Driving sustainability

Sustainability report 2022 Bobst Group SA ˍ

Water pollution, depletion of natural resources, climate change: we are degrading and putting pressure on our environment so fast that the lives and homes of millions of people across the globe are at stake. It is everybody’s responsibility to act NOW to improve the situation. The private sector has a critical role to play in mitigating environmental damage and in proposing solutions. BOBST, as one of the world’s leading suppliers of substrate processing, printing and converting equipment and services for the label, flexible packaging, folding carton and corrugated board industries, takes the future of humanity at heart and is now implementing actions to address sustainability issues. These initiatives may be a drop in the ocean of the global problem, but this is our responsibility to undertake them for the sake of a better world.

2

Bobst Group SA

Editorial 4 BOBST is committed to help solve global 4 issues Strategy 6 Our vision 8 Sustainability strategy 9 Materiality assessment 10 Stakeholder engagement 14 United Nations’ sustainable 16 development goals Operations reporting 18 Climate change 19 Energy 23 Water & waste 25 Occupational health & safety 30 Women & youth, diversity & 37 equal opportunity Innovation 42 Procurement & supply chain 44 Business ethics 46 Digitalization & data management 49 Talent attraction & satisfaction 52 Equipment reporting 54 Machinery energy consumption 55 Extending the life of BOBST machines 57 Machine safety for the user 59 Packaging use & 62 end-of-life reporting Environmentally improved packaging 63 TCFD 68 Task Force on Climate-related Financial 69 Disclosures (TCFD) GRI index 71 GRI index 72 Content Bobst Group SA 3

BOBST is committed to helping solve the climate issues

With the release of this sustainability report, Bobst Group is proud to share its progress toward its sustainability goals.

We recognize the importance of environmental and social responsibility in all aspects of our operations from the supply chain to our manufacturing processes. Sustainability is not just a word, it has become part of our lives, whether we like it or not. Our business decisions should be carefully considered as they have sometimes unexpected consequences for the planet. We remain committed to reducing our impact on the planet, respecting nature and people, while also creating long-term value for our stakeholders. Over 2022, we made significant strides by reporting on three additional material topics – Water & waste, Energy, Talent attraction & satisfaction – and climate-related financial reporting in line with the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD). Today our sustainability scope includes

considerable actions, but we are only at the beginning of the journey. Whether it’s calculating the carbon footprint of our machines, creating an equitable and good environment in the company, committing to offer equal working opportunities and remuneration to employees for equal responsibilities throughout the Group, encouraging the development of young talents in management, or promoting family welfare, BOBST is committed to sustainability throughout its operations and beyond. Success is based not only on good products but also on the ethical behavior of our employees: by fostering our core values and establishing a strong company culture we encourage our employees to act with integrity, accountability and respect throughout our operations. Our core values of Passion, Respect, Performance and Trust are embedded in our business and guide our decisions and actions. We firmly believe that our commitment to sustainability will bear fruit in the long run, leading to increased brand reputation and attractiveness as an employer.

Sustainability report 2022

> Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Editorial

“BOBST is actively shaping a sustainable world for packaging”

Bobst Group SA 4

Sustainability report 2022

> Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reportinge

> TCFD

> GRI index

While BOBST stays a small group compared to the largest multinationals, reducing the environmental impact of packaging throughout its life cycle is a challenge we are determined to take on.

Our commitment matters, and we recognize our responsibility to contribute to solving global sustainability issues. The Board of Directors works hand in hand with the Group Executive Committee (GEC) on sustainable development.

The recent environmental and energy crisis have shown us that a financial report alone does not fully reflect the consequences, risks, and costs of running a company.

BOBST’s commitment to the Environmental, Social, and Governance (ESG) standards is driving positive change and shaping a sustainable future for both the packaging industry and the world.

Alain Guttmann Chairman of the Board

Jean-Pascal Bobst Chief Executive Officer

Alain Guttmann Chairman of the Board

Jean-Pascal Bobst Chief Executive Officer

Editorial

Strategy

Sustainability report 2022

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

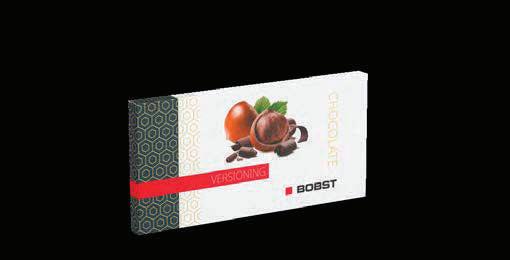

Sustainability has taken a consistent and important place in BOBST’s strategy and actions. With the three pillars defined in its strategy – operations, equipment, packaging use & end-of-life – BOBST is committed to make progress in this field with relevant business indicators.

Innovations that will change the way packaging is produced, together with mixed teams, are at the heart of all BOBST’s sustainability efforts with, amongst others, reduction of waste, an increase of efficiencies, compliance with the latest regulations, and the development of environmentally improved flexible packaging solutions.

We are shaping the future of the packaging world, and we do our utmost to help the packaging sector to deliver better quality, efficiency, control, in a sustainable manner at a time when these qualities have never been more important.

Bobst Group SA 6

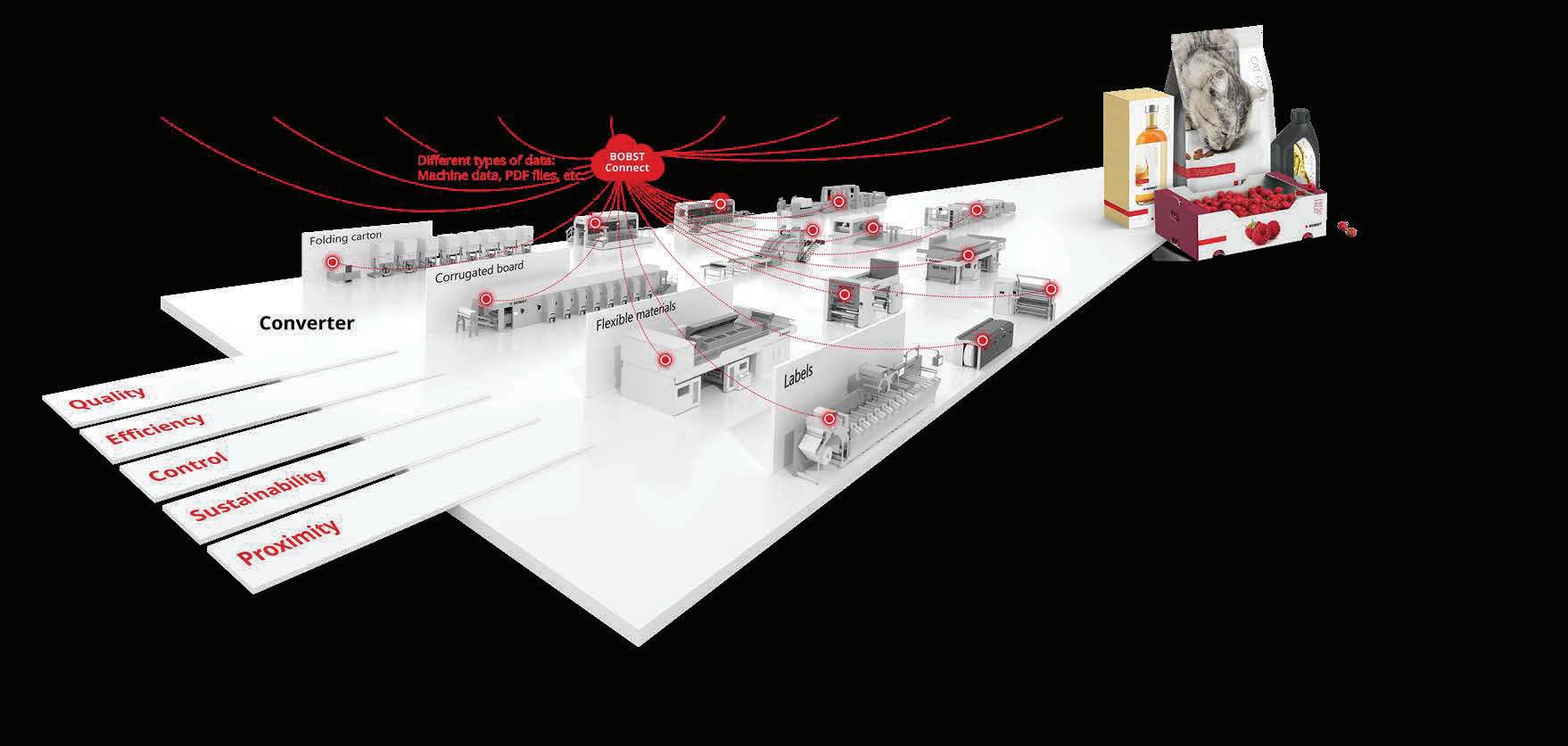

Converters BOBST Brand owners Brand owners’ needs Time to market Fast turnaround time More sustainable packaging Cost Quality Efficiency Control

Sustainability

needs Automation Connectivity Sustainability Digitalization Equipment, services and a wide range of solutions for the packaging industry Strategy Bobst Group SA 7 Sustainability report 2022 >Strategy > Operations reporting > Equipment reporting > Packaging use & end-of-life reporting > TCFD > GRI index

