Recommended Cutting Condition

Technical Data [ WHPB902 series ]

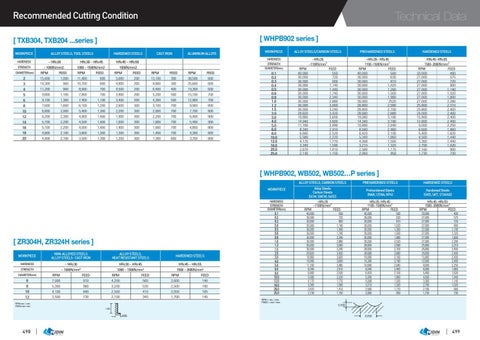

[ TXB304, TXB204 ...series ] WORKPIECE HARDNESS STRENGTH DIAMETER(mm)

2 3 4 5 6 8 10 12 14 16 18 20

ALLOY STEELS, TOOL STEELS

HARDENED STEELS

~ HRc30

HRc30 ~ HRc45

~ 1000N/mm2

1000 ~ 1500N/mm2

CAST IRON

ALUMINUM ALLOYS

HRc45 ~ HRc50 1500N/mm2

RPM 15,400

FEED 1,000

RPM 11,400

FEED 600

RPM 5,000

FEED 200

RPM 13,100

FEED 300

RPM 38,500

FEED 600

14,300

900

10,700

600

4,800

200

8,800

300

25,600

600

11,200

900

8,900

700

4,500

200

6,400

400

19,300

600

9,800

1,100

7,800

700

3,900

200

5,200

500

15,100

700

9,100

1,300

7,400

1,100

3,400

200

4,300

500

12,900

700

7,600

1,600

6,100

1,200

2,600

300

3,100

700

9,900

800

6,800

2,000

5,400

1,300

2,200

300

2,600

700

7,700

800

6,200

2,300

4,900

1,400

1,900

300

2,200

700

6,400

900

5,700

2,200

4,500

1,400

1,600

300

1,800

700

5,400

900

5,100

2,200

4,000

1,400

1,400

300

1,600

700

4,800

800

4,800 4,400

2,100 2,100

3,800 3,500

1,300 1,300

1,300 1,200

300 300

1,400 1,300

700 600

4,300 3,700

800 800

WORKPIECE

ALLOY STEELS/CARBON STEELS

PREHARDENED STEELS

HARDENED STEELS

HARDNESS STRENGTH DIAMETER(mm)

~HRc35 ~1100N/mm2

~HRc35~ HRc45 1100~1500N/mm2 RPM FEED 40,000 500 30,000 630 30,000 810 30,000 1,020 30,000 1,260 30,000 1,500 30,000 1,980 30,000 2520 28,800 2,580 28,800 2,700 28,680 2,880 19,080 3,180 14,340 3,180 10,680 2,940 8,040 2,460 6,420 2,100 5,340 1,860 4,008 1,500 3,210 1,320 2,580 1,170 2,060 950

HRc45~HRc55 1500~2000N/mm2 RPM FEED 33,000 400 27,000 575 27,000 720 27,000 900 27,000 1,140 27,000 1,320 27,000 1,800 27,000 2,280 25,800 2,310 25,800 2,400 24,000 2,400 15,900 2,400 12,000 2,400 9,000 2,250 6,600 1,860 5,400 1,620 4,500 1,440 3,360 1,440 2,700 1,020 2,160 900 1,730 730

0.1 0.2 0.3 0.4 0.5 0.6 0.8 1.0 1.2 1.5 2.0 3.0 4.0 5.0 6.0 8.0 10.0 12.0 16.0 20.0 25.0

RPM 40,000 30,000 30,000 30,000 30,000 30,000 30,000 30,000 30,000 30,000 29,820 19,860 14,940 11,160 8,340 6,660 5,580 4,170 3,340 2,670 2,130

FEED 550 720 900 1,140 1,440 1,740 2,340 2,880 3,060 3,240 3,420 3,600 3,600 3,480 2,910 2,520 2,220 1,770 1,590 1,410 1,150

[ WHPB902, WB502, WB502…P series ] ALLOY STEELS, CARBON STEELS WORKPIECE WORKPIECE

DIAMETER HARDNESS

(mm) STRENGTH DIAMETER(mm) 20

0.1

250.2 300.3 400.4

0.5

500.6

[ ZR304H, ZR324H series ] WORKPIECE

N0N-ALLOYED STEELS ALLOY STEELS · CAST IRON

ALLOY STEELS, HEAT RESISTANT STEELS

HARDENED STEELS

HARDNESS

~ HRc30

HRc30 ~ HRc45

HRc45 ~ HRc55

STRENGTH

~ 1000N/mm2

1000 ~ 1500N/mm2

1500 ~ 2000N/mm2

DIAMETER(mm)

RPM

FEED

RPM

FEED

RPM

FEED

6 8 10 12

7,000

910

4,200

560

3,000

140

5,300

980

3,200

530

2,500

190

4,100 3,500

840 730

2,500 2,100

410 340

2,050 1,700

165 140

RPM=rev. / min. FEED=mm / min.

0.8 1.0 1.2 1.5 2.0 3.0 4.0 5.0 6.0 8.0 10.0 12.0 16.0 20.0 25.0

RPM = rev. / min. FEED = mm / min.

Alloy Steels SM50C,SCM,GC Carbon (~HRc30)Steels (SCM, SNCM, S45C) RPM ~HRc35 FEED -1 2 (mm ) ~1100N/mm (mm/rev) RPM FEED 1600 152 40,000 550 130030,000 136 720 110030,000 120 900 80030,000 96 1,140 30,000 1,440 65030,000 88 1,740 30,000 2,340 30,000 2,880 30,000 3,060 30,000 3,240 29,820 3,420 19,860 3,600 14,940 3,600 11,160 3,480 8,340 2,910 6,660 2,520 5,580 2,220 4,170 1,770 3,340 1,590 2,670 1,410 2,130 1,150

PREHARDENED STEELS

HARDENED STEELS

STD61,STD11Steels Prehardened (HRc30 ~ HRc45) (NAK, CENA, KP4)

STD61Steels Hardened (HRc45 ~ HRc55) (SKD, SKT, STAVAX)

RPM HRc35~HRc45FEED 2 (mm-1)1100~1500N/mm (mm/rev) RPM FEED 950 88 40,000 500 750 72 630 30,000 30,000 650 64 810 30,000 500 561,020 30,000 1,260 400 481,500 30,000 30,000 1,980 30,000 2,520 28,800 2,580 28,800 2,700 28,680 2,880 19,080 3,180 14,340 3,180 10,680 2,940 8,040 2,460 6,420 2,100 5,340 1,860 4,008 1,500 3,210 1,320 2,580 1,170 2,060 950

RPM HRc45~HRc55 FEED 2 (mm-11500~2000N/mm ) (mm/rev) RPM FEED 560 44 33,000 400 450 36 575 27,000 27,000 370 32 720 27,000 280 24 900 27,000 1,140 220 20 27,000 1,320 27,000 1,800 27,000 2,280 25,800 2,310 25,800 2,400 24,000 2,400 15,900 2,400 12,000 2,400 9,000 2,250 6,600 1,860 5,400 1,620 4,500 1,440 3,360 1,140 2,700 1,020 2,160 900 1,730 730

0.03D

1.0D

0.2D

Ap 0.05D

0.05D

498

499 ap

ap

0.2D