39 minute read

LITERATURE STUDY

from Fishing Harbour

by beeeee

Fish Market

By Frans Snyders and Anthonis van Dyck Medium - oil on canvas

Advertisement

HISTORY OF THE FISHING INDUSTRY IN INDIA

Fishing is a very prominent industry in the coastal states of India with more than 14 million Indians earning a living from fishing. The practice of fishing dates back to very many centuries ago before modern methods and practices were birthed and fishing became a major recognized addition to the Indian economy. For many centuries, the country of India has had a cultural practice of fishing in small ponds. Without the mechanized and modern systems which are prominent today, fishing has stayed a tradition in India with many people engaging in this for personal use. With the passing of time and the coming of the nineteenth century,commendable improvements had been made in productivity with breeding carps in tanks and with controlled systems.

Crab farming in the country of India began between the years of 1970 and 1980 and this was as a result of high production levels shown in 8 to 10 tonnes/hectares in a single year, in an incubation center. The 1980s came with the practice of aquaculture in India. This practice transformed the culture of fishing in India to a more modern business rolling more money into the economy. A system called Brackishwater farming was also done in those days and Brackish water fisheries were created in salinity waters.

Coming forward and with the continuous practice of fishing, the fishing industry in India has recorded more and more success. Between 2016 and 2017, the country of India exported 11,34,948 metric tonnes of seafood which were worth US$5.78 billion, the equivalent of ₹37,870.90 crore with frozen shrimp being the highest exported item of all the others.

The Food and Agriculture Organization (FAO) of the United Nations reports that the production of fish has multiplied by more than 10 since the year 1947 and has doubled between the years 1990 and 2010.

India as a country comfortably boasts of 8,129 kilometres which is 5,051 mi of marine coastline, 3,827 fishing villages as well as 1,914 traditional fish landing centers. Speaking of fresh water resources, India has 195,210 kilometres which is 121,300 mi of rivers and canals. The country also boasts of 2.9 million hectares of minor and major reservoirs, about 0.8 million hectares of flood plain wetlands and water bodies as well as 2.4 million hectares of ponds and lakes. As at 2010, India’s marine and freshwater resources offered a combined sustainable catch fishing potential of more than 4 million metric tonnes of fish. What’s more? India’s water and natural resources have a tenfold potential for growth in aquaculture (farm fishing) judging by the harvest levels of 2010, 3.9 million metric tonnes of fish, if India would choose to adopt the knowledge of fishing, regulatory reforms as well as sustainability policies.

With a very long standing history of fishing which has conveniently become a culture in the country of India, fishing has remained an intricate part of the Indian culture and economy. Today, the practice of fishing has remained prominent with more and more people taking fishing as a full time occupation and earning their living off from fishing.

• Apron: The open space left immediately in front of a berth of a ship is known as apron. • Approach channel: The dredged clear channel through which ships proceed from the open sea to the harbour basin is known as approach channel. • Barges: The vessels which require less depth of water are called barges. • Basin: The water area formed in a port on the sea coast protected by an out laying break water is called Basin. • Berth: The space where cargo is unloaded or loaded into a vessel is known as berth. • Breakwaters: The protective barriers constructed to enclose harbours and keep the harbour waters undisturbed by the effect of heavy and strong seas are called break waters. • Buoys: it is a floating device that can have many purposes. It can be anchored or allowed to drift with the sea wave. • Dismemberment: the act of passengers and crew getting off a ship or aircraft . Debarkation landing the act of coming to land after a voyage, going ashore- debarkation from a boat or ship . • Docks slipways: a sloping track used to move boats into or out of the water . • Dock: the enclosed area provided for berthing ships to keep them afloat at a uniform level to facilitate loading and unloading is called the dock. • Embankment: it is the process of loading a passenger shipboard an airplane with passengers or military personnel, related to and overlapping with individual boarding on aircraft and ships. • Estuary: The harbour constructed along the banks of a river is known as estuary harbour or river harbour. • Fishing port: a type of port or harbor facility particularly suitable for landing and distributing fish. • Harbour: The sheltered area of the sea in which vessels could be launched, built or repaired, or could seek refuge during storm time and provide loading and unloading facilities of cargo and passengers is called harbour. • Hinter land: The area on the land side of the port from where the port may get freight and passengers for transportation is known as hinterland. • Jetty: A piled solid or open type structure built out from the shore to deep water to berth vessels along side is called a jetty. or It is a narrow structure projecting from the shore into the deep water with berths on both sides and some times on end also. • Littoral drift: The exposed coasts are subjected to erosion at certain sections and siltation at some other sections due to wind and waves striking the shore. These waves tend to stir up and move the lighter particles of the sand in suspension. This process of movement and deposition of sand near the fore shore is known as littoral drift. • Navigational aids: the devices such as lights, signals used to guide and warn safe, efficient, economic and comfortable travel of ships in rivers, oceans and harbors are known as navigational aids. • Piers: The structures constructed perpendicular or oblique to the shore of the sea or river to provide bathing facilities are known as piers. • Quays: a quay is a general term used to describe a marine structure for the mooring or tying up of vessels, and for loading and unloading of goods and passengers . A pier or finger jetty is a quay that projects into the water. orms for loading and unloading purposes are called quays. • Wharf: a level quayside area to which a ship may be moored to load and unload. • Wharves: The landing platforms or places in the form of walls built near the shore for vessels to berth are known as wharves. • Transit sheds: A covered arrangement for a temporary storage of incoming and out going cargo requiring protection and storage for a short time is called transit shed. • Ware houses: The permanent structures provided on shore or behind transit sheds for storage for goods for longer periods are known as ware houses or storage go downs.

