5 minute read

Special lssue: Hardwood Hardwood training school maintains industry standards

By S. Crnoll Whlte Executive Manager National Hardwood Lumber Assn.

lN THE mid-1940s the National lHardwood Lumber Association recognized the need for an institution devoted exclusively to training hardwood lumber inspectors.

Through the years the industry had grown, more and more sawmills and purchasers were becoming grade<onscious, and there was a pressing need for qualified hardwood inspectors. Planning began, and, in February 1948, the first class was convened in Memphis, Th., under the direction of NHLA assistant chief inspector Earl S. Swartzbaugh.

Memphis was selected as the site for the school, not only because of the great amount of hardwood activity in this area, but also because the Lumbermen's Club of Memphis afforded an organizing group of hardwood lumbermen who could assist in setting up the school and monitoring its operation. Their interest in school activities has continued, and today the Inspection School Committee remains as one of the standing committees of the Lumbermen's Club.

Nickey Brothers, Inc., in the 194.0s, operated a large hardwood sawmill, flooring plant and plywood operation

Did You KnoW?

in an industrial area of Memphis and offered NHLA the use, rent free, of approximately one acre of ground for the purpose of erecting school facilities. Thus the school came into being and occupied this site until the spring of 1980.

In the late 1970s several conditions combined to make this original building and site no longer suitable. The building itself was never a quality structure and was in extensive need of repair. The capacity of this original school was 50 students per class which was not large enough to meet the demands of the industry, resulting in waiting periods of one to one and one-half years before an applicant could attend class. Furthermore, in the period of some 30 years the character of the neighborhood had changed. It became apparent that a new building in a new venue was badly needed.

A search produced a new site on the eastern outskirts of Memphis. Ultimately, the association offices were moved from their leased highrise building in Chicago to the Memphis site. Today, the association executive offices and inspection training school o National inspectors handled 55,967,000 feet of lumber in fiscal year 1983, while working 5,418 inspection days. o In 1983, 25 one-week short courses in hardwood lumber grading were held by NHLA inspectors in locations scattered from coast to coast. o Through NHLA's reinspection process and financial guarantee, shipments can be insured as to quality and quantity if loaded by a "National man." share a handsome, virtually all wood, dual-purpose building that has become "home" for the hardwood industry and an excellent working showplace of hardwood products. This building is on a beautifully landscaped l0 acre site. The total investment of approximately $1,300,000 was raised through gifts of NHLA

. NHLA Inspection Training School has operated in Memphis since 1948 with 3,914 persons attending.

. NHLA Rules and Sales Code are the standards for hardwood shipped in the U.S. and Canada and the industry would be in chaos without them.

Story at a Glance

4,fl)0 hardwood Inspectors produced by NHLA school In 36 years only training of its kind In lhe world .. well sup. porled and recognized by the industry.

members. The buildings were dedicated in September, 1980, totally debtfree.

Through the years there have been significant changes in the length of the sessions due to the introduction of visual aids and textbooks that have permitted improvements in methods of instruction.

The school operates as a trade school or vocational school, as opposed to a technical or university level. The only course of study is the measurement and inspection of hardwood lumber. Although some information is provided concerning related subjects and field trips are held, these are for course enrichment rather than separate courses of study per se.

The school accommodates 70 students per class and three sessions each year. T[rition fee is $600 for the l4-week course of study.

Instructors for the inspectionschool have always been highly qualified tradesmen from NHLA's inspection staff. The current director is Robert

B. Sabistina, a 1976 graduate of the school and a respected member of the NHLA inspection staff until assuming his present responsibilities in the fall of 1983.

Since this is the only school in the world offering such an indepth study of the hardwood rules, students are attracted from all over the world.

There are no entrance requirements pertaining to race or sex and it is not unusual for the classes to contain several foreign students, women, or minorities who reside in the United States. The only basic requirements for admission are a high school education or equivalent and a knowledge of basic fractions and percentages. This knowledge of simple math is extremely important as it is the basis of the entire grading system. Prior experience in the industry is obviously desirable, but is not required or necessary, and it is not unusual for students to have no industry background whatsoever.

Each applicant must be sponsored by an NHLA member firm. This does not necessarily mean that the individual is an employee of his sponsoring firm, but his request for admission must come through an NHLA member. This sponsor will interview the applicant to determine his seriousness of purpose, basic ability, and any physical handicaps that might prevent the applicant from functioning well if admitted.

The association does not have scholarships; however, several lumbermen's clubs or industry trade associations regularly make scholarship funds available to those who meet their qualifications. The school is approved for funding by the Veterans Administration for those who qualify.

