6 minute read

AIDYantages Aduertising system

r 36 Different Promotional Themes

Mo 36 Feature llems o 36 Sub-Features o 432 Generic Product lllustrations

All in a sensational line drawing technique that makes it easy for you to adapt to your own advertising image.

'and you gel 2 sets ol all art wotk!

GUAFIANTEED! lf you're not fully satisfied we'll refund your money and pay the shipping costs both ways

Home Center

(Continued from page 35) that we were interested in considering purchasing an IBM word processor and would they send someone to talk to us. We were told "Everyone is outplease call back later. t' o Radio Shack showed us printed samples of how their mini computer can be used as a word processor and some of the test in their presentation letter wereprintedthisclosetogether while other lines were about this far apart! r And, more than one operator's handling of a phone call made us question whether we could get th€ service we needed for this expensive electronic equipment.

. When we asked Xerox why the print in their presentation samples was blurry and not clean and crisp, we were told these were copies, not originals. (It sure doesn't say much for their copy equipment.)

Why am I writing about IBM, Xerox, and Radio Shack in a Home Center column? Because if big companies like these can let their guard down, I wonder what's happening at the local retail level?

It's a buyer's market. Buyers can pick and choose and make their purchases at the stores where they feel most comfortable, most appreciated. Maybe it's time for the building material operator to check to see how easy it is to get a phone call through to his operationor to place a phone orderor get waited on in the storeor get credit OK'edor get lumber tallied in the yard!

Maybe it's time to check to see if some of the people who talk with customers at your store treat them as an interruption of their non-selling duties. And maybe it's time for management to review their systems and procedures and to make sure that everyone who has the responsibility of talking to potential buyers knows specifically how management wants them to respond to, and, to ask questions ofthe customer. Maybe nobody explained it before!

Thot's How

Goes!

Service-oriented wholesaler

LeBeck Forest Products is a specialist in redwood.

Our contacts and sources can get you the redwood items and products you need. Our experience in redwood is a plus for you in finding those hard-to-get items.

In addition to redwood, we can supply your needs in Douglas Fir, Particleboard md Plywood, (7O7) 542-0820 Dave leBeck o You'Il see lots of new sales opportunities! o You'll find it easier to sell your "tlow - movlrrg" itemg! o You'Il discover manynew buyers never knew existed for both gradee and high grades! o You'll have 8fi) pages full of up-todate lumber purchaslng factg on most of the woodworking plants in the U.S.A. and Canada. o You'Il know who is buying what . in epeeies, grades, thickneesee and quantlties of HABDWOODS, SOFTWOODS and IMPORTED WOODS

New Dimension, an Old Name

In the West the 99-year-old Winton Lumber Co. is remembered for the years it operated the pine mill at Martell, Ca., before selling it to the American Forest Products Co. in 196/..

The firm also is remembered for building the first all white fir plywood plant in 1959. Now, it is a leader again with a mill, the Pas Lumber Co., Ltd., producing structural grade finger-jointed long length dimension lumber.

In the early '50s, when the Winton family did finger-jointing of white fir and pine moulding, they hoPed that one day they could use the surPlus short length lumber from the spruce mill in a higher dollar return product. Twenty five years later technology developed by Dr. Suezone Chow of the Western Forest Products Laboratory, Vancouver, B.C., made this possible.

They opened the Pas mill in Prince George, B.C., in l979toproduce2x4 through 2x12,22 ft. through 40 ft., structural #l and #2 SPF. Built at a cost of over $2% million, the plant is said to be the most modern finger- joint facility in the world.

The process starts with 6 to l0 ft. lengths of spruce, pine and fir. This raw material is sized in the planning mill to an oversize of l/8" over in thickness and V+" over in the width before entering the finger-joint plant where it is trimmed andvisuallygraded before fingers are cut in each end.

After the cutting, the material flows through a huge oven 73 ft. long where a 175" temperature is maintained. As the raw material leaves the oven, phenol resorcinol exterior marine glue is applied to the fingers at both ends. They are then jointed together with approximately 400 p.s.i. of pressure. The heat stored in the fingers helps to cure the glue.

