September/October 2023 DECK Ideas & Strategies for Outdoor Living Professionals BUILDER PAYS IT FORWARD • BUILDER’S TOOLBOX • WHAT CLIENTS WANT What’s Hot in Outdoor Kitchens SPECIALIST Digital Edition Sponsored by

September/October 2023 DECK Ideas & Strategies for Outdoor Living Professionals BUILDER PAYS IT FORWARD • BUILDER’S TOOLBOX • WHAT CLIENTS WANT What’s Hot in Outdoor Kitchens SPECIALIST BUILDER PAYS IT FORWARD • THE DECK BUILDER’S TOOLBOX • WHAT CLIENTS WANT

PWT Treated™ LVL saves you time and labor.

It’s the only LVL that’s treated for exterior deck construction. And because it’s LVL, it’s stronger, straighter and more stable—resulting in the most level structure for any deck regardless of size or design. It also comes with a 25-year warranty thanks to the unique Tru-Core® treatment—applied between each veneer layer—protecting against damage from decay, fungal rot and wood-destroying insects. To learn how we’re revolutionizing deck building, visit www.pwttreatedlvl.com.

TREATED LVL JOISTS | BEAMS | LEDGERS | STAIR STRINGERS | BRIDGING

TREATED LVL JOISTS | BEAMS | LEDGERS | STAIR STRINGERS | BRIDGING

DECK SPECIALIST

Ideas & Strategies for Outdoor Living Professionals

WHAT’S HOT

The Deck Builder’s Toolbox

Tool experts share what builders should consider when choosing their tools.

Outdoor Kitchens

Outdoor kitchens are being designed to match the patio area, deck and pool

FEATURE STORIES

Building with Intention

Top deck builders share what their clients are asking for

with composite fencing

ALSO

with Bobby Parks Set the Standard with Brendan Casey

Tool Reviews with Andy Henley & Mike Mitchell

Market Yourself with April Edwards

New Products

Date Planner Ad Index

ON THE COVER: Sean Collinsgru, Premier Outdoor Living, creates transitional spaces in which every zone has a purpose.

Industry News Parks

Deck

INSIDE Editor’s Note

&

Creation

Paying it Forward Premier Outdoor Living builds a backyard space for a deserving New Jersey man 8 10 38 42 46 50 52 56 57 12 18 16 24 32 18 24 12 16

Maximizing Profits Boost business and customer satisfaction

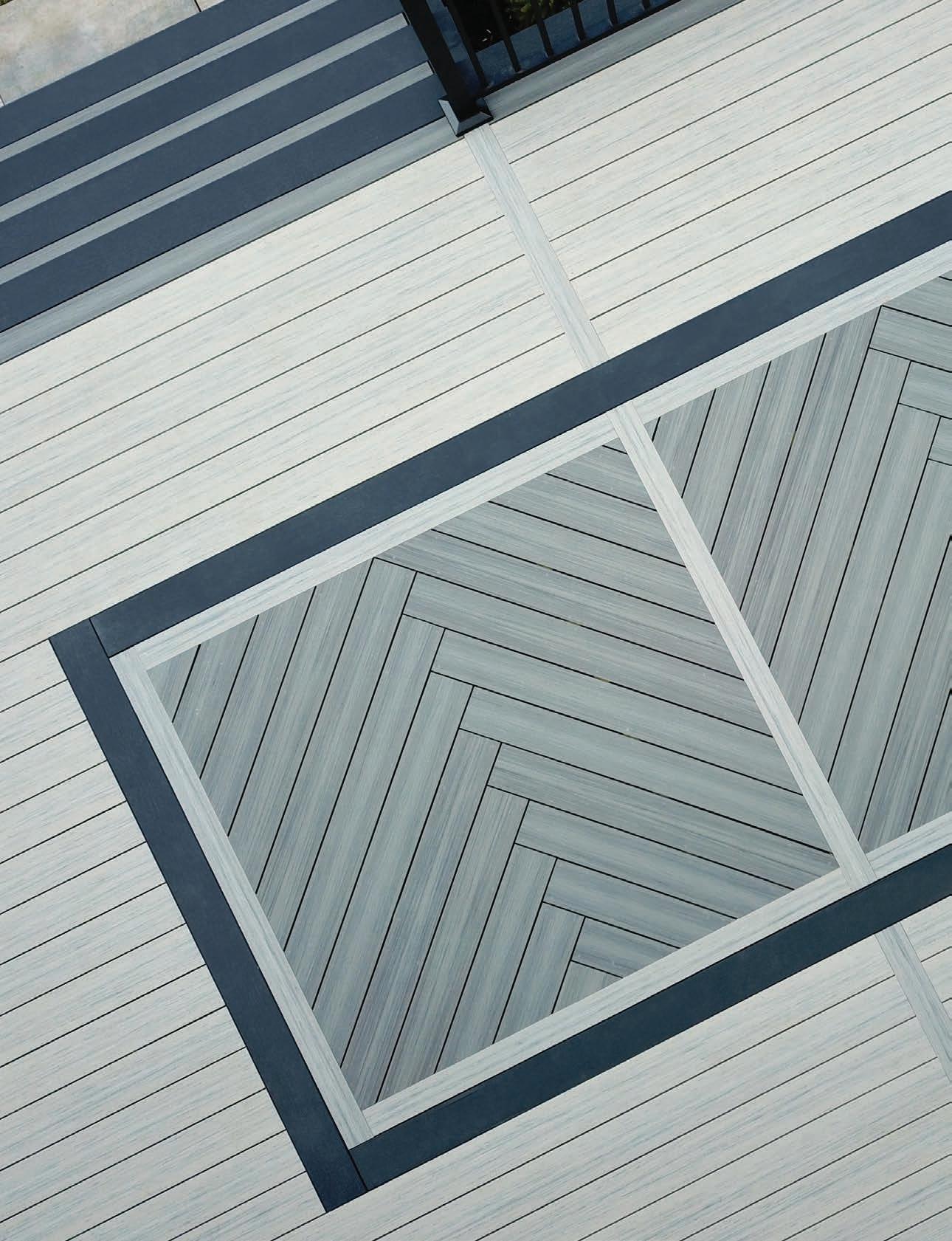

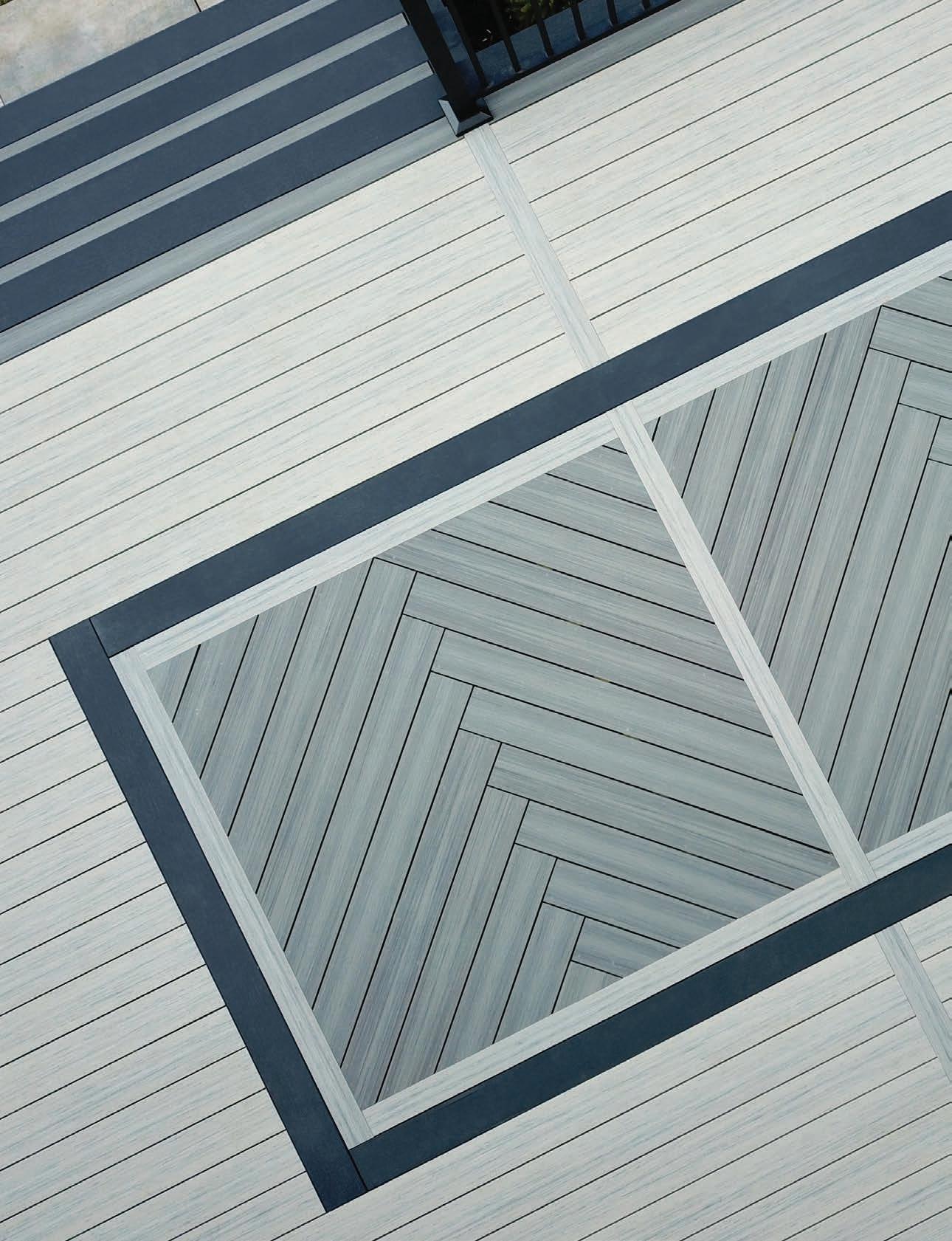

Creating an amazing outdoor living space for your clients takes trust. When you partner with Deckorators, you’ll get unmatched versatility in a product backed by industry-leading warranties – so you can trust the deck you’ve built, long after it’s finished. See our full style guide at Deckorators.com creating WORKS OF ART IMAGINE Picture-framingonsteps Herringbonepatterninlay VoyageDecking inTundra

DECK SPECIALIST

President/Publisher Patrick Adams padams@526mediagroup.com

Vice President Shelly Smith Adams sadams@526mediagroup.com

Managing Editor Sara Graves sgraves@526mediagroup.com

Editorial Director David Koenig dkoenig@526mediagroup.com

Columnists

Brendan Casey, April Edwards, Andy Henley, Mike Mitchell, Bobby Parks

Advertising Sales (714) 486-2735

Chuck Casey ccasey@526mediagroup.com

John Haugh jhaugh@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

Digital Support

Alek Olson aolson@526mediagroup.com

Stephen Ornelas sornelas@526mediagroup.com

Circulation/Support

info@526mediagroup.com

DECK SPECIALIST is published five times a year at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626, (714) 486-2735, www.deck-specialist.com , by 526 Media Group, Inc. (a California Corporation). It is an independently owned publication for U.S.-based builders and contractors that specialize in decking and other outdoor living projects. Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. Deck Specialist reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

Sept/Oct 2023

• Volume 7 • Number 4

SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! Deck Specialist is available on a qualified requester basis to senior management of U.S.-based contractors specializing in decking and other outdoor living projects and to others at the rate of $22 per year. Subscribe now by emailing info@526mediagroup.com or calling 714.486.2735, or heading to www.deck-specialist.com SUBSCRIBE NOW INFO@526MEDIAGROUP.COM or 714.486.2735 THE SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The ultimate publication for qualified industry decision makers! • Update your subscription •Sign up key colleagues •Enroll multiple locations T for qualified industry decision makers! • • Sign • Enroll A publication of 526 Media Group, Inc. 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

Rewarding Kindness

IN REREADING the “Paying it Forward” article on page 32, it got me thinking about the kindness of our industry.

