3 minute read

OPERATING TEMPERATURE

element to prevent ripping the filter body from the head.

o Be sure all funnels and other equipment used in transferring oil are clean and leakproof.

o Fill the crankcase to within one quart of capacity. Then start the engine and let it run briefly, carefully watching the oil pressure gauge or warning light. After several minutes of running, stop the engine and check the oil level (wait a minute or so to be sure all the oil has filtered down from the engine into the reservoir). Now add the final quart a bit at a time to bring the oil level to the full mark. The process eliminates the possibility of over filling, which can place undue pressure on gaskets, boost oil consumption and lead to oil foaming.

o Check the drain plug for possible leakage.

o Carefully dispose of the old oil. Do not store it in open containers.

By properly maintaining your engine's oil system, you can extend engine life thousands of miles and avoid premature operating defficiencies

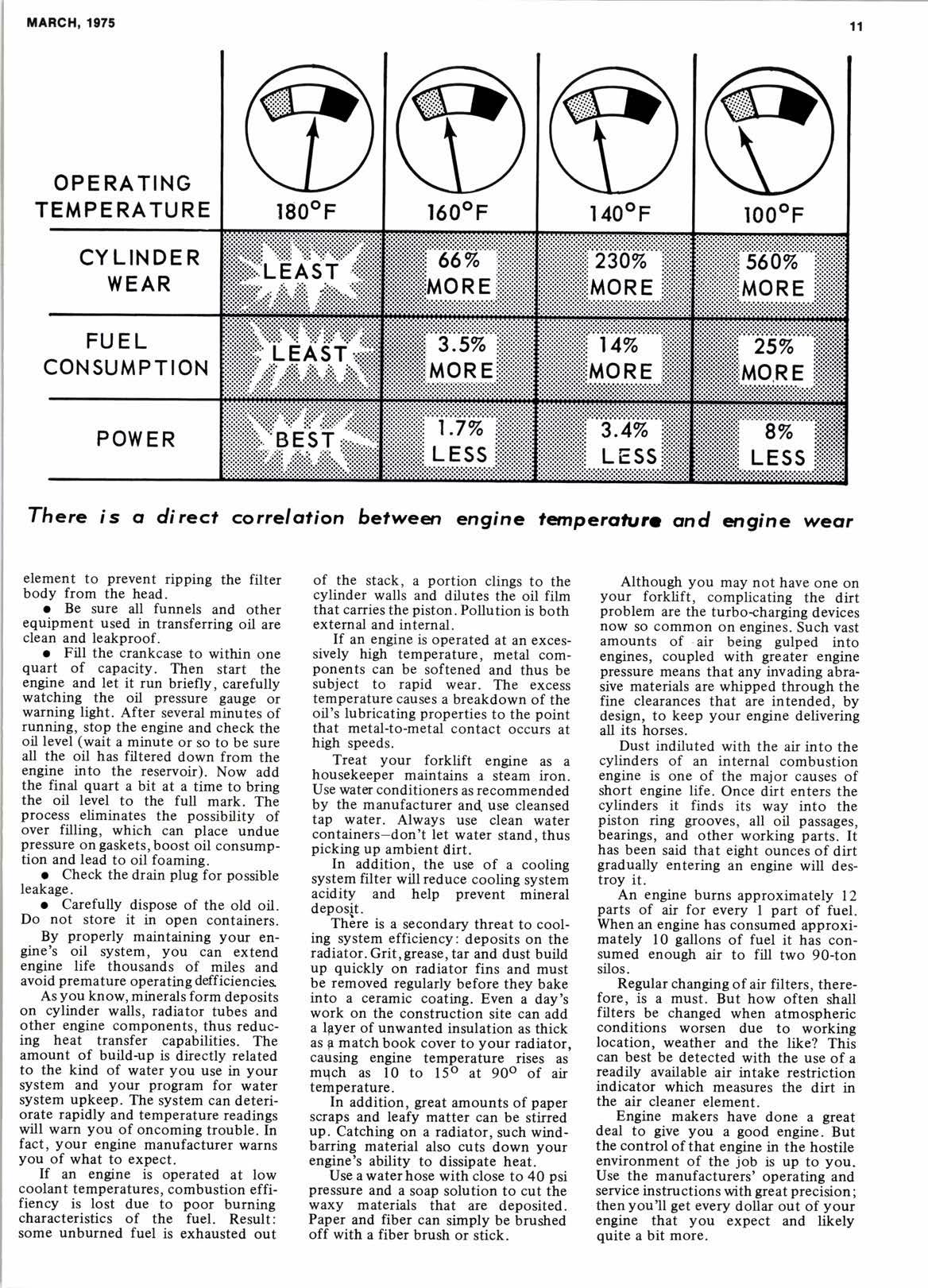

As you know, minerals form deposits on cylinder walls, radiator tubes and other engine components, thus reduc- ing heat transfer capabilities. The amount of build-up is directly related to the kind of water you use in your system and your program for water system upkeep. The system can deteriorate rapidly and temperature readings will warn you of oncoming trouble. In fact, your engine manufacturer warns you of what to expect.

If an engine is operated at low coolant temperatures, combustion effifiency is lost due to poor burning characteristics of the fuel. Result: some unburned fuel is exhausted out

1600f

I 400f

of the stack, a portion clings to the cylinder walls and dilutes the oil film that carries the piston. Pollution is both external and internal.

If an engine is operated at an excessively high temperature, metal components can be softened and thus be subject to rapid wear. The excess temperature causes a breakdown of the oil's lubricating properties to the point that metal-to-metal contact occurs at high speeds.

Treat your forklift engine as a housekeeper maintains a steam iron. Use water conditioners as recommended by the manufacturer an( use cleansed tap water. Always use clean water containers-don't let water stand. thus picking up ambient dirt.

