4 minute read

Panel Glossary

A-A: sanded plywood panel witb A-grade face and back plies and D-grade inner plies, bonded with interior or exerior glue.

A-A Exterlor: exterior-type sanded plywood panel witb A-grade face and back plies, C-grade inner plies, bonded witb exterior glue. Exterior or high moisture applications.

A-B: sanded plywood panel witb A-grade face, B-grade back Dgrade inner plies, bonded with interior or exterior glue.

A-B Exterlor: sanded plywood panel with A-grade face, B-grade back, C-grade inner plies, bonded with exterior glue.

A-C Exterior: sanded plywood panel, A-grade face, C-grade back and C-grade inner plies, bonded witb exlerior glue. High moisture applications where appearance of only one side is important.

A-D: sanded plywood panel, A-grade face, D-grade back, Dgrade inner plies, bonded with interior or exterior glues, interior or protected applications where appearance of only one side is important.

APA Performance Rated Panels: panel products (Rated Sheatbing, Rated Sturd-I-Floor and Rated Siding) designed and manufactured to meet performance criteria for specific end-use applications. (see related storY P. l3)

Backstamp: approved agency mark on back of panel.

B-B: sanded plywood panel, B-grade face and back, D-grade inner plies, bonded with interior or exterior glue. Interior or protected utility uses.

B-B Exterior: sanded plywood panel, B-grade face and back, Cgrade inner plies, bonded witb exterior glue. Utility uses.

B-B Plyform: concrete fomt grade.

B-C Exterlor: plywood panel with sanded B-grade face, C-grade back, C-grade inner plies, bonded with exterior glue. Utility uses.

B-D: plywood panel with sanded B-grade face, D-grade back, Dgrade inner plies, interior or exterior glue. Utility uses.

Brushed: siding surface trea0nent.

Story at a Glance

Structural wood panel product terminology information about APA Performance Rated Panels, plywood siding, sanded grades, composite panels and grading.

Bundle: unit or stack of wood panels banded for shipment.

C-C Plugged Exterior: touch-sanded plywood panel witb CPlugged-grade face, C-grade back and inner plies, bonded with exterior glue. For severe moisture conditions.

C-D Plugged: toucb sanded plywood panel witb C-Plugged-grade face, D-grade back and inner plies, interior or exterior glue. lndoor. outdoor use.