In that story, we share how Premier Outdoor Living recently built a free backyard deck for Troy Green, who has positively impacted a lot of people in his New Jersey community.

Initially, when the Premier staff decided they wanted to build a free deck for a deserving member of their community, they solicited the help of others to name that person. Green’s reputation for helping others brought him to the top of their list.

It is kindness like Green’s that I’m seeing is being rewarded in the industry right now. For instance, I was speaking with Bobby Parks about his column for this issue. He mentioned that he was having his own deck built, and seemed shocked by the assistance he has been receiving from others, including New Castle Steel, in building his deck.

That didn’t come as a surprise to me, though. I knew from speaking with Bobby, and from hearing and reading positive comments from so many other builders, that others would naturally want to lend him a hand if they could. I told him, “When you are the kind of person who is always sharing goodwill among the industry, and you offer advice and encouragement to everyone you talk to, it’s no wonder that people want to help when they can.”

My conversation with Bobby reminded of a time in my own life when others helped me when I needed it most. I, like Bobby, was humbled when they showed unexpected kindness without asking. To this day, I have never forgotten what they did for me then, nor have I forgotten their advice to “pay it forward.”

A few days later, this all came full circle for me. I was standing in line at the grocery store, waiting for the clerk to check out my groceries on the conveyer

belt. Although the people ahead of me didn’t have very many groceries, our line still hadn’t moved after nearly 10 minutes. I figured something must be holding up the line.

It was then that I realized that an older lady in front of the clerk was trying to run her card through the credit card machine, but the card’s magnetic was worn down and the reader wouldn’t recognize her card. It was clear that she needed those groceries by the urgency with how she was trying to get her card to work.

On the verge of tears, the lady must’ve tried a dozen times with a few, different PIN numbers, thinking maybe she had entered in the wrong PIN. She looked in her wallet twice to see if she had a different card to use.

Just as she was about to give up and walk away without her groceries, I slid up next to her and told the clerk I would help her. As I explained to the older lady that someone had done something similar for me once upon a time, she asked me, “How can I get the money back to you?” Without a second thought, I told her to “pay it forward.”

8 | Deck Specialist | September/October 2023

EDITOR’S NOTE

Sara Graves is the managing editor of Deck Specialist. Reach her at sgraves@526mediagroup.com

Premier Outdoor Living built Troy Green’s deck for free to honor him for his community efforts.

The Most Valuable Player on Your Next Job

Introducing FastenMaster MVP: the ultimate multipurpose wood screw that combines ease of use, durability, and versatility, making it the MVP for all your wood construction projects. MVP’s ProjectLife™ coating offers superior corrosion protection in pressure treated applications and is guaranteed for the life of the project. Visit your local lumberyard to try it for yourself!

SCAN

To learn more about MVP and watch a video

Scan to learn more about MVP and watch a video

Scan to watch a video of MVP in action

FastenMaster.com 800·518·3569

TORX® ttap® Drive System wobble-free

ProjectLife™ Coating superior

SureSink™ Head prevents

SureStart™ Point for fast starts

drive

protection

spin-out

NEW

Accoya On Track with U.S. Plant

Construction of Accoya USA’s modified wood manufacturing facility in Kingsport, TN., remains on schedule, to begin operations in mid-2024.

The reactors, essential for the wood acetylation process, arrived in May and were successfully installed at the 100,000sq. ft. facility, a joint venture between Accoya and Eastman.

North America represents the largest potential regional market for Accoya, and the new plant will ensure a ready supply of Accoya to the U.S. Once operational, the new facility will only supply the North American market, representing an additional 67% increase in capacity compared to 2022 volumes worldwide.

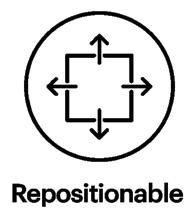

Reclaimed Tropical Hardwoods Added to Nova’s Hardwood Line

Nova USA Wood Products has added reclaimed tropical hardwood products to its premium line of Real Wood Solutions.

The descendants of European marine projects, all of Nova USA’s reclaimed tropical hardwoods are 100% FSC certified and available for the building of outdoor projects ranging from large construction applications to beams, posts and frames due to their superior strength and durability.

“Reclaimed tropical hardwoods have become increasingly popular among government agencies and environmentally conscious builders, architects and homeowners looking to preserve forests, trees and existing wood supplies,” said Laurens van Kleef, Nova USA’s timbers & marine lumber program manager.

Superior Aluminum Expanding HQ

Superior Aluminum Products recently held a groundbreaking ceremony to celebrate a 50,000sq. ft. expansion at its Russia, OH., facility. It is expected to be completed by April 2024.

The new addition represents a 45% increase in the facility’s current 100,000 sq. ft. and will have space for both manufacturing floorspace and administrative offices, along with engineering, design, research & development, and customer service, while adding 17 new jobs over the next three years.

Superior Aluminum Products manufactures aluminum railings and fencing, aluminum, and fiberglass columns, and Snap-Tite PVC column wraps.

Manufacturers Expand Distribution in Various Markets

Deckorators has integrated its composite decking and railing with Sunbelt Forest Products’ portfolio for distribution into the Nashville, TN., market.

Digger Specialties Inc. is partnering with Alexandria Moulding to expand into the Pacific Northwest.

Carolina Atlantic will deliver Fortress Building Products’ steel railing, framing and pergolas to its dealer network in North and South Carolina.

MoistureShield is partnering with Great Southern Wood Preserving, Inc. to expand distribution of MoistureShield’s composite decking portfolio and newly added railing product line in Fombell, PA., and Millwood, KY.

Fortress Sells Composite Decking Subsidiary to Eva-Last Americas

Fortress Building Products has completed the sale of its composite decking subsidiary (which includes products such as Fortress Decking, Cladding and HULK Fasteners), as well as the associated exclusive North American distribution rights, to Eva-Last Americas, Plano, TX.

This sale will allow Fortress to pursue additional growth in its core metals business strengths, which includes steel and aluminum railing, Evolution steel deck framing, fencing, pergolas and lighting.

Headquartered in South Africa, Eva-Last produces composite decking, railing, cladding, and fencing.

10 | Deck Specialist | September/October 2023 INDUSTRY NEWS

The Deck Builder’s Toolbox Toolbox

BY SARA GRAVES

BY SARA GRAVES

12

A BUILDER’S FAVORITE TOOLS

can be as personal to a builder as their projects. Yet, in speaking with tool experts about what builders are looking for in choosing their favorite tools, we learned that it is often the availability of an exterior power source on the job site, the materials being installed, and whether a builder prefers to stand while working that determines the ideal tool for a project. Here’s what we learned.

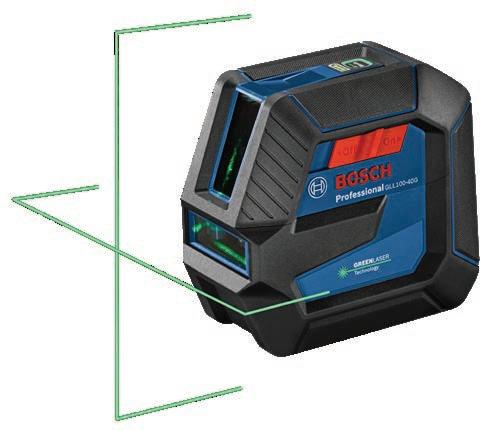

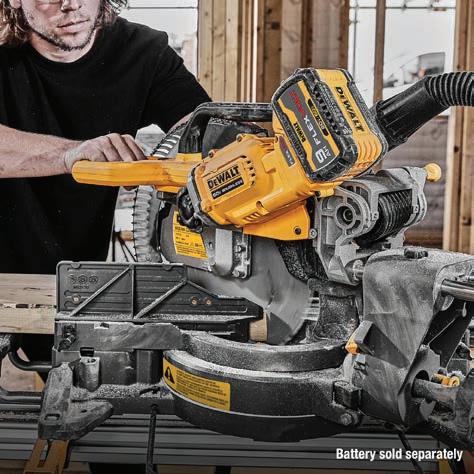

CORDED VS. CORDLESS

When it comes to deciding which tool is best for your project — corded vs. cordless power tools — DeWalt’s Scott Simmons, director of product management, advises builders to first determine if they have easy access to a power source on the jobsite. If not, cordless tools might be the only option to avoid costly generators and bringing in large compressors.

“Battery technology is advancing, allowing for heavy duty applications to switch to cordless, allowing for the freedom of cordless without sacrificing performance,” Simmons explains.

Anthony DiSanto, FastenMaster product manager, agrees, adding that as battery technology has continued to develop and evolve, “more professionalquality, battery-powered hand tools have become available and are prevalent on most jobsites.” Builders in turn are avoiding related job-site issues, such as cord management and cord trip hazards, while reducing generator noise and the need to tap into the customer’s electrical power.

“As the professional market continues to advance in this space, it is important for professionals to consider their power and run-time needs to best take advantage of the various benefits introduced by cordless power tool technology,” says Tyson Apfelbeck, VP of product management, Milwaukee.

Apfelbeck adds that advancements in battery, motor, and electronics have increased power tool performance in applications across the jobsite, eliminating the common tradeoff for users between the power provided by corded solutions and the ease of use by cordless alternatives.

With these advancements, Apfelbeck says the jobsite has increasingly gone cordless, delivering improved productivity and efficiencies for professionals on the job. “As new cordless solutions continue to enter the market offering more power, speed, and run-time capabilities, users shift towards new innovations. It is important for users to invest in battery platforms that deliver disruptive innovation for the continued drive of power, speed and performance that is required on the job.”

Milwaukee’s M12 Jig Saw, for example, provides fast blade speed, more control in application, and maximum versatility, offering deck-building professionals the ability to make intricate cuts around deck posts and pergolas, Apfelbeck says.

DeWalt’s Simmons adds that if a builder prefers to use stainless steel nails instead of deck screws on a job, cordless nailers offer the same freedom that the other cordless tools do without the need for cords, large and noisy compressors, and air hoses that represent lost time to set up and further trip hazards.

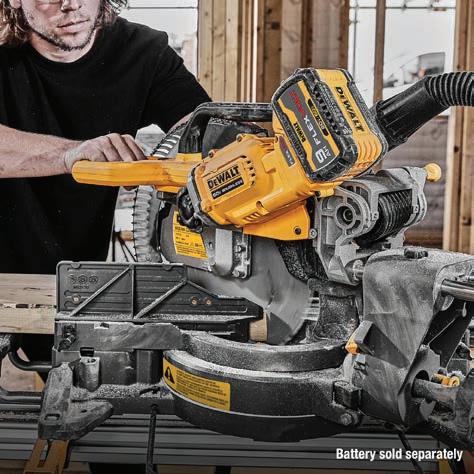

RIGHT TOOL FOR THE RIGHT APPLICATION

Simmons stresses that using the right tool for the right application is paramount. If the builder is installing harder woods, for instance, they will need a saw with enough power “to make all of the necessary cross, rip, bevel, miter, and compound cuts they will need to do without shutting down, especially in such expensive material.”

