0.05D 0.05D 0.05D

2D

2D 2D

0.05D

2D

2D 2D 2D 0.05D 0.05D 0.05D

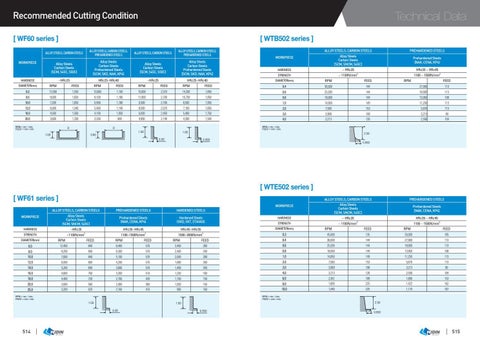

Recommended Cutting Condition

0.05D0.02D 0.02D 0.02D

1.5D1.5D 1.5D

1.5D 1.5D1.5D 1.5D

[ WF60 series ] 0.5D

0.5D0.5D ALLOY STEELS, CARBON STEELS

D

D

D

D

D

D

Alloy Steels 1.0D Carbon Steels (SCM, S45C, S50C)

0.03D 0.2D

0.05D

DIAMETER(mm)

6.0

0.2D

8.0

ap

10.0

1.0D 1.0D 1.0D1.0DHRc25~HRc40

~HRc25 Ap ApAp Ap

HARDNESS

D

D

0.05D0.02D 0.02D 0.02D

D 0.03D

D

Alloy Steels 1.0D Carbon Steels Prehardened Steels [SCM, SKD, NAK, KP4]

Alloy Steels Carbon Steels [SCM, S45C, S50C] 0.2D 2.5D2.5D 2.5D

D

D

FEED 0.05D 0.05D 0.05D

2.0D 1.0D1.0D 1.0D HRc25~HRc40

RPM

12,000

1,550

10,600

1,100

RPM FEED 0.05D 0.05D 0.05D 0.05D 15,800 2,570

14,300

1,850ap : D1~D6=0.2mm

9,000

1,650

8,100

1,180

11,900

2,700

10,700

1,950

1,650

6,400

0.02D 1,180

9,500

2,700

0.05D 8,500

1,950

0.2D ap

RPM0.02D FEED 0.05D 0.02D 0.02D

0.2D

0.2D D8~D12=0.3mm ae : 0.2×D

ap

HARDNESS

0.2D~ HRc35

STRENGTH

~ 1100N/mm2

1.5D

1.0D DIAMETER(mm)

RPM

0.4 0.03D ae 0.03D 0.03D 0.03D

0.02D

0.6 ap : D1~D4=0.05×D D5~D8=0.25mm 0.8 D10~D12=0.3mm ae : 0.1×D 1.0

e

e

ae 0.02D ap : D1~D6=0.2mm D8~D12=0.3mm ae : 0.05×D 0.02D

ae

0.4D

2D

STRENGTH D

DIAMETER(mm)

0.4D

2D

0.5D

514

1.0D 0.35D

144

D

1.5D

27,9000.05D

113

18,900

113

13,950

108

5,670

0.3D

0.05D

1.0D 113

11,250

108 126

1.0D

FEED

1.0D

0.8D

153

0.5D

3,969 3,213

0.03D D

149

113

0.5D

3,213 2,556

0.35D

90 104

1.0D 0.02D2.5D

0.05D

0.02D

0.015D

0.4D

2D

2D 0.05D

0.4D

2D

0.02D

1.5D

2D

0.02D

0.05D

PREHARDENED STEELS

0.02D

HRc45~HRc55

1100~1500N/mm2

1500~2000N/mm2

D

RPM

0.05D

8,400

570

840

6,300

570 (UP TO Ø3:0.4mm) 2,400

840

5,100

570

2,000

800

4,200

570

1,680

260

840

3,600

570

1,400

200

3,300 1.0D 2.5D

510

1,200

160 1.0D

2,700

420

1,100

360 410

1,000 900

1.0D 1.0D 760 720

560 620

0.02D0.05D

FEED

RPM 0.3D

2.0D

0.03D 0.05D

2,400 2,160

D

3,400

0.05D STRENGTH

0.02D (UP TO Ø3:0.2D)

FEED

DIAMETER(mm)

D

260 0.05D 240 Ap

1.0D

290

0.02D

1.0D

150 1.5D 150 160

1.5D

0.1D

0.05D

2.5D 0.8D 0.05D

1.0D 0.05D

1.0D

1.5D 0.3D

0.05D

0.05D

1.5D

0.02D

0.03D

0.1D

0.05D

0.3 0.4 0.6 0.8 1.0 0.05D 2.0 3.0 4.0 1.0D6.0 8.0 10.0

2.5D 0.05D

0.8D 0.3D

1.0D

HRc35 ~ HRc45 1100 ~ 1500N/mm2

RPM

FEED 105

36,000

144

27,900

113

25,200

144

18,900

113

2.0D 18,000

144 1.0D

13,950 1.0D

14,850

0.02D

149

0.02D

108

11,250

0.03D113

113

7,560

153

5,670

3,969

108

3,213

90

3,213

126

2,556

104

1,890

153

1,422 0.3D 1,170

162 167

1.0D

189

1.5D

225 0.05D 225

2.5D

1.0D 0.5D

D 0.05D

35,000

1,800 0.05D 1,440

0.05D

Prehardened Steels [NAK, CENA, KP4]

135

2,367

1.5D

PREHARDENED STEELS

0.02D

45,000

RPM = rev. / min. D / min. FEED = mm

1.5D 1.0D 0.05D

D

HARDNESS

0.5D

0.05D

HRc35~HRc45 D

D

1.5D Hardened Steels (SKD, SKT, STAVAX)

1.5D

1.5D

ALLOY STEELS, CARBON STEELS 0.05D Alloy Steels Carbon Steels [SCM, SNCM, S45C] D ~ HRc35 2 0.3D ~ 1100N/mm (UP TO Ø3:0.4mm) RPM FEED

WORKPIECE

HARDENED STEELS

Prehardened Steels (NAK, CENA, KP4)

840 0.05D

1.5D

D 1.0D

7,560

0.05D

D 1.0D

0.05D

0.05D

0.05D

144 144

18,000 0.03D 14,850 1.0D

0.015D

RPM = rev. / min. FEED = mm / min.