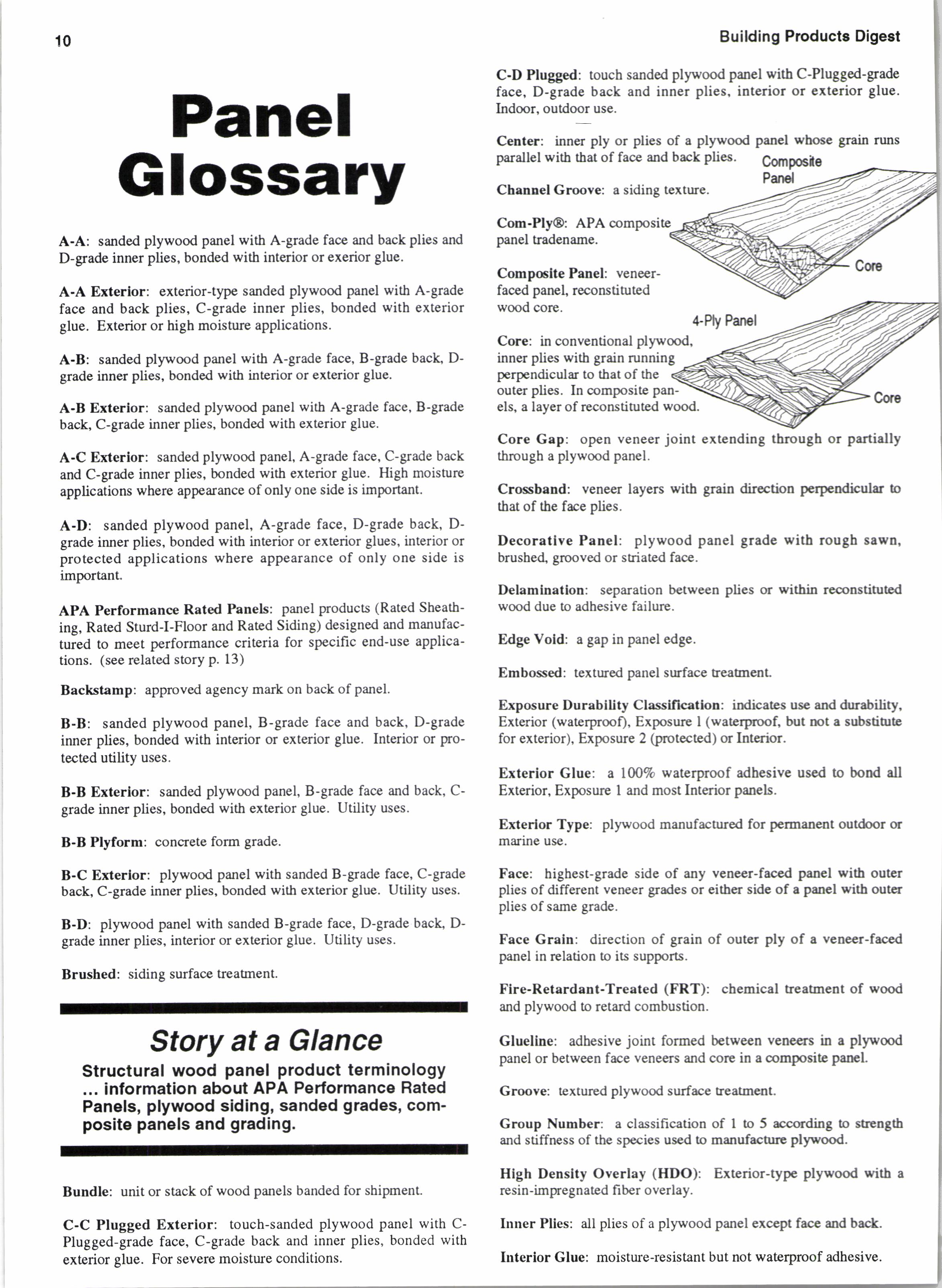

Center: inner ply or plies of a plywood panel wboce grain runs parallel with that of face ud brck plies. Conpcle Panel

Chrnnel Groove: a siding texture.

Com-Ply@: APA composite panel tradename.

Compclte Panel: veneerfaced panel, reconstioted wood core.

+Ply Pansl

Core: in conventional plywood, inner plies with grain running perpendicular to tbat of the outer plies. In composite pan- CdB els, a layer of reconstituted wood.

Core Gap: open veneer joint extending through or partially through a plywood panel.

Crossband: veneer layers with grain direction perpendicuLr to that of the frce plies.

Decoratlve Panel: plywood panel grade with rough sawn, brushe4 grooved or striated face.

Delamlnation: separation between plies or wirhin reconstituted wood due to adhesive failure.

Edge Vold: a gap in panel edge.

Embossed: textured panel surface treafilenl all plies of a plywood panel except face and back.

Exposure Durabllity Classlllcatton: indicates use and durability, Exterior (waterproof), Exposure I (waterp,roof, but not a substiurte for exterior), Exposure 2 (protected) or Interior.

Exterior Glue: a 100% waterproof adhesive used to bond all Exterior, Exposure I and most Interior panels.

Exterlor Type: plywood manufacurred for pemraneot outdoor or marine use.

Face: highesrgrade side of any veneer-faced panel with outer plies of different veneer grades or either side of a panel witb outcr plies of same grade.

Face Graln: direction of grain of ouler ply of a veneer-faced panel in relation to its supports.