A continuous ribbon of lumber is the result of this process. As it feeds out, a flying cut-off saw automatically cuts it to pre-determined lengths. After traveling on a series of carefully timed belts to allow additional curing, the lumber goes to the Planer where it is surfaced to standard, structural dimension sizes.

Each piece of lumber produced is passed through a 40 ft. Metriguard Tension tester which clamPs the lumber at each end and applies a load in tension to 1.3 times the Ft. values for #1 SPF grade. Results show 390 or less of the pieces fail. In addition' 9990 of those that do fail break not at the joint, but in the lumber.

Uses for long dimension lumber include rafters and joists in residential, commercial, and agricultural construction. According to those who use it, its straightness makes it unnecessary to sight in the crowns. The availability of long lengths for floor joists, plates, ceiling joists and rafters is said to make it possible to build with approximately 4090 fewer pieces of lumber, eliminating butt joints, spliced joints and overlaP joints.

In addition to long dimension lumber, the Prince George Plant can run 2 in. decking to lengths uP to 40 ft. with precision trim to exact length and rough faced sidings in DollY Varden, Channel and carsiding Patterns.

All Winton long dimension lumber is sold through the Winton Sales Co., Minneapolis, Mn., with Lou Huettl, sales manager, and a staff including Paul Williams, assistant sales manager, and Steven From.

REDWOOD ADVANTAGES

(Continued from page 12)