• Kitchen All the catering facilities should be serviced from the kitchen. The size of the kitchen depends on the following: the capacity of the restaurant which they serce, food stuff storage, cooking equipment size and the catering policy. The kitchen must be well ventilated for effective use. Provisions must be made for a large delivery bay storage area for food items I.

• Technical facilities These facilities are necessary to ensure the proper functioning of the building with minimal automation. This Includes access stairs,lifts, mechanical and electrical installation.

• Environmental These are facilities to ensure general well-being of the building.They include a well landscaped environment,adequate car parks, well-lit premises, etc.

• Tourist facilities The additional facilities that will be provided to boost the tourism potential of the site will include a garden park near the buildings, a restaurant andan observation deck.

• Administrative offices The administrative offices are spaces required for the proper functioning of the ferry terminal. Just like the Terminal discharges several functions so will there be officers for them. These offices are needed for the daily procurement accumulation and processing of information management and handling of physical items and the policies of the term inal.

• Auction hall The size of the hall will depend on the number of auctioneers present at single time the hall must be well ventilated and lit provisions must be made for storing and washing of fishes. Also there must be provision of small office for the head of this department

• Net mending area This Is provided for mending of nets required to catch the fish. This can be open or semi open areas close to it should be well lit.

• Loading And unloading platform This platform is provided for the loading of fish to export it or to unload it. The platform can be open or cover the height depending on the type of trucks coming on the port there must be a provision of a large Storage Area beside this platform.

• Cold storage building Cold storage is provided for food items that require refrigeration.These items are shipped by refrigerated boats and distributed for use.

• Restaurant and Cafeteria The Size and variety of the restaurant will depend on the following factors - The number of workers - The number of visitors - The peak periods

• Administrative offices The administrative offices are spaces required for the proper functioning of the ferry terminal. Just like the Terminal discharges several functions so will there be officers for them.

The basic service facilities required at a small-scale fisheries landing centre are:

Services for boats and crews: for unloading the catch (sometimes they might be needed for 24 hours/day), for loading fishing gear, fuel, water, ice, supplies, etc.

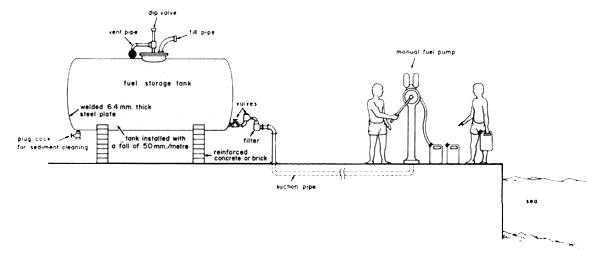

Bunkerage: a simple diesel or petrol (sometimes both) fuel station should be available at a point from which fishing vessels can take their supply directly from a pump by a hose or by hand-carried fuel containers (Figure 3).

Engine repair workshop: facilities and qualified personnel should be available for efficient engine repairs. A properly equipped workshop should provide a basic repair service for small fishing craft and maintain a stock of spare parts most often used in the area.

Boat repair area: a properly equipped boat repair area, including some boat lift out facilities, should be provided to enable fishermen to repair their vessels on shore.

Fishing gear repair area: a small shed with a dry, clean floor for the repair and storage of nets and for other fishing gear should be provided.

Figure 3 Fuel station for small-scale fisheries landing site

Berthing services: dock side services such as fresh water outlets should be available and properly designed to avoid wastage; dock side electricity supply outlets with power points for small tools may also be needed in more sophisticated small-scale fishing communities.

Food supply and washroom facilities: it might also be desirable to provide a takeout canteen, a fishermen's food store; and sanitary facilities, including toilets and showers are necessary both for the comfort of the crews and shoreside workers and to ensure that hygiene standards are maintained.

Fish handling, marketing and processing facilities: these facilities should be designed according to the type of fish and the products currently marketed as well as for any future products which may be under consideration; a more detailed description and design parameters of these facilities is listed in the following section.

The basic data needed for assessing the appropriate size and location of small-scale fish handling and marketing facilities should, partly, come from a detailed fish marketing survey. Such a survey should provide accurate data on products demand to provide for a sound design which should be adequate to take account of both present needs and expected near future developments. Design factors used should take account of available raw material, local climate, type of fish products (fresh fish, dried-salted, smoked or fermented, etc.). For example, a simple roofed platform with parking space could facilitate wholesale marketing operations in a small-scale fishing village trading in fresh fish.

Main construction design considerations

Technical and economWic considerations are normally primary factors ruling the best form of construction of improved facilities for fish utilization, but it should be kept in mind that the selected materials and design should be adapted to suit local conditions.

Thus, for example, access roads to fish landing and marketing facilities should possibly be designed to match the quality of the trunk roads in the country by which it is intended to reach the main markets.