Proximity

Converter

Our vision

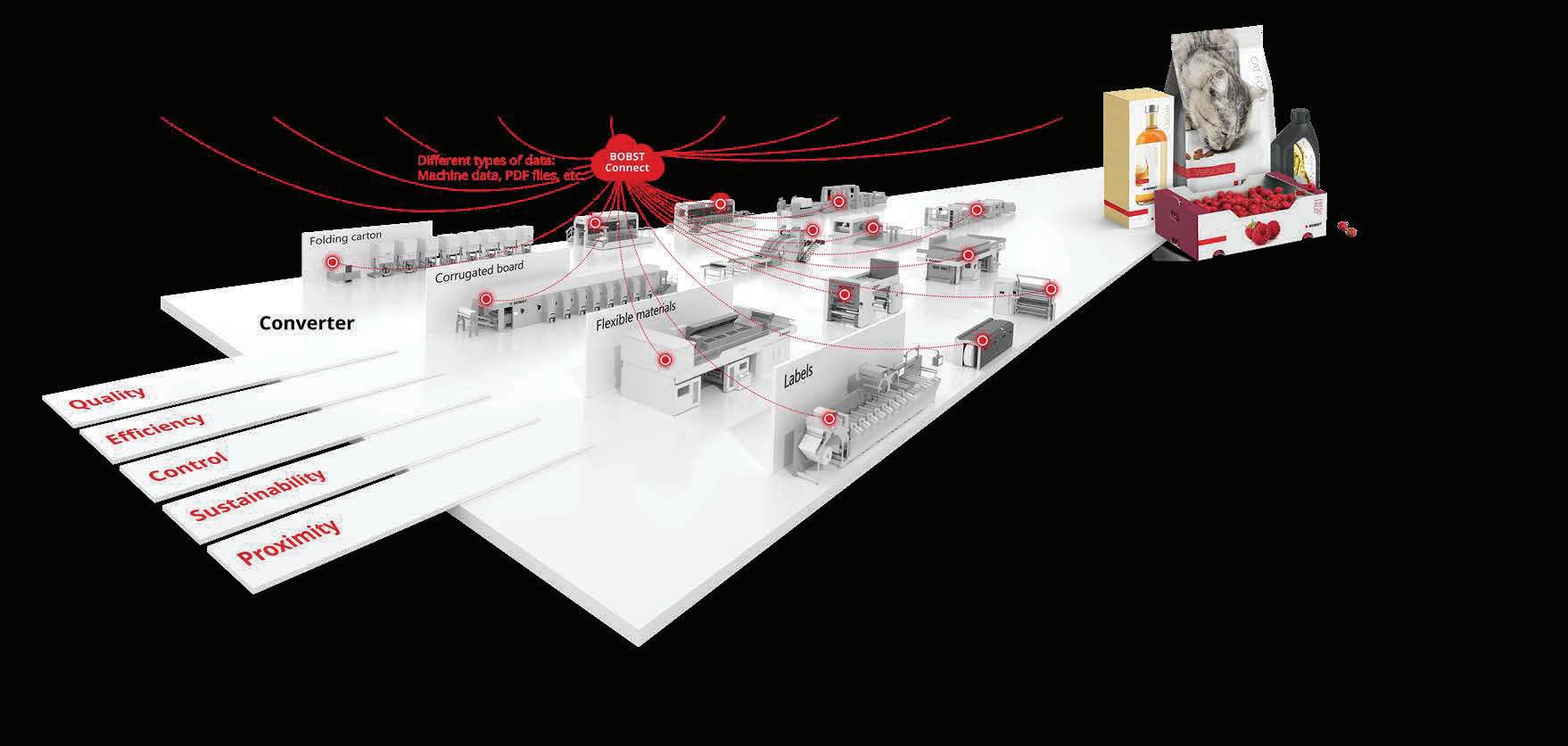

We have set out to shape the future of the packaging world by actively driving the industry transformation: from a mechanical to a digital world, and from manufacturing machines to process solutions along the entire workflow.