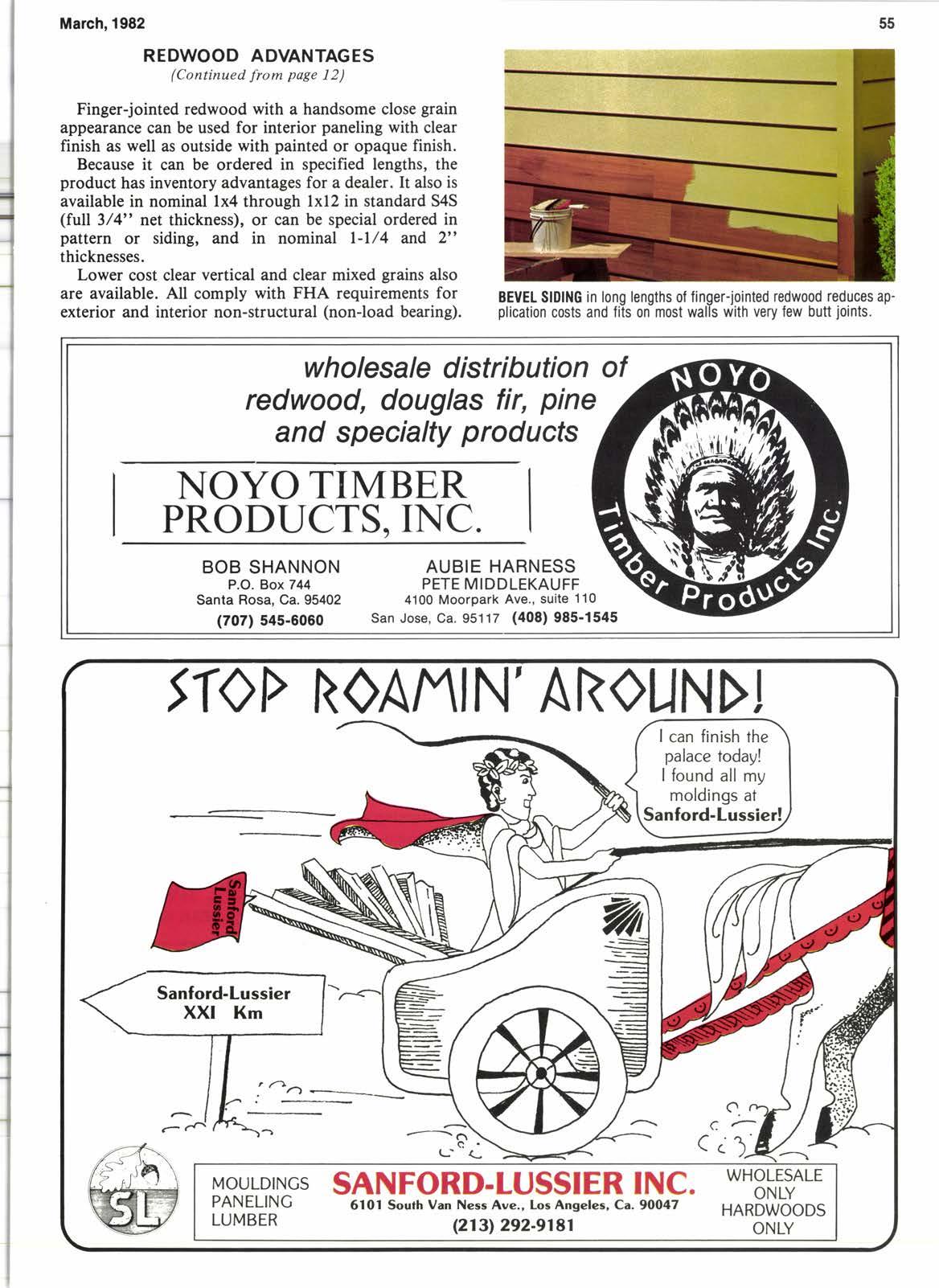

Finger-jointed redwood with a handsome close grain appearance can be used for interior paneling with clear finish as well as outside with painted or opaque finish.

Because it can be ordered in specified lengths, the product has inventory advantages for a dealer. It also is available in nominal lx4 through lxl2 in standard S4S (fitll 3/4" net thickness), or can be special ordered in pattern or siding, and in nominal l-l/4 and 2" thicknesses.

Lower cost clear vertical and clear mixed grains also are available. All comply with FHA requirements for exterior and interior non-structural (non-load bearing).

wholesale distribution ot redwood, douglasfir, pine and specialty products

BOB SHANNON

P.O. Box 744 Santa Rosa, Ca.95402 (707) s4s-6060

I can finish the palace today! I found all my moldings at Sanford-Lussier!