Or if a builder is cutting Trex or composite materials, choosing the correct blade type is essential. DeWalt’s composite decking blade, for instance, uses a special tooth geometry for shearing through the wood fibers without melting the plastic caps for a cleaner finish.

Simmons similarly advises builders to consider the material being used: pressure treated wood, hardwood, composite, or PVC. He adds, while the material may not specifically dictate which tool to use, it may drive the accessory need (such as the saw blade or fastener).

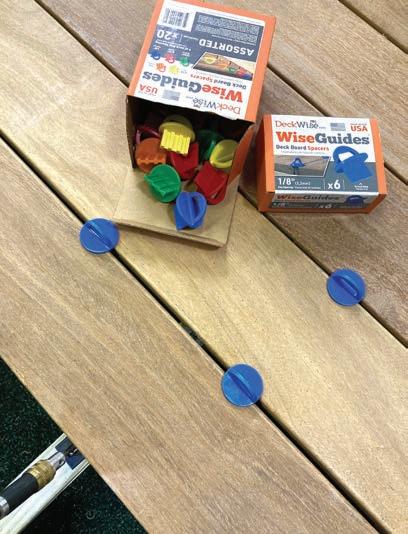

And if a builder is looking to straighten or align warped deck boards, especially hardwoods, thermal woods, pressure-treated or composite, DeckWise’s Hardwood Wrench or lighter-weight, multi-directional Hardwood Wrench Jr., would be useful additions to a builder’s arsenal, advises DeckWise Marketing Director Roderick Kabel.

FASTENERS/SCREWS

With fasteners and screws continually being improved according to the variety of materials they are being installed into, it’s no wonder that the tools to install them are evolving just as quickly.

“As wood substrates are becoming denser, added tool power is required in order to consistently drive fasteners to the proper depths,” say SENCO product managers Ryan Distler and Ryan Schuler.

For deck boards and railings, Distler and Schuler explain, a collated screw system not only speeds up the job, but also assist in the quality of the work. “When driving screws into the deck boards, having a straight line and a consistent depth of drive is key to a clean and uniform look.”

September/October 2023 | Deck Specialist | 13

September/October 2023 | Deck Specialist | 13

In addition, FastenMaster’s new EVO Joist to Ledger Deck Framing Connectors are making it easier and faster to secure deck joists to ledger boards, turning a two- or three-person job into a one-person job for maximum productivity.

Made of reinforced engineered polymer, the EVO connectors are stronger than traditional steel connectors, won’t rust, and are temperature and UV stable. In addition, the design is adjustable and enables decking professionals to align either 2x8 or 2x10 pressure treated lumber to the ledger in seconds, without needing to temporarily tack joists in place during installation.

“This is a game-changer for professional deck builders,” says DiSanto. “The installation speed of EVO deck connectors helps pros frame decks faster. EVO provides the quickest way in the industry to perfectly level joists to the ledger, meet code, produce a long-term connection that is guaranteed for the life of the project, and provide a better finished deck.”

Product marketing manager Robert Shirley adds that with advancements in Simpson Strong-Tie’s low-torque fastener design of its Deck-Drive DSV Wood screws and Strong-Drive WSV Subfloor screws, contractors are now able to drive more screws per battery charge than ever before. And since cordless tools require less skill training to use, an apprentice installer can keep pace with seasoned veterans using heavier duty tools.

ERGONOMICS

Tool weight, portability, and ergonomics are important issues for many pros, DiSanto states. Stand-up tools, and tools that minimize bending, stretching, and twisting can help prevent or significantly reduce musculoskeletal disorders that can be debilitating.

Greg Groenhout, CAMO product manager, agrees, adding that the benefits of stand-up tools, including the CAMO ClipDrive, which features a height-adjustable handle that is designed to enable contractors fasten deck clips to grooved decking while standing, help contractors get the job done faster and more efficiently so they can take on more jobs. Builders experience less fatigue on the body as the tool is more ergonomic, allowing them to work longer.

Another ergonomic-friendly tool is FastenMaster’s

extension pole that easily converts from a stand-up to a short tool for a variety of fastening applications including decks, railings, pergolas, and other outdoor living structures. It can be used in hardwood, pressure treated lumber, as well as in composite materials.

Simpson Strong-Tie’s Shirley adds that he expects to see a continued, high-level focus on innovation and the development of ways to make installations faster, safer, and more efficient.

To help deck contractors and builders save time and money while increasing user productivity and comfort, he says Simpson Strong-Tie continues to enhance its Quik Drive auto-feed screw driving systems to provide improved cordless, ergonomic means of delivering fasteners.

Powered by a DeWalt cordless driver motor, Simpson Strong-Tie’s new Quik Drive Cordless PRO300SG2 Decking System is designed for stand-up operation to make deck and subfloor installations fast and easy, and is now available without having to purchase the duplicative charger and 5-amp batteries that most contractors already own.

SENCO has also addressed the need of improved ergonomics in its products. The company’s DS530-D1 3” auto-feed screwdriver attachment, for example, is perfect for those looking to extend beyond the reach of the traditional power screwdrivers, thereby making the screwdriver into a stand-up tool that is ideal for decking.

“With the DS530 series extension pole, installers no longer have to fasten deck boards while crawling around the surface,” Distler and Schuler explain. DS

14 | Deck Specialist | September/October 2023

PRODUCT DESCRIPTION

American Pro Porch Flooring is a new product in the outdoor living space market. The product is designed to enhance the porch experience with its exceptional features, attractive colors, and high durability.

WHY CHOOSE AMERICAN PRO?

American Pro Porch Flooring is known for its quality and durability, produced from premium PVC materials. This ensures it can withstand various elements and provide long-lasting durability. It is also resistant to moisture, fading, and staining, preserving its appearance over time. It’s scratch-resistant surface is another significant advantage, especially in high-traffic areas such as a porch.

BENEFITS:

• High-Quality Materials: Made with premium materials domestically sourced.

• Low-maintenance Solution: It does not need to be painted or sealed. as the everlasting colors and woodgrain is backed by our 25-year fade and stain warranty.

• Scratch-Resistant Surface: Whether it’s outdoor furniture, pet’s running in and out of the house, our scratch-resistant feature can preserve the porch look.

• Multiple Colors Selection: With 6 different colors to choose from, the ability to customize your porch has never been easier.

ACCESSORY PRODUCTS:

Matching Decking for Stairs

Matching Finish Trim Nosing

Fascia Board for Skirting

All colors match each other for a picture-perfect porch.

High-quality PVC Material

Long-lasting durability. No installation issues due to slitting or cracking.

Moisture Resistant Suitable for any climate. Resistant to mold or mildew.

Low Maintenance

Easy to clean and maintain. Provides the beauty of wood without the maintenance.

Slip-resistant Surface

Safe option for families with children and pets.

Manufacturer’s Reserve Supply is now distributing American Pro Porch Flooring exclusively in New Jersey, Eastern PA, lower New York (including Long Island), Connecticut, Northern Delaware, and Northern Maryland. Visit them at MRSLumber.com or Scan Code:

Beachwood Chestnut Tuscany Redwood Slate Driftwood

phone: 1-877-44AMPRO • email : sales@americanprobp.com • web : americanprobp.com

Fade

Limited

25 Year

and Stain Warranty

Residential

Building with intention

FOR THE SECOND YEAR IN A ROW,

Deckorators hosted a panel of top deck builders discussing the most important trends in outdoor living. “Contractor Insights: Deckorators’ Pro Deck & Dock Builders Share the Future of Outdoor Living” brought together five leading contractors — Sean Collinsgru and Catherine Lippincott, Premier Outdoor Living, Palmyra, N.J.; Michael Scott, Simcoe Decks, Barrie, Ontario, Canada; Leif Wirtanen, Cascade Fence & Deck, Vancouver, WA., and Jason Varney, Dock & Deck, Knoxville, TN. The panelists shared that homeowners are strategically designing their outdoor spaces by creating multi-functional zones that transition from the inside to the outside. Here is how the builders incorporated that multi-functional, indoor/outdoor feel into their recent projects.

Top deck builders share what their clients are asking for

CONTINUED ON PAGE 18

Good deck. Perfect deck!

SUNSCAPE® Roof Covering System

The Contractor’s Choice for better outdoor living spaces.

As the outdoor living space trend continues to rise, give your customers new options to protect their space, rain or shine! Meet the sleek, architectural SUNSCAPE system featuring a sophisticated, glass-like appearance and all-weather, long-lasting protection.

► 3-part system easily installs on a new or existing roof structure

► Virtually unbreakable polycarbonate in a variety of colors

► Lightweight aluminum profiles with a durable anodized finish

► Blocks 100% UV rays to protect the ones you love

•

© 2023 Palram Americas. All Rights Reserved

the perfect system to complete their

projects.

in

Polycarbonate innovation for 60 years. sunscapesystem.com

Offer your customers

deck

Pioneers

PVC &

800-999-9459 FREE SAMPLES

“We’re looking to create multi-functional spaces within one covered zone. From the inside to transitional outdoor space, every zone needs to have a purpose,” said Collinsgru.

In one of his projects, Collinsgru explained the client wanted a covered space that felt like multiple rooms. “We’re able to fit three different functionalities into one covered space. We tried to fit as much indoor feel as we could to this outdoor space, and that came with all of the features with the heaters, the lighting, the fireplace, the kitchen. And it’s super functional so they get a ton of use out of it, and we didn’t waste a lot of square footage.”

Lippincott added that they like to approach the overall deck design as designing for individual rooms rather than one large space. In one of their projects, for instance, half of a large deck was enclosed so the client “can really be outside — they have that outside/outside feel, or they can come into this screened-in porch area to have that more intimate, homey feel.” The screenedin deck area gave the homeowner “that opportunity to treat a room for flexibility in their outdoor living with more intimate spaces for more purposeful usage.”

Efficiency and style are what Leif Wirtanen’s clients are looking for. On one build, the client incorporated his garage into the project. “The upstairs of his garage is kind of a like a lounge chill area with a TV and a cool table and all of that, but he wanted was a space to be able to ... kind of spill out on that upper deck in between breaks. But then, also, if you go down that spiral staircase, there’s an entire outdoor kitchen, a bar, he’s got a TV, heaters, speakers. So really, both levels and (the) inside is just all intermixable, and so you can have quite a large party enjoying the game on Sundays.”

A client of Michael Scott was focused on the overall design of their space. “We did a chevron pattern in the middle and then we basically flanked it all four sides ... but it actually ... flares out like the sun all the way around. Everything is designed to be intentional.”

Having it all, including lighting, fans, heaters in the ceiling, a TV, and retractable screens, is what one of Premier’s clients wanted. “This space, they wanted everything, and they got everything, and we were able to provide them with a beautiful end result,” Lippincott said. DS

18 | Deck Specialist | September/October 2023

Easy to install. Built to last.

