4 minute read

Assurance salesmen

Using panel quality marks as a sales tool

InHANCES are 1ou \cc {)nc ulrrro:r \-zercr'1 da1 ...thut I'rrrrriliur .\P.\ stamp on plywood or oriented strand board. Or perhaps voLl ve noticed the APA-EWS stamp on -glulam beants. More and more engineered u ood products-includin-g pl1 * ood. OSB. glulams. I-joists and rinrboard being stamped with the APA and APA-EWS mark of qualitl

Just what does that stamp represent'l Why is it on some panels und not others l Who marks it on the panels? And. most of all. uhat docs it mean to you'l

The evolution of neu building rnaterials. enhancements of eristins materials und chunging eon:truclrorr techniques lre affecting the rr;.tr builders. distributors and design professionals do business. Feu areas of the buildin-c products industrr have seen more chan-te or taster grorith in recent years than the engineered uocld products sector. Buildin-s ntaterial retailers who just a decade ago \\ere warv of these emer-gin-s: technologies lrrc n()\\ increasinclr intcrc':ted in lhc potcntial cost sar ings and superior pcrlolnrance uhich thcsc products ol'l'er.

As the production and use of engineered sood products increases. the need lirr third-ptrtr qualitr ilssurancc and pertbrnrance testing gro\\ s.

\\'hat's Behind the Stamp

Der eloping and rnaintainin!r indLrstrr standards has bc'en a printarr t'unction ol-.\P.\ rirrec itr ineeptittlr irr |9.f-1. The 7( )-lirld rnereu.c rn.tnr.tural pancl industrr production durin:: the past 60 r'ears is contpellinr te'ti-

Story at a Glance

What APA stamps represent and what that means to dealers, wholesalers and distributors ... selling assurance.

nt()n\ l() the tn.'ritr ol rr hat rctnair.ts thc lt::ociatit)tt \ c()rttcr\l(rne pl.tilrr:trph) nraintaining eonsistentlr hiSlr qualitr rtandardr.

In approrirnatclr l-10 en::tnce rcd ri o()d prtldUe tr plantr trcr()\\ \()rth .\rtrcrrca. thc auditins antl le.tin! lunction: ol .{P.{'. Qualitr Scrr icc. Dii ision pror ide thc lirundltron ltrr thc high qualitr reputation L'rrncd h\ .\P.\ nrcrnh.'r rni I l'.

Thc' .{P.\ tradL.nlark idcntitic. nranutaeturer: crrnrnrtted lo sati:t'rinr requircrncnt: ot' thc \trndi.rrd :houn on thc rlr.tntp. That .tandard tttrtr be a nrlnufacturirtg .lantlard. rueh ;.r: \'()luntar) Prtrduet Standard PS | or u pc'rlirrrrtance standard. ruch a\ .\P.\ PRP-10S. Pert.trrrrrancc' Strrndards and Policic' lirr StruetLrralL 'c Panelr.

Pcrl'orntancc rtandard\ ilrL' dc.icned t() en\urc that product. nrcct lhc rr'quirenrcntr ol' thcir intcndcd cnd Ll\!'. Ftrr i11r1rtta.'. thc.tandard lirr .\P.\ Ratcd Shcathing \\a\ dc\c'lopcd t() cn\urc thlrt protluet: beuring thc