Flre-Retardant-Treated (FRT): chemical treatment of wood and plywood to retad combustion.

Gluellne: adhesive joint formed between veneers in a plywood panel or between face veneers and core in a composite panel.

Groove: textured plywood surfrce treatment.

Group Number: a classification of I to 5 rcccding to strenttb and stiffness of the species used to manufacurre plywood.

Hlgh Denslty Overlay (HDO): Exterior-type plywood witb a resin-impregnated fiber overlay.

Jolnted Core: core veneer has edges machined square.

Knothole: void produced when a knot drops out of veneer.

Layer: one or more adjacent plies having wood grain in same direction.

Lay-Up: stacking of veneers or reconstituted wood layers in complete panel "press loads" after gluing and before pressing a skuctural wood panel.

Lumber Core: plywood manufactured with a core of lumber strips.

Marlne Grade: plywood panels meeting marine use criteria.

Medlum Denslty Overlay (MDO): Exterior plywood with an opaque resin-treated fiber overlay.

Noncprtifled: not covered by product or performance standards.

Open Defects: irregularities in veneer.

Orlented Strand Board (OSB): shuctural wood panels manufactured from reconstituted, mechanically oriented wood strands bonded with resins under heat and pressure.

Overlald Plywood: faclory-applied, resin-treated fiber faces on one or both sides.

P & TS: plugged and touch-sanded face of a plywood or composite panel.

Peeler Log: softwood log used to produce veneers.

Performance Standard: APA perfomrance criteria.

Plastlc Overlay: see Medium Density Overlay and High Density Overlay.

Plug: see Repairs.

Plugged Core: inner ply construction of solid CPlugged-grade veneer preces.

Plugged Crossbands

Under Face (PCUF): a sanded panel for underlayment.

Ply: a single veneer in a panel.

Plyron: plywood panel manufactured with a hardboard face.

Preflnlshed: a ready-touse panel with factoryapplied finish.

Preprlmed: panel with factory-applied primer or undercoat.