Strength and selection go together with Outdoor Accents ® decorative hardware from Simpson Strong-Tie. We’re always expanding our Mission Collection ® and Avant Collection™ lines with new products and accessories, making it easy to enhance outdoor structures and living spaces. Both feature an innovative hex-head washer and fastener combo that looks like a bolted connection but installs as simply as a screw. It’s the only approved fastening solution for Outdoor Accents connectors. Plus, our code-listed connectors and fasteners are rigorously tested for performance. So whether you’re building a pergola or a pavilion, it will be strong, safe and beautiful for years to come.

To see our complete lines of Outdoor Accents decorative hardware and download free project plans, visit go.strongtie.com/outdooraccents or call (800) 999-5099.

©2023 Simpson Strong-Tie Company Inc. OA23-C Mission Avant Outdoor Living Solutions | Products, Software and Service for Smarter Building

Hot OUTDOOR KITCHENS Still a Commodity

ACCORDING TO A 2023 OUTDOOR

Living Trends Report by fixr.com released earlier this year, outdoor kitchens were expected to be the most sought-after trend this year according to 52% of the experts because they come in a wide variety of sizes, materials, features and styles, and they create a space that resembles interior living.

“When the pandemic forced all entertaining outdoors, homeowners reclaimed their backyards from the kids or the dogs,” said Amanda Pendleton, Zillow’s home trends expert. “Now they’re rethinking how that space could serve as an extension of their home in new, creative ways.”

“Now, more than ever, builders are looking at outdoor kitchens to rival interiors in terms of both style and functionality,” added Mitch Slater,

founder of Danver Stainless Outdoor Kitchens, which also manufactures and sells Trex Outdoor Kitchens under a trademark agreement with Trex Company. “Increasingly, we’re seeing builders opt for bolder colors and aesthetics outdoors, with the rise of vibrant options like bold blues and greens, in particular. An outdoor living space presents a fantastic opportunity to showcase fun and different color selections compared to a home’s interior kitchen.”

“Outdoor kitchens continue to be a rapidly growing design and home improvement category–becoming “standard for new luxury home builds,” according to the first Luxury Outdoor Kitchen report released by the National Kitchen & Bath Association (NKBA). Sandra

make the outdoor kitchen an extension of their indoor kitchen, matching the cabinetry and countertop.

Slater added that the outdoor living market continues to grow with accessories, and builders are adding a variety of off-the-shelf options, such as pizza ovens, wine refrigerators, kegerators (that dispense beer from a keg), and more, to elevate the outdoor kitchen into a true entertaining space.

“The outdoor kitchen has come a long way from a grill for hamburgers and hotdogs in a brick enclosure,” Scott said. “Today’s quality grills offer the performance and features that allow cooking anything outdoors that you can cook in an indoor commercial kitchen.” Outdoor chefs look for grills that allow searing, slow cooking,

Gjesdhal, who was interviewed for the organization’s recent report, said, “There will never be a home we design without an outdoor kitchen, ever.”

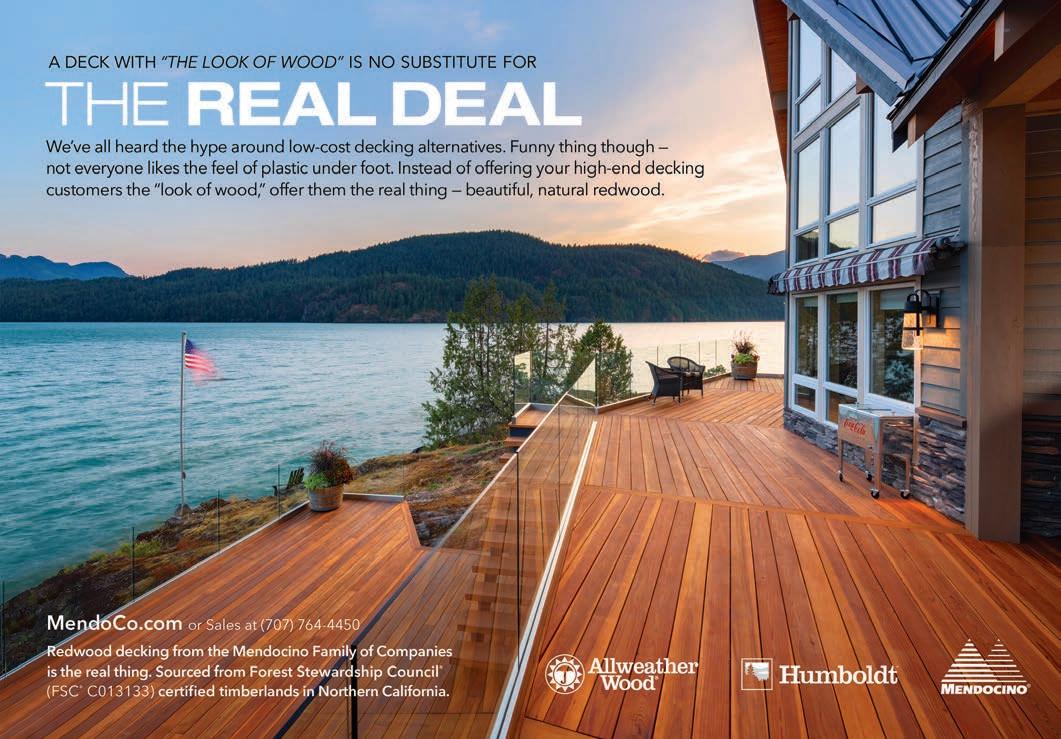

“Outdoor kitchens are being designed to match the styling of the home, patio area, deck and pool,” said Jerry Scott, senior VP of RH Peterson Co., manufacturer of outdoor living products including Fire Magic Grills, American Outdoor Grill and American Fyre Designs fire features and Real Fyre gas logs.

If the home is built with brick, river rock or ledge stone accents, he said, the outdoor kitchen cabinet can be built using the same materials. In addition, countertops can be used that match the color or styling of the pool area or backyard motif. Even building on and matching the wood of the deck can be done, making sure that insulation from the heat of the cooking equipment is provided. Some may even opt to

rotisserie cooking and indirect cooking. Other cooking appliances for the outdoor kitchen that expand the cooking experience include outdoor pizza ovens that can also function as a standard oven for baking, and side cookers that allow for the preparation of sauces and side dishes.

“With outdoor living becoming a year-round activity, homeowners want tailor-made solutions that support their lifestyles and cooking needs throughout the year,” Slater added. “What was once a basic grilling station has become a full-fledged outdoor entertainment space for hosting friends and family.”

An important consideration builders need to consider is the flow from indoors to out, Slater said. “Builders and designers can take advantage of the nearly limitless styles and colors provided by Trex Outdoor Kitchen to create a space that seamlessly

September/October 2023 | Deck Specialist | 21

integrates the aesthetic of their interior or that creates a unique outdoor experience by leaning into a distinct design statement.”

Another consideration is budget and knowing where to invest, Slater said. “When it comes to permanent design details like outdoor cabinetry, it’s important to invest in high-quality solutions upfront rather than needing to replace the product in a few years.”

He added that high-quality cabinetry can raise home values, so builders may need to educate homeowners on the importance of investing in quality materials.

In addition, when choosing outdoor cabinetry, homeowners want to see a variety of sizes and layouts options. He said builders are looking for luxurious features that can meet any of their needs, including soft-close doors and drawers, adjustable shelving, and magnetic closures.

The recently introduced Trex Outdoor Kitchens Explorer Series, for instance, makes some of the most popular kitchen layouts available. The Trip, Voyage, and Oasis kitchens provide customers with functional, simple, and sophisticated solutions for outdoor kitchens, aiming to offer an easy template to start the design process for any outdoor entertainment space.

According to the NKBA, it should come as no surprise that luxury outdoor kitchens have become an expected “standard” for luxury home builds. “Most ground-up new projects are taking outdoor spaces into consideration,” noted Nar Bustamante of Nar Design Group. “New construction definitely includes outdoor living kitchens, pools, decks. It’s a priority.” DS

22 | Deck Specialist | September/October 2023

Photos by Danver, Trex and DCS

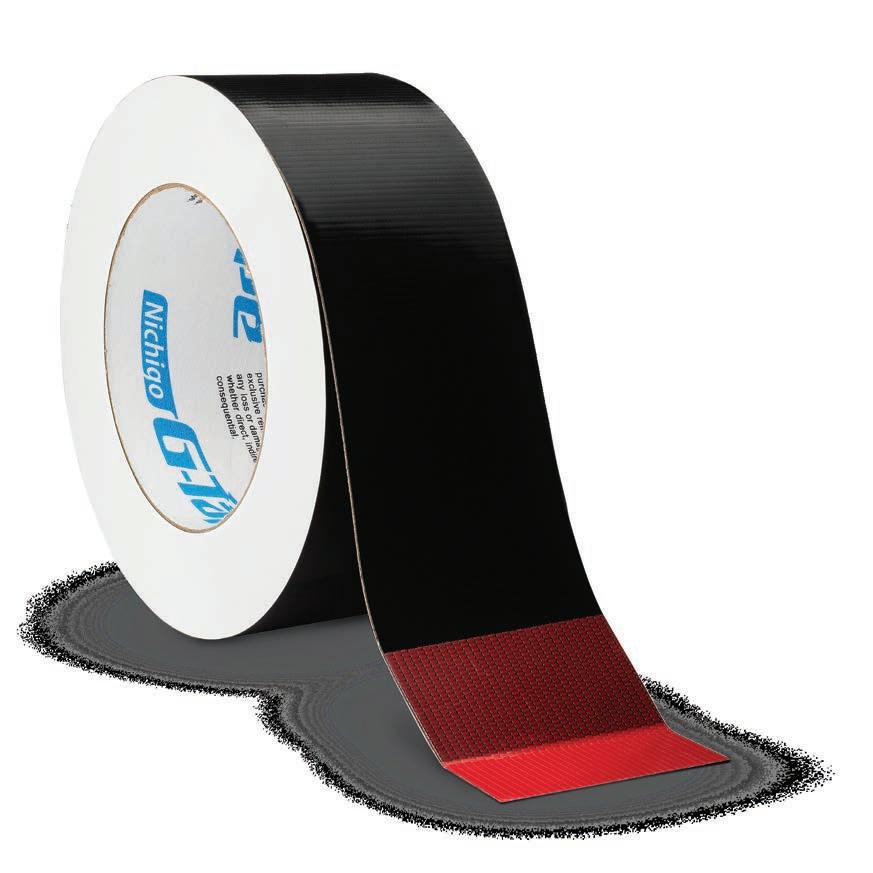

Decking solutions to prevent wood rot for up to 20 years. DIATEX CO., LTD.

Flashing Tape 3040BK 2” x 65’ | 4” x 65’ | 6” x 65’ 9” x 65” | 12” x 65’ Visit gtape.com to learn more.

Photo courtesy of Fraser Decks and Patios Covers - @fraserdecksandpatiocovers

Self-Adhering

MAXIMIZE PROFITS WITH FEWER PROJECTS

Boost Business and Customer Satisfaction with Composite Fencing

BY EDMUND ROSE

BY EDMUND ROSE

WHEN IT COMES TO THE FENCING BUSINESS

, success can be a vicious cycle. To make more money, you have to install more fences, but pursuing more projects means hiring more employees, which instantly eats into any additional profits. Wouldn’t it be better if you could increase your annual revenue without needing to add projects or employees? Well, you can do just that with composite fencing.