How to read APA panel trademarks

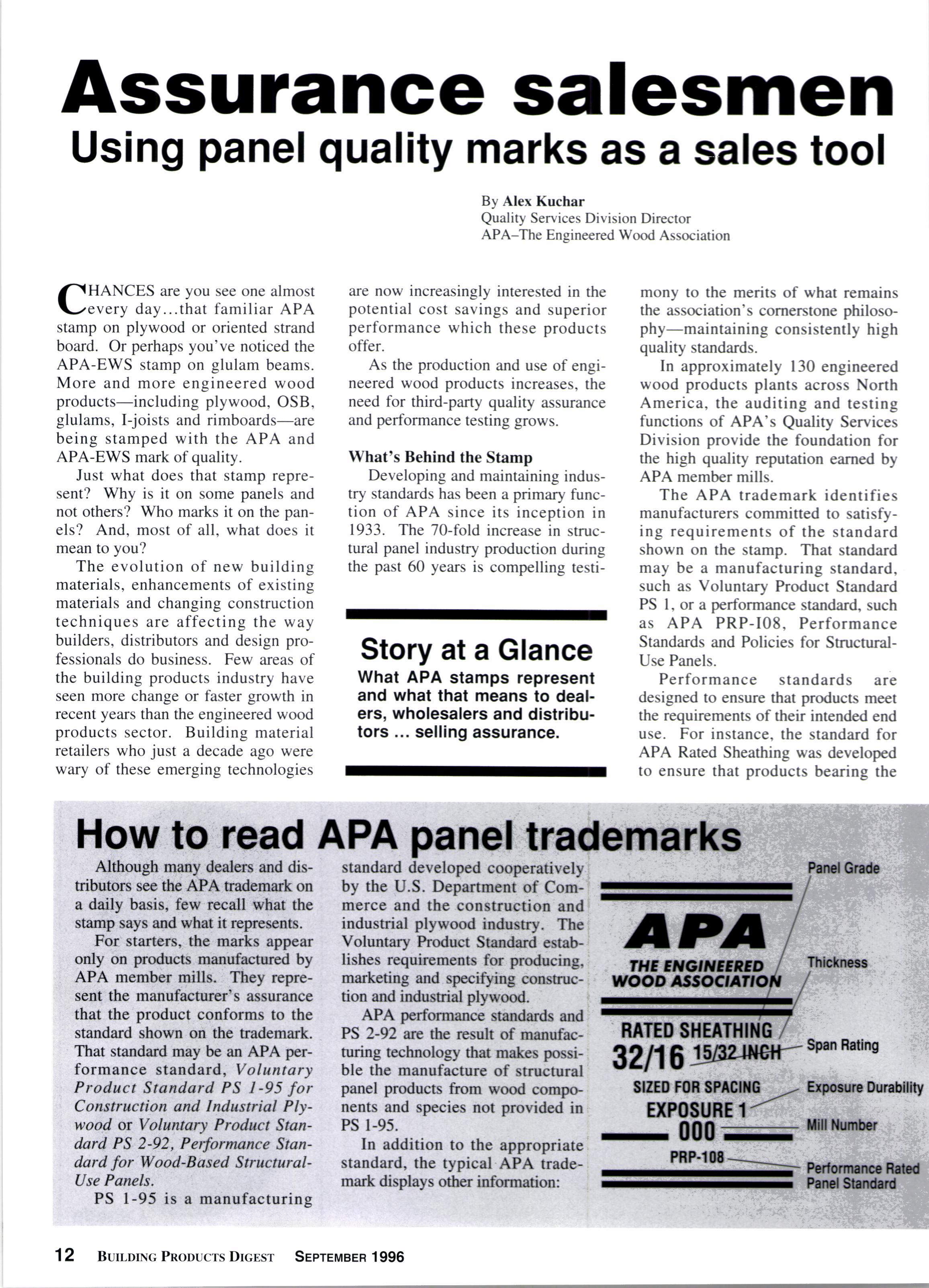

Although many dealers and distributors see the APA trademark on a daily basis, few recall what the stamp says and what it represents.

For starters. the marks appear only on products manufactured by APA member mills. They represent the manufacturer's assurance that the product conforms to the standard shown on the trademark. That standard may be an APA performance standard, V oluntary Product Standard PS I -95 for Construction qnd Industrial Plywood or Voluntary Product Standard PS 2-92, Peformance Standard for Wood-Based StructuralUse Panels.

PS l-95 is a manufacturins standard developed cooperatively by the U.S. Department of Commerce and the construction and industrial plywood industry. The Voluntary Product Standard establishes requirements for producing. marketing and specitying consrruction and industrial plywood.

APA performance standards and PS 2-92 are the result of manufacturing technology that makes possible the manufacture of structural panel products from wood components and species not provided in PS l-95.

In addition to the appropriare standard, the typical APA trademark displays other information:

Panel Grade Thickness

32 11 6 Ynzluret+soan Ratins srzEo FoR sPAcnG EXPoSURE 1--'' -000PRP-I08 --..-.-

Erposure Durability llillNumber

Perlomance Raled

Panel Standard

APA Rated Sheathing name meet or exceed code requirements and in-service demands for floor, wall and roof sheathing.

Qualifying for the Trademark

The first step a mill takes to qualify a Performance Rated product for an APA trademark is to submit panel samples for testing. Qualification tests may vary depending on whether the panels are wall or roof sheathing, subfloor or combined subfloor-underlayment, or siding. To ensure adequate structural performance, panels undergo tests for concentrated loads, uniform loads, impact loads, wall racking, moisture exposure and more.

In concentrated static load tests panel specimens are placed in a steel frame and a metal disk is placed on top of the panel. A load is applied to the disk at a prescribed rate. During loading, the deflection of the panel is also measured. If the deflection and load required to break the panel falls within the range accepted by the standard, the panel passes the test. This test simulates concentrated loads like supporting a water heater or grand piano on a floor, where the load is distributed over a small area.

Concentrated impact load tests simulate sudden impact loads, such as dropping a bundle of shingles on a roof or jumping on a floor. A leather bag loaded with a specified weight of steel shot is dropped on a specimen from various heights. Following the impacts, the panel must be able to support the specified minimum load

in order to meet requirements.

Linear expansion tests determine if the panel will expand excessively when exposed to rain or other moisture. Other tests measure panel bending properties and racking resistance.

If a panel passes all of the tests, APA develops a Mill Specification. The Mill Specification essentially describes the physical and mechanical properties of the panels that passed the tests, forming the basis for future quality assurance. Only then, when the panel has been tested and the Mill Specification has been written, is the APA trademark stamp issued.

Assuring Continued Quality

In order to maintain trademarking privileges, APA member mills must continue to fulfill the Mill Specification requirements. APA's Quality Services Division administers ongoing testing and auditing of mill products to assure that appropriate standards are being met.

APA maintains five quality testing labs: Tacoma, Wa.; Eugene, Or.; Shreveport, La.; Kennesaw, Ga., and

Duluth, Mn. The function of the labs is to perform routine tests on samples taken from mills in their region. A series of quality assurance tests make sure the products consistently meet or exceed APA requirements.

APA is recognized by all three major model building code agencies in the U.S. (ICBO, BOCA and SBCCI) as a quality assurance agency for structural panels and other engineered wood products. In Canada, APA is recognized by the Standards Council of Canada as a certification organization for structural panels and other wood products.

APA's services go far beyond quality testing and inspection. Research and promotion programs play important roles in developing and improving engineered wood construction systems and in helping users and specifiers to better understand and apply panel products. APA provides technical and field support and is the only quality assurance agency that offers a full range of market support services, including dealer training.

Over the past several decades, technological advancements and a decreasing raw material supply base have transformed the way we manufacture, produce and distribute building materials. With these changes in production, now more than ever, a strong quality assurance program is essential to ensure product performance and customer satisfaction.

The APA trademark is how dealers and distributors know that these engineered wood products are designed to meet the needs of their customers and the demands of actual applications.