2 minute read

Non-Com'lumber is stoying ot this Holidoy Inn.

Advantages offered by Non-Com f ire-protected lumber were so impressive that the building contractor for the new Holiday Inn Motel in East Orange, New Jersey, changed his original specif ications from steel studs to Non-Com wood studs. And for a lot of qood reasons:

For savings in constructio"n costs. Use of Non-Com f ireprotected wood studs meant savings on cost of materials used elsewhere in the building. Insulation, for example, and door bucks cost less. The contractor felt that an optimistic estimate of eventual savings might run as high as 20%.

For sheer workability. Non-Com retains all the workable characteristics of wood, and that meant easy adaptability to extensive wirlns.

For savings in labor costs. Non-Com stud partition systems go up fast. Carpenters use ordinary tools. No special accessorles necessary.

For lightweight ruggedness and a fire-protection excellence that is rapidly gaining building-code acceptance cross-cou ntry.

What this story adds up to is a whole lot of good reasons for using Non-Com lumber. lt could be your story, too.

For more information on Non-Com, write for Product Folder W-57B,or call Don C. Smith, (213-830 2860) in Wilmington, Calif

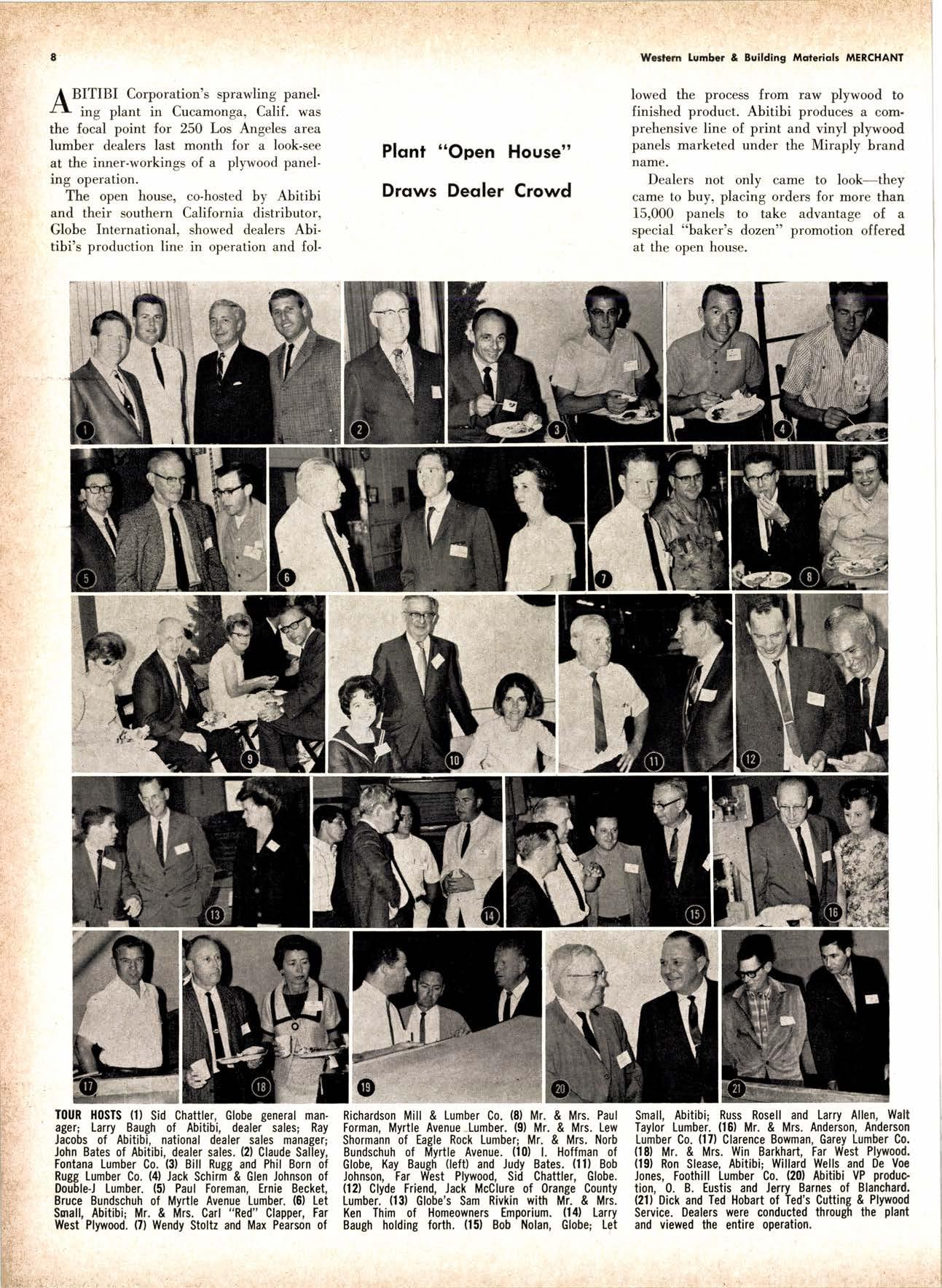

A Bl'f llll for'lrolution : sl)r'u\\lilrF l)unt'1. n i"g plutrl irr (.rt, um,,n;.ir. Culif. nas thc foctrl point {or' 250 Los Arrgt'lt's ar-cu Iumbel tlt'alcrs last morrtlt ftil a look-scc at tltt'irrrrer'-\r()rkiltgs of a plvvot,<l pant'ling opt'r'ittion.

'Ihe r,1rt'rr ]rorr,.t'. < o-ltostt'd bl Ahitibi anrl llrt'ir soullrt'r'n (-ali[olrria <listributor'. (llobc Tntt'r'national. shru t'rl dcalcrs Abitibi's ;rrotlrrctiorr lirrt' irt olrtlatiotr antl fol-

Plont "Open Drqws Deoler

House" Crowd

Wesletn Lumber & Building Mqteriols MERCHANT