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

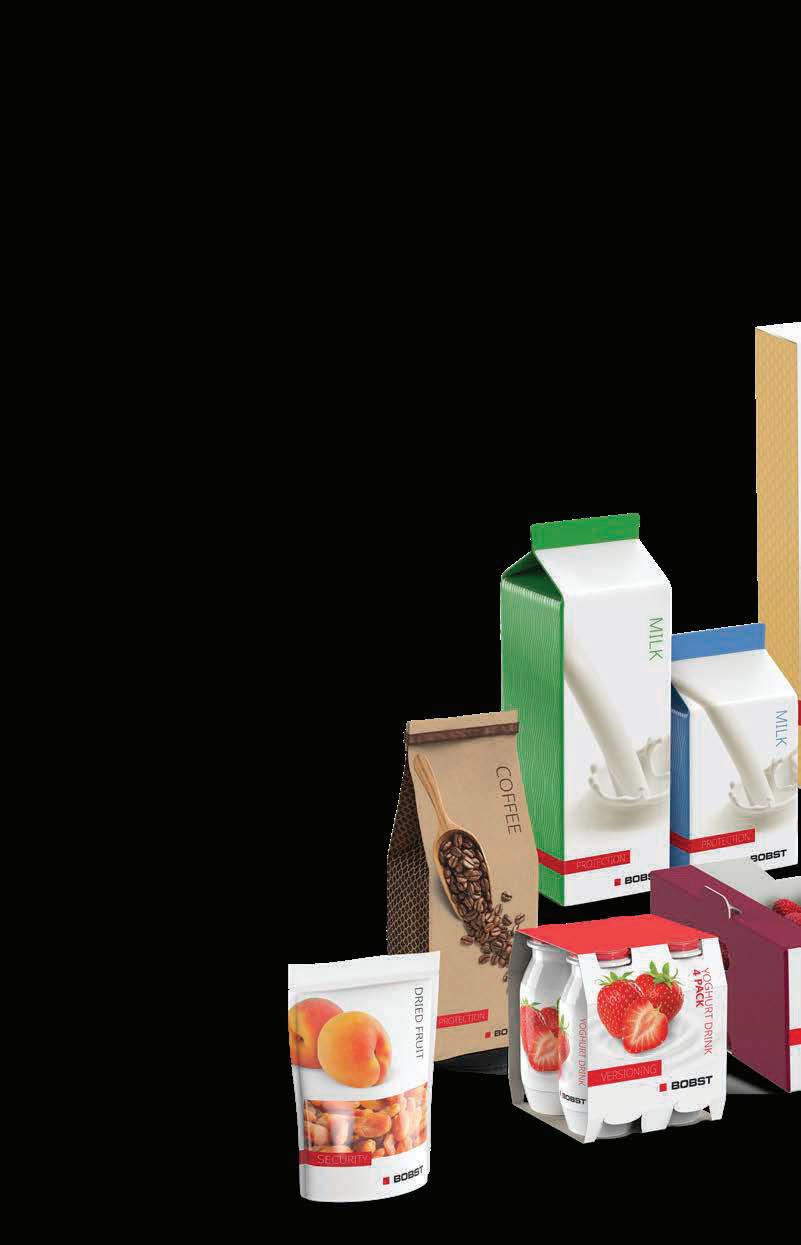

Four industries served

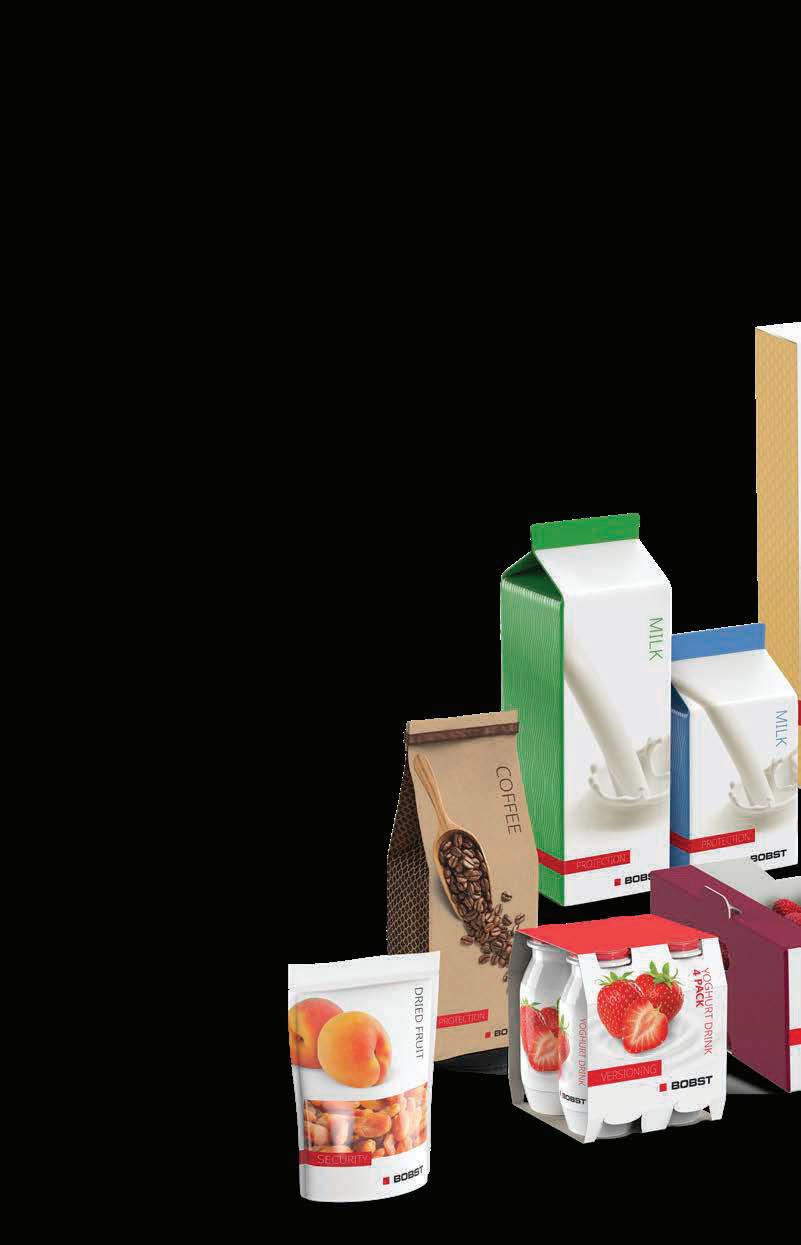

BOBST serves four industries with innovative packaging and label solutions:

– Labels

– Flexible packaging

– Folding carton

– Corrugated board

Brand owner DesignerPre-press Workflow solutions Supplier of substrate, tooling, ink and services

Converting partner Packer Consumer e-tailer/ retailer Our vision ˍ

Equipment

Connectivity Digitalization Automation Sustainability Bobst Group SA 8

Empowering the future

Sustainability report 2022

Anticipating change

Materiality assessment motivated the articulation of BOBST’s sustainability strategy into three streams. Each stream brings together a dedicated team under the coordination of a Head of stream. BOBST’s Head of corporate sustainability and a Steering Committee oversee their work.

>Strategy

>

>

>

>

>

BOBST operations

To provide work and life conditions within the company and along the supply chain, which are ethical, supportive, and respectful of the environment.

BOBST equipment

To reduce the environmental and social impact of future and existing packaging machines at the customer’s site with improvements on machine performance and new services.

Packaging use & end-of-life

To contribute with solutions in the value chain to generalize more sustainable packaging, which have minor environmental impact and a well-managed end-of-life. At BOBST we do almost all that is possible today to reduce the environmental footprint of packaging with pragmatic solutions and ongoing innovations.

Sustainability strategy

BOBST is committed to sustainability beyond its sole operations

ˍ

Bobst Group SA 9

report 2022

Sustainability

Operations

reporting

Equipment

reporting

Packaging

use & end-of-life reporting

TCFD

GRI

index

Prioritizing challenges

Materiality assessment is a methodology to identify which Environmental, Social, and Governance (ESG) issues are the most significant for an organization. BOBST’s materiality showed that the most significant topics address challenges at three different levels of the value chain: operations, equipment, and packaging use & end-of-life. This finding motivated the articulation of BOBST’s sustainability strategy into three streams.

BOBST’s materiality assessment

In 2020, BOBST conducted a materiality assessment for the first time. The process began with a thorough review of ESG challenges in the packaging industry, which led to a list of potentially relevant topics.

To prioritize these topics, focus groups and bilateral interviews were organized with key stakeholders, both internal and external, chosen to reflect the diversity of perspectives in BOBST’s ecosystem. In particular, the various functions, managerial levels, geographies, ages, and gender within the Group:

– More than 100 BOBST employees took place in face-to-face consultations, including amongst others: Local Entity Heads, Environmental Health & Safety (EHS) managers, HR representatives, R&D engineers, administrative functions, together with Group Executive Committee and Board of Directors members;

– In addition, 25 external key industry stakeholders were consulted, including brand owners, converters, associations, and others (e.g. partners).

Materiality matrix

The materiality matrix provided a visual representation of the issues that were prioritized according to their importance to the company’s stakeholders.

The result of BOBST’s materiality analysis shows the topics relevant to BOBST’s value chain based on the rankings given by the participants as represented in the materiality matrix (see graph on page 11).

Several sustainable issues are drawn from the Global Reporting Initiative (GRI) standards, and some are sector-specific topics not covered by the GRI standards but deemed to be of material importance by stakeholders.

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

ˍ

Materiality assessment

Bobst Group SA 10

report 2022

Sustainability

Materiality assessment

Materiality matrix established in 2020

High priority topics, which must be addressed in the strategy, are those which are ranked high by internal and also external stakeholders.

29

30

31

32

33

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

34

35

36

37

38

Significance for external stakeholders 3 1 0 4 2 5 0 3 1 4 2 5 Significance for internal stakeholders High significance Medium significance 13 09 19 39 32 31 25 26 27 23 22 35 37 A B C 07 14 16 04 10 18 05 06 11 38 36 03 01 02 08 12 21 29 30 C 17 24 28 A 15 20 33 34 B Detailed view Environment 01 Air pollution 02 Climate change 03 CO2 neutral machines 04 Design for recyclability 05 Eco-design 06 End-of-life of the machinery 07 Energy efficiency of the machinery 08 Energy in operations 09 Environmentally improved packaging 10 Extending the life of the machinery 11 Hazardous substances 12 Mobility 13 Packaging end-of-life 14 Plastic packaging 15 Plastic 16 Resource efficiency of the machinery 17 Responsible use of materials 18 Waste & circularity 19 Waste from the machine operation Social 20 Diversity & equal opportunity 21 Fair working conditions 22 Human rights

Labor relations

Local community engagement, charity & volunteering

Occupational health & safety

Machine safety

Woman & youth, training & empowering

Agility & resilience to changing market conditions

23

24

25

26

27

Governance 28

Business ethics

Client satisfaction

Digitalization

Innovation

Integration

in decision-taking

of nonfinancial information

process

Responsible

&

leadership

governance

Talent attraction

Machine productivity

Optimization

of the organization & operational excellence

Packaging

safety

39 Sustainable procurement & supply chain management

07 Bobst Group SA 11

Sustainability report 2022

Materiality assessment

Main findings of BOBST’s materiality analysis

The identified topics address challenges at three different levels of the BOBST value chain.

In quantitative footprint studies, such as the BOBST equipment life cycle assessments, it has become clear that the most significant sustainability impacts occur down the value chain at the customer sites and at end-of-life phase, where BOBST has little influence and leverage.

The three streams and their priority topics for the years 2022-2023

Priority topics for 2022-2023

BOBST operations

Climate change

Energy*

BOBST equipment

Machinery energy consumption

Extending the life of BOBST machines

(technically not a priority, but included in this report)

Water & waste* Machine safety for the user

Occupational health & safety

Women & youth, diversity & equal opportunity

Innovation

(technically not a priority, but included in this report)

Procurement & supply chain

Business ethics

Digitalization & data management

(technically not a priority, but included in this report)

Talent attraction & satisfaction*

Sustainability report 2022

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Packaging use & end-of-life

Environmentally improved packaging

(This is an umbrella topic that addresses the environmental footprint of packaging holistically throughout its life cycle. A main focus area is the EoL of packaging, in particular the design for recyclability of packaging. However, other EoL pathways, e.g. compostability and biodegradability, are also considered.)

Other important topics

Waste from the machinery

* New topics included in this report.

This report covers all BOBST branded local entities, which can be consulted in the annual report:

> https://investors.bobst.com/fileadmin/user_upload/Investors/Reports/Annual_Report_2022_EN.pdf

Bobst Group SA 12

Sustainability report 2022

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Materiality assessment

Group SA 13

The highest impact occurs downstream in the value chain, where BOBST has little leverage

Bobst

Stakeholder engagement

Stakeholders

Brand owners

Converters

Interaction with stakeholders

Personal contacts, Packaging Masterclass seminar, Personalized consultations about sustainability.

Personal contacts, Satisfaction survey, Virtual and in-person demonstrations, Personalized consultations about sustainability.

Associations, Partners Conferences, Partnerships, Personalized consultations about sustainability.

Suppliers, Folding carton, Corrugated board, Labels, Flexible packaging manufacturers

Regular correspondence, Personal contacts, Supply management, Personalized consultations about sustainability.

Issues and concerns

Communication about the possibilities offered by BOBST machines, Partnership of trust, To produce eco-friendly packaging.

Excellent after-sales service, Spare parts available quickly, Online assistance in case of production problems, Fast response times, reliable and highly productive products, Production of zero-fault packaging.

Environmental impact of packaging, Health and safety impact.

Price, Volumes, Specifications, Partnership.

Sustainability report 2022

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Competitors

Competitive intelligence.

Technology watch. Municipality, Political authorities Development plan, Specific events.

Compliance with laws and regulations, Tax contribution, Durability, Certifications.

Media, Financial Analysts

Shareholders, Investors, Families related to BOBST

Next Generation (young people from families connected to BOBST)

Annual report, Press releases, Press conferences.

Annual Report, sustainability report, annual profile, Press releases, General Assembly, Roadshows.

