1 minute read

Pre-staining can help cute dealer headaches

EALER A sold some cedar siding to his customer, who came back a few days later to buy stain. But the third time he returned, it was angrily, with a cargo of complaints.

It seemed that the stain wouldn't go on evenly, it streaked and left lap marks. And the new wood had shrunk leaving noticeable bare spots. And

Dealer B has solved these problems before his customers ever see the wood. He offers an alternative, pre-stained wood. His customers don't return grumbling; they've been sold a product guaranteed never to crack, peel, flake or blister. They've also been saved the stainingjob inconveniences of potential weather delays, the clutter of equipment and scaffolds, and cleanup.

More and more dealers are following Dealer B, offering their customers the satisfaction of pre-stained product.

Machine-stained wood is readily available from a growing number of outlets.

Olympic Stain is a pioneer in providing their machine staining process and equip- ment for use by lumber sellers. Since 198, approximately Vz billion board feet of lumber has been machine stained.

And the market's still expanding. Hedlund Lumber in Sacramento. Ca.. in business for more than 30 years, began specializing in cedar sidings about 12 years back. Fouryears ago, they adopted a staining service. "Like anything else, it's something that takes time to catch on," observes Gary Steiner, Hedlund vice president. "But it seems that once somebody uses the product, they're really sold on it." Hedlund actively promotes the service, saying that it betters an already quality product.

Machine operators such as Hedlund can stain lumber or plywood including siding, trim and soffit materials in any widthrp to 50 inches and in any thickness from '/e to 4 inches. The materials can be stained in any of 67 semi-transparent or solid colors.

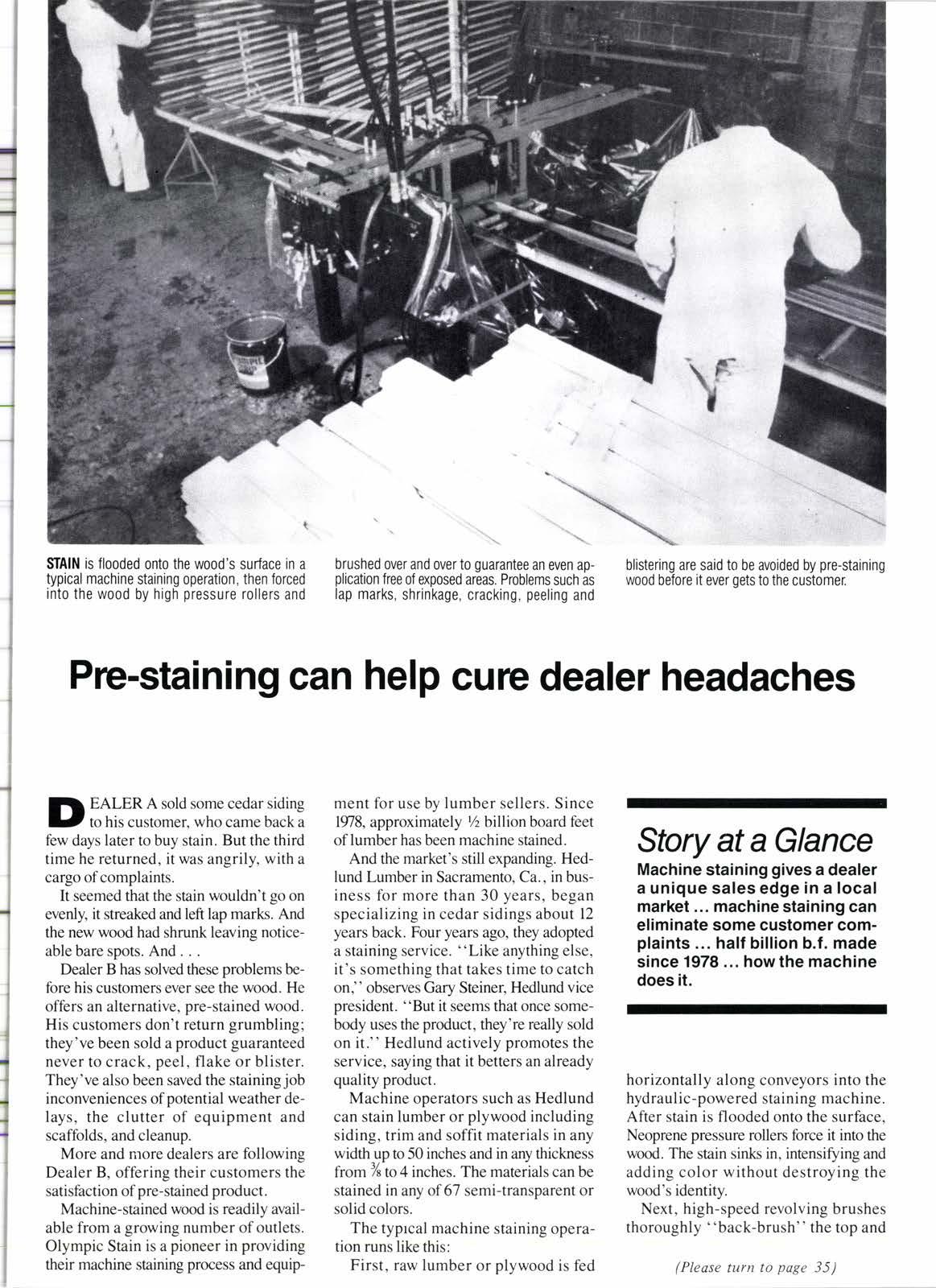

The typrcal machine staining operation runs like this:

First, raw lumber or plywood is fed

Story at a Glance

Machine staining gives a dealer a unique sales edge in a local market ... machine staining can eliminate some customer complaints ... half billion b.f. made since 1978... howthe machine does it.

horizontally along conveyors into the hydraulic-powered staining machine. After stain is flooded onto the surface, Neoprene pressure rollen force it into the wood. The stain sinla in, intensiffing and adding color without destroying the wood's identity.

Next, high-speed revolving brushes thoroughly "back-brush" the top and

(Please turn to pase 35)