2 minute read

Structural panel market keeps growing

l\ t:SPlTl: tremendous g,rowth in use over the past 50 l/ years, structural wood panels still offer potential for increased sales.

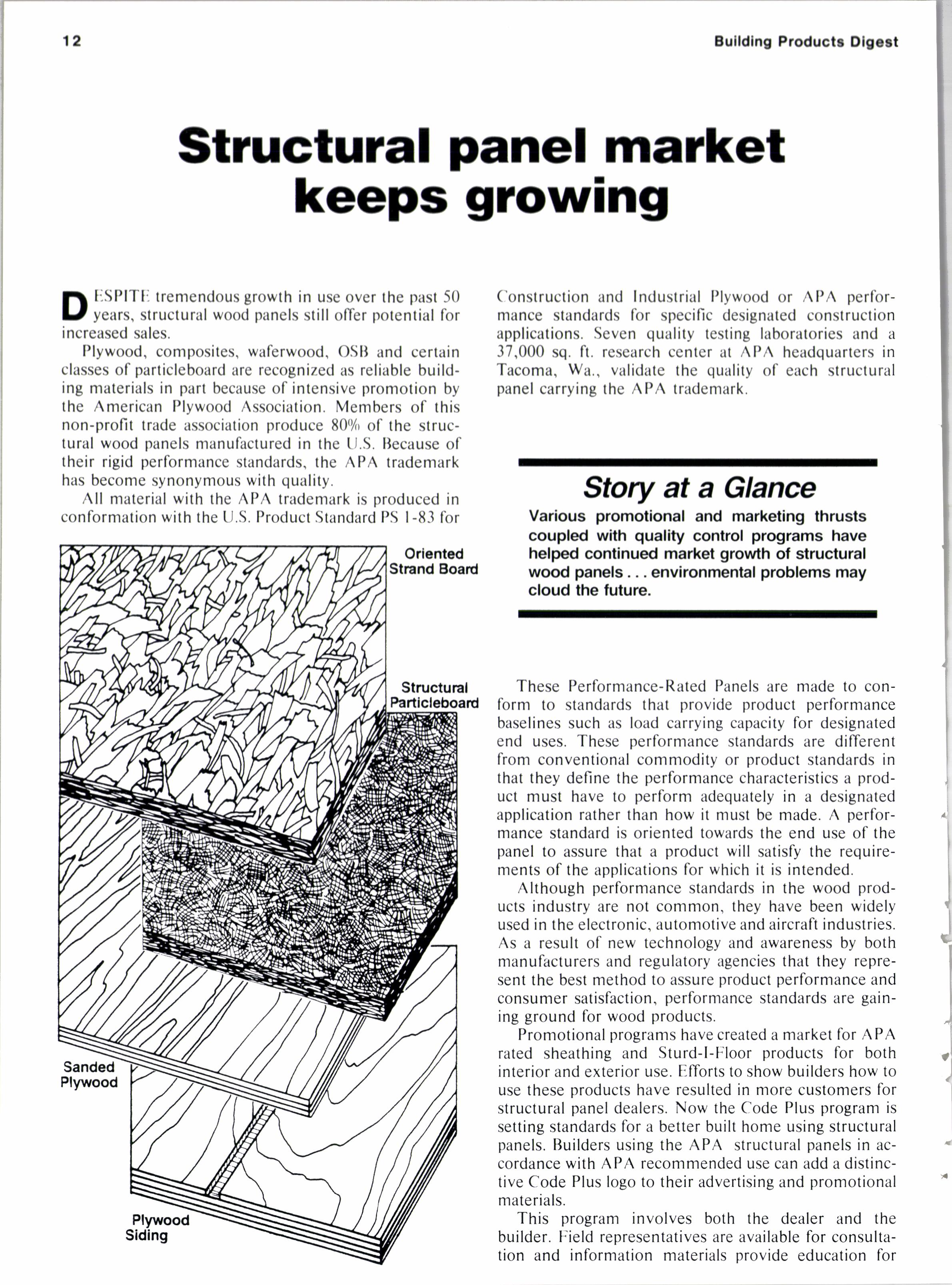

Plywood, composites, waferwood, OSI] and certain classes of particleboard are recognized as reliable building materials in part because of intensive promotion by the American Plywood Association. Members of this non-profit trade association produce 80'l' of the structural wood panels manufactured in the tl.S. llecause of their rigid performance standards, the n PA trademark has become synonymous with quality.

All material with the APA trademark is produced in conformation with the U.S. Product Standard PS l-8-'] for

Orlentod Strand Eoad

(-onstruction and Industrial I'lywood or APA performance standards for specific designated construclion applications. Seven quality testing laboratories and a 37,000 sq. [t. research center at APA headquarters in Tacoma, Wa., validate the quality of each structural panel carrying the APA trademark.

Story at a Glance

Various promotional and marketing thrusts coupled with quality control programs have helped continued market groMh of structural wood panels... environmental problems may cloud the future.

Structural Partlcleboad

These Performance-Rated Panels are made to conform to standards that provide product performance baselines such as load carrying capacity for designated end uses. These performance standards are different from conventional commodity or product standards in that they define the performance characteristics a product must have to perform adequately in a designated application rather than how it must be made. A performance standard is oriented towards the end use of the panel to assure that a product will satisfy the requirements of the applications for which it is intended.

Although performance standards in the wood products industry are not common, they have been widely used in the electronic, automotive and aircraft industries. As a result of new technology and awareness by both manufacturers and regulatory agencies that they represent the best method to assure product performance and consumer satisfaction, performance standards are gaining ground for wood products.

Promotional programs have created a market for APA rated sheathing and Sturd-l-Floor products for both interior and exterior use. Efforts to show builders how to use these products have resulted in more customers for structural panel dealers. Now the Code Plus program is setting standards for a better built home using structural panels. Builders using the APA structural panels in accordance with APA recommended use can add a distinctive Code Plus logo to their advertising and promotional materials.

This program involves both the dealer and the builder. Field representatives are available for consultation and information materials provide education for both seller and user. Special brochures which explain the benefits of Code Plus homes to home buyers are another part of the promotion.

Do-it-yourself, non-residential and industrial markets offer a potential to offset any slump in home building trade. Remodeling is considered a prime market.

The association has vigorously pursued nonhousing markets until they account for 500/o of the total structural panel market. Materials handling is a growing use as are roof decks in industrial buildings. Now with attention to training and merchandise assistance, how-to project materials and magazine marketing, APA is just as actively pursuing the do-it-yourselfer.

Although structural panels have been considered environmentally sound since they often use second growth logs, underutilized species and recovered fiber to some extent, preservationists are creating problems for the industry. Log shortages have closed five plywood mills in the northwest. Southern states, too, face pressure as preservationists extend their area of concern to private timberlands, Obtaining the raw materials necessary to manufacture the structural panels necessary to meet the demands they have created is the industry's biggest challenge at present.