Regular sessions and workshops, Personalized consultations about sustainability.

Operating profit (EBIT), Strategy, Durability.

Long-term financial goals, Durability, Sustainability, Long-term success and corporate reputation.

Identify young leaders to ensure the succession, Opportunities to work at BOBST.

Board of Directors

Regular sessions, Personalized consultations about sustainability.

Good operation and sustainability of the company. Group Executive Committee, extended management team Regular sessions, Personalized consultations about sustainability.

Health and safety, Job security, Exchange of regular information, Workload,

Good operation and sustainability of the company. Employees Daily interactions, Staff meetings, Intranet communications, Training, Meetings with the Management and the Personnel Commission, Personalized consultations about sustainability.

Salary and other benefits, Training.

Stakeholder engagement

Bobst Group SA 14

Stakeholders

Interaction with stakeholders

Personnel Commission Meetings with Management, Meetings with staff.

Retirees Newsletters and regular events, Access to BOBST employee benefits.

Apprentices, Training Center

Universities of Applied Sciences

Neighborhood, Various audiences

Associations, charities

Ceremony for the presentation of certificates, Open house of the Training Center.

Issues and concerns

Salary negotiations and other employee benefits, Employee representation.

Benefit from attractive prices, Stay informed about BOBST activities.

Train young people in the mechanical and electrical engineering industries, Ensuring succession, To acquire, provide vocational training, education.

Trade shows, School visits. Find young leaders, Opportunities to work at BOBST.

Correspondence, Company visits.

To know the activities of BOBST, Good relationships.

Collection of donations within BOBST. Sponsorship.

Sustainability report 2022

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Stakeholder engagement

Bobst Group SA 15

Embracing global initiatives

Quality education

Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all.

BOBST operations

Responsible consumption and production

Ensure sustainable consumption and production patterns.

Partnerships for the goals

Strengthen the means of implementation and revitalize the global partnership for sustainable development.

Climate action

Take urgent action to combat climate change and its impacts.

Gender equality

Achieve gender equality and empower all women and girls.

Decent work and economic growth

Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all.

Industry, innovation and infrastructure

Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation.

Clean water and sanitation

Ensure availability and sustainable management of water and sanitation for all.

United Nations’ sustainable development goals

ˍ

Bobst Group SA 16

As a Group leader in the global industry, BOBST is committed to advancing environmental and societal solutions on a worldwide scale

United Nations’ sustainable development goals

Industry, innovation and infrastructure

Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation.

Packaging use & end-of-life

Responsible consumption and production

Ensure sustainable consumption and production patterns.

Partnerships for the goals

Strengthen the means of implementation and revitalize the global partnership for sustainable development.

Decent work and economic growth

Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all.

Sustainability report 2022

>Strategy

> Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD > GRI index

Life on land

Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, halt and reverse land degradation and halt biodiversity loss.

BOBST’s initiatives support the objectives, within its reach, of the United Nations’ sustainable development program.

BOBST equipment

BOBST equipment

Bobst Group SA 17

To provide work and life conditions within the company and along the supply chain, which are ethical, supportive and respectful of the environment.

Bobst Group SA 18 Sustainability report 2022 > Strategy >Operations reporting > Equipment reporting > Packaging use & end-of-life reporting > TCFD > GRI index

Operations reporting

Climate change

BOBST’s carbon footprint reduction to prevent climate change takes a high-priority position in the Group’s sustainability strategy. It is relevant for BOBST because the CO2 emissions of packaging production and consumption are considerable. Therefore, BOBST is committed to reducing the intake of energy and natural resources in all Group’s operations to decrease its carbon footprint.

Within the packaging industry, BOBST’s carbon footprint and impact on climate change occurs in several main areas.

The Group operates industrial sites, produces equipment, and ships machines and spare parts to its customers worldwide. All these activities consume energy (e.g. electricity and fuel) as well as natural resources (e.g. iron) and generate carbon emissions.

On the other end, the machinery sold by BOBST enables converters worldwide to produce packaging from a wide variety of substrates. However, their energy consumption is considerable and causes Greenhouse Gas (GHG) emissions.

BOBST carbon footprint breakdown

When BOBST’s activities are broken down according to the GHG protocol (see detailed figures on page 21), it turns out that the direct and energy-indirect emissions generated by the production of a

BOBST machine (scopes 1 and 2) represent only a half-percent share of its overall carbon footprint. The highest impact, 99.5% of GHG emissions, occurs up & downstream in the value chain (scope 3), where BOBST has little leverage. This result points out an inverse relationship between BOBST’s direct scope of action and the carbon footprint of packaging in general.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Scope 3 upstream –indirect GHG

Procurement of raw materials, business travel, staff commuting, water and waste treatment, transport inbound.

Scope 1 – direct GHG related to BOBST’s operations

Fuel from owned and leased vehicles, emissions from burning fuels on BOBST sites (e.g. manufacturing and heating).

Scope 2 – indirect GHG

related

to BOBST’s

operations

Purchased electricity.

Scope 3 downstream –

indirect GHG

Energy consumed by the machines (sold in the report year) during their whole lifetime, transport outbound of machines and spare parts.

Upstream activities Reporting company Downstream activities Climate change Bobst Group SA 19

Most of BOBST’s GHG emissions occur at the customer’s premises

Accountable for 77.6% of total BOBST GHG emissions in 2022, BOBST machines in the use phase at the converters’ plants over their lifetime represent the most significant fraction of the carbon footprint of the Group. Two main reasons explain the importance of GHG emissions related to the equipment sold by BOBST. First, a packaging machine consumes energy while operating. Second, a BOBST machine is designed to last (15 to 30 years), and thanks to the maintenance programs and solutions provided by BOBST services the machines can function optimally and for a long time (see section Extending the life of BOBST machines page 57). As the carbon footprint of the Group’s activities is primarily concentrated in its downstream GHG emissions (scope 3), BOBST has a crucial role to play in the design and maintenance of its machines to lower their environmental impact during their lifetime, jointly with clients.

The Group is committed to the Science Based Targets initiative (SBTi), which supports companies setting GHG targets consistent with the Paris Agreement. The latter aims to limit global warming to well below 2°C compared to pre-industrial levels. As a result, BOBST is currently working to define reduction targets based on this methodology and will announce them in its sustainability report 2023. The Group is also in the process of implementing the recommendations of the Taskforce for Climate-Related Financial Disclosures (TCFD). The goal is to identify the most material climate-related risks and opportunities over different time horizons and to assess their potential impacts on the business to enable decision-useful, forward-looking information (see TCFD details below on page 69).

2022 carbon accounting of the Group’s activities

Since the publication of its first full GHG protocol aligned carbon accounting in 2021, BOBST has strived to improve the quality of the datasets and emission factors used. The figures presented here integrate these slight methodological changes, including recalculations of past emissions for better comparability (1). In the carbon accounting for 2022, all local entities for which the Group has operational control have been taken into account (except for Bieling & Petsche Stanzforme, Cito Group, Gordon, and Boxplan, which are entities that do not operate under the BOBST brand).

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD > GRI index

(1) Changes in 2021 (base year)

– Scope 3 – Machine use: Improvement of the data collection method and update of the electrical mix emission factor has a significant impact (-35% compared to the value in SR 2021);

– Scope 3 – Transportation: The emission factor for the transportation of machines sold by road has been updated (-19% compared to the value in SR 2021) with a minor impact on the total.

Changes in 2019

– Scope 3 – Machine use: Improvement of the data collection method and update of the electrical mix emission factor has a significant impact (-44% compared to the value in BOBST SR 2021);

– Scope 1 & 2 – The update of the emission factors followed minor changes in emission values.

Changes in 2019 and 2021

Business travel accounting for 2019 and 2021 was updated after identifying an aggregation error. However, this correction has a minor impact on the total emissions for both years.

Climate change

Bobst Group SA 20

Greenhouse gas emissions (GHG) – scopes 1 to 3 (in tonnes of CO2 equivalent)

BOBST’s scopes 1 and 2 have slightly increased since last year but have largely been counterbalanced by a decrease in scope 3. The latter was mainly due to a lower impact of the machine use phase due to product mix sales. In contrast, procurement and business travel emissions increased, mainly due to the end of Covid restrictions, especially in Asia.

Databases, tools, standards, and methodologies used in the calculation

All gases mandatory to be reported by the GHG protocol were included in the count, i.e. carbon dioxide, methane, HFCs, nitrous oxide, nitrogen trifluoride, perfluorocarbons, and sulfur hexafluoride.

Databases used: Ecoinvent 3.8, DEFRA 2021, and Exiobase Input-Output database.

The tool used: SIMAPro.

Method of impact calculation: IPCC 2021 GWP100.

Standard used: GHG protocol standard.