The most innovative and versatile material to hit the category since vinyl, composite fencing delivers premium aesthetics, durability and convenience that are winning over today’s customers, while the higher per-project pricing translates into greater profits for contractors from fewer jobs. Following are just a few of the many reasons to consider composite fencing for your business and clients:

• Superior durability – Composite is one of the most durable fencing materials available. Unlike wood, high-performance composite fencing resists cracking, chipping, rotting, splintering, and insects. Additionally, composites are thicker than wood and much less prone to brittleness and breakage. Composite material also stands up to outdoor elements and is warrantied for superior performance for decades.

• Premium aesthetics – Pairing wood-like looks with rich colors, composite fencing delivers a natural appearance. This makes it particularly appealing to consumers who prefer the semblance of wood over the plasticky look of vinyl. Designs like Trex Fencing remain fully private throughout their lives due to cleverly engineered interlocking pickets. Additionally, both sides of a Trex Fence have a finished look, adding curb appeal and making it a hit with neighbors.

• Low maintenance – A particularly compelling aspect of composite fencing is that it requires minimal upkeep, so homeowners are able to spend more time enjoying–rather than maintaining–their outdoor spaces. Composite fencing never needs to be sanded, stained or painted; just an occasional cleaning with soap and water is all it takes to maintain a like-new appearance.

• Sustainability – High-performance composite fencing provides the look and feel of real wood, but without the environmental impact of deforestation. Trex Fencing, for instance, is sustainably made of 95% recycled and reclaimed content, and keeps plastics like grocery bags and shrink wrap out of waterways and landfill. Another point in composite fencing’s favor is that it isn’t laced with chemicals like pressure-treated wood or completely synthetic like PVC or vinyl.

• Easy to install – Composite fencing is easy to work with and install. It requires no special tools and can be customized to accommodate topography or create unique designs.

• Longevity – The typical wood fence has an average lifespan of just 15 years and, because wood is highly susceptible to moisture penetration, it begins to degrade the day it is installed. Conversely, moistureresistant composite fencing is warrantied to last up to 25 years or more. Its ability to hold its value makes it a smart long-term investment for homeowners, property managers and business owners.

• Fewer callbacks – The quality of lumber entering the market today is so poor that contractors report frequent callbacks for product issues. Some contractors choose to install high-quality lumber, often-times kilndried and pre-stained. However, this type of material carries a much higher cost. Although it will last longer, it will still degrade, eliminating any initial cost advantage. Because composite fencing is not susceptible to these issues, it results in fewer callbacks and, with virtually no maintenance and no decay, proves to be the better value over time.

Considering its many benefits, composite fencing offers a tremendous opportunity to drive business and profits, along with customer satisfaction and referrals. For more information about high-performance composite fencing, visit trexfencingfds.com. DS

Edmund Rose is business development manager for Trex Fencing with FDS Fence Distributors, which promotes, sells and distributes Trex Fencing throughout the United States and Canada. For more information, call (877) 700-8739 or email info@trexfencingfds.com.

September/October 2023 | Deck Specialist | 25

Keeping the Flow

Pennsylvania Builder Maximizes a Small Deck Project

IF YOU ASK JASON FREED OF JR FREED

Construction, Pennsburg, PA., what was the most important factor he considered when designing his recent nearly $75,000 deck project in, he’d tell you traffic flow.

In the small, nearly 320-sq.-ft. deck rebuild in Gilbertsville, PA., Freed wanted to create a smooth traffic flow, but also ensure the customer received everything they asked for. To do so, he said planning was critical.

“You plan. You go back and forth with the customer 50 times if it’s necessary to make sure that they understand everything, and that they are okay with the placement. You can put so much into it, but you’ve got to make sure that your pathways are still clear.”

Freed provided the customer with a 3D rendering that featured a BBQ Guys’ Blaze grill and doors, prefabricated Pro-Fit Outdoor Living outdoor kitchen covered with PVC decking in the color Onyx, Trex Transcend Lineage composite decking in Biscayne, an Intex sealed PVC pergola, a custom bar with an inset granite top and multiple seating areas.

According to Freed, the customer “freaked out” because they thought the outdoor kitchen was going to be “a big black box in the middle of the deck.” He assured them, however, that it would all come together in the end.

“You never undergo a project like this without going back and forth at least as many times as you possibly can with the customer to try and get an understanding. The end result is going to give them what they want, but during the project, it’s a little scary because there’s so much going on and it’s such a big investment.”

One of the highlights of the project was the custom bar that Freed built that sits adjacent to the pool. The customer requested to have a bar with an “open feel” so

guests could see the pool from anywhere on the deck.

Not sure how to achieve it, Freed searched on Pinterest for inspiration, where he came across bars topped with deck boards. “I hate bars with decking boards on top,” he admitted. “Sometimes we build them, but I try to avoid it.”

That’s when he found a picture of a bar with its top sitting partially inside a tray. Taking the design a step further, he developed the idea of placing a granite bar top sitting inside a metal tray on top of eight, flat-black posts with stainless steel RDI cable railing in between. This would provide the unobstructed view of the pool that the customer requested.

Once the design was approved by the customer, Freed drew out his bar top concept on graph paper. Then he asked his friend to re-create the idea in a CAD program. The CAD drawing was then taken to a local metal shop that fabricated and coated the tray according to the

26 | Deck Specialist | September/October 2023

provided specs. On the job site, Freed mounted the tray on top of the railing posts, then dropped in a customcut piece of granite inside the tray, so the only part of the bar top customers could see was the top 1/2” of the granite on top of the railing.

To balance the space out, he bumped out the front rail of the bar top with 45s, giving the bar area enough room for barstools, without compromising the walkway around the pool. And to make the space look cohesive, he added a small rail to the left, a tiny rail to the right, and added granite to the top of the outdoor kitchen.

Over top of the deck, Freed added a pergola with installed lighting. He first drilled out the holes where he wanted the flush-mount Trex recessed lights to be placed inside the pergola beams and ran the wires through it prior to installation. “If it was a roof and you get recessed lights, it’s simple, but when you’re doing rafters like this, nobody really offers that.” In addition, he installed adjustable Lightology track lighting above the outdoor kitchen to light the grilling area, and more recessed lighting into the deck for better visibility on the steps at night.

Another obstacle Freed overcame was adjusting the height of the deck to flow seamlessly between the back door of the home and the lower inground pool. The previous deck in the space, that was installed approximately 10 years prior, featured one awkward set

of high steps that were flush with the back door and stepped down on the far side by the door.

“There (were) no steps on the pool house side; there was only one set of steps on the far side by the door that were very narrow that ... came off on a weird angle,” he added. To fix it, Freed added enough steps to make it flow, so it felt open, while adding enough railing so they felt “it was a decline out of a patio.”

In addition, another challenge faced by the team was the delays due to the paver patio being installed next to the deck at the same time. Freed’s team had to wait until the overdue shipment of pavers came in, and then wait longer as the correct pavers were reshipped to the site. This delayed the deck project about a month, he said.

Ultimately, however, the customer was delighted with the look of the final project, commenting on Facebook, “We now have completed our dream outdoor space that will now be used to its full potential.”

For Freed, although trying new design ideas can at first be daunting, he’s confident his building experience helps him bring those ideas to life. “I’ve been doing this for (nearly) 20 years so it’s not really difficult to overcome these obstacles because I’ve been doing it for so long.”

He added, with customers, such as this one, who have great vision, and his team’s incredible talent and craftsmanship, it makes his job easier. DS

September/October 2023 | Deck Specialist | 27

Hardy Hardwoods

How to make your hardwood decks last longer

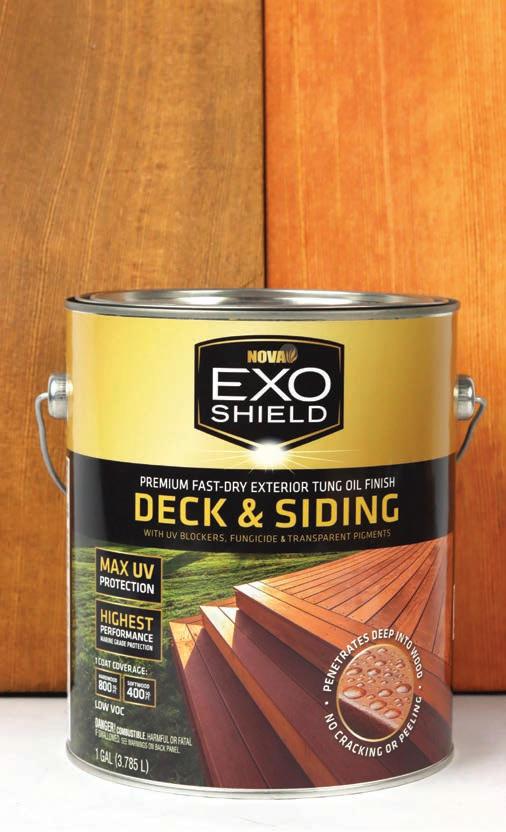

WITH KEATON SMITH, NOVA USA WOOD PRODUCTS

WE RECENTLY REACHED OUT to Keaton Smith, western U.S. sales, at Nova USA Wood Products to ask him about tips on installing and protecting hardwoods. Here’s what he had to say:

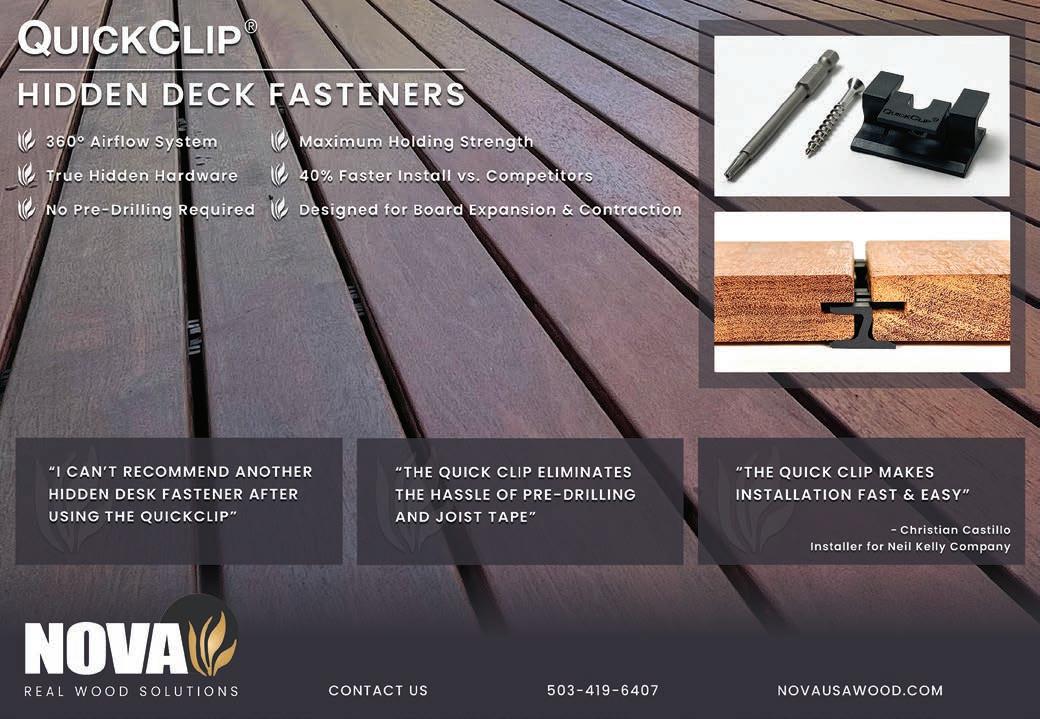

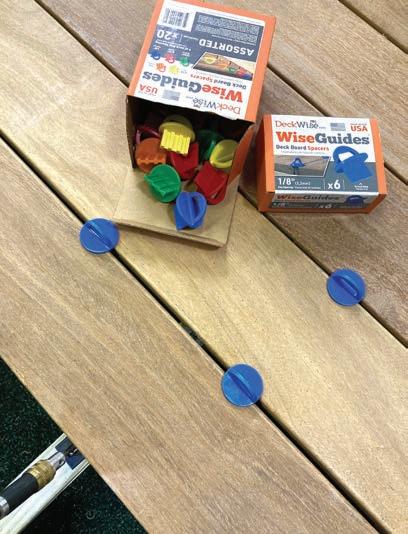

Q. Should hidden clips should be used on hardwoods?

A. We recommend a minimum of 36” of clearance for 5/4x6 and 1x6 and 24” of clearance for 5/4x4 and 1x4 is required for adequate ventilation—leave a minimum of 50% open area around the edges of the deck. This allows for the natural expansion and contraction of the wood as is takes on seasonal moisture.

