Bullding Materlalr MERCHANT should only be specified where a load is simply too flexible to handle otherwise.

Because traverse is limited to deck width, standard forks are aPproximately equal to deck width. Longer forks should not be sPecified.

One other specification concerning a sideloader deck is the well width - the hole in the deck through which the mast traverses. If pallets are to be handled, this well should be wide enough to allow the pallets to be drawn into it. Thus, pallets can be stored in racks all the way to ground level and still be reached by the sideloader.

Attachments: The most common attachment for a sideloader is the spreader beam, which is an extra set of forks attached to the mast carriage and extending over the ends of the deck. Spreader beams help in pickup of flexible loads such as loose bar stock, reinforcing rods and sheet steel. They prevent excess bending and vibration.

If a spreader beam is used, the sideloader must'be down-rated in capacity. Because a spreader beam complicates pick-uP oPeration, it

Other possible attachments are magnets, slings and extendable spreader beams. Each has its own application peculiarities.

Facility Rearrangement

A major factor in anY new sideloader installation is facility rearrangement. Any area previously serviced by alternate handling equipment generally must be rearranged to obtain maximum sideloader benefit.

This usually includes ribbon stacking loads with the working aisles (aisle between loads) parallel to the longer dimension of the Yard or storage area. A turning aisle is usually required at each end of the area. This facility rearrangement coupled with sideloader operation saves money through better selectivity and stock rotation; better inventory control and faster operation.

Summary

The sideloader is a relatively new cost cutting tool in the industrial engineer and plant manager's material handling bag. Properly used, it can save a lot more than space in any material handling jobs involving Ioads larger than pallets.

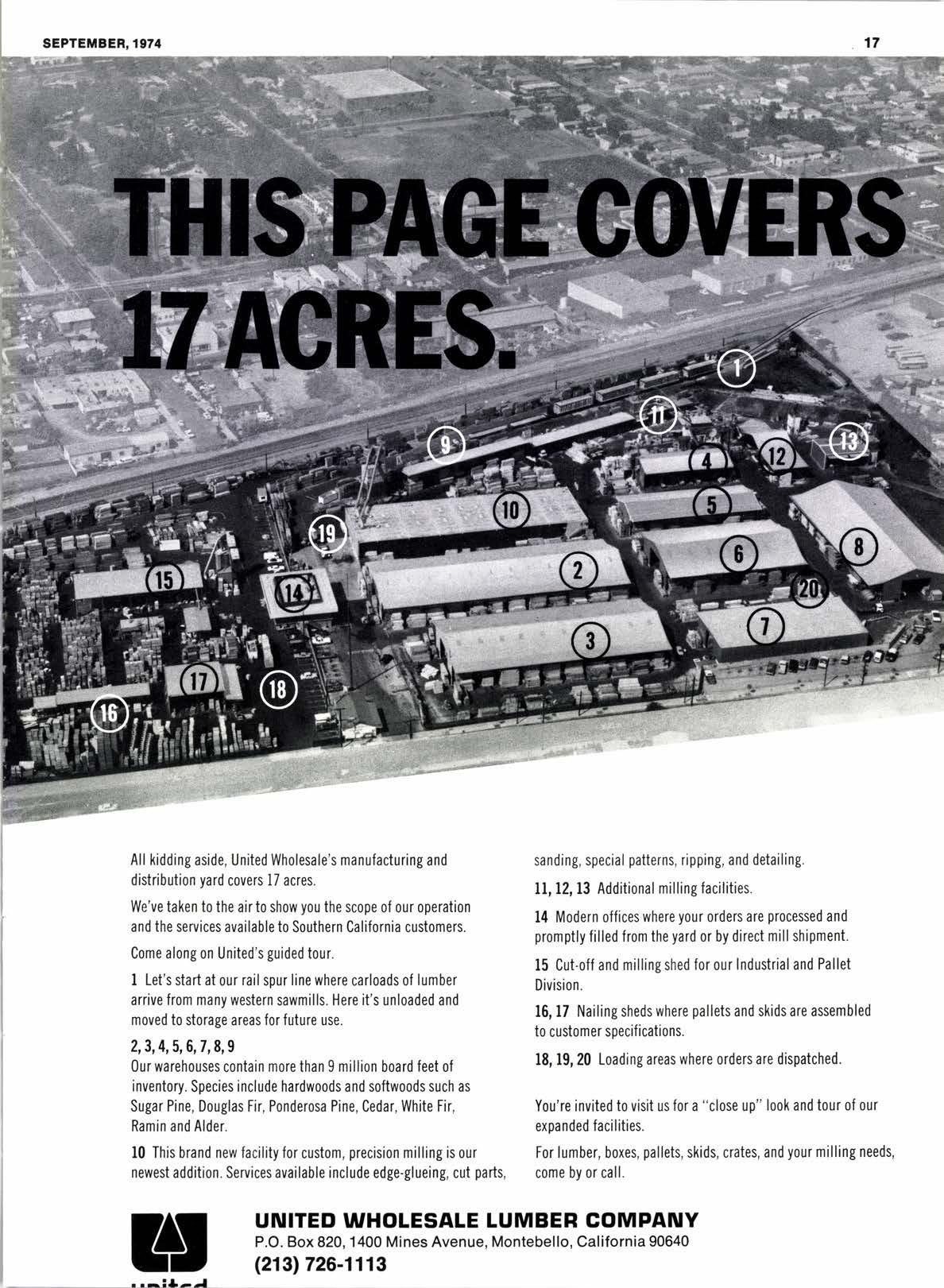

All kiddrng aside, United \{holesale s manu{acturing and distribution yard cotlers 17 acres.

Wc've taken to the air to show you the scope ol our operation and the services available to Southern California cust0mers.

Come along on United s guided tour

I Let s start at our rail spur line where carloads of lumber arrive from many western sawmills. Here it s unloaded and moved to storage areas ior future use.

2,3,4,5,6, 7, 8, 9

0ur warehouses c0ntain m0re than 9 million board feet of inventory, Species include hardwoods and softwoods such as Sugar Pine. Douglas Fir, Ponderosa Pine, Cedar, White Fir. Ramin and Alder l0 This brand neur faciiity for custom. precision milling is our newest addition. Services available include edge-glueing, cLrt parts sanding speciaJ patterns, ripping, and detailing ll, 12, l3

Additional milling facilities l4 i\4odern offices where y0ur 0rders are processed and promptly filled from the yard or by direct millshipment

15 Cut'off and miiling shed for our lndustrial and Pallet

D iv isio n.

16, l7 Nailing sheds where pallets and skids are assembled to customer specif ications.

18, 19, 20

Loading areas !!here orders are dispatched.

You're invited to visit us for a close up" look and t0ur 0f 0ur expanded facilities.

For lumber, boxes, pallets, skids, crates, and your milling needs, come by or call