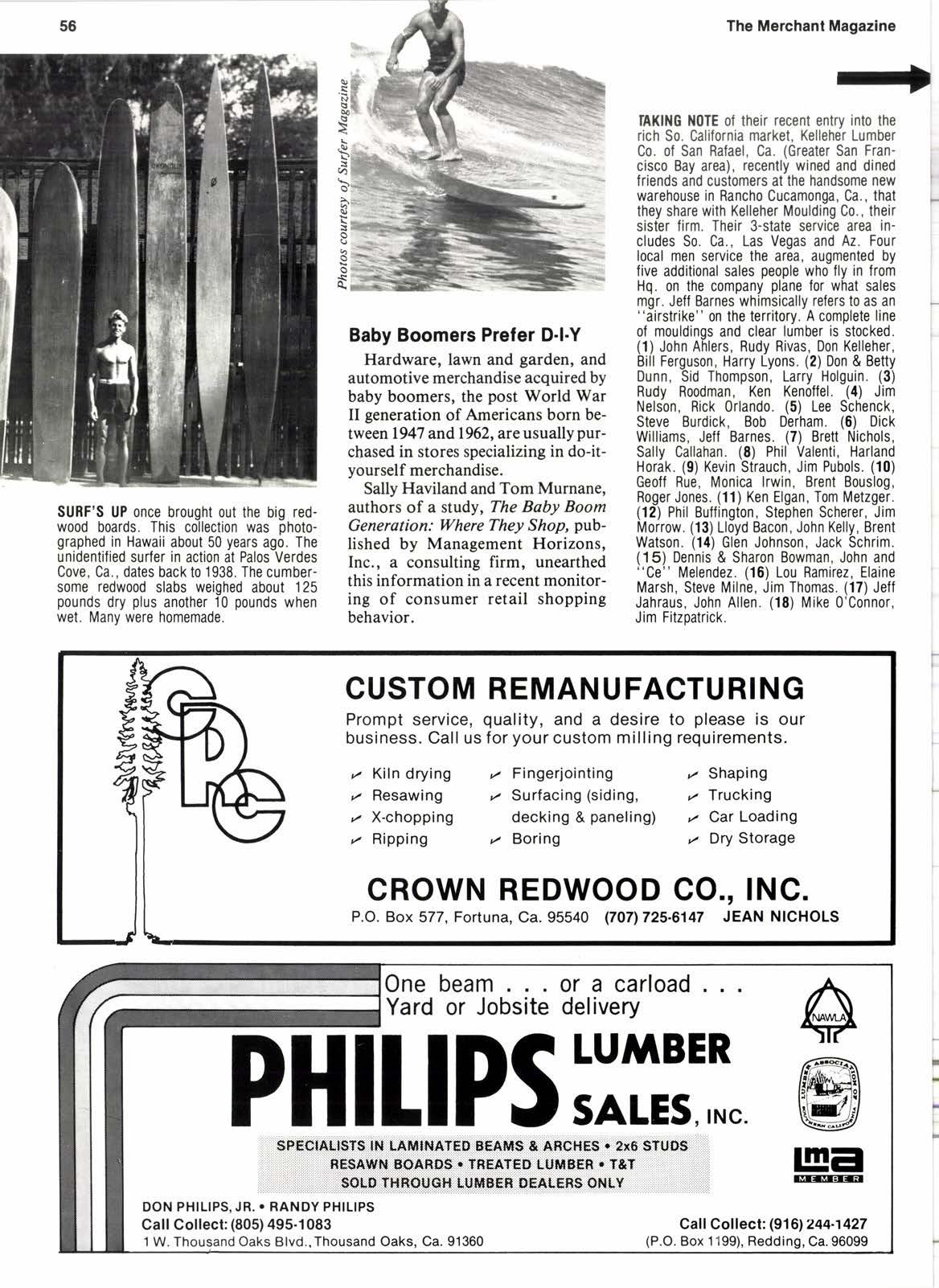

SURF'S UP once brought out the big redwood boards. This collection was photographed in Hawaii about 50 years ago. The unidentified surfer in action at Palos Verdes Cove, Ca., dates back to 1938. The cumbersome redwood slabs weighed about '125 pounds dry plus another 10 pounds when wet. Many were homemade.

Baby Boomers Prefer D-l-Y

Hardware, lawn and garden, and automotive merchandise acquired by baby boomers, the post World War II generation of Americans born between 1947 and 1962, are usually purchased in stores specializing in do-ityourself merchandise.

Sally Haviland and Tom Murnane, authors of a study, The Boby Boom Generotion: lilhere They Shop, published by Management Horizons, Inc., a consulting firm, unearthed this information in a recent monitoring of consumer retail shopping behavior.