lorvt'd thc pro(x)ss f rom raw plyrvootl to linislred prodrrr:l. Abitibi produces a (,omprlt'ht'nsivt' line oi print and vinvl plr.rvood lilil;l: -".octt'd trnder thc Nliruplv brand l)t'alt'r's not. txtly <:anrt'to kxrk tlrt'v camt' lo buv. placing orrlt:r's for molc than l;.000 partt'ls to lakc acivanlagt' of .l spt'cial "bakcr''s tkrzctr'' plontotiorr r,ffered rtt tltt' opt'n lroust'.

T0UR H0SIS (1) Sid Chattler, Globe general manager; Larry Baugh of Abitibi, dealer sales; Ray Jacobs of Abitibi, national dealer sales manager; John Bates of Abitibi, dealer sales. (2) Claude Salley, Fontana Lumber Co. (3) Bill Rugg and Phil Born of Rugg Lumber Co. (0 Jack Schirm & Glen Johnson of DoubleJ Lumber. (5) Paul Foreman. Ernie Becket. Bruce Bundschuh of Myrtle Avenue Lumber. (6) Let Small, Abitibi; Mr. & Mrs, Carl "Red" Clapper, Far West Plywood. 0) Wendy Stoltz and Max Pearson of

Richardson Mill & Lumber Co. (8) Mr. & Mrs. Paul Forman, Myrtle Avenue Lumber. (9) Mr. & Mrs. Lew Shormann of Eagle Rock Lumber; Mr. & Mrs. Norb Bundschuh of Myrtle Avenue. (10) l. Hoffman of Globe, Kay Baugh (left) and Judy Bates. (11) Bob Johnson, Far West Plywood, Sid Chattler, Globe. (12) Clyde Friend, Jack McClure of 0range County Lumber. (13) Globe's Sam Rivkin with Mr. & Mrs. Ken Thim of Homeowners Emporium. (14) Larry Baugh holding forth. (l5l Bob Nolan, Globe: Let

Small, Abitibi; Russ Rosell and Larry Allen, Walt Tavlor Lumber. (16) Mr. & Mrs. Anderson. Anderson Lu'mber Co. (17) Clarence Bowman, Garey Lumber Co. (18) Mr. & Mrs. Win Barkhart, Far West Plywood. (19) Ron Slease. Abitibi: Willard Wells and De Voe Jones, Foothill Lumber Co. (20) Abitibi VP production,0. B. Eustis and Jerry Barnes of Elanchard. (21)'Dick and Ted Hobart of ied's Cutting & Plywood Service. Dealers were conducted through the plant and viewed the entire ooeration.