2 minute read

lard layout

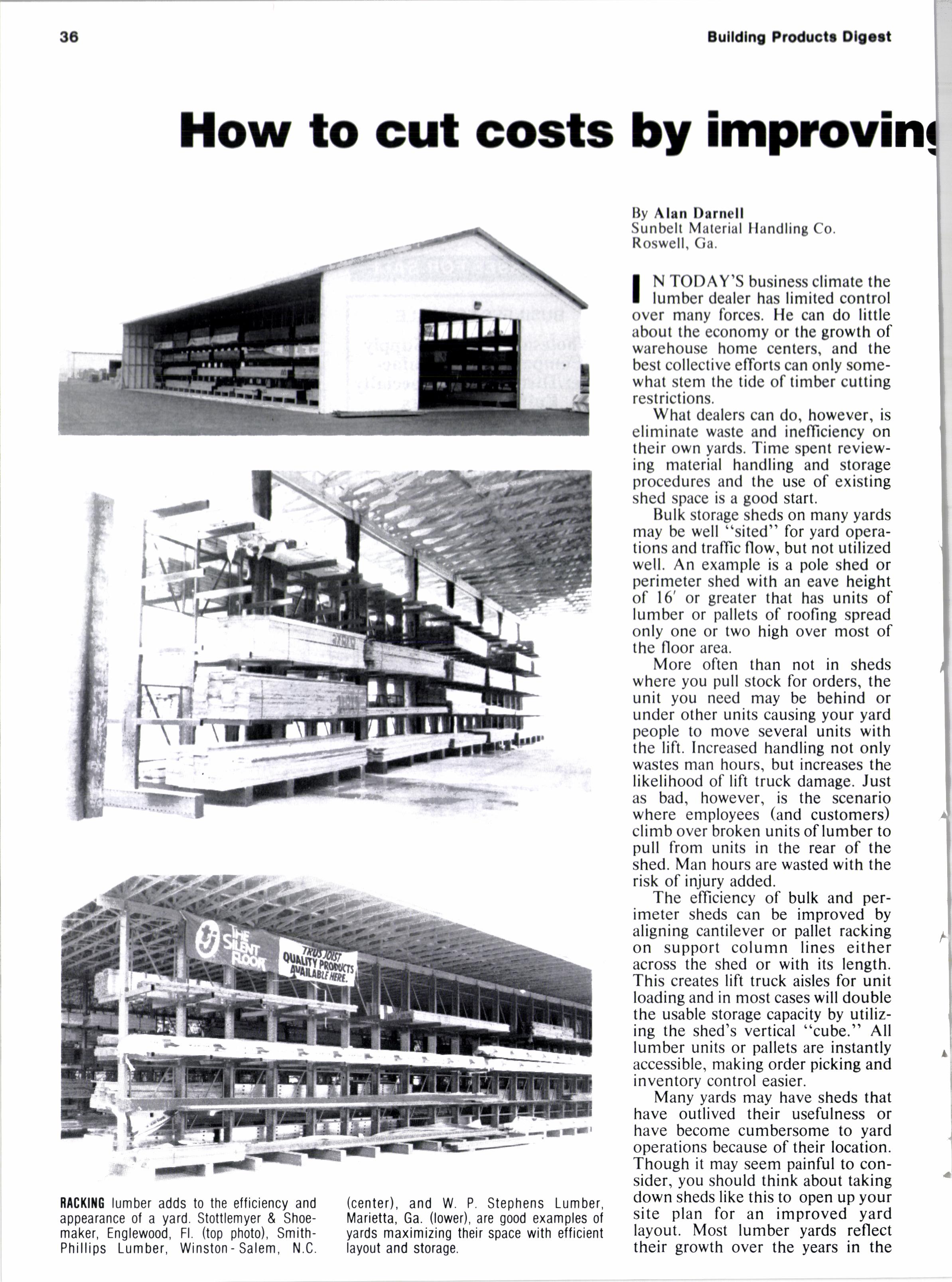

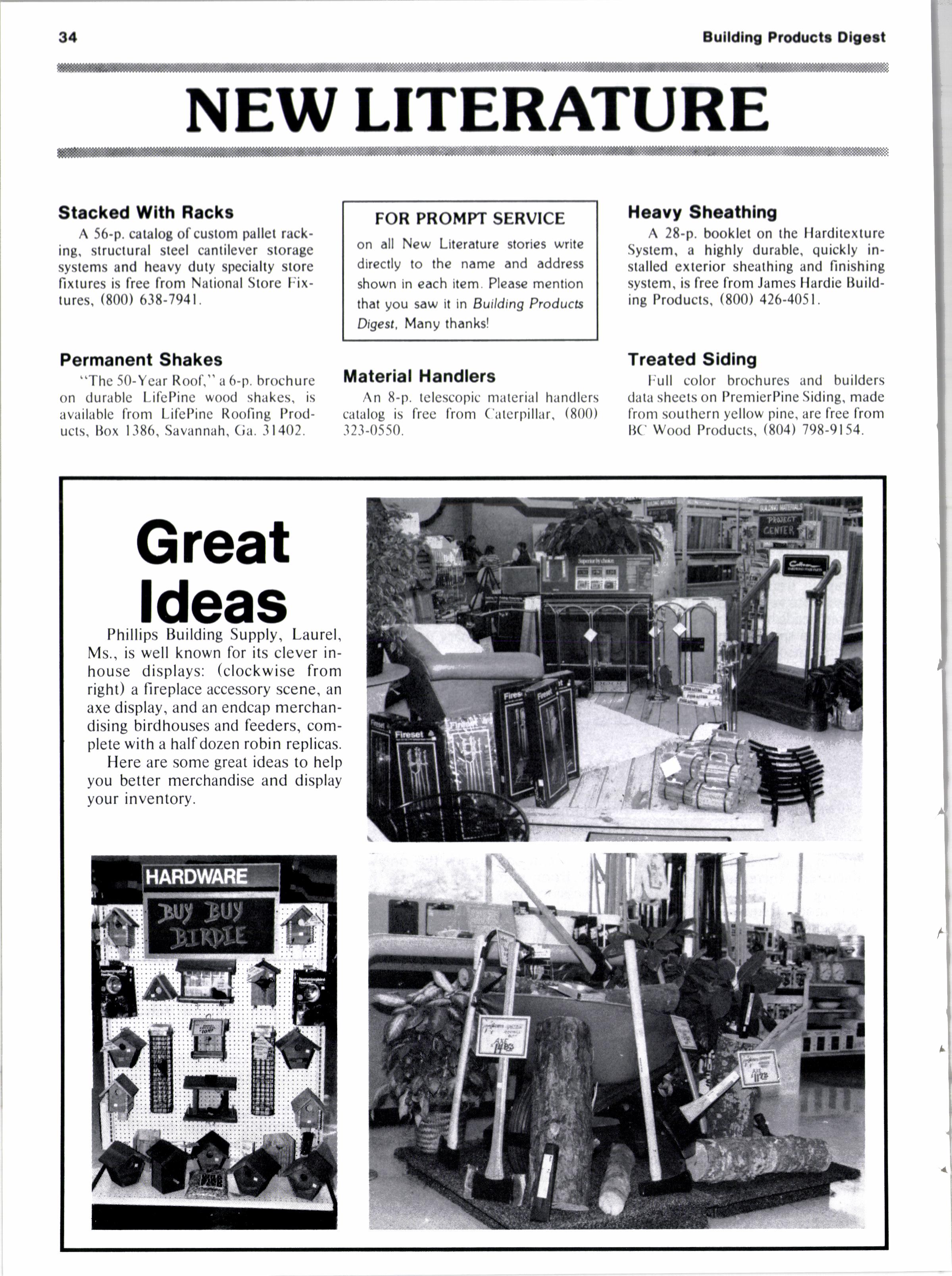

buildings and sheds added, and while the customer base and product mix may have changed dramatically, the physical layout may not have kept pace. When this happens, yard operations and customer service may suffer or increased man hours are needed to make things work.

Story at a Glance

Morc efficlent material handling and storage lessens waste, man hours and accklent risk. rede signing yard, eliminatiqg no longer useful sheds has immediate and long term benetrts with shoi payback

