2 minute read

Taki ng more than your share of wood siding profits

I I 2,:',ilT ;'"1: :?"-",j#:'3ij;

sales in the past decade. Prices were escalating unpredictably with changes of 203OVo not unco[rmon. which in tum cteated additional headaches for retailers trying to ensure adequate prcfit margins.

A growing number of lumber dealers and retailers are now able to take part of the uncertainty of tbe profit pichtre out by offering their siding prefinished to the builder. Besides being a particularly strong sales opportunity for the builder and homeowner, it greatly increases retail margins (by up to 3OVo), helping to smooth out the price fluctuations.

Prefinished siding is protected from the elements, then dried to a moisture content of L9Vo or less and then the coating appted. The builder realizes significant benefits, according to Joe Kastelic, manager of factory finishing for Olympic Stain and PPGAF Products. "Problems typically associated with finisbing at the building site (weatber delays, painter callbacks, uneven application lap marks, costly clean-up, etc.) are non-existent creating a satisfied builder who realizes cost and time savings."

The consumer wins because the siding product has been shipped directly to the operator without weathering. Studies by US Forest Service and US Department of Agriculture show unprotected siding can dramatically decrease the ability of a coating to bond to wood. Even a weatherlng perlod of four weeks before coatlng (common on Job sltes) can decrease the abillty of palnt adheslon by 5O%.

For the homeowner it means less cuP ping, splitting and chipping as well as providing a maintenance-free coating and appeiuance that is guaranteed not to crack, peel, flake or blister.

Since 1978, approximately I billion board feet of lumber has been stained through a factory process at authorized applicators. Olympic Stains, PPG Industries, is the pioneer in the process and remains the industry leader in providing a consistent quality process and products for over 30 years.

The process itself insures a quality job done in a matter of minutes. "Our siding material is checked for proper moisture control and then actually put on a conveyer which pre-heats the lumber for maximum coating adhesion," states Ron Cooper of MacMillan Bloedel Building Material. "It is then coated with hiSh speed revolving brushes to ensure a smooth finish. At that point it is dried and cured under ideal conditions before being packaged and shipped tojob sites."

Olympic's operators can prefinish lumber or plywood including him and soffit materials in any width up to 50 inches and in any thickness fiom 3/8" to 6". Material can be offered in a wide variety of semitransparent or solid colors in oil stains. Authorized Machinecoat operators can also offer Olympic's exclusive Machinecoat which includes a 15 year warranty.

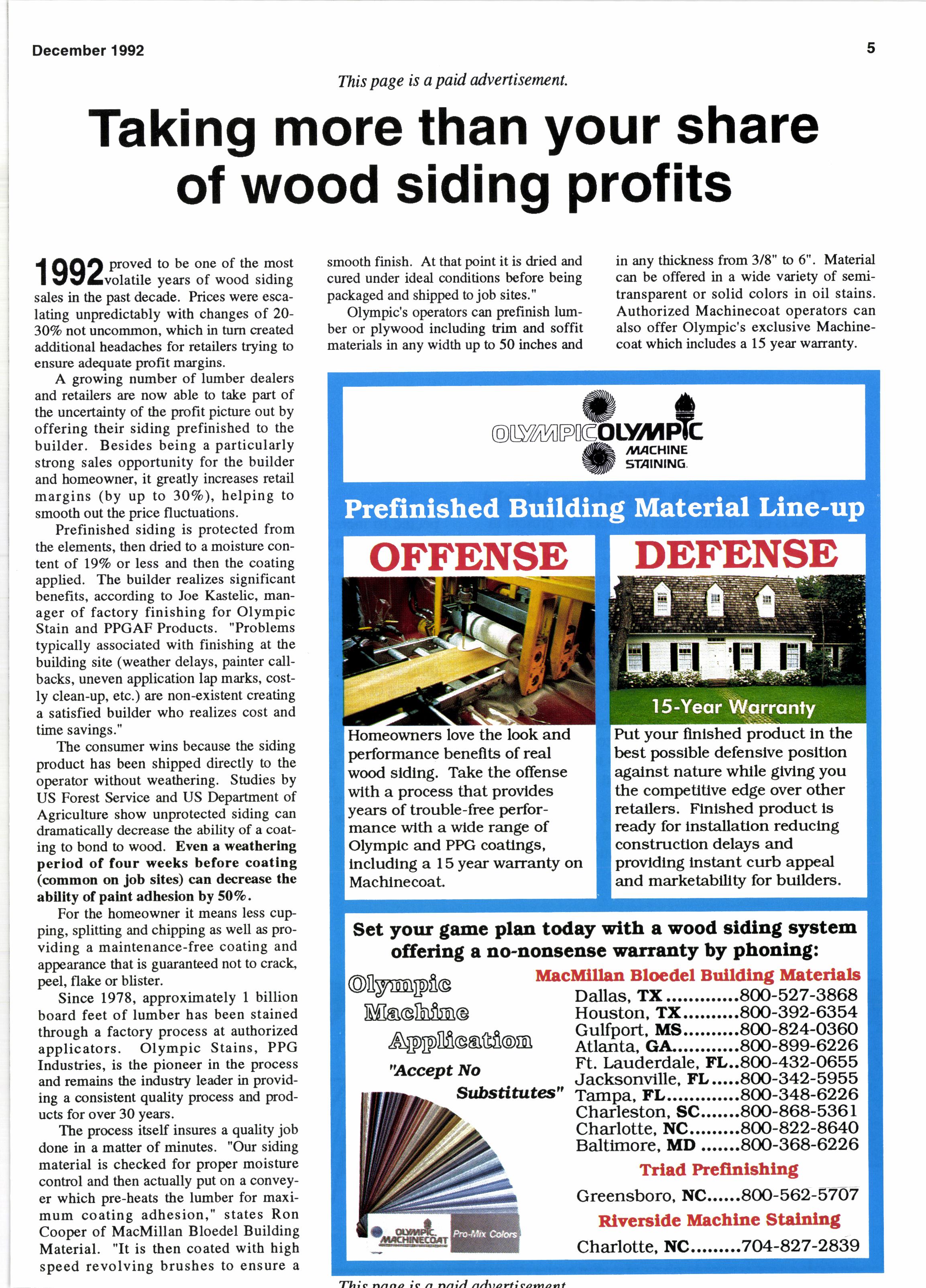

Homeowners love the look and performance beneflts of real wood sldlng. Take the offense wlth a process that provldes years of trouble-free performance wlth a wlde range of Olymplc and PPG coatlngs, tncludlng a l5 year waranty on Machlnecoat"

Put your flnlshed product ln the best posslble defenslve posltlon a€lalnst nature whlle glvlng you the competltlve edge over other retallers. Flntshed product ls ready for lnstallatlon reductng constructlon delays and provldtng tnstant curb appeal and marketablllty for bullders.

Set your gamc plan today wtth a wood stdtng system offertng a no-nonsense warranty by phonln$:

MacMtllan Bloedel Buildfng Materlals Dallas, Tx .............800-527-3868

Baltimore, MD .......800-368-6226

IHad Prefinbhrrg

Greensboro. NC......8OO -562-5707

Rlverslde Machlne Strfnfng