1.5D

0.02D

RPM

0.4D

0.02D

0.4D

ALLOY STEELS, CARBON STEELS Alloy Steels 1.5D Carbon Steels (SCM, SNCM, S45C) 0.02D 0.05D ~HRc35 ~1100N/mm2 D D FEED RPM

12,400 6.0 0.3D 0.5D 9,200 (UP8.0 TO Ø3:0.4mm)(UP TO Ø3:0.2D) 7,600 10.0 6,000 12.0 5,200 14.0 4,800 16.02.0D 4,400 18.0 Ap 0.05D 0.02D 3,600 20.0 3,200 25.0

1.5D

HRc35 ~ HRc45 1100 ~ 1500N/mm2

1.0D

1.5D

0

0.05D

Prehardened Steels (NAK, CENA, KP4)

[ WTE502 series ]

[ WF61 series ] 0.05D0.05D

HARDNESS

0.05D

0.02D

0.02D

WORKPIECE 1.5D

0.1D

0.02D

ap : D1~D4=0.05×D D5~D8=0.25mm 2.5D 2.5D2.5D 2.5D D10~D12=0.3mm 0.015D ae : 0.05×D 0.05D 0.05D 0.05D 0.05D

0.05D

2.0D

2.5D

PREHARDENED STEELS

0.2D

25,200

1.5D 1,540 1.5D1.5D 1.5D 5,400

0.05D

1.0D

FEED

36,000

1.5D 1.0D 1.5D1.5D 2,570 1.5D 7,100 1.0D 1.5D 1.5D 1.0D 12.0 1,140 8,000 1.0D 1.0D 1.0D1.0D 1.0D 1,850 1.5D1.5D 1.5D 2.0 ae ae 16.0 4,500 1,500 0.1D 4,100 1,050 6,000 2,450 5,400 1,750 3.0 0.05D 0.05D 0.3D 0.05D 0.05D 0.05D 0.05D 0.05D 0.3D0.3D 0.3D 0.1D 0.05D 0.05D 0.05D 0.05D 0.05D 0.05D 0.05D 0.1D0.1D 0.05D 0.05D ap : D1~D6=0.2mm ap : D1~D4=0.05×D ap 20.0 3,600 1,330 3,200 900 4,800 2,140 4,300 1,500ap 4.0 D8~D12=0.3mm D5~D8=0.25mm 0.03D 0.03D 0.03D 0.03D ae : 0.2×D D10~D12=0.3mm RPM = rev. / min. RPM = rev. / min. D D D ae : 0.1×DD D D D D FEED = mm / min. FEED = mm / min. ae ae 2.5D 2.5D2.5D 2.5D 1.0D 1.0D 1.0D1.0D 1.0D 1.0D1.0D 1.0D 0.3D 0.5D 1.0D 1.0D 0.8D 1.0D1.0D0.5D 0.8D0.8D 0.8D ap : D1~D6=0.2mm 0.3D ap : D1~D4=0.05×D D8~D12=0.3mm D5~D8=0.25mm 0.35D 0.5D 0.5D0.5D 0.5D 0.35D 0.35D 0.35D 0.05D 0.05D 0.05D ae 0.05D : 0.05×D D10~D12=0.3mm ap ap ae : 0.05×D 1.0D 1.0D

6,0001.5D 1.5D1.5D

1.0D

ALLOYAp STEELS, CARBON STEELS Alloy Steels Carbon Steels [SCM, SNCM, S45C]

WORKPIECE

0.02D

0.3D

(UP TO Ø3:0.4mm)

0.2D

Ap

0.02D 0.02D 0.02D ae

0.02D

0.05D

1.0D

D

1.0D1.0D 1.0D

1.0D

FEED

0.05D

[ WTB502 series ]

D

D

0.05D

RPM

7,200

0.02D

1.0D

ap

2.0D2.0D 2.0D

2.5D ~HRc25

D

(UP TO Ø3:0.2D)

(UP TO (UPØ3:0.4mm) TO Ø3:0.4mm) (UP TO Ø3:0.4mm)

Alloy Steels 1.0D Carbon Steels Prehardened Steels 0.05D Ap (SCM, SKD, NAK, KP4)

Technical Data

0.5D

1.5D

ALLOY STEELS, ALLOY0.3D STEELS, CARBON 0.5DSTEELS, CARBON 0.05D 0.3D STEELS, 0.05D 0.05D 0.05D 0.05D 0.05D ALLOY 0.05D 0.05D STEELS, CARBON STEELS0.3D0.3D 0.05D PREHARDENED STEELS PREHARDENED STEELS (UP TO Ø3:0.4mm)

TO Ø3:0.2D) (UP TO Ø3:0.2D) (UP TO (UPØ3:0.2D) TO (UP Ø3:0.2D)

WORKPIECE

0.02D

D

0.05D 0.05D 0.05D

D

2D

0.35D

0.05D

D 1.0D

2.5D

1.0D 0.5D

0.35D

0.05D

2.5D

515