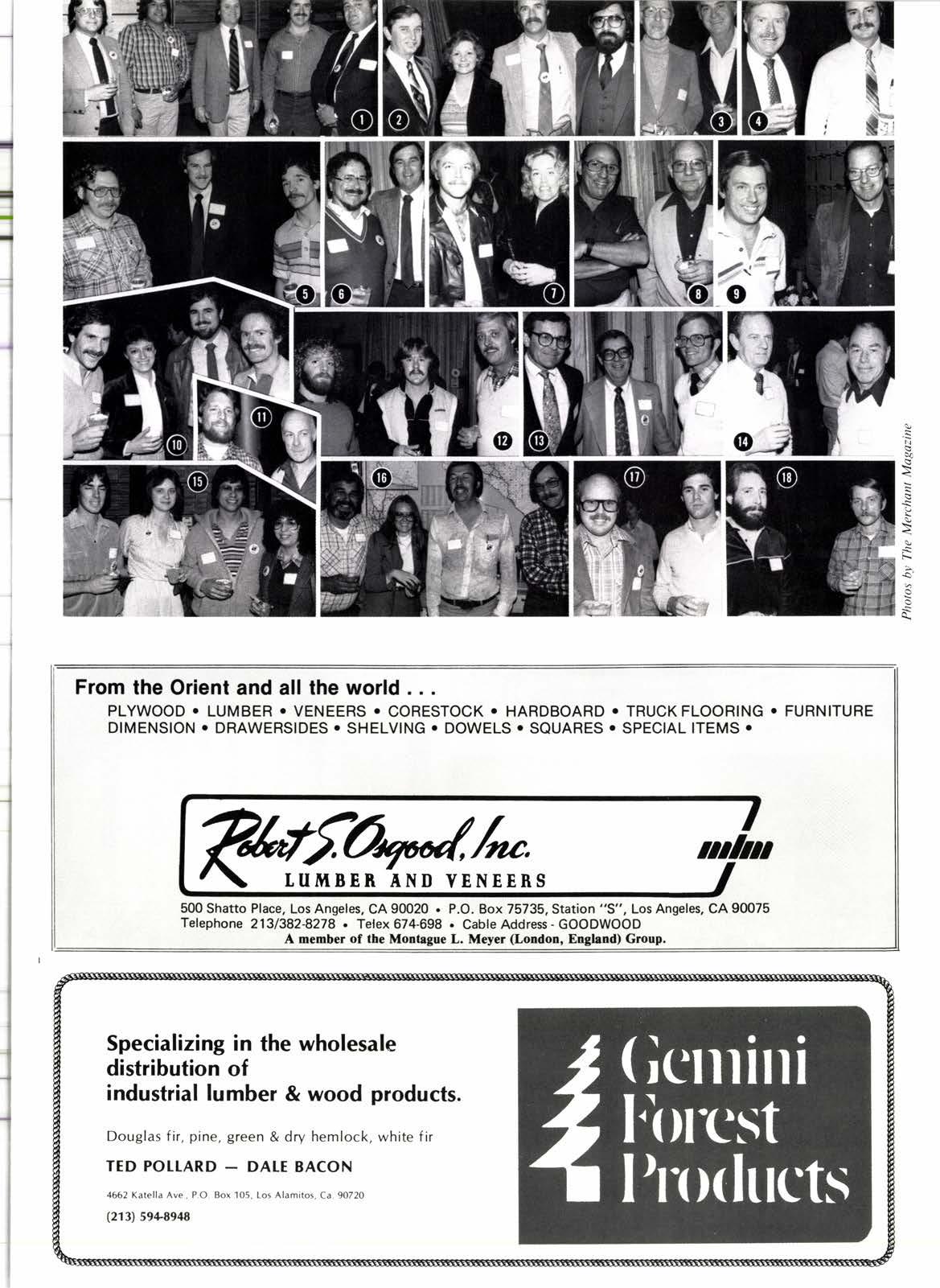

IAKING ll0IE of their recent enlry into the rich So. California market, Kelleher Lumber Co. of San Rafael, Ca. (Greater San Francisco Bay area), recently wined and dined lriends and customers at the handsome new warehouse in Rancho Cucamonga, Ca., that they share with Kelleher Moulding Co., their sister firm. Their 3-state service area includes So. Ca., Las Vegas and Az. Four local men service the area, augmented by five additional sales people who fly in from Hq. on the company plane lor what sales mgr. Jeff Barnes whimsically refers to as an "airstrike" on the territory. A complete line of mouldings and clear lumber is stocked. (1) John Ahlers, Rudy Rivas, Don Kelleher, Bill Ferguson, Hany Lyons. (2) Don & Betty Dunn, Sid Thompson, Larry Holguin. (3) Rudy Roodman, Ken Kenoffel. (4) Jim Nelson, Rick 0rlando. (5) Lee Schenck, Steve Burdick, Bob Derham. (6) Dick Williams, Jefl Barnes. (7) Brett Nichols, Sally Callahan. (8) Phil Valenti, Harland Horak. (9) Kevin Strauch, Jim Pubols. (10) Geoff Rue, Monica lrwin, Brent Bouslog, Roger Jones. (11) Ken Elgan, Tom Metzger. (12) Phil Buffington, Stephen Scherer, Jim Morrow. (13) Lloyd Bacon, John Kelly, Brent Watson. (14) Glen Johnson, Jack Schrim. (15) Dennis & Sharon Bowman, John and "Ce" Melendez. (16) Lou Ramirez, Elaine Marsh, Steve Milne, Jim Thomas. (17) Jelf Jahraus, John Allen. (18) Mike 0'Connor, Jim Fitzoatrick.

Prompt service, quality, and a desire to please is our business. Call us for your custom milling requirements.

