3 minute read

Panel ratings made simple

wx#ftffi;,f1?#i

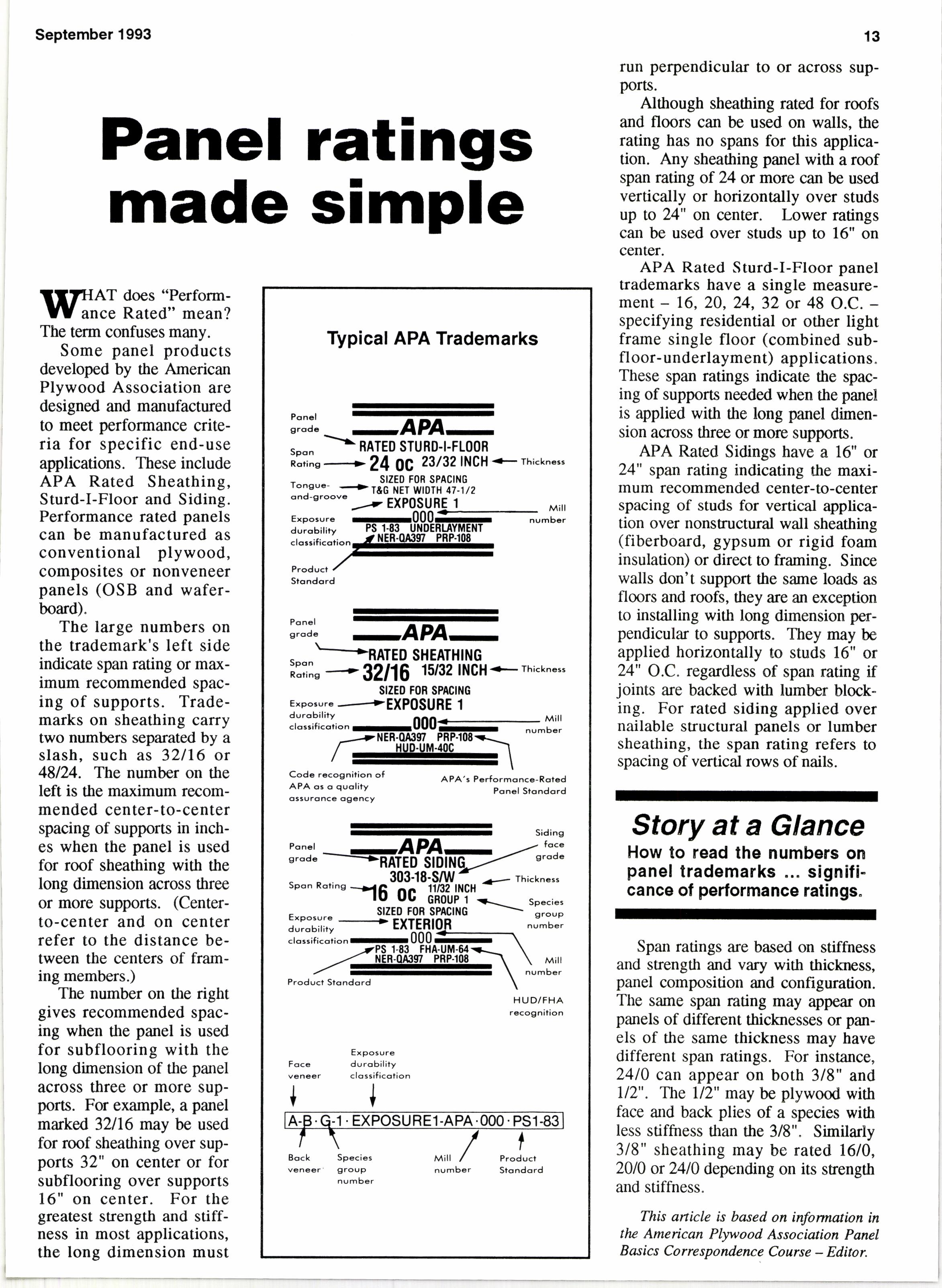

The term confuses many. Some panel products developed by the American Plywood Association are designed and manufactured to me€t perfomrance criteria for specific end-use applications. These include APA Rated Sheathing, Sturd-I-Floor and Siding. Performance rated panels can be manufactured as conventional plywood, composites of nonveneer panels (OSB and waferboard).