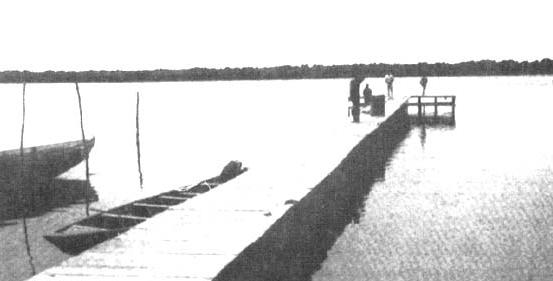

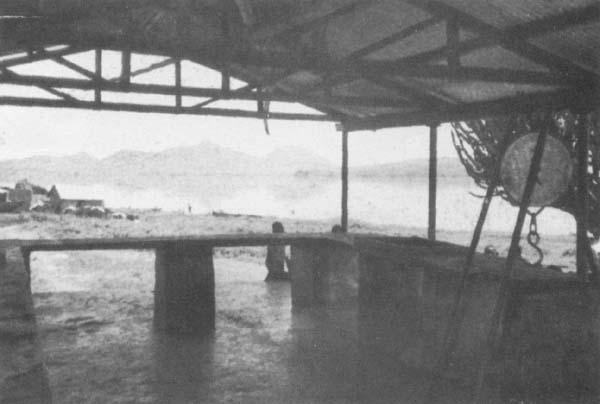

Figure 4 Landing services Figure 5 Landing operation

Layout

During the preparation of the layout of the facilities, two basic requirements should be kept in mind :

hygiene and functionality, and

economy.

The layout of a fish-marketing facility should be arranged so as to avoid the possibility of cross-contamination, have proper drainage, and allow easy access to all equipment for effective cleaning and maintenance; follow the process flow diagram in such a manner as to obtain the best quality product at the lowest possible cost; provide space for the staff managing and supervising the daily operations; provide space for the quality inspector's operations and the storage of quality control equipment.

Buildings

In designing new fish marketing premises, a smooth sequence of operations from the receipt of the fish to its loading and transportation should be achieved. All operations should be conducted off the floor, at a height convenient for workers to perform their tasks in a standing position. For example, a single storey building, at a short distance from the landing area, will enable fast and minimum handling of fish along the quay, conduct marketing operations inside the market hall, and also reduce costs for drainage and structural civil works. This type of design will also enable ready access to vehicles to the market for loading purposes.

Ample, natural air circulation should be provided, especially in the tropics, where hollow-brick walls or grills are often used and a part of the building is sometimes open, without walls. Proper long eaves for protection against sunshine and rainshowers are essential in the humid tropics. An adequate pitch of the roof and the building orientated in relation to the prevalent direction of sunshine are also important considerations.

• Floors should be hard-wearing, non-porous, washable, easy to drain, non-slip and resistant to possible attack from brine, weak ammonia, fish oils and offal. The choice of flooring materials will depend on the characteristics of the materials available in the area and their cost. For this purpose, granolithic concrete, terrazo and clay tiles can be used, but clay tiles are the best. Generally speaking, the harder tiles are less absorbent but more slippery than the softer tiles which are more absorbent and less easy to keep clean. Tiles with slightly abrasive surface are quite good as they are less slippery. Light-coloured tiles are recommended because they reflect light and show up dirt. Care should be taken when laying tiles in cement that all joints between tiles are complete and permanently sealed. The junctions with the walls should be coved for ease of cleaning. A sufficient slope of 2% from the highest point to the drainage outlets will be necessary, and at least 10 cm diameter drains will be required.

• Walls should be constructed of materials that have smooth, washable and impervious inside surfaces of light colour. For easy cleaning they should be rounded at the junctions with other walls and ceilings should be kept as free as possible from ledges, projections or ornamentations to avoid dust collection. Walls, whose internal surfaces are not tiled, should be finished in plaster. Walls which are intended primarily as partitions should be strong enough for fish boxes or other light equipment to be piled up against them; good partitions can be erected from prefabricated concrete blocks and finished to a hard smooth surface, especially the lower parts, which are subject to constant wear.

• Doors should be of simple and functional design. The main doors should be sufficiently high and wide to permit safe circulation of internal transport vehicles, e.g., when fork lifts are used in medium size fish terminals a 2.8 m high door will be required, and the width will be between 1.5 to 2.5 m. Internal doors should be self-closing and fitted with metal kick plates at the bottom.

• Lighting should provide for adequate natural light, as well as artificial overhead lighting when necessary, in order to allow personnel to perform their duties without eye strain. Maximum use of natural daylight should be always part of the design, by providing adequate windows and skylights. It is also cheaper than artificial lighting. Fluorescent lighting is particularly suitable (daylight type) for fish-market areas where a shadowless light with very little glare is required continuously for a long time; even though the initial costs are relatively higher than other lighting systems, operational costs are lower and generally such a lighting is found to be economical. A light level of 220 lux as minimum is considered adequate. All artificial lighting fixtures should be water-proofed and shielded to protect against broken glass.

To estimate space requirements, it is necessary to have reliable information on the daily fish landings in the area, on the basis of the normal average daily quantities expected to be handled. However, care should be taken to ensure that, during the high fishing seasons, especially in seasonal fishing areas, there is adequate space to handle peak landings. An estimate of:

a)yearly average daily landed catches, and b)average daily catches landed during the peak season

could show the degree of increase in the peak season. It would often be advisable to allow, for this contingency, a 25% excess of space requirements on top of the average daily landings found for the peak season estimate. In general, it is estimated that around 12 to 15 m2/ton of fish boxed and displayed on the floor, can be a good compromise for estimating the space for the sales market hall.