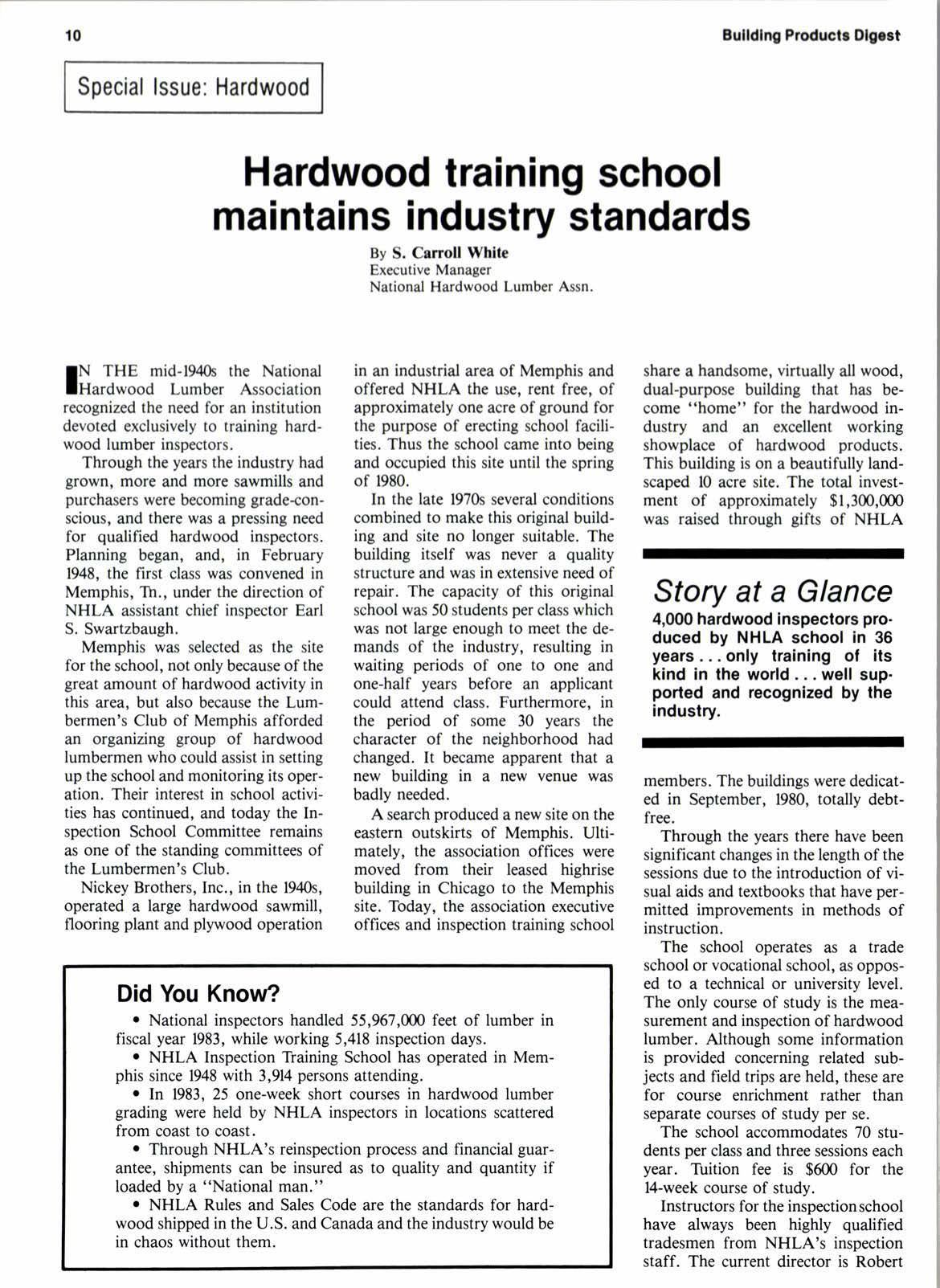

HANDS 0N experience is part ol the National Hardwood Lumber Association's Insoection Training School curriculum. (lop photo) Students insoect lumber under a 10.000 so. ft. grading shed adjacent to class rooms. (center) Entrance hall contains group photographs ol each graduating class since 1948. Floor is red and white oak parquet. Walls and ceiling are paneled in white oak. (botlom) Studenls work in classroom under eye ol director Bob Sabistina (striped shirt). Study tables are made of oak lrailer-deckino stock. Walls are red oak with maole oarouei floor.

Special lssue: Hardwood

FIETAILERS and consumers

Jlalike can count on the integrity of hardwood plywood because of the work of the Hardwood Plywood Manufacturers Association.

As guardians of the industry, they make sure that every panel, square of flooring, panel door and kitchen cabinet utili2ing hardwood plywood that you stock in your store meets high standards.