The large numbers on the trademark's left side indicate span rating or mrximum recommended spacing of supports. Trademarks on sheathing carry two numbers separated by a slash, such as 32116 or 481U. The number on the left is the maximum recommended center-to-center spacing of supports in inches when the panel is used for roof sheathing with the long dimension across three or more supports. (Centerto-center and on center refer to the distance between the centers of framing members.)

The number on the right gives recommended spacing when the panel is used for subflooring with the long dimension of the panel across three or more supports. For example, a panel marked 32116 my be used for roof sheafting over supports 32" on center or for subflooring over supports 16" on center. For the greatest strength and stiffness in most applications, the long dimension must

;;i----*f,-r$6672;:

run perpendicular to or across supports.

Although sheathing rated for roofs and floors can be used on walls, the rating has no spans for this application. Any sheathing panel with a roof span rating of 24 or more czln be used vertically or horizontally over studs tp Io 24" on center. Lower ratings can be used over studs up to 16" on center.

APA Rated Sturd-I-Floor panel trademarks have a single measurement - 16, 20, 24, 32 or 48 O.C.specifying residential or other light frame single floor (combined subfl oor-underlayment) applications. These span ratings indicate the spacing of supports needed when the panel is applied with the long panel dimension across three or more supports.

APA Rated Sidings have a 16" or 24" span rating indicating the maximum recommended center-to-center spacing of studs for vertical application over nonstructural wall sheathing (fiberboard, gypsum or rigid foam insulation) or direct to framing. Since walls don't support the same loads as floors and roofs, they are an exception to installing with long dimension perpendicular to supports. They rny be applied horizontally to studs 16" or 24" O.C. regardless of span rating if joints are backed with lumber blocking. For rated siding applied over nailable structural panels or lumber sheathing, the span rating refers to spacing of vertical rows of nails.

Story at a Glance

How to read the numbers on panel tradEmarks ... significance of performance ratings.

Span ratings are based on stifftress and strength and vary with thickpss, panel composition and configuration. The same span rating may appear on panels of different thiclnesses or panels of the same thickness may have different span ratings. For instance, 2410 can appear on both 3/8" and 112". The Il2" may be plywood with face and back plies of a species with less stiffuess than the 38". Similarly 3/8" sheathing may be rated 16/0, 2010 or 2410 dependrng on its srength and stiffuess.

This anicle is based on informabn in the Anerican Plywood Association Panel Basics Correspondence Course - Editor.

WfiH S:,' i#['Jft1,"""*:?

prices escalating, competition gecing stiffer and customers demanding better seryice, building products retailers are being forced to carefully evaluate the efficiency of all aspects of their businesses.

Greater attention is being paid to operational and material handling inefficiencies caused by the way a yard and its storage facilities are designed and fimction. These inefficiencies can include poor traffic flow, inadequate storage space or a lack of weather protection for some materi. als. Illogically organized and difficult to reach materials, storage which requires unnecessary or excessive material handling and a lack of self-service access for customers are not unconrmon.