The methodology relies on the GHG protocol standard for scope 3 and a spend-based method for procurement. Other indirect (scope 3) GHG emissions categories and activities included in the calculation: procurement, energy upstream, waste, water, business travel, commute, distribution of machines, machine use, and distribution of spare parts.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Climate change

2019 2021 2022 Variation 2021/2022 Scope tCO2 % (total scope 1,2,3) tCO2 % (total scope 1,2,3) tCO2 % (total scope 1,2,3) % Scope 1 (inc. scope 3.3 – Energy upstream) 9 175 0.3% 11 292 0.3% 11 549 0.3% 2% Scope 2 (inc. scope 3.3 – Energy upstream) 5 898 0.2% 6 748 0.2% 6 943 0.2% 3% Scope 3 3 002 772 99.5% 3 970 395 99.5% 3 803 292 99.5% -4% Scope 3 – Machine use 2 418 695 80.1% 3 301 028 82.8% 2 965 265 77.6% -10% Scope 3 – Procurement 548 477 18.2% 640 330 16.1% 807 545 21.1% 26% Socpe 3 – Commuting 13 662 0.5% 11 328 0.3% 8 575 0.2% -24% Scope 3 – Business travel 11 112 0.4% 3 751 0.1% 9 640 0.3% 157% Other scope 3 10 826 0.4% 13 957 0.3% 12 267 0.3% -12% Total 3 017 845 100.0% 3 988 435 100.0% 3 821 784 100.0% -4%

BOBST’s carbon footprint reduction to prevent climate change takes a high priority position

Bobst Group SA 21

Objectives for 2023

Bobst Group aims to pursue the reduction of its carbon footprint to prevent climate change. BOBST is committed to reducing its scope 1 and 2 emissions which are under the Group’s direct operational control (e.g. energy used in operations).

In 2023, BOBST is assessing decarbonization options for its operational activities in the SBTi submission target process framework.

Reduction of scope 3 emissions is more a long-term effort. Dedicated streams take up this task, mainly the stream equipment, since machines in use at BOBST customers’ plants are responsible, over their lifetime, for the majority of scope 3 emissions. Reducing emissions from BOBST machines remains a priority area for action (see Machinery energy consumption on page 55), and a reduction target for scope 3 is also in preparation for submission to SBTi.

Bobst Group shares climate change commitments and greenhouse gas (GHG) emissions results externally, through its sustainability report, and internally, to the relevant experts and working group in charge of defining the action plan for emissions reduction.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Climate change

Bobst Group SA 22

Energy consumption is a key issue in BOBST’s sustainability strategy. In all the countries where the Group operates, it monitors and manages the consumption of the energy required for its industrial and service activities. BOBST makes energy savings where possible. It also invests in the infrastructure of its local entities to reduce their consumption or to enable them to produce renewable energy.

Within the framework of its operational activities, Bobst Group uses energy from renewable sources (solar photovoltaic), fossil fuels (methane, propane, diesel, fuel oil) or from the grid (electricity).

Energy shortage and soaring costs

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Solar energy –

For local entities equipped with photovoltaic panels, the electricity produced is either used, in addition to the power purchased from local suppliers, or fed back into the public grid. Within the Bobst Group, the production of photovoltaic solar energy represents 11.6% of the total electricity consumption.

The global energy crisis and soaring electricity and fuel prices have a direct impact on the operating costs of BOBST’s production and service sites. In many of the countries where it operates, the Group must also comply with new government directives concerning the reduction of gas and electricity consumption by individuals and companies.

Non-renewable energy

–

At BOBST, fossil fuels are used to heat the premises, for certain production processes and for company vehicles used for business travel. In Switzerland, the Mex site has a fossil gas-fired combined heat and power system. This system not only contributes to the heating of the buildings, but also produces electricity that is consumed directly on site.

In terms of indirect energy consumption, the machines manufactured and sold by the Bobst Group use energy both upstream and downstream of the value chain (see breakdown of BOBST’s carbon footprint in the section Climate change on page 21).

Bobst Group has thus taken measures to limit the impact of these actions on its activities and costs and has also developed crisis scenarios in case of shortage:

– Analysis of gas and electricity needs of seven of its European production sites;

– Installation of adapted generators at six European production sites to prevent possible load shedding or power cuts. There was no need to use this equipment in 2022.

At the same time, the energy supply contracts were reviewed.

Energy

Bobst Group SA 23

Energy

Sustainable energy management

BOBST follows the commitments of the Charter of Bobst Group policy with regard to health, safety at work and environmental protection to define the axes of its energy management policy and the reduction of its environmental impact (see carbon footprint in the section Climate change on page 21). All over the world, projects and initiatives are underway. In Europe, BOBST is studying and investing in several projects to increase and diversify its production of renewable energy, to reduce the use of fossil fuels and the Group’s dependence on the

Energy consumed by the Bobst Group in 2022

All energy sources combined, the total consumption of BOBST’s operational activities in 2022 is equivalent to 66 530 MWh.

During the same period, the Group’s sites equipped with solar photovoltaic installations produced 4 895 MWh, of which 168 MWh were sold/reinjected into the public grid.

>

The figures in this table are taken from the Group’s carbon footprint databases (see Climate change section page 21) and have been processed according to Conversion factors from DEFRA 2021

>

Energy

Energy consumption from BOBST’ vehicles fleet Electrical consumption for facilities Diesel 12 757 MWh 24 035 MWh (Fuel source depends on the electric mix from the country) Oil 5 734 MWh Electrical 26 MWh -> from the grid Total 18 517 MWh Total 24 035 MWh Percentage of overall energy Percentage of overall energy consumed 29.37% Percentage of overall energy consumed 32.58%

Bobst Group SA 24

report 2022

Strategy >Operations

Equipment

Sustainability

>

reporting >

reporting

Packaging

& end-of-life

use

reporting

TCFD

GRI index

>

Sustainability report 2022

> Strategy

Water & waste

As a manufacturer of packaging equipment, BOBST uses water and raw materials (metals, paper and plastic) in its operations. Its industrial and service activities have a direct impact on water resources and generate waste. To limit its environmental footprint, the Group is working to reduce the quantity of its waste, to improve recycling (currently reaching 75%) and to limit its water consumption.

The activities of the Bobst Group generate several types of waste that are subject to recycling. These are mainly metal residues linked to machining operations, but also paper and cardboard, and plastics used for packaging and transport of machines as well as for shipping spare parts to the Group’s customers throughout the world.

Common industrial waste

Depending on the country where the Group operates, local waste management systems dispose of the waste through two different methods: landfilling, and incineration.

Special waste

The construction of packaging machines requires the use of lubricants or coolants (oils or emulsions) as well as chemicals (paints, varnishes, inks, cleaning and degreasing solutions). All residues of these industrial substances are collected separately and treated by specialized companies.

Organic waste

At all BOBST production sites, the packaging of components, modules and machines contains wood that the Group’s sites must eliminate. Two ways are used: recycling or thermal recovery depending on the country.

In accordance with the Charter of Bobst Group policy with regard to health, safety at work and environmental protection (see https:// investors.bobst.com/fileadmin/user_upload/About_us/Documents/ EHS_Policy_2020_EN.pdf), all BOBST production sites have a waste sorting concept that complies with the requirements of the countries where they operate and with the capacities of local recycling channels. The treatment of a part of the waste also has an economic interest, such as the recycling of metals whose resale offers a source of profit.

The Group has set up an annual monitoring of the quantities of waste treated (see table on page 26), and this will be part of local sites’ objective settings.

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Water & waste

Bobst Group SA 25

* Data on the quantity of waste is provided by the specialized companies mandated by BOBST for its treatment or recycling. These data are compiled at the various sites before being consolidated at Group level. As regards the service entities, most of them operate in rented commercial premises, the volume of waste from which remains unknown, since its disposal is included in the rental price. However, as their waste is typical of office activities, no extrapolation has been made.

Water consumption related to BOBST activities

The Group’s organization is based on two business units: the Business Unit Printing & Converting (BUPC), which is responsible for the manufacture of packaging machines, and the Business Unit Services & Performance (BUSP), which is in charge of services and of machine overhauling provided to customers. Taken as a whole, BOBST’s operational activities have a limited impact on water resources. Its consumption within the Group mainly concerns three activities:

Industrial use

– Preparation of emulsions circulating in closed circuit in its machining centers;

– Degreasing of parts in open or closed circuit installations depending on their size and type;

– Aqueous baths in a closed circuit in the paint line at the Mex site (Switzerland) for surface preparation (16 m3), whose water is replaced once a year on average.

Watering, sanitary facilities and cleaning

For the rest, water consumption is limited to the use of sanitary facilities, cleaning of the premises and watering of the outdoor facilities. At the Mex site, the vegetable garden where employees buy organic vegetables is equipped with a drip irrigation system that is taken into account in the site’s water consumption.

Water quality and management

Present in more than 50 countries around the world, the Bobst Group uses water of variable quality. For example, in Southeast Asia (Malaysia, Indonesia, Thailand and Vietnam), mineral water is preferred as drinking water. To prevent any risk to the health of its employees, the water supplied by the local services is only used in the sanitary facilities and for cleaning.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

As for waste, BOBST relies on its Charter policy with regard to health, safety at work and environmental protection (see https://investors. bobst.com/fileadmin/user_upload/About_us/Documents/EHS_ Policy_2020_EN.pdf) to limit its impact on water resources.