In fish landing terminals, facilities are required to maintain the quality of fish and also to store it during seasonal peak landings. Several options are available such as chilled rooms with mechanical refrigeration to maintain a temperature of 0° – 1°C, insulated rooms, chilled or refrigerated sea water stores (or tanks), insulated containers or simple fish boxes. The choice will depend mainly on the degree of marketing sophistication required and local conditions.

Some design factors for calculating area and capacities for fish storage facilities are outlined below:

Type Characteristics

Refrigerated,chilled, rooms Storage capacity: Area required:

Chilled seawater storage facility (fixed) Type: Manual operation, held overnight and sold next day Storage capacity:

Area required: 3–4 m3/ton of iced fish in boxes 2.1 m2/ton of iced fish stored in boxes

1.25 to 2 m3/ton of fish

1.5 m2/ton of fish

Portable container with Chilled seawater system Storage capacity:

Ice plants (ice maker and refrigeration plant only): (a) Block ice

(b) Flake ice

(c) Tube ice

(d) Plate ice Area required:

Plant capacity: Area required: Plant capacity: Area required: Plant capacity: Area required: Plant capacity: Area required: 1.57 m3/ton of fish

1.5 m2/ton of fish

10 ton/24 hours 100 m2 10 ton/24 hours 20 m2 10 ton/24 hours 30 m2 10 ton/24 hours 9 m2

Plate and flake ice machines are normally located over the ice store enabling gravity feed of ice to the store with a consequent, considerable, reduction in ground area requirements. In all cases storage space for empty fish boxes should be provided as well as ample water supplies for cleaning and an area for box washing (preferably manually).

The ice plant should have sufficient capacity for, at least, the expected daily fish landings in the fish handling facility plus an additional production capacity if a fish collection system is also operated. The daily demand for ice can be estimated as follows:

• ice for chilling of fish to be stored and transported for marketing outside the area and for un-sold fish which will be stored overnight and sold next day..... A tons • additional ice needed for a fish collection system.… B tons • required daily capacity of the ice plant A+B tons

The ice store should, at least, have the capacity to handle quantities sufficient for two days of ice production. Further information can be obtained from FAO Fisheries Circular No. 735 (Myers, 1981). The capacity of the chilled room for storage of iced fish should be calculated based on the expected market turnover. At a minimum, a capacity to store the average daily throughput of the fish landing facility should be provided; additional capacity would be needed if it is planned to operate a collection system.

Space for fish preparation

In some cases, a line for gutting and/or filleting might be required. Simple concrete or stainless steel tables should be provided. If crabs or other shellfish are to be processed (boiling, shucking, cooling) small boiling pans would also be required. Space for these operations as well as ample water supplies for washing should be provided.

Water supplies

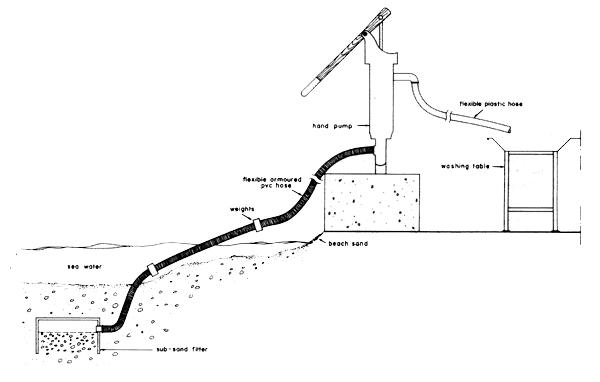

There is a need for clean, fresh or sea water both at landing points and within the market premises. Sometimes, well water or sea water supplied from nearby beaches cleaned up by simple filtering devices, such as, for example, sub-sand filters are used in certain Southeast Asian facilities. Piped city water is, however, the most convenient.

The estimated volume of water required for only the basic fish marketing operations should provide for at least:

for fish washing, 1 litre per kg of fish/day;

10 litres/m2/day for cleaning the market premises;

10 litres/box/day for fish box washing;

100 litres of fresh water/person per day for personnel use; and,

an additional 15% of the total daily consumption of water calculated above for other uses (e.g., canteens and vehicles washing).

In addition, water for ice-making, to supply fishing boats and for cooling diesel engines and refrigeration equipment should also be considered where appropriate. Care should be taken to plan for the fact that fish markets are sometimes used twice a day, in which case an estimate of peak water demand on an hourly basis is necessary. In the design of small reservoirs and pipeline networks care should be taken to ensure that the system is capable of taking the peak demand at any time of the day, and an elevated reservoir should, possibly, have a capacity to store the maximum daily water consumption requirements. Hydraulic factors such as, for example, the frictional resistance of the water against the piping system (head losses) as well as type of piping materials to be used should be given detailed consideration. In the selection of materials, especially for seawater network systems, where the galvanic potentials between the various materials has to be considered in order to ensure that corrosion effects are minimal. Care should also be taken in selecting plastic materials, and the fillers used to make the plastic material must be relatively inert when in contact with the pumped water. Either manual or mechanically driven pumps can be used to lift water as shown in the Figures 6,7 and 8. For a more detailed study of these factors, reference should be made to FAO Fisheries Technical Paper No. 174 (Blackwood, 1978).