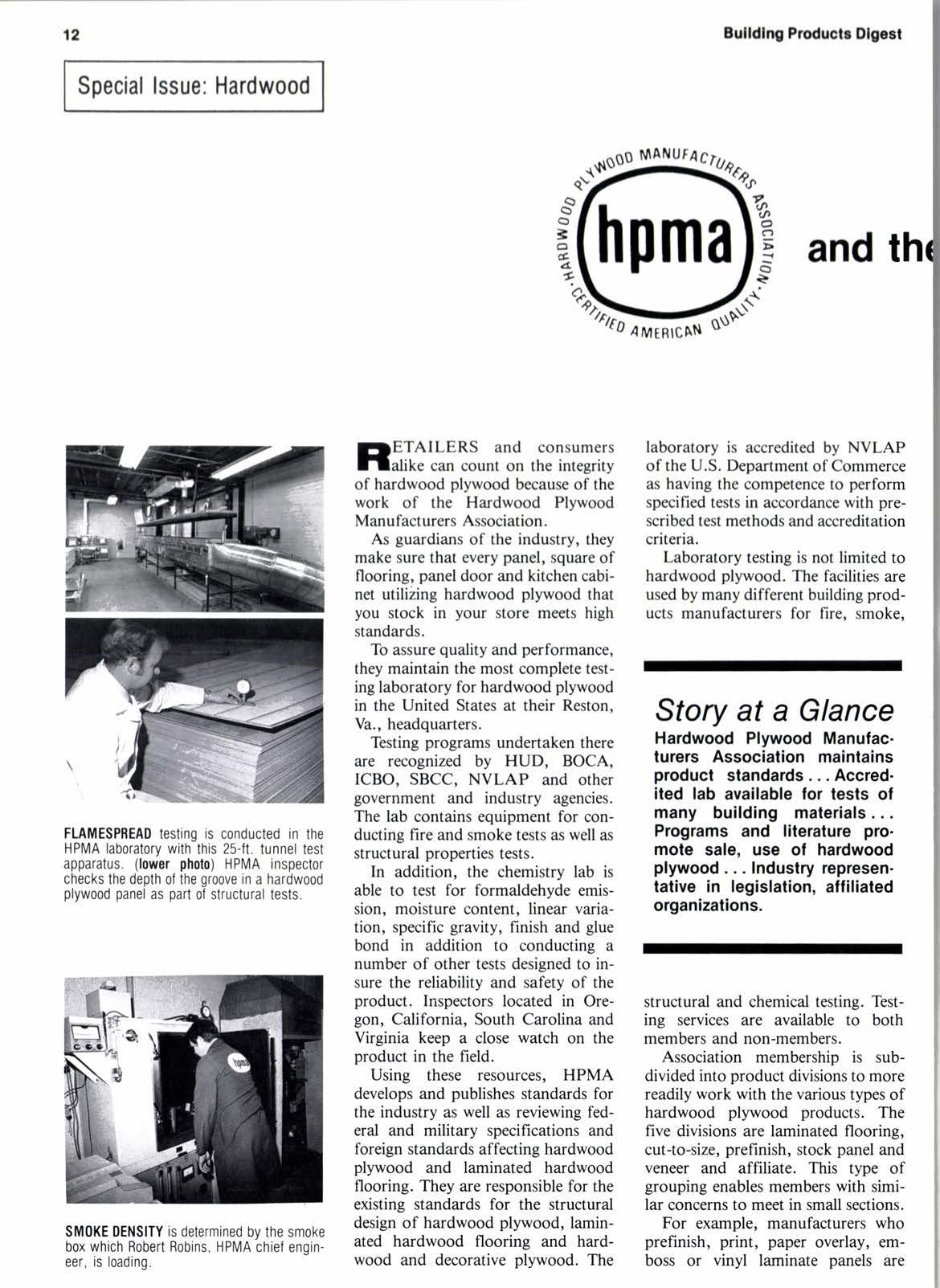

To assure quality and performance, they maintain the most complete testing laboratory for hardwood plywood in the United States at their Reston, Va., headquarters.

Testing programs undertaken there are recognized by HUD, BOCA, ICBO, SBCC, NVLAP and other government and industry agencies. The lab contains equipment for conducting fire and smoke tests as well as structural properties tests.

In addition, the chemistry lab is able to test for formaldehyde emission, moisture content, linear variation, specific gravity, finish and glue bond in addition to conducting a number of other tests designed to insure the reliability and safety of the product. Inspectors located in Oregon, California, South Carolina and Virginia keep a close watch on the product in the field.

Using these resources, HPMA develops and publishes standards for the industry as well as reviewing federal and military specifications and foreign standards affecting hardwood plywood and laminated hardwood flooring. They are responsible for the existing standards for the structural design of hardwood plywood, laminated hardwood flooring and hardwood and decorative plywood. The laboratory is accredited by NVLAP of the U.S. Department of Commerce as having the competence to perform specified tests in accordance with prescribed test methods and accreditation criteria.

Laboratory testing is not limited to hardwood plywood. The facilities are used by many different building products manufacturers for fire, smoke,

Story at a Glance

Hardwood Plywood Manufacturers Association maintains product standards. .. Accredited lab available for tests of many bullding malerials... Programs and literature promote sale, use of hardwood plywood . . . Industry representative in legislation, affiliated organizations.

structural and chemical testing. Testing services are available to both members and non-members.

Association membership is subdivided into product divisions to more readily work with the various types of hardwood plywood products. The five divisions are laminated flooring, cut-to-size, prefinish, stock panel and veneer and affiliate. This type of grouping enables members with similar concerns to meet in small sections.

For example, manufacturers who prefinish, print, paper overlay, emboss or vinyl laminate panels are