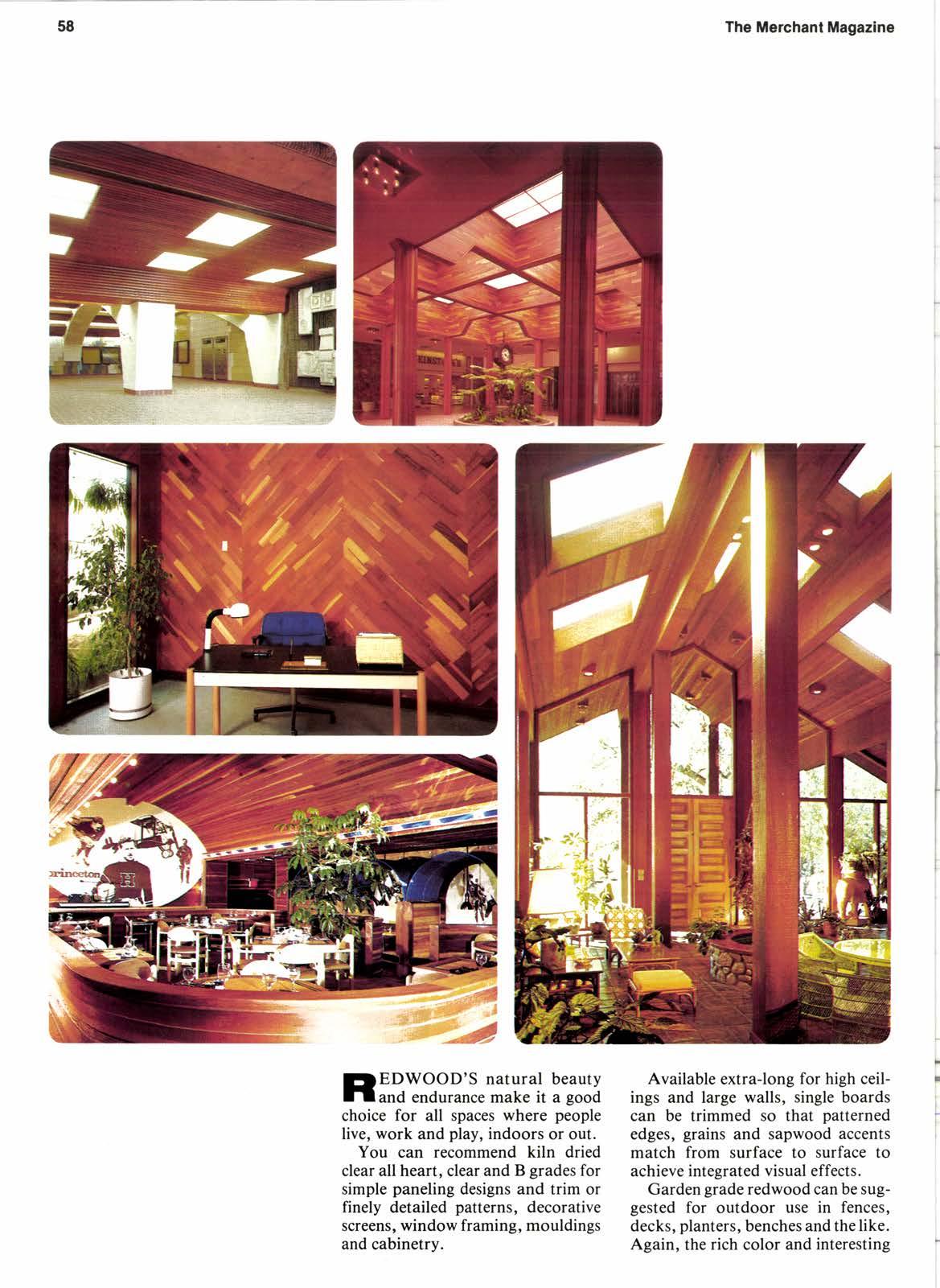

EEDWOOD'S natural beauty l-I and endurance make it a good choice for all spaces where people live, work and play, indoors or out.

You can recommend kiln dried clear all heart, clear and B grades for simple paneling designs and trim or finely detailed patterns, decorative screens, window framing, mouldings and cabinetry.

Available extra-long for high ceilings and large walls, single boards can be trimmed so that patterned edges, grains and sapwood accents match from surface to surface to achieve integrated visual effects.

Garden grade redwood can be suggested for outdoor use in fences, decks, planters, benches and the like. Again, the rich color and interesting