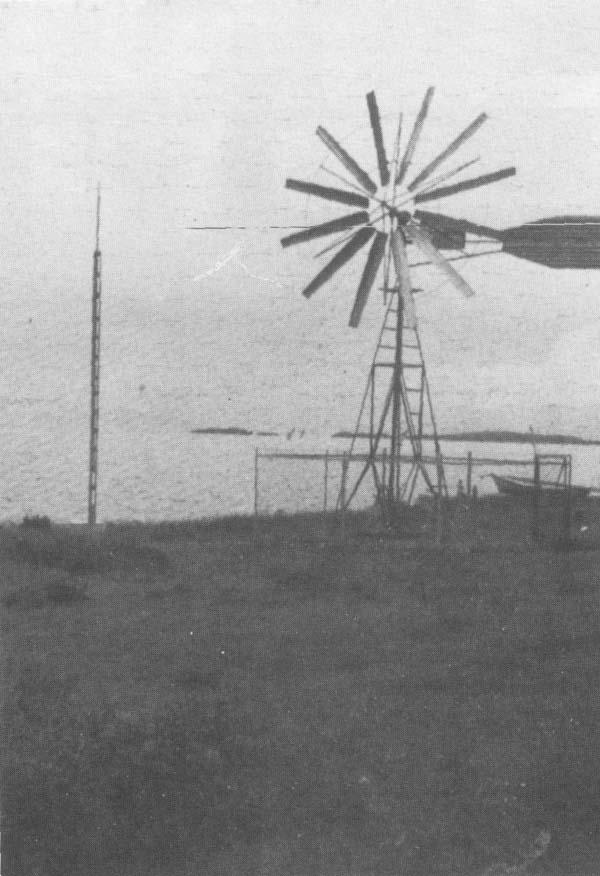

Figure 6 Manually operated sea-water supply system

Figure 7 Village type water supply system Figure 8 Mechanical type sea-water supply system with elevated reservoir

Mechanical pumps are driven either by an electric motor, small petrol engine or by windmills. Small, mechanical, centrifugal, pumps are suitable for lifting against not more than 7 m of suction lift. Hand operated reciprocating pumps (low-lift type), with a capacity of 35 1/minute, and maximum lift of about 6 m height, are commonly used either for seawater or freshwater.

Installation of elevated water storage tanks (header) from which water is supplied to the usage point by gravity provide a good technical alternative for fish landing centres, where large volumes of water must be stored. They consist of mechanically or windmill driven pumps supplying water to elevated storage tanks from which water is carried by gravity through a pipeline network to users. The usual locations for elevated tanks are either on top of a tower near the facilities, on the top of the building where the facilities are housed, or on a nearby hill. The size and type of water pump to use will depend upon such factors as :

volume of water to be pumped; whether it is seawater of freshwater; vertical distance from the level the pump is installed to the level of the source of water; distance from the storage tank; total height against which the water pump has to work; and, kind of driving power available.

The pumps should be of a self-priming type and properly mounted and protected against floods, rain and vandalism. Windmill power should be considered only where the prevailing winds blow strongly enough (wind velocities not less than 2.2 to 3 m/sec, preferably above 4 m/sec) for the required number of hours a day and dependable enough to drive the pump so as to supply the required amount of water to a storage tank almost every day, or where no other form of power supply is available or appropriate. On-site chlorination systems for rural areas, which should be simple to operate, together with a sand filter (sub-sand biological types are commonly used) are essential for providing bacteriologically safe water to fish landing centres.

Waste disposal

Waste material is one of the outputs from the operations of fish handling and marketing facilities. It is, by its nature, highly prone to spoilage and can easily contaminate the fish and fish products being handled. Therefore, it should be immediately removed from the vicinity of areas where it can easily come into immediate contact with fish and fish products and, as soon as possible thereafter, removed altogether from the fish landing site and the market/handling premises themselves and their surroundings.

This waste material can be divided into solid and liquid waste. Waste of a mainly solid type should be stored in waterlight bins with covers. Such bins should be stored in an area with a concrete base sloping to a drain. These bins and the waste they contain should be removed at frequent intervals and disposed of in such a way as to avoid pollution. Such waste might be used for animal feed or fish silages or could be buried in pits.

Waste of a prevalently liquid type (effluents) should be removed from the landing site and the handling/marketing premises by draining it into the public sewage system where such exists. The drains should be designed to remove waste water without risk of flooding. At least 15 cm diameter drain pipes are needed in fish terminals. However, local health authorities should be consulted in order to comply with possibly more strict national regulations.