Q. What should builders understand about installing the different species of hardwood decking?

A. Hardwood decking requires proper moisture management and air flow for the best long-term results. The below items are key for a successful installation.

• Material should be stored out of direct sun and weather

• Material needs to be acclimated at the site for 7-14 days

• Air Dried at 18%+ moisture content - Set spacing between boards at 3/32” for 4” and 1/8” for 6” decking

• Kiln Dried at 10-14% moisture content - Set spacing between boards at 3/16” for 4” and 1/4” for 6” decking

• Adequate ventilation under deck. 4” decking material requires 16” off ground, 6” decking requires 36” off ground

• Span of 16” max for 1x4 and 1x6

• Span of 24” max for 5/4x4 and 5/4x6

• Stainless steel fasteners screwed through the face, two per joist

• Pre-drilling required for face-screwed installations

• Only use approved hidden fastening systems

• End cuts must be sealed with a wax end-sealer

• Use an appropriate oil-based finish on all four sides prior to installation

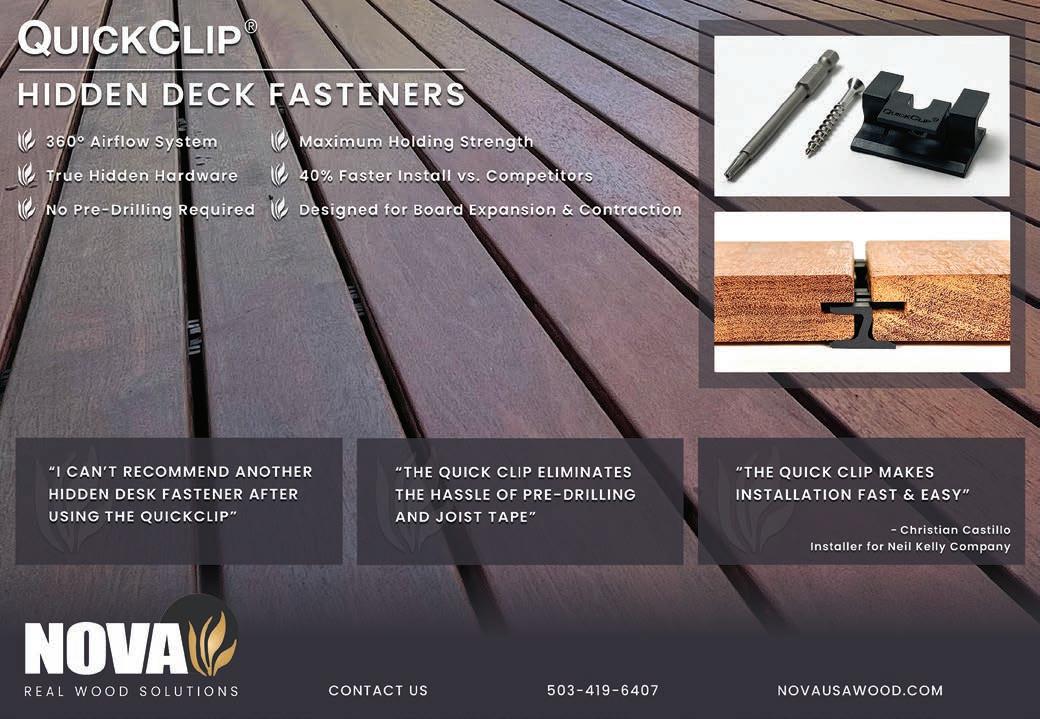

Q. It is important for hardwood decking to be properly protected to preserve its natural beauty. Can you explain the importance of how to prepare and seal hardwood decking for its preservation?

A. The proper prep and application instructions are quite lengthy, and it all depends on the condition of the deck prior to staining.

If the wood is new and not yet installed, we recommend coating all sides of the boards prior to installation. In this instance, you could apply the stain

28 | Deck Specialist | September/October 2023

with a roller or brush, followed by wiping the board down after 10-20 minutes with a micro-fiber rag to remove any excess stain and prevent building up a film on the deck’s surface.

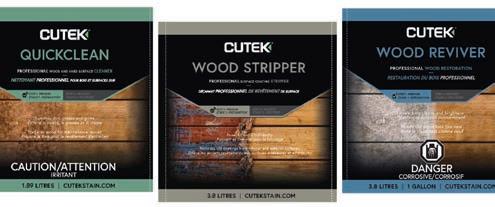

How to Prepare Your Deck Correctly for Wood Stain

Start the surface preparation by cleaning the deck boards. The goal is to apply stain to clean, fresh and bright wood — as close to the wood’s original color as possible.

Proper Steps for Deck Preparation

There are three distinct steps that can optionally be utilized for proper deck preparation:

The first optional step is using wood cleaners and brighteners — these can help, but are rarely enough on their own unless you are starting with practically new wood.

If you are satisfied with the appearance of the wood after using the wood cleaners and brighteners, then pressure washing is not necessary, and you can go straight to applying stain once the deck has had enough time to dry out, usually a minimum of five days.

Pressure Washing

If you have a hardwood deck, such as ipé, cumaru, batu, Brazilian redwood, tigerwood, cambara, mahogany/ meranti, etc., then you can use a high-powered pressure washer that will run up around 2,800 psi. I always use a turbo nozzle, which is a pinpoint needle nozzle that spins really fast, but only when pressure washing hardwood.

If you’re working with softwood such as pine, cedar, redwood or pressure treated, then you can’t use a highpowered pressure washer without tearing up the wood. Start with low setting on the pressure washer and use a wide fan nozzle to prevent damaging the wood. Test very carefully. If light pressure washing on softwood doesn’t do the job then your best bet is to sand the deck using a belt sander.

In most cases, pressure washing the wood is necessary to fully clean the wood fibers. You must use extreme caution when pressure washing softwoods, such as cedar, redwood and pine, since these species of wood are much softer than typical hardwoods. We recommend a fan nozzle, as opposed to a needle-point turbo nozzle, and a maximum pressure of no more than 2,000 psi. Be sure to test a small section of the deck before just

blasting the whole area. Damaging the wood fibers is very easy and can’t be remedied.

After you finish pressure washing and or cleaning with other methods, let the wood dry for a minimum of seven days. In terms of rain, it is best to wait for three to four days of clear weather prior to finishing. We recommend at least two days of dry weather after staining. Finishing your wood when the weather is dry is absolutely necessary; if it does rain right after finishing your deck, wipe off the deck immediately and keep it as dry as possible; and then wait for dry weather. A light top coat should be all that you need to remove any water spots.

Sanding Your Deck

As a final and optional step, sanding your deck before finishing has several advantages. Pressure washing will generally raise the grain and leave a rough surface, so sanding is the final step to give you the smoothest possible surface. If you decided to skip pressure washing and want to bring the deck back to original wood, sanding with a wide belt drum sander can help you get there in the fastest manner possible. We’ve used grits as low 24 on a wide belt sander and then finished it off with an 80 grit belt so the wood doesn’t end up too rough.

For a light sanding, a hand-held belt sander works okay, but you should expect to do only 100 SF per hour; a large deck will take all day or longer! If you’re trying to remove significant weathering, to get the job done quickly, a wide belt flooring sander can probably sand close to 800 SF per hour!

Other recommendations:

• Use microfiber rollers and cloths (for applying stain) because they prevent cloth fibers from being left on the surface of the finish.

• For large job applications, use a 3/8” nap microfiber roller.

• Allow the stain to soak into the wood for 10 to 20 minutes, then wipe off any excess material with a clean, dry microfiber or other lint free cloth.

• When applying in temperatures above 80° Fahrenheit or in direct sunlight, wiping off excess within 10 minutes may be necessary.

• Do not over-apply. Excessive finish on the surface of the wood will not be absorbed, and must be avoided. DS

30 | Deck Specialist | September/October 2023

The goal is to apply stain to clean, fresh and bright wood — as close to the wood’s original color as possible.

Paying it Forward

search and rescue efforts.” In the past few years, he and his crew have bought groceries for others at a grocery checkouts, surprised a worker at their local Chick-fil-A with extra cash, raised over $400,000 in donations for hard-hit Puerto Rico in the wake of Hurricane Maria, and collected 1,000 toys this past holiday season for local toy drives, including the toy drive held at the Lumberton Township Police Department.

Premier Outdoor Living builds backyard space for deserving New Jersey ma n

WHEN PREMIER OUTDOOR LIVING

founder Sean Collinsgru and his business partner Catherine Lippincott wanted to give back to their community of Lumberton, N.J., they ran a contest asking who in the area deserved a free backyard space. Troy Green was the name that stood out.

Green is the founder of The Kindness Crew, a non-profit organization created “to support the surrounding community with random acts of kindness, from small give backs to emergency response to

“We had been talking about doing a giveaway project for almost two years, and we’re so happy that we finally got the opportunity to bring it to life,” Collinsgru said. “We couldn’t have been happier with Troy’s nomination after hearing about all of the amazing things he does in the community.”

As part of the giveaway, the Premier crew solicited the help of Deckorators to help transform Green’s previous 225-sq. ft. deck into a 350-sq. ft. deck, and add a 400-sq. ft. patio.

First, GoliathTech helical piles were installed in the space, then ProWood MCA treated lumber was used for the framing. Next, the team installed Deckorator’s Venture Decking in Saltwater and Sandbar.

Collinsgru said they used UFP-Edge thermally modified wood in Lost Trail and the Venture decking in Saltwater for the feature wall, Adorn Stone mortarless veneer–Granite series in Birch on the water feature wall and Daltile Xteriors 2cm porcelain pavers for the patio.

And although they only gave themselves seven days to complete the project, Lippincott said, they

32 | Deck Specialist | September/October 2023

Photos by Premier Outdoor Living

finished on schedule. “We knew this would be tight for us regardless, but to add in to the stress, we had rain almost every day. We were able to pull it off in the time frame allotted.”

“We were so happy to be able to do this for Troy. He is such an incredible person who deserves all the nice things in the world,” Lippincott said. “We were very happy with the outcome, but what made us the happiest was to see him and his family truly enjoying themselves on what we built. The design was a perfect flow for the space and really fit what they needed.”