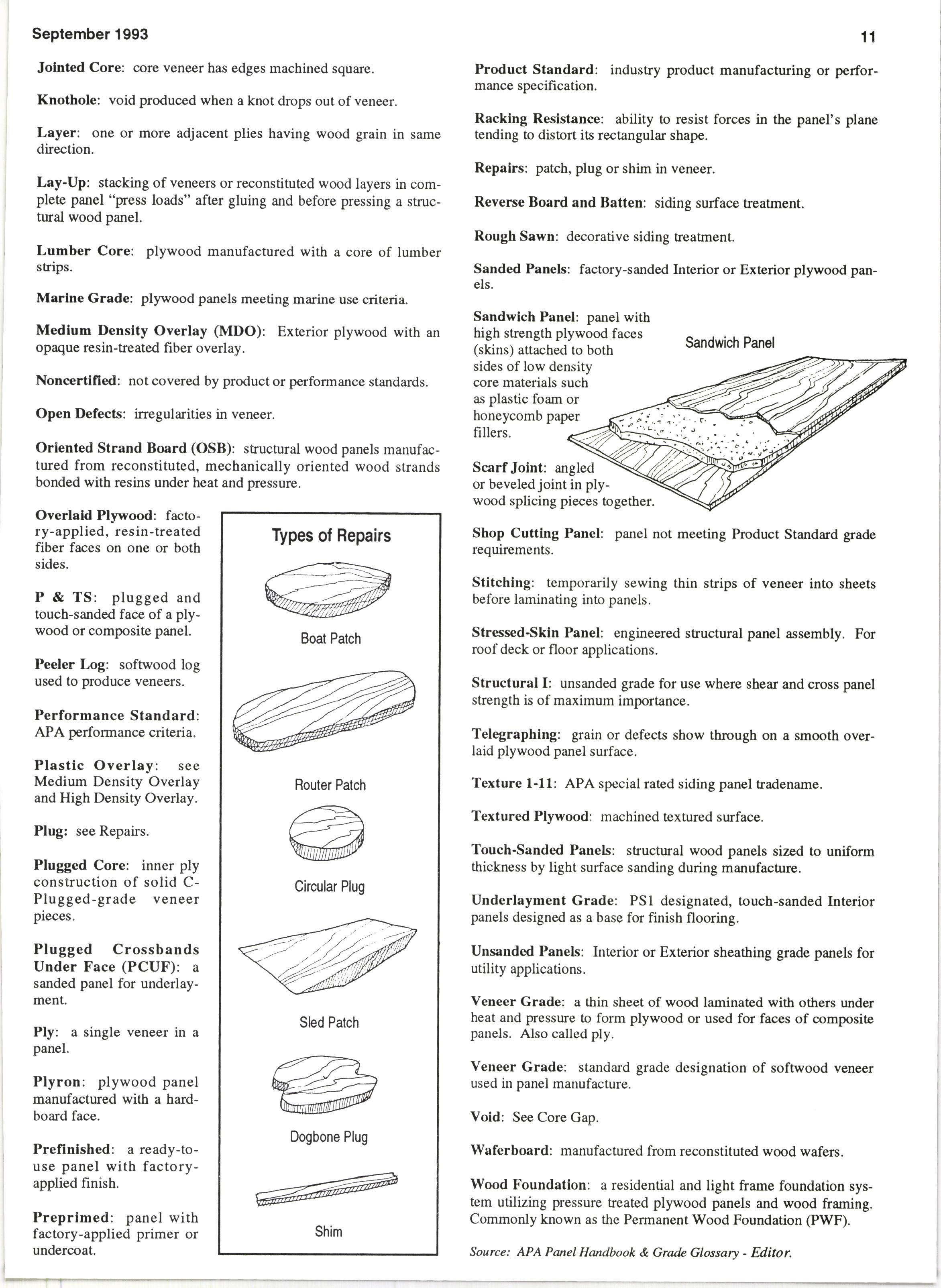

Types

Product Standard: industry product manufacturing or performance spcification.

Racking Resistance: ability to resist forces in the panel's plane lending to distort its rectangular shape.

Repairs: patch, plug or shim in veneer.

Revetse Board and Batten: siding surface treatment.

Rough Sawn: decorative siding treatment.

Sanded Panels: factory-sanded Interior or Exterior plywood panels.

Sandwlch Panel: panel with high strength plywood faces (skins) attached to both sides of low density core materials such

Sandwich Panel as plastic foam or honeycomb paper fillers.

ScarfJoint: angled or beveledjoint in plywood splicing pieces together.

Shop Cuttlng Panel: panel not meeting Product Standard grade requirements.

Stitching: temporarily sewing thin strips of veneer into sheets before laminating into panels.

Stressed.Skln Panel: engineered sEuctural panel assembly. For roof deck or floor applications.

Structural I: unsanded grade for use where shear and cross panel strength is of maximum importance.

Telegraphlng: grain or defects show through on a smooth overlaid plywood panel surface.

Texture 1-11: APA special rated siding panel hadename.

Textured Plywood: machined textured surface.

Touch-Sanded Panels: sftuctural wood panels sized to uniform thickness by light surface sanding during manufacture.

Underlayment Grade: PSI designated, touch-sanded Interior panels designed as a base for finish flooring.

Unsanded Panels: Interior or Exterior sheathing grade panels for utility applications.

Veneer Grade: a thin sheet of wood laminated with others under heat and pressure to form plywood or used for faces of composite panels. Also called ply.

Veneer Grade: standard grade designation of softwood veneer used in panel manufacture.

Vold: See Core Gap.

Waferboard: manufactured from reconstituted wood wafers.

Wood Foundation: a residential and light frame foundation system utilizing pressure treated plywood panels and wood framing. Courmonly known as the Pemranent Wood Foundation (PWF).

Source: APA Panel Handbook & Grade Glossam - Editor.