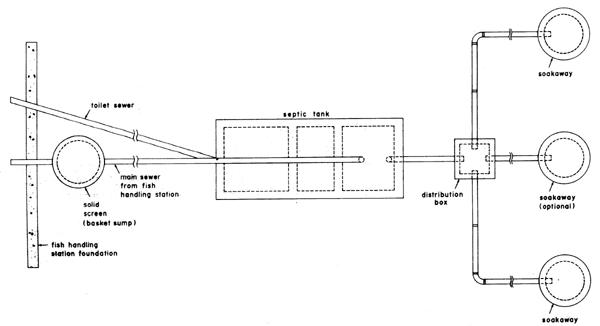

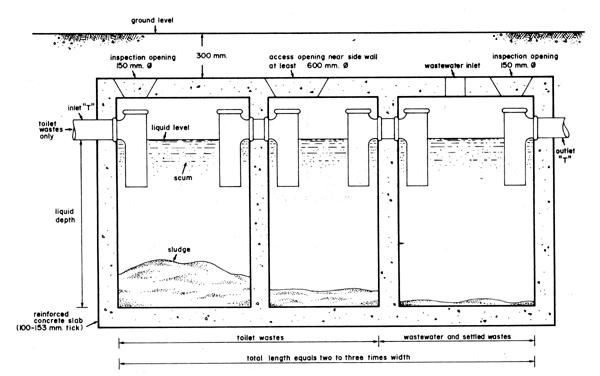

In rural areas, two options are available for water effluent disposal: water effluents from the landing/marketing facility could be drained into a septic tank and percolated into a field trench or soakaway; water effluents could be discharged into the main sewage system (if available) after course screening to retain solids.

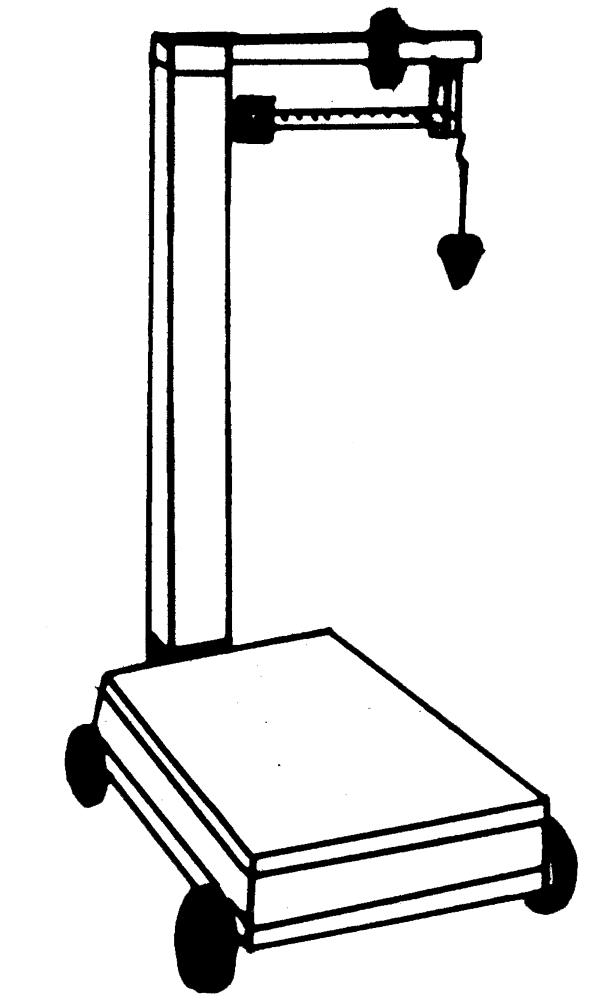

The first option is, presently, most widely used in rural fishing centres. Septic tanks are rectangular chambers (two or three compartments), usually sited just below ground level, receiving both water effluents from the fish handling area (after coarse screening) and those from sanitary facilities. This material is stored in the tanks for a retention time of 1 to 3 days. During this period, the solid fraction settles to the bottom of the tank where it is digested anaerobically (without oxygen), which results in appreciable reduction in the volume of the sludge and releases gases (carbon dioxide, methane, hydrogen sulphide). The effluent, although clarified to some extent, will still contain some dissolved organic solids and viable pathogens which will require further treatment in the soakaway. (A septic tank and schematic view of a sewage disposal system for fish receiving stations are provided in Figures 9,10 and 11). Septic tanks may be constructed of brickwork, stone masonry or concrete and, for design purposes, the overall length to breadth ration is 2 or 3 to 1. The location of the septic tank and soakaways should be at as far as possible a distance from buildings and sources of water, or from trees whose roots may damage them. Care should be taken to avoid contamination of the ground water. The minimum distance requirements for septic tanks and saokaways will depend on the type of soil and its percolative capacity. For example, in sand and gravel type of soils (very often found at landing beaches) the septic tank should be located up to 30 m away from wells and water streams. The design of septic tanks and soakaways as well as the piping system should be based on the maximum daily flow of sewage to the system, the detention period required and the frequency of cleaning the sludge in the bottom. It should be noted that soil permeability is a basic factor determining the use of on-site septic tank/soakaways/trenches sanitation systems; with impermeable soils these are not feasible. For the design of soak soakaways the rate of infiltration should be investigated in the area; however, for purposes of design, a 30 1/m2 of side wall area per day infiltration rate can be assumed in landing beaches.

Figure 9 Sewage disposal system (not to scale)

Figure 10 A three compartment septic tank Figure 11 Soakaway for secondary treatment of sewage

The electricity supply should satisfy the present demand and the likely future requirements. The wiring should be of ample capacity and properly insulated. The choice of power source will depend on the local conditions. A dependable public supply power is the most convenient, however, it is advisable to have, in addition, an emergency diesel electric generator to be able to supply enough power to run the most important refrigeration equipment (chilled rooms) and water pump and lighting. When it is necessary to operate a diesel electric generator an overall energy assessment will be required to determine the capacity of the generator to be selected. Diesel electric generators have good efficiency, quick starting, relatively low capital cost especially for small ratings, and simple maintenance. The 4-stroke engine is more common for the higher speed engines (750 and 1 500 rev/min) which are desirable to drive electric generators. Fuel consumption ranges between 0.2–0.3 kg/kwh. Maintenance requirements consist of routine inspection and servicing of fuel-injection nozzles and an overhaul after about 5 000 hours of running.