Green was greatly moved by Premier’s act of kindness. “This past week has been a life-changing experience for me. From the bottom of my heart, I want to thank everyone involved with this project. It has given me a new perspective on life, and the will to push harder to spread our message: Kindness can go a long way if you share it.” DS

September/October 2023 | Deck Specialist | 33

Call 866.427.2547 or Chat Online Whether you are a Pro deck installer or a weekend DIYer, increase your deck installation efficiency on any type of hardwood, composite or thermally treated boards. The Ipe Clip ® Fastener Company, LLC The Ipe Clip ® Fastener Company, LLC The Ipe Clip ® Fastener Company, LLC Manufacturers of Hidden Deck Fasteners & Accessories TM SELF LOCKING DECK BOARD STRAIGHTENER r r STRAIGHTEN MORE BETTER Light Weight Economical Multi-Directional THE ULTIMATE BOARD BENDING TOOL! Give yourself the freedom you need with a tool that delivers true “One-Man, One-Hand Installation® ” for hidden clips or face screws. SET LOCK FASTEN

EDUCATION BIG AT DECK EXPO

DECK EXPO ONCE AGAIN PROMISES

to deliver an exciting array of decking, railing and outdoor living show products that every builder needs to see in person.

Held in conjunction with the International Pool/ Spa/Patio Expo at the Las Vegas Convention Center, Las Vegas, NV., from November 10-15, Deck Expo not only provides the opportunity for builders to meet up with fellow builders, but it provides a place for those builders to meet with industry representatives to learn about the latest in the industry.

“Expo to me is about connecting with the other builders and friends, the comradery is the primary driver for attending,” said Scott Kelly, owner of Precision Construction, Golden, CO. “This year I am really looking forward to seeing and spending some time with Clint Webb, Andy Henley, Mike Mitchell and

the other members and experts of the Deck Building 101 community. The group has exploded and is doing some really great things and I’m excited to talk about what’s next with those guys.”

Mike Mitchell agreed. “I love going to Deck Expo to stay on top of industry innovation and see what we have ahead of us. It’s a great event to learn about products and growing your business,” said Mike Mitchell. “I’m also looking forward to seeing old faces and make new acquaintances. The relationships that are built at these trade shows, whether it’s with sales reps or other builders, are great and last a lifetime. Relationships are the key that has helped to raise up the industry through the years. I can’t wait to see everyone down in Vegas!”

Deck Specialist will be moderating the Decking Power Panel at 4 pm on Monday, Nov. 13. Builders

34 | Deck Specialist | September/October 2023

Protection for your deck starts UNDERNEATH IT .

DeckWrap PowerBond® is the quick and easy way to extend the life of deck support systems and posts. Our patented PowerBond® adhesive aggressively adheres to all wood types, even in temperatures as low as 25°F. Self-adhering and self-sealing for protection you can trust, roll after roll.

2023 DECK EXPO

Brendan Casey, John Lea, Mike Mitchell, Andy Henley and Clint Webb will be on hand to discuss their tips on how to run your deck business to become an awardwinning builder.

Other education and panel discussions at the show will focus on Trends in Outdoor Designs, 2027 ICC Code Hearings (led by NADRA), Glenn Mathewson’s discussion on “Everything but the Deck.” Deckx Talks (speakers to be announced) will discuss “Design as a Differentiator: The Power of Distinctive Design,” “Maximizing Social Media Impact,” “Profitable Paradise: Mastering Estimating,” “Thinking Outside the Wood: Exploring Alternative Deck Framing Methods,” “From Chaos to Clarity: Mastering the Model of Scaling Your Business,” and “Digital Distinction: Elevating Your Outdoor Brand Online.” DS

September/October 2023 | Deck Specialist | 35

Request a free sample at www.mfmbp.com. PROTECTION FOR LEDGER BOARDS • JOIST TOPS • JOIST ENDS • POSTS

Making History

Builder adds Victorian porch to 1930s home

THE HISTORICAL PROJECT SAT UNFINISHED in scaffolding on the main road in Bolton, Ontario, Canada, for 10 years. The 1930s property had previously been burnt and flooded, and the property owner had been unsuccessful at renovating it before seeking the help of nearby Toronto-based builder Lawrence Winterburn, owner of Garden Structure.

“(The owner) owned it during that entire time, but just had not moved forward on the project,” says Winterburn. “He’s an absolute perfectionist. (If) he can’t do it absolutely perfectly, he’s not doing it, and for whatever reason, it just stalled.”

When Winterburn looked at the property, the owner had done as much of the work as he could. Therefore, he was only asked to provide a quote on finishing the house foundation in wood.

Later on, however, the project scope was expanded to include a covered, Victorian porch with gingerbread trim on the front of the house, along with decking, siding, and soffits.

“I wanted to have the deck cover both doors, but they’re at different heights so it was a bit wonky, but (the customer) was set on just having the porch done. I think he wanted to do (the deck) himself,” he adds, “but once he saw the porch and how nice it

was compared to the last deck that he built, he said, ‘Just go ahead.’”

The design took place over about a year and a half, Winterburn adds. “We worked through five versions to hone in on their vision. I showed them three or four different layouts, shapes and styles.”

Winterburn explains that he likes to take his time on the initial consultation in a homeowner’s space. “Every client is a little different and you have to zone in on who they are in order to kind of give them what they want. To get an idea of their tastes, you really have to soak in their style from within their home. These clients had collectibles from around the globe, which helped me to get a sense of their style quickly.”

The homeowner was quite pleased with the final plans, saying to Winterburn, “When you sent the final concept over, I nearly fell out of my bed!”

But before Winterburn could acquire building permits on the project, he had to first obtain the approval of the city’s Heritage Committee. “This is harder than it might seem,” he adds. “Designing something that looks to be in place is easy, but guessing at the taste of a group of people is a gamble — pure and simple.”

36 | Deck Specialist | September/October 2023 1 2 3 4 5 MM/DD/YY _ _ /_ _ /_ _ _ _ /_ _ /_ _ _ _ /_ _ /_ _ _ _ /_ _ /_ _ _ _ /_ _ /_ _ GardenStructure.com

Thankfully, the committee was pleased with the plans. They only required Winterburn to change the size of the support posts on the porch, which conflicted with the city’s building department requirements. “Most porches in the ’30s, when this home was built, featured 4x4 posts. Through negotiation, we agreed to reduce them from 7” with 5-1/2” cladding.”

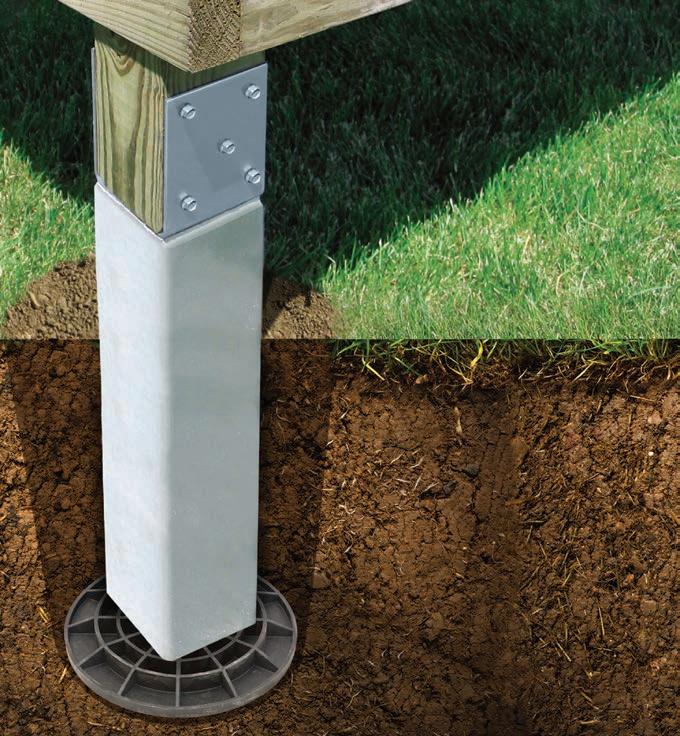

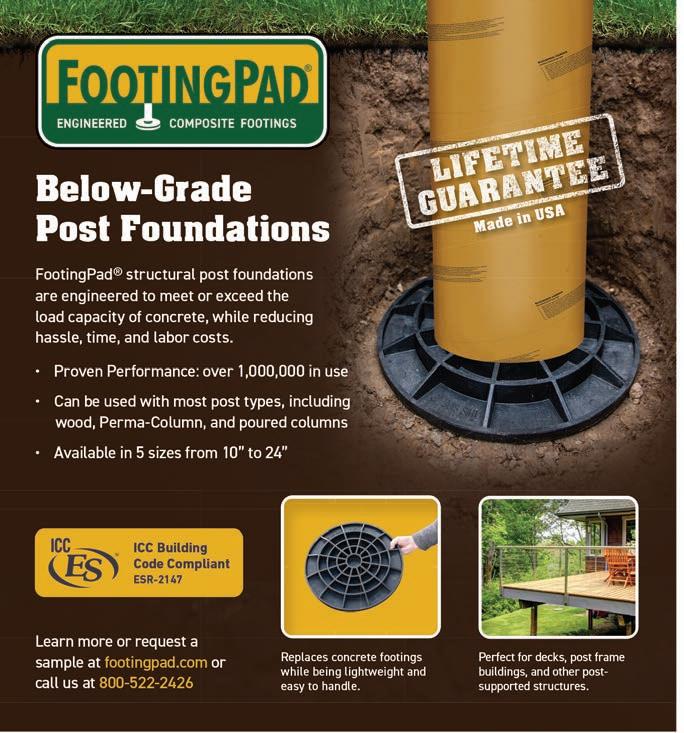

The final porch design featured a full-width, western red cedar deck built upon Techno Metal Post helical piers, with a custom-milled gingerbread trim on the front porch composed of a mixture of cedar and marine ply for durability.

“We use helicals to avoid possible movement, which (is) the enemy of all old porches,” he explains, adding that underground voids, soft soil, and water flowing below grade can lead to shifting traditional footings.

All the materials (aside from the framing) were prefinished in the crew’s Mississauga, Ontario, shop. Ends were sealed with a high VOC paint, to prevent them from soaking up moisture. In addition, the deck joists were taped so that if the deck boards rot, they can be changed out at a later time.

The client loved the initial porch work and ended up requesting more work, including recladding sections of the home’s walls and reworking the existing deck in front of the small door adjacent to the porch.

Although the framing of the porch was started in 2022 and only took about a month to complete, the full project was only recently completed this May due to supply shipment delays.

At one point, for example, the roofing held up the project. Winterburn preferred the more historical corrugated steel roof with cedar shingles up the side

of the house, but the design didn’t work with the home. In the end, after waiting 18 weeks for the roofing to be delivered, the corrugated steel roofing was installed, but was later replaced by the homeowner with a colored roof.

Another delay was the project’s angled windows, which also took 18 weeks to arrive, but weren’t what Winterburn had ordered. “They did them in the wrong color in the wrong size, so really rather than return them, I just reframed the wall (instead of) waiting another 18 weeks.”