Cr",*hr

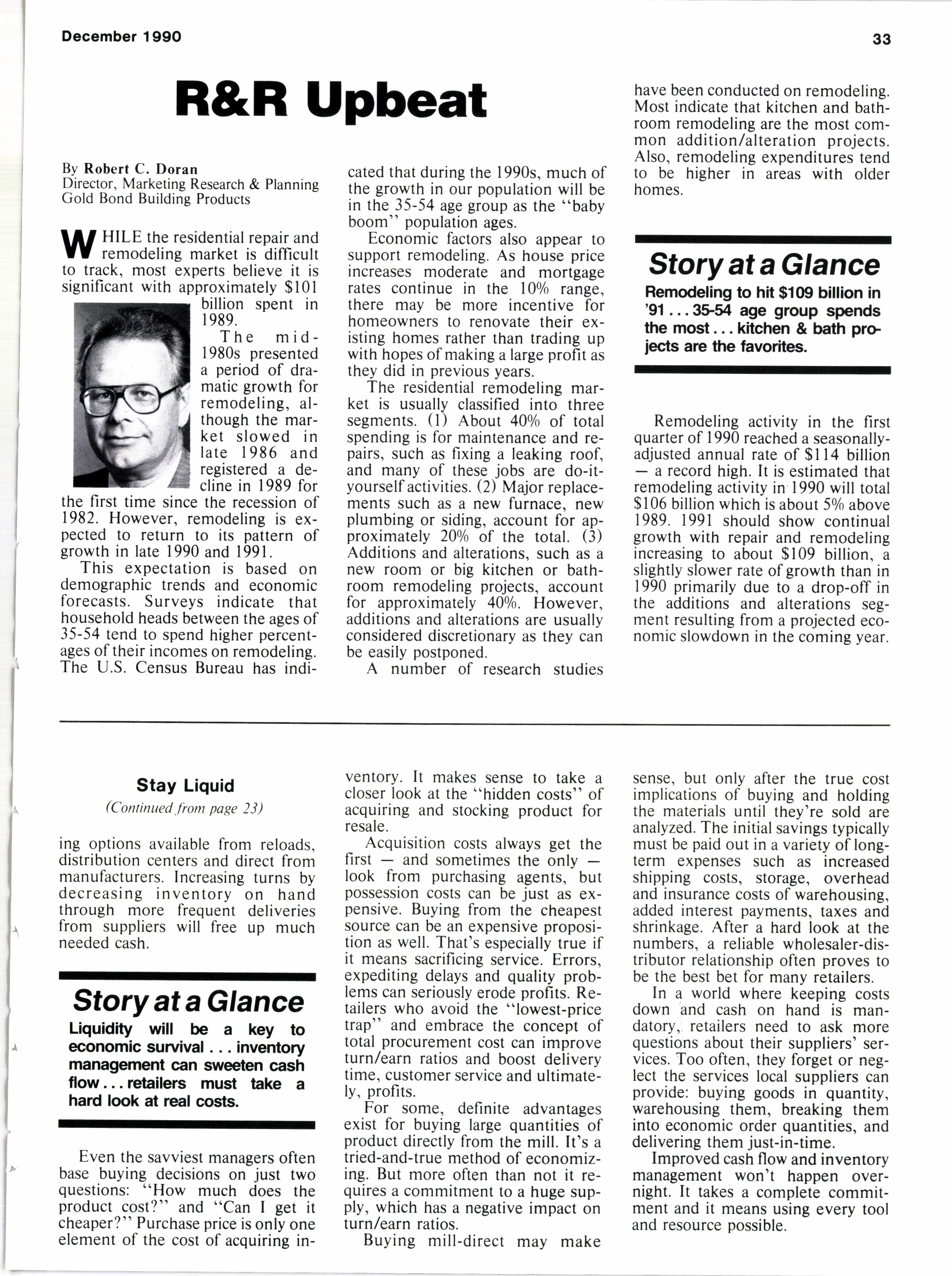

If your site plan will accommodate a cantilever rack supported drivethrough shed and you feel you're maximizing your other shed space as we've discussed, then this option should be considered. In my opinion this building is the most cost eflicient way to store dimensional and treated lumber for order picking.

The "footprint" of a typical single aisle shed with a24' drive aisle would be about 60' x 120'. Depending on unit size mix, this shed would store from 150 to 200 units of lumber. Ideally the site of the drive-through shed should be somewhat central on the yard with bulk sheds nearby. This facilitates loading your delivery trucks and those of your customers with little lost motion for a lift operator and yard personnel. To site a drive-through cantilever shed for operational efficiency, you may need to take down sheds of marginal usefulness that occupy prime locations on your yard.

If you haven't already faced the problem of storing long length manufactured joist and laminated beam units, you probably will soon since the "timber crisis" will accelerate the use of manufactured framing components. There are cantilever rack storage solutions that might fit well in your yard plans. A cantilever drive-through building sited with adequate turning room to load 48' units onto the outside facing arms is an excellent alternative for long length covered storage. Ifsite restrictions make a drive-through building impossible, consider a cantilever "T" shed or single side covered cantilever adjacent to an existing building or property fience. All work equally well in handling long length manufactured framing components.

Cantilever rack systems can be engineered in both drive-through building designs and cantilever "T" sheds to suit any local building codes. Soil conditions, wind and snow loads and seismic requirements are variables that can be designed into the system to adapt it to an area.

Aside from the operating efllciency gained, there are other benefits from proper yard planning and material handling. Getting treated lumber under cover minimizes sun warpage. Sun and rain damage to other dimensional lumber is reduced. Having a covered drive aisle in which to load lumber during bad weather is a plus, as is the ability to stage trucks for morning deliveries the afternoon before.

There are accelerated depreciation benefits with a rack supported building versus a pole shedseven year schedule instead of 30 years. An intangible benefit is the impression a well planned, well organized yard makes on customers. After we recently erected a cantilever supported building, the yard manager told me one contractor customer remarked, "l would drive l0 miles past your competitor to get here, because you get me loaded and back to my job site quicker." This summarizes what proper yard planning and customer service is all about.

Take time now to review your existing yard plans and storage options. Whether you add cantilever or pallet racking to existing sheds to solve immediate problems, or consider options such as cantilever supported drive-through sheds or cantilever "T" sheds, you will find both immediate and long term benefits with.the payback a lot sooner than you lmaglne.