Non conventional sources of energy such as mini-hydroelectric generators, wind, biogas, photovoltaic cells and flat-plate solar collectors may be alternative options. However, careful consideration should be given to their potential application in the area under study and factors to be considered include: costs and performance in the actual village situations, availability of skilled personnel for operation and maintenance, as well as spare parts.

Parking areas

A detailed traffic study will help to quantify the area needed for parking. In small-scale fish landing facilities a convenient way of estimating is that access roads and loading yards should be large enough to absorb the anticipated peak traffic and that the loading area should be wide enough to allow for the necessary movement for the handling equipment (hand pallet trucks, trolleys, etc.) in order to move the fish quickly from the market hall to the vehicles.

Equipment

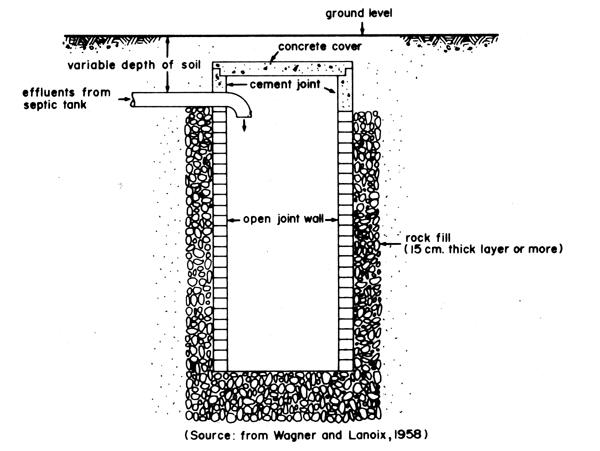

Some of the most important equipment used for small-scale fish handling marketing and distribution facilities is described in this section. It is needed to preserve the quality of the raw material and to facilitate efficient and economic handling and marketing. (i) Weighing scales

Weighing scales should be of a heavy duty type and precise. They are needed both at landing places and also at sea for the fish collecting vessels when these are operated. Weighing scales used at landing places should be of the platform type with a counter-balanced arm and a tare device which can be set to compensate for the weight of the fish boxes. As an example, suitable specifications for a platform weighing scale would be:

graduated in increments of 100 g; capable of weighing loads of up to 200–300 kg; incorporate a rapid tare device with a range of 50 kg; be constructed of corrosion resistant material; portable, that can be rolled on four wheels for easy movement (see Figure 12).

For weighing scales used on collecting vessels, heavy duty, spring dial, type hanging balances are quite suitable, provided that they are made of corrosion-resistant material; a tare device that allows deduction of tare weights is also useful.

Figure 12 Platform weighing scale

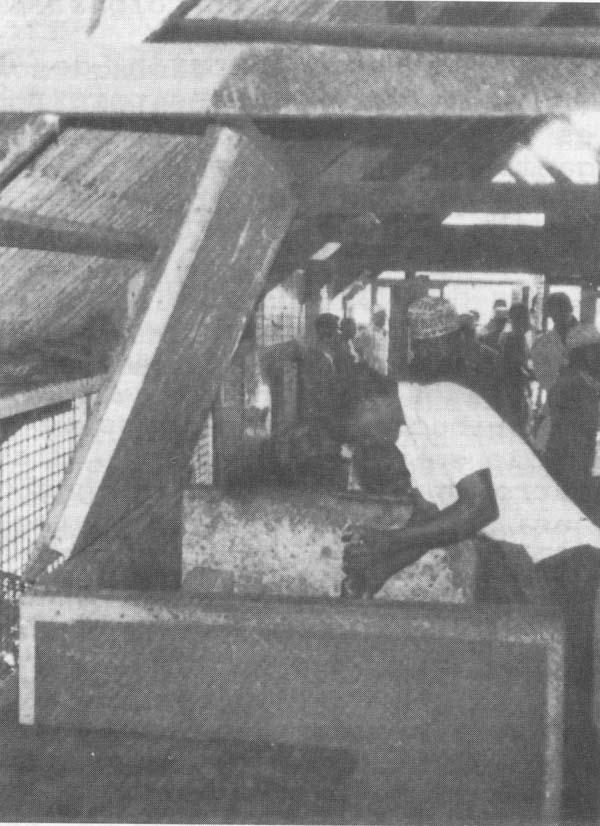

At landing places, fish should, normally, be unloaded from the vessels, tipped into market containers, if not already boxed at sea, washed and sorted according to species and sizes, weighed into containers and chilled for either local marketing or further storage and transportation.