Water & waste

Waste related to the Bobst Group's operational activities Quantity (tons)* In % Metal 1 368 30 Cardboard, paper 408 9 PET, PVC, other plastics 246 5 Special / hazardous waste (chemicals) 572 13 Urban waste 531 12 Wood 1 382 30 Other 43 1 Total 4 549 100 Recyclable waste in percent 75%

Bobst Group SA 26

(1) The premises occupied by the services entities are rented. For four of the Group’s 19 entities, the owners are not able to provide the water consumption related to the surfaces in question. In these cases, the data has been extrapolated by calculating the average annual consumption per person on the sites where consumption is known. The value obtained was multiplied by the number of employees at the four sites where water consumption is not known. For the production sites, which are owned by BOBST, the local water authorities provide the consumption data.

(2) Carried out on the basis of data provided by the “Aqueduct Water Risk Atlas” (https://www.wri.org).

(3) Surface water: water that occurs naturally on the earth’s surface in ice sheets, ice caps, glaciers, icebergs, bogs, pounds, lakes, rivers and, streams.

(4) Groundwater: water that is being held in, and that can be recovered from, an uderground formation.

Several Group sites are equipped with water consumption reduction devices: waterless urinals – Bobst Mex SA (Switzerland) – rainwater recovery systems – Bobst Lyon (France), Bobst India (India), Bobst Mex SA (Switzerland), Bobst Italia (Italy) – as well as push-button or motion detection taps. A monitoring system for water consumption is in place at the production sites, allowing the manual detection of cases of over-consumption.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Water & waste

Water consumption (1) Water withdrawal by source All areas (metric tonnes) Areas with water stress (2) (metric tonnes) Remark Surface water (total) (3) Freshwater (<= 1 000 mg/l total dissolved solids) 47 468 17 664 Other water (< 1 000 mg/l total dissolved solids) 14 659 3 609 Rain water harvesting for WC and gardening Ground water (total) (4) Freshwater (<= 1 000 mg/l total dissolved solids) 33’6 33 623 16 644 Other water (< 1 000 mg/l total dissolved solids) 0 0 Mix of ground and surface water For three sites, the water supplied can come either from surface or ground water Freshwater (<= 1 000 mg/l total dissolved solids) 872 180 Other water (< 1 000 mg/l total dissolved solids) 0 0 Total third-party water withdrawal in water stress areas Surface water X 21 273 Ground water X 16 644 Mix of ground and surface water X 180 Total water withdrawal 96 622 38 097

Bobst Group SA 27

For the first time, BOBST is sharing data on the Group’s water consumption, according to the requirements of GRI303 for thirty local Group entities (production and services). In the past, only the water consumption of local production entities was taken into account. However, the latter represents 95% of the Group’s total consumption. Taking data from the past five years, the evolution of water consumption at production sites is changing as follows:

In the future, an annual comparison will be set up for all local entities (production and services).

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Water & waste

Water consumption (m3 per person) 17.5 18 18.5 19 19.5 20 20.5 21 2018201920202021 2022 20.620.819.820.3 18.8

Bobst Group SA 28

In the future, an annual comparison will be set up for all local entities (production and services)

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD > GRI index

(1) The analysis of water stress, which characterizes a situation of water scarcity or a demand for water that exceeds available resources, was carried out on the basis of data provided by the “Aqueduct Water Risk Atlas” (https://www.wri.org). The latter defines water stress as follows: a measure of the ratio between total water withdrawals and the renewable reserves of surface and groundwater available. Water withdrawals include domestic, industrial, agricultural (irrigation) and animal husbandry uses with or without consumption. Available renewable water reserves take into account the impact of upstream water users and large dams on downstream water availability. Higher values indicate greater competition among users. Source: WRI Aqueduct 2019.

BOBST conducted a water stress assessment of each of its local entities. Areas that are rated as “high” or “extremely high” in the Aqueduct Water Risk Atlas were included in the “water-stressed areas” category. Eleven of the thirty sites evaluated are in a “high” or “extremely high” water stress area.

(2) Legend:

BAM: Bobst Africa & Middle East Ltd, Tunis, Tunisia.

BCL: Bobst (Changzhou) Ltd, Changzhou, China.

BES: Bobst Iberica S.L., Barcelona, Spain.

BFL: Bobst Firenze srl, Capalle-Campi Bisenzio, Italy.

BIN: Bobst India Private Ltd, Pune, India.

BIS: Bobst Istanbul Packaging JSC, Istanbul, Turkey.

BLN: Bobst Latino América Norte SA de CV, Mexico D.F., Mexico.

BNA: Bobst North America Inc, Roseland, USA.

BPL: Bobst Polska Sp. Z o.o., Łódź, Poland.

BSL: Bobst (Shanghai) Ltd, Shanghai, China.

FKG: Bobst Bielefeld GmbH, Bielefeld, Germany.

Water & waste Local entities in areas of water stress (1) Water withdrawal (clause 2.2.1) High risk Extremely high risk Facilities in areas with water stress (2) BCL BES BNA BPL BSL FKG BAMBFL BIN BIS BLN Total Surface water [m3] 4 604 44 12783 65 3609168 21 273 Ground water [m3] 1608223 6761 17446308 16 644 Mix of ground and surface water [m3] 180180

Bobst Group SA 29

Occupational health & safety

With more than 6 100 people operating worldwide in over 50 different countries, BOBST manufacturing activities for the packaging industry and equipment maintenance at the customers’ sites are subject to hazards and risks. To prevent or mitigate dangers that can negatively impact the health and safety of its employees and the machines’ users, the Group applies internationally recognized standards in the security field that meet its own needs, as well as local legal requirements.

For BOBST, its employees’ physical and moral integrity in all their professional activities is an absolute priority. It is a prerequisite for the smooth running of its business, its employer reputation, and achieving its objectives in terms of sustainable development. Bobst Group defines, in a dedicated charter, (see https://investors.bobst.com/ fileadmin/user_upload/About_us/Documents/EHS_Policy_2020_EN. pdf ), the framework and policy for its actions in the field of safety, health at work, and environmental protection. Management recognizes its responsibility in these areas and treats them with the same consideration as economic matters. To achieve its commitments, BOBST relies on integrated management systems, with respect to the legal requirements of the countries where its local entities are located, and involves its employees in its thinking.

Charter implementation

Thirty local entities of Bobst Group have been evaluated, divided into eleven production sites and nineteen service centers. Each local entity deploys the charter within its organization using its resources. Whether it is a production site or a service center, its approach and occupational health & safety (OHS) resources are different. Production sites employ specialists and OHS management systems. The organization and structure of service centers vary according to their size. But in both cases, they all comply at least with the local safety at work legal requirements. The BOBST SR 2021 highlighted significant differences within the Group in the level of OHS maturity. Bobst Group OHS maturity level will be improved by developing and gradually implementing a harmonized and appropriate OHS framework by the end of 2025 (see 2022 accomplishments on pages 35-36).

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Occupational health & safety

Bobst Group SA 30

Throughout the Bobst Group, more than 6 100 employees, thus 91.6% (1) of the workforce (i.e. employees and temporary workers) are already covered by a certified OHS management system: 53.4% of them according to the ISO 45001 standard by accredited bodies and 38.2% after OHS systems complying to local legal requirements. The scope and level of safety measures are proportionate to the risks incurred by employees and meet local legal requirements everywhere.

BOBST pursues an international industrial strategy and owns manufacturing sites in Asia, South America, India, and Europe. Production sites at Grenchen and Mex (Switzerland), Changzhou (China), San Giorgio Monferrato (Italy), and Lyon (France) have adopted the ISO 45001 OHS management system. Each possesses its own organization and specialists to implement it. Regarding the service centers, they all meet the legal requirements of the countries where they operate. In addition, all employees, trainees, temporary workers, and external companies working on these sites are integrated into their management systems.

Identification of hazards, risk assessment and investigation of adverse events

The objective of the risk reduction principle is to put in place measures to eliminate or isolate hazardous situations. Their identification, the training of employees, and the distribution of personal protective equipment are applied in all Bobst Group production sites (see https:// investors.bobst.com/fileadmin/user_upload/About_us/Documents/ EHS_Policy_2020_EN.pdf ). Employees can use their right to withdraw from a dangerous situation at any time according to the processes and legislation in force.

BOBST carries out a risk analysis of workstations following local legal requirements or the ISO 45001 standard, conducted by OHS specialists and based on the knowledge of employees and managers. Each production entity has its own process for identifying hazardous situations.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

(1) The remaining BOBST workforce, thus 8.4%, is covered by at least the local legal requirements but without a dedicated management system. That means the local entities deal with safety issues on a case-by-case basis according to legal requirements without a management system.

Occupational health & safety

Bobst Group SA 31

Corrective approach

Every accident is investigated to determine the root causes. The investigation is carried out by trained and qualified agents collaborating with employees and managers. Its conclusions include corrective measures and action plans. Although disparities exist between the various service entities, their risk analysis, accident investigation, and employee participation processes are similar to those of the productive entities. In ISO 45001 certified sites, audits and internal controls are performed regularly to ensure the follow-up and implementation of preventive and corrective measures. In addition, a management review is conducted annually.