In addition, the use of a cooling system filter will reduce cooling system acidity and help prevent mineral deposit.-Thire is a secondary threat to cooling system efficiency: deposits on the radiator. Grit,grease, tar and dust build up quickly on iadiator fins and must be removed regularly before they bake into a ceramic coating, Even a day's work on the construction site can add a lpyer of unwanted insulation as thick as p matchbook cover to your radiator, causing engine temperature rises as mqch as l0 to l5o at 90o of air temperature.

In addition, great amounts of paper scraps and leafy matter can be stirred up. Catching on a radiator, such windbarring material also cuts down your engine's ability to dissipate heat.

{Jse a water hose with close to 40 psi prossure and a soap solution to cut the waxy materials that are deposited. Paper and fiber can simply be brustred off with a fiber brush or stick.

Although you may not have one on your forklift, complicating the dirt problem are the turbo<harging devices now so common on engines. Such vast amounts of air being gulped into engines, coupled with greater engine pressure means that any invading abrasive materials are whipped through the fine clearances that are intended, by design, to keep your engine delivering all its horses.

Dust indiluted with the air into the cylinders of an internal combustion engine is one of the major causes of short engine life. Once dirt enters the cylinders it finds its way into the piston ring grooves, all oil passages, bearings, and other working parts. It has been said that eight ounces of dirt gradually entering an engine will destroy it.

An engine burns approximately 12 parts of air for every I part of fuel. When an engine has consumed approximately l0 gallons of fuel it has consumed enough air to fill two 90-ton silos.

Regular changing of air filters, therefore, is a must. But how often strall filters be changed when atmospheric conditions worsen due to working location, weather and the like? This can best be detected with the use of a readily available air intake restriction indicator which measures the dht in the air cleaner element.

Engine makers have done a great deal to give you a good engine. But the control of that engine in the hostile environment of the job is up to you. Use the manufacturers' operating and service instructions with great precision; then you'll get every dollar out of your engine that you expect and likely quite a bit more.

HIGH