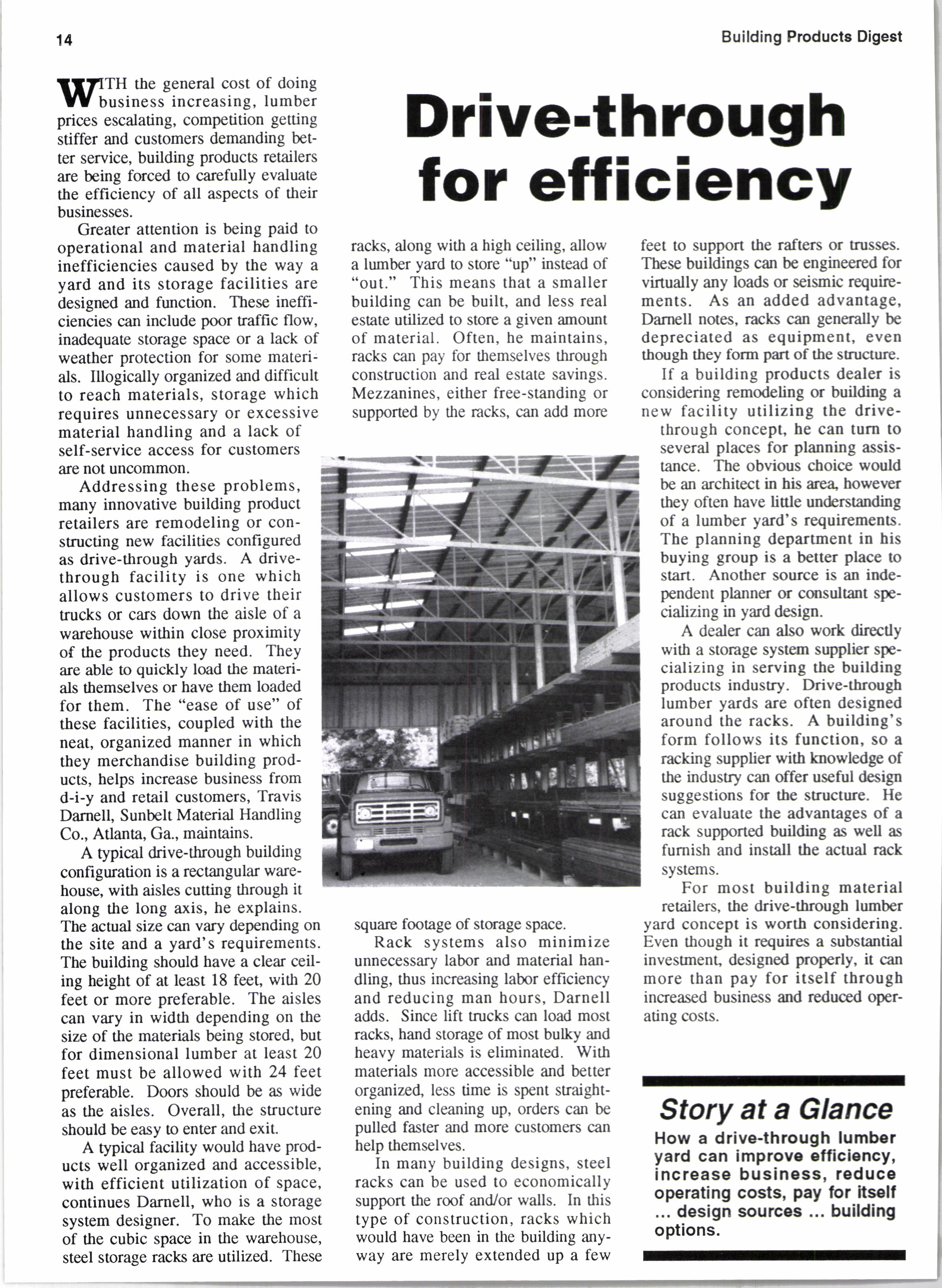

Addressing these problems, many innovative building Product retailers are remodeling or constructing new facilities configured as drive-through yards. A drivethrough facility is one which allows customers to drive their trucks or cars down the aisle of a warehouse within close ProximitY of the products they need. They are able to quickly load the materials themselves or have them loaded for them. The "ease of use" of these facilities, coupled with the neat, organized manner in which they merchandise building Products, helps increase business from d-i-y and retail customers, Travis Darnell, Sunbelt Material Handling Co., Atlanta, Ga., maintains.

A typical drive-through building configuration is a rectangular warehouse, with aisles cuuing througlt it along the long axis, he exPlains. The acu:al size can vary depending on the site and a yard's requirements. The building should have a clear ceiling height of at least 18 feet" with 20 feet or more preferable. The aisles can vary in width depending on the size of the materials being stored, but for dimensional lumber at least 20 feet must be allowed with 24 feet preferable. Doors should be as wide as the aisles. Overall, the structure should be easy to ent€r and exiL

A typical facility would have products well organized and accessible, with efficient utilization of space, continues Darnell, who is a storage system designer. To make the most of the cubic space in the warehouse, steel storage racks are utilized. These