Work health services

Except for Manchester (United Kingdom), each production site has OHS engineers trained to assess and reduce occupational health risks. The sites at Mex (Switzerland), Lyon (France), Pune (India), San Giorgio Monferrato, and Firenze (Italy), as well as Changzhou (China), rely mainly on occupational physicians or specialist nurses to deal specifically with occupational health issues. Whether provided by in-house staff or independent consultants, OHS services are subject to quality audits in all ISO 45001-certified production sites. In France, Italy, and Switzerland, the production site’s health, safety, and environmental services provide support and expertise to the local service entities. In the few entities with no occupational health & safety specialists, incidents are managed on a case-by-case basis.

Employee participation, consultation and communication on health & safety at work

All production sites and some service entities (France, Italy, United Kingdom, Scandinavia, North Latin America, Poland, Russia, and Spain) have an OHS Committee or Commission with Employee Representatives. In Mex (Switzerland) and San Giorgio Monferrato (Italy), there is also a procedure for employees to put forward their ideas or expertise to reduce the risk of accidents or improve health at work.

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Occupational health & safety

Bobst Group SA 32

report 2022

For BOBST, its employees’ physical and moral integrity in all their professional activities is an absolute priority

Sustainability

When local entities do not have an ad hoc committee, as at BOBST in the United States, they set up a process enabling their employees to take part in improving working conditions and reducing risks. Where no procedure is defined, employee suggestions go up through reporting channels.

Committee proposals, as well as individual suggestions, are evaluated by the OHS specialists for integration into continuous improvement programs. The process also foresees that each local entity takes the necessary investments into account in its financial planning. Commissions use the Intranet, billboards, or internal publications to inform staff. Employees’ participation and suggestions bring the management systems of the Group’s various sites to life.

At Mex, the Health, Hygiene, Safety at Work, and Environment Committee meets quarterly. Its members are representatives of the staff, production, services, an occupational physician, and occupational health and safety specialists. It deals with cross-functional improvement projects regarding safety, health, and the environment and serves as a communication channel between employees and management. The site management receives the minutes, and decisions follow the usual decision-making channels.

Health & safety training for employees

In the area of health & safety at work training, the Group’s local entities have qualified and accredited personnel or commission external specialists. In Switzerland and Italy, the follow-up of employee training is ensured with learning management systems (LMS).

BOBST offers generic programs, such as Environmental Health & Safety (EHS) training courses for new employees or fire alarm and evacuation drills. In addition, in its production sites and service entities, the Group provides specific training for risky activities (see 2022 accomplishments on pages 35-36).

Product lines for folder-gluers and die-cutters have developed a comprehensive training program for their technicians that incorporates safety instructions during machine installation and troubleshooting. For the few service entities that do not yet have a defined training program, support in this area is planned to improve the skills of their personnel.

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Occupational health & safety

Bobst Group SA 33 Sustainability report 2022

In 53% of its sites, BOBST can offer healthcare access beyond the legal framework

Promotion of employee health

In several local entities, BOBST organizes vaccination campaigns for its employees and provides them with sports clubs or extra-professional activities, as in Mex (Switzerland), Lyon (France), Shanghai, and Changzhou (China). Health benefits for non-work activities depend on local legislation. In 53% of its sites, representing 80% of employees,, BOBST can offer healthcare access beyond the legal framework.

Impact of occupational health & safety prevention on business relationships

Several local service entities already use prevention plans for the health & safety of their field service technicians during the installation, maintenance, or repair of machines. These programs comply with the legal framework of the countries in which they operate and each customer’s specific requirements. They include a risk analysis and a detailed description of the roles and responsibilities of the parties involved. Machines’ pre-installation visits regulate the process and the health & safety aspects. To reduce OHS maturity gaps pointed out in BOBST SR 2021, the Group took action (see 2022 accomplishments on pages 35). As for the use of BOBST products by its business partners, the Group’s strategy is based on four axes: establishment of a safety community by product line; maintenance of a high level of expertise; perfect knowledge of standards, as well as regular updating of skills (see section Machine safety for the user on page 59).

Workplace accidents in 2022

Most BOBST staff work in the Group’s production sites, building packaging machines. These manufacturing operations involve extensive handling, manual activities, and machine tools, exposing the workforce to potential sources of accidents. Statistically, the most frequently injured body parts in the workshops are the fingers, hands, and eyes. The main hazards identified that can lead to major injuries are lifting loads, working at heights, using handling equipment (forklifts and pallet trucks), moving mechanical parts, and working near live parts.

In 2022, the Bobst Group’s local production and service entities recorded no severe accidents involving temporary staff and only one work-related accident with serious consequences among its employees as the result of a fall from height (work from height). Accidents with work-related injuries involved 130 Group employees (99 in 2021) and 34 temporary employees (22 in 2021).

Preventive measures (resulting from hazard risk analyses at the workstations, internal audits, controls, or feedback from employees) or corrective measures (resulting from accident investigations) are listed in action plans, such as making work at heights safer by using appropriate protective equipment (lifelines and harnesses, lifting platforms, secure platforms). In addition, occupational safety specialists in various entities regularly monitor their implementation.

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Occupational health & safety

Bobst Group SA 34

Sustainability report 2022

Number of hours worked by BOBST employees: 10 882 859 hours.

Number of hours performed by temporary staff employed by BOBST: 1 167 549 hours. Each entity annually reports the number of employees, temporary staff, and trainees. The data is then consolidated at the Group level to calculate the various KPIs. The worked hours are calculated for each entity by multiplying the weekly contractual hours by the number of weeks per year (52) and by the number of full-time equivalents (FTE).

Objectives are set by the local management teams of production sites regarding accident frequency rate. For example, Bobst Mex (Switzerland) and Bobst Lyon (France), representing more than 40% of the Bobst Group workforce, planned the following objectives between 2021 and 2022:

– Bobst Mex: 10% reduction of the accident frequency rate;

– Bobst Lyon: stabilization of the accident frequency rate.

A common approach on a harmonized accident frequency rate objectives setting is one of the topics to be addressed within the Bobst Group EHS specialists network which will be launched in 2023.

2022 accomplishments

The Group EHS (Environmental Health & Safety) Lead function was created to conduct gap and risk analysis to level down the differences in maturity that BOBST SR 2021 highlighted within the production sites and the Service and Performance Business Unit (BUSP) as well as to meet the need for harmonization in occupational health & safety and better exchange throughout the Group.

Objectives for 2023

– A checklist was launched to assess gaps between local entities after GRI and ISO 45001 standards and will be completed in the first half of 2023;

– A guideline based on the requirements of GRI 403 has been developed to ensure an identical approach at all Group sites (production plants and service entities), with each BOBST entity being responsible for collecting the data required for the annual sustainability report. The data is then consolidated at the Group level to calculate the various KPIs;

– A dedicated EHS resource has been appointed within the Group to define a common framework and reliable indicators and promote the exchange of best practices in EHS using existing communication tools. Relevant best practices will be made available to service entities. In 2023, the effectiveness of these exchanges will be assessed by introducing evaluations specific to the EHS field during internal audits carried out by Corporate Audit.

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Occupational health & safety Accident frequency in 2021 and 2022 Frequency of accidents 200 000 hours worked 2021 2022 Category of personnel concerned by work-related accidents 0.02 0.02 Frequency rate of accidents at work with serious consequences among BOBST employees 0.64 0 Frequency rate of accidents at work with serious consequences among temporary staff employed by BOBST 3.05 2.39 Frequency rate of accidents with injuries among BOBST employees 4.71 5.82 Injury frequency rate for temporary staff employed by BOBST 2.23 2.74 Injury frequency rate for BOBST employees and temporary staff employed by the Group

Bobst Group SA 35

Health & safety training for employees – Bobst Group’s different entities set up more than 15 100 hours of training on specific risky activities (working at heights; risks related to electricity; material handling machines; lifting loads; use of chemical products; traffic safety; first aid; use of fire extinguishers). Already 2 988 employees and temporary staff attended these courses.

Impact of occupational health & safety prevention on business relationships – BOBST conducted a gap analysis to identify the needs and expectations of its various product lines (PLs) and service entities. It highlighted areas for improvement, such as implementing a dynamic reporting process and developing synergies between the different PLs and service entities regarding best practices, training, and administrative follow-up of EHS aspects based on local regulatory requirements and customer needs. To achieve these goals, BOBST will rely on a network of contact persons coordinated by the Group’s EHS lead, who took office on 1 January 2023.

Workplace accidents – The method of calculating hours worked has been harmonized for the entire Group, and the 2022 Accident Frequency figures meet GRI disclosure 403-9 requirements.

Occupational health & safety

Bobst Group SA 36 Sustainability report 2022 > Strategy >Operations reporting > Equipment reporting > Packaging use & end-of-life reporting > TCFD > GRI index

Bobst Group entities set up more than 15 100 hours of training on specific risky activities

Sustainability

Social mission statement

From our earliest days, our company’s foundation has been built on our core values. They inspire the leadership behaviors and principles which guide us and make us distinct and unique in all our actions. We operate our business in a socially responsible and ethical manner. We treat people as we would like to be treated and we strictly respect rules, laws and the environment wherever we operate.

People: Women & youth, diversity & equal opportunity

Ensuring equality and diversity in the workforce is an essential success factor for BOBST’s sustainable development. The Group fosters transparent corporate management, intergenerational communication, and the promotion of tomorrow’s young talents in all local entities to strengthen its employees’ loyalty and employer brand attractivity.