Ultimately, the homeowner and his wife were pleased with the project’s final outcome, which Winterburn says is the key to future jobs. “When you’re designing something, and you’re working with people who like what we do and see what we do and value it... that’ll keep us in business.” DS

September/October 2023 | Deck Specialist | 37 REVISIONS REMARKS 01

Original architectural drawing

MANY DECK BUILDERS and outdoor living contractors have gifts and talents that go beyond what technical training can teach you. Many are inspired visionaries who can take a stack of raw material and convert it into unique physical structures. You remove what has reached it expiration date or lacks function, and replace it with something that’s often equivalent to outdoor artwork leaving the homeowner and others in awe.

In addition, you possess an ability to mentally assess an existing situation and then visualize a solution, provide options, and design projects for others who don’t possess this visionary or 3D ability. If you had function keys on each side of your head you could “screenshot” the image in your brain and show others what could be built the instant the vision appears in your mind.

Your creations improve people’s lives, relieve stress, and add to homeowners’ recreational enjoyment. You provide sanctuaries that allow humans to escape the day-to-day challenges and put them in an environment where they breathe fresh air and spend time outdoors. You offer a unique treatment for lowering blood pressure, heart rates, and supplying better vitamin C absorption.

In addition to all the pre-mentioned attributes, you are the trusted consultant that the homeowner expects to

To all the outdoor creators

Are you building risk into your jobs?

guide them through the process and make good choices and decisions. You, as a professional, are trusted and expected to be aware of the strengths and weaknesses in techniques and material products. The customer counts on you make them aware of their best options, avoid pitfalls, and make a good long-term investment. So, it’s up to you to diplomatically lead prospects in the right direction and build in a way that they don’t have future problems.

The approaches you take and the blend of products you incorporate into the build impacts the immediate and long-term outcome. Your delivery history and the types of jobs created, establish your reputation, and define what you’ll be remembered for.

I say the above because that’s what I see when it comes to most of today’s deck builders. I believe most have honest and sincere intentions to deliver quality and long-term performance. But I also see an aspect that may be compromising these genuine efforts to deliver

38 | Deck Specialist | September/October 2023 PARKS AND DECK CREATION BOBBY PARKS

ABOVE: Builder installs Owens Corning Wear Deck composite decking.

good work. That aspect is the wood frame that supports the customer’s investment.

If the objective is to deliver mid- to higher-end projects and create a perception in a customer’s mind that the project will last them for 20-plus years, do you really trust what you’re installing your composite or PVC decking and alternative railing on? Your customer is going to.

This is a different age and today’s wood has not had the performance track record that it had in the earlier years of deck building. Quick growth lumber and treatments have yielded mixed results ever since the transition from CCA treated lumber.

Vertical measurement discrepancies, planing down high-crowned joists (which can compromise the treatment depending on penetration), and dealing with double crowns have always been part of the routine. It takes time, but for the most part you can manage this aspect. Joist sag after the build seems to have become more common and you have less control over this.

To tape and coat, or not tape and coat, seems to be a common debate. Sliding the level across a smooth frame has become a cool social media demonstration, but will you be able to do that same smooth slide six months from now? There are reliability question marks that represent

Coming November 2023 MOSO® Bamboo X-treme

risk. Will the deck have waves in it later? Will rot occur years down the road with framing, under the inlays and decorative features (especially if you’re flat blocking below or in other critical areas), even if you taped or coated? If so, how will you handle it if you were to have a widespread outbreak with your jobs? What would that do to a reputation that you spent years building?

This is a good time to start reconsidering what most consider to be the norm. A safer more predictable approach would be to start looking into the alternative options, such as steel, aluminum, or manufactured framing materials, if you haven’t already. If you’re using pressure treated, look at using UC4B.23 Treated Framing or the equivalent as a minimum standard. If you decide to continue forward with regular pressure treated wood, at least make taping or coating protection a standard. The latter may alleviate some of the potential wood rot issues, but not the other problems associated with wood. If you must continue forward with regular pressure treated wood, at least make taping or coating protection a standard, and not an option.

For steel framing, you have New Castle and Fortress. And in 2024, TimberTech will be releasing its aluminum framing option. Or, if you prefer a composite alternative, Owens Corning recently released its Lumber.

From its new headquarters in Holland, MOSO® is proud to introduce the next generation of bamboo Decking, Siding and Lumber: MOSO® Bamboo X-treme . We have re-engineered our product to decrease waste and increase CO2 capture. Learn more about it at Deck Expo Booth #4738 West Hall.

September/October 2023 | Deck Specialist | 39

Having had my personal deck built by New Castle, I had a chance to see and experience the difference. It’s impressive and easier than I expected. I will discuss more about this in my next column.

Yes, these options will add cost and strain budgets. Yes, they will be more challenging to sell. Yes, you might have to push your vendor to bring in certain items or have packages shipped. And yes, there’s a slight learning curve, but if you’re going to create higher-end projects, or even more reliable lower-end jobs, why not combine the best possible product options and techniques? Why build in a possible defect?

In my opinion, you at least need to broach certain subjects during customer consultations. That would include potential problems using standard treated wood. Keep in mind you have the opportunity to demonstrate the personal talents mentioned earlier because you gained a prospect’s trust and converted them into a customer. Realizing no one wants to shoot themselves in the foot and kill a sale by spooking a prospect, being honest and discussing potential issues, or that wood may not have the matching lifetime expectancy of the composite or PVC decking, seems like the right way to go.

To discuss the possibility of rot or joist sag causing unevenness in the deck surface seems appropriate. If you at least point these risks out and let them know their options, you should not be held responsible. You can state up front that your structural warranty does not cover rot or sagging joist (unless you want to accept responsibility).

By providing them all the information, you’ve given them the chance to complete a good investment or to make an investment with some risk involved. If you have concerns about losing jobs to competition, you can give them two different cost options: one for a taped wood frame and one for an alternative frame. But, if it isn’t discussed and they were not made aware, it’s easy for a customer to blame you if problems occur.

You are their influencer, and your decisions based on your beliefs dictates a customer’s decision. Again, when recommending alternative decking and railing products that are intended to last 20-plus years, what kind of frame do you want to match it up with? Are you really confident in what you’re delivering now, or do you have doubts about the frame’s life expectancy? Should you have more fear about telling a customer a higher price using alternative framing or more fear of what might happen a few years down the road if you don’t educate them about the options and exclude yourself from liability?

I have friends on the wood and treatment side of the industry, so I don’t mean this as an attack on wood. The wood market is here to stay and will dominate the industry and account for the higher percentage of use simply because of price. And I believe using the top grades of treated lumber can be a positive approach and hopefully will perform for the long term. But if you operate in the mid- to higher-end niche of deck building, then I believe you and the customer will be better served by reassessing the pieces you incorporate into the build and remove any questionable or weak links.

Furthermore, I can tell you from experience that the years go by fast and during your careers you will likely see something fail on your projects. Don’t let it be what you already knew could be a problem. At least look at alternatives for framing or insist on top grades of treated wood so that your jobs won’t come back to haunt you or the customer.

There are milestone moments in every industry where a change in direction occurs. It seems to me that this may be such a moment in ours. It’s up to you as a group to drive the change. DS

40 | Deck Specialist | September/October 2023

Bobby Parks is a wellknown contractor who has delivered more than $40 million in outdoor living projects. He is the former owner of Peachtree Decks & Porches.

BELOW: Bobby Parks’ deck was built using TimberTech Weathered Teak with an English Walnut border, Impression Rail Black drink rail, and a custom routed PVC rail cap.

September/October 2023 | Deck Specialist | 41 YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, and technologies of unrelated third parties. For details regarding the Preservatives, methods, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood.com/preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Safety Data Sheet (SDS), please visit us at www.yellawood.com/warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. All other marks are trademarks of their respective owners and are used with their permission. Put our reputation behind your craftsmanship. Build with YellaWood® brand pressure treated pine. The only brand homeowners know and ask for by name. Its high standards, unrivaled protection and naturally beautiful appearance are all backed by some of the strictest quality testing in the industry. Find your local YellaWood® brand dealer at YellaWood.com BY HOMEOWNERS AND NEIGHBORS

SOUGHT AFTER

ALIKE.

Be the solution, not the problem

LONG BEFORE the first time I ever shaved, my dad sat me down and said life is full of choices and one of them is to either be a part of the problem or the solution. You will come to many forks in the road that will sometimes require you to pick the hard path; it won’t be easy, but it may be the right one.

Whew, Dad was right. There have been tons of forks and choices too numerous to count. We all like to think we chose correctly 100% of the time, but I’m pretty sure my batting average is below .500.

A lot of us don’t see things in black and white — much of society sits somewhere in the shades of gray — so the decisions aren’t always simple. Not everyone is wired to take a hard stand and forge on as a solution seeker. The masses will generally sit back and watch others like Meriwether Lewis and William Clark blaze the trail to a new frontier.

Fortunately, an exception to that rule are the business owners of deck building companies. We elevate ourselves to that leadership role because we tend to be the solution seekers. We are on a never-ending journey to make our own worlds a better place for everyone in it.

We are blessed to be involved in one of the most awesome and lucrative segments of the residential outdoor industry. We are also fortunate enough to come along at a period where artisans have the opportunity

to take their creativity to amazing new levels, such as Andy Henley and his Stratocaster guitar deck, or Daniel Eric Pettit and his insane CNC-cut metal backdrops emulating Minnesota sunsets with fiber optic lighting. A few years ago, we were clipping lights to what looked like speaker wire and now he’s turning the industry upside down with fiber optic lighting. Mike Mitchell, with his classically beautiful projects that could be in any upscale neighborhood in North America, or David Settlemyer, who is harnessing his inner Van Gogh on a daily basis. Deck Nerds’ Lou Lattanzio, who never met a board he didn’t want to bend. The guys at Deck South, Ridgeline, Deck Remodelers, Mosaic, or Keefer that blow my mind with every single project photo they ever post.

We have steel, aluminum, or fiberglass framing, PVC, mineral-based or acrylic-coated temperature manipulating composites, or exotic, thermally modified, or higher treatment levels of wood decking. The doors are open for us all to venture out into uncharted waters and be the solution our clients are seeking.

So, with all the options and opportunities for us to lead and become that resolution, why do we seem to have such a high level of negativity popping up these days? You can’t go on social media without witnessing the choosing up of sides, like kids on a grade school playground. Factions separated by over-exaggerated-

42 | Deck Specialist | September/October 2023 SET THE STANDARD BRENDAN CASEY

brand or product-line loyalty. Builders and manufacturers propagating an overzealous sentiment that if you don’t use the same decking, framing, or footings as the rest of that tribe, you are somehow not as good. You are cheating your clients or doing them a disservice. You aren’t elite if you don’t do “our way.” I can say this openly because with some self-reflecting, I too have been guilty of frequently pushing my opinions on others. I stepped back over the line and allowed myself to become part of the problem by forgetting that everything in our industry varies on a regional basis, and yes, my dad reminded me of that too. It’s easy for many of us to get sucked into the quicksand of the problem side by manufacturers that feed our egos. They want the tribes, they want to create an air of elitism with their products, they want to see contractors go to battle on their behalf. They are breaking down the brotherhood every time we choose up sides.

Another problem is that we know there are manufacturers, especially in the treated side, that have the ability to bring a far better, longer-lasting product to market, yet refuse to make them readily available to the masses. I once had a treated rep tell us there is nothing wrong with standard ground contact framing, even though it rots out in five years. That’s a problem, not a solution.