BOBST wishes to create an equitable and good environment for our society, committing to offer equal working opportunities and remuneration to employees for equal responsibilities throughout the Group. We promote family welfare with child care centers and flexible working time for parents. Our engagement will increase loyalty towards the company and strengthen our brand reputation and attractiveness as an employer.

In addition, the Group focuses on the development of the next generation of leaders by promoting their talents and leadership skills. In 2015, while celebrating our 125th anniversary, we proudly launched initiatives “For the Next Generation”, to encourage equal remuneration (women to men) within the organization. Our main

asset is our people: diversity will always be part of our culture and workforce, promoting innovation, fostering corporate culture across regions and positively impacting management and leadership styles. Respecting our social mission statement has become essential in a world moving towards more sustainability.

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Women & youth, diversity & equal opportunity

report 2022

Women & youth, diversity & equal opportunity

Diversity of governance bodies and employees (% of women vs. men)

* Variable pay plan

Diversity of governance bodies and employees (by age)

Managerial positionsAge bracket Employee category 20-2425-2930-3435-3940-4445-4950-5455-5960-6465-69 Total Employee 0 2 7 8 7 10 11 10 5 0 60 VPP employee 0 7 34 62 63 46 36 22 7 4 281 Middle management 1 0 9 38 53 58 50 49 20 4 282 Senior management 0 0 1 8 28 25 42 35 11 2 152 Executive & extended management 0 0 1 0 0 1 4 2 0 0 8 Total 1 9 51 116 151 140 143 118 43 10 783

Year Employee VPP employee* Middle managementSenior management Executive & extended management Board of directors Total (in %) 2022 Women 14 Women 18 Women 17 Women 13 Women 0 Women 0 Women 16 Men 86 Men 82 Men 83 Men 87 Men 100 Men 100 Men 84 Year Employee VPP employee* Middle managementSenior management Executive & extended management Board of directors Total (in %) 2021 Women 15 Women 18 Women 17 Women 11 Women 0 Women 0 Women 16 Men 85 Men 82 Men 83 Men 89 Men 100 Men 100 Men 84 Bobst Group SA 38 Sustainability report 2022 > Strategy >Operations reporting > Equipment reporting > Packaging use & end-of-life reporting > TCFD > GRI index

Young leaders (< 35 years old) present in management of Bobst Group

BOBST initiatives and achievements 2022

For many years, BOBST has undertaken initiatives to train young employees, so better to integrate them into the Group’s management and encourage their access to leading positions.

Youth Committee

This is a group of young and diverse employees, aged between 25 and 35, from all business areas of a local entity, chosen by their management for their talents and development potential. They are entrusted with specific projects (continuous improvement with a transversal approach) and collaborate with the top management. 2022 marked a turning point in developing this concept within the Group. The Youth Committee redefined its governance and objectives to prepare the ground for its implementation in other Group entities.

Apprenticeship

For over 130 years, BOBST has ensured that its skills and values are passed down to the younger generation. In specially designed vocational training centers, apprentices acquire technical, methodological, social, and personal skills to build the company’s future. More than 3 500 apprentices have successfully been trained since 1929. More than 10% of middle and senior management positions of Bobst Mex SA are held by former apprentices.

Women & youth, diversity & equal opportunity

Women Men 2021202220212022 Senior management 0 1 1 1 Middle management 2 6 5 19 Bobst Group SA 39

report 2022

Strategy

reporting

Equipment reporting

Packaging use & end-of-life reporting

TCFD > GRI index

More than 10% of middle and senior management positions of Bobst Mex SA are held by former apprentices

Sustainability

>

>Operations

>

>

>

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

Immersive mission in foreign languages. As part of BOBST’s initiatives to further develop apprentices for national and international challenges, Bobst Mex Training Center successfully launched a pilot project allowing two youths to experience an immersive three month mission in another language.

Bobst Mex

Year

(Switzerland)

Equal remuneration of women to men

Bobst

Bielefeld (Germany)*

* An error occurred in the Bielefeld data in SR 2021. As a result, the published figures for 2021 showed the total number of apprentices in training, not the number of youth who completed their apprenticeship. No apprentice finished its training this year, since Bobst Bielefeld relaunched its apprenticeship program in 2020.

Young leaders development program

This development program (pilot in 2021) involves 20 young leaders (max. 35 years old) with a diverse representation of countries and functions, with a statistical over-representation of women (30% of women on the program against 16% of women in the Group).

Bobst Mex (Switzerland) is the most mature site in compensation, salary, and benefits analysis within the Bobst Group. Its management board and Representatives of the Employee Commission regularly discuss these topics. Since the Swiss Gender Equality Act (GEA) revision on 1 July 2020, wage transparency has been mandatory in Switzerland. The administrative compliance workload was substantial for BOBST in Mex (Switzerland), and accreditation costs amounted to around CHF 20 000.–. Starting in October 2020, the internal analysis of staff compensation was completed in June 2021. From July 2021 to June 2022, PricewaterhouseCoopers carried out the verification process and delivered the certification of equal remuneration to Bobst Mex.

At Group level, BOBST will deploy a similar approach to perform a remuneration analysis compared to Bobst Mex by 2025.

Group objectives by 2025

– Increasing the proportion of women within the Group and strengthening youth inclusion training;

– Appointment of female members into the Board of directors;

– Remuneration ratio 1:1 between men and women within the Group.

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Women & youth, diversity & equal opportunity

Total of successful apprenticesTotal of women

2

2022 40 apprentices

women

2

2021 39 apprentices

women

0

Year Total of successful apprenticesTotal of women 2022 2 apprentices

women

2021 17 apprentices 3 women

Bobst Group SA 40

SwissSkills Championship 2022

Two BOBST apprentices won gold medals.

This is a first. Until now, a Frenchspeaking team had never won the title in this category

The mecatronics duo Bastien Chaignat and Marius Fabbri also part in the competition. First they managed to qualify for the semi-finals and then for the finals of this national championship in which over than 1 000 apprentices in 150 different trades participate yearly.

We are pleased and proud that our two mecatronics won the gold medal and thus became the 2022 SwissSkills Champions in the mecatronics branch. Bravo for your commitment, your motivation, your rigor and your discipline!

Congratulations and thanks!

Gold medalists at the Swissskills 2022

National Education Award 2022

Sustainability report 2022

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Bastien

Chaignat, Mecatronics

Marius Fabbri, Mecatronics

In 2022, BOBST was awarded the national education prize by the Hans Huber Foundation and Foundation FH SCHWEIZ. The prize is awarded to companies that demonstrate outstanding services in vocational training and serve as a role model throughout Switzerland.

Women & youth, diversity & equal opportunity

Milovan Ilic, Head of Professional Training

Bobst Group SA 41

Innovation

Essential to the competitiveness and profitability of companies, innovation has also become a priority driver for greater sustainability in the packaging industry through even more resource-saving solutions.

BOBST and its partners have been developing new solutions, addressing every step of the packaging value chain, from ecofriendly substrates (see section Environmentally friendly packaging on page 63) to more energy-efficient production processes, less waste, and higher recyclability. This holistic approach changes the way packages are designed and produced, to reduce effectively their environmental footprint and advance the packaging industry sustainably and economically in the long term.

Connectivity, digitalization, automation, and sustainability: the four cornerstones of BOBST’s vision to shape the future of the packaging world, has set high-level ambitions on innovation. Along with the delivery of best-in-class machines, it emphasizes new technologies and capabilities within the entire packaging value chain that will orchestrate the whole production workflow and enable it to generate long-term social and environmental benefits while creating economic profits for itself and its customers.

At BOBST, the different product lines and Group Research and Development drive innovation at their respective levels, particularly in developing incremental and trailblazing innovations for the machines. In addition, our group level development process, Product Development Process (PDP) includes mandatory sustainability deliverables (see section Machinery energy consumption on page 55). That means a systematic rethinking of how BOBST’s Equipment Stream designs and engineers new products to meet performance and quality requirements while using fewer resources across the complete life cycle of the equipment.

Anchoring sustainability in R&D processes

To better anchor sustainability into BOBST innovation culture, the Group embedded sustainability in every new product and function development. Since this first implementation step in 2021, it has already been used in new product introductions.

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD

> GRI index

Innovation

Bobst Group SA 42 Sustainability report 2022

In 2022, BOBST developed a trio of improvements on its die-cutterstamper-flexo (DSF) printing product line, with possible use on both new machines and old ones:

1. A new Bernoulli suction 3D-printed part that allows up to 8% in electricity savings by using smaller pumps that achieve similar performance;

2. Vacuum claw pumps replacing vane pumps, leading to 5% in electricity savings;

3. A brake energy recovery system that saves 1% electricity, with a possible implementation on other machines.

When combining those improvements on a single flatbed die-cutter, customers can save up to 14% of electricity.

> Strategy

>Operations reporting

> Equipment reporting

> Packaging use & end-of-life reporting

> TCFD > GRI index

Up to 14% electricity savings

Innovation

Bobst Group SA 43

report

Sustainability

2022

Procurement & supply chain

Supply chain and procurement due diligence are essential to identify and address human rights and environmental risks. BOBST’s new supplier transparency requirements enable it to source more responsibly up the value chain.