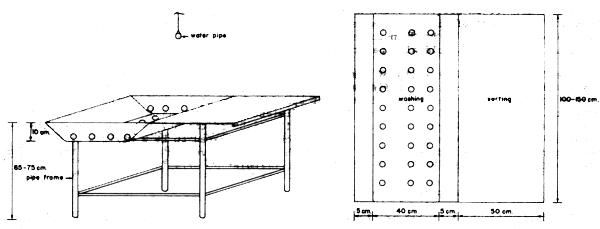

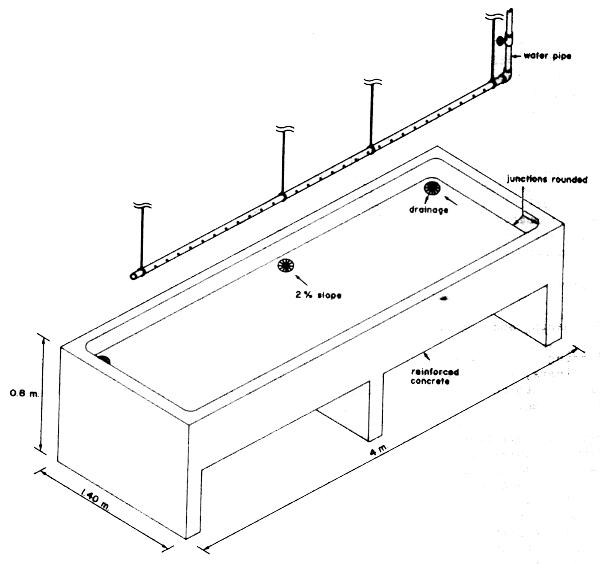

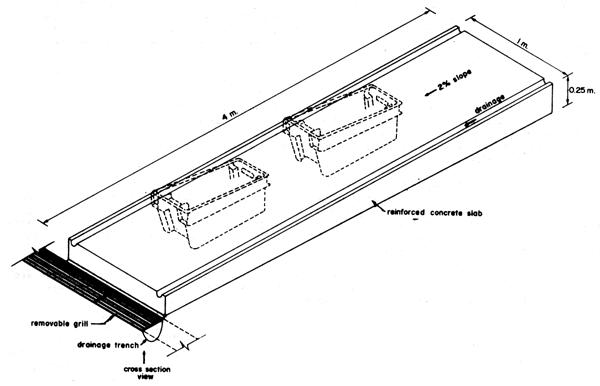

In order to facilitate the washing and sorting of the catch, simple tables constructed of aluminium, stainless steel, galvanized iron or concrete can be used. The primary aim of using washing and sorting tables is to speed up the operations of sorting the catch into species and to effectively remove blood and dirt by thoroughly washing the catch in clean seawater or freshwater and to reduce, to a certain extent, the number of bacteria present on the surface of the fish. After washing and sorting, the catch should then be handled according to the different needs of the market for which it is destined, e.g., removal of gills, gutting, filleting, packaging or boxing before chill storage and delivery to that market. Tables for washing and sorting should be constructed of non-corrosive metal or other impervious material, of rigid construction, with no open seams, and should also be constructed in such a way that they and the areas beneath them can be easily cleaned. In designing such tables, care should be taken to ensure that the dimensions are suited to the physical characteristics of the people who will be working at them (see Figures 13, 14).

Figure 13 Metal fish washing and sorting table

(iii) Fish boxes

Figure 14 Concrete fish washing and auctioning table

The design of a good fish box for efficient fresh fish handling, under tropical conditions, should take account of the varying needs it will have to satisfy on board fishing vessels, in warehousing, transport and at the landing and marketing places. It should have a constant tare weight, be strong, easy to handle, with adequate drainage, be easy to repair, have stack/nesting capabilities and be economical.

There must be an adequate stock of boxes at the landing sites, sufficient to allow the quick turn round of fishing vessels with clean boxes, thus allowing the boxes in which the fish was landed to be used in the market or by traders. An area for washing fish boxes (preferably manually) should also be provided for.

The first step to be taken in designing the most appropriate internal transportation equipment, is to study the internal operating practices and select the equipment that will permit flexibility of movement with emphasis on the use of manual handling aids such as small four wheeled push carts, platform trolleys, hand pallet trucks, manually operated two-wheel case trucks, etc. The use of a particular handling aid will depend upon the total load to be carried, type of floor surface, cost of the equipment and maintenance considerations. More detailed information on internal transportation equipment is given in Planning and Engineering Data, Fish Handling, FAO Fisheries Circular No. 735 (Myers, 1981).

(v) Ice plants

Figure 15 Wholesale auctioning table for boxed fish

Ice is of major importance in small-scale fish landing and marketing facilities. It is needed to maintain the quality of fresh fish during handling on board the vessel, collection, storage, transportation, marketing and distribution. Ice has good cooling capacity and its use will maintain low, chilling, temperatures, which is the most important factor in influencing the quality and storage life of fresh fish. At present, there are several types of ice plants for the manufacture of either block, plate, tube, or flake ice.

Block ice plants have the advantage that ice blocks can be transported relatively easily over long distances with low meltage losses; however, they lack flexibility in production, require large floor space and lifting devices to lift the blocks; they also have higher maintenance costs.

Flake, plate or tube ice plants (small ice) have the advantage of a more flexible production pattern, as the output of ice will start almost immediately they are switched on; handling is simplified if the flake or plate ice plant can be located on top of an insulated ice store which also reduce grand area requirements.

Small ice causes less damage to fish than crushed, block, ice but tends to melt faster and requires more storage space than block ice. In addition manpower requirements for small ice plants should be less than for block ice plants, as the labour required for the storage of ice is minimized. For example, a 10 t/24 h capacity small-ice plant requires about 29% less labour (man hours/24 h) than a block plant of the same output.

With any ice plant it is necessary to install an adequate ice store and its size will depend on the type of ice being manufactured and the local demand for ice. It can take the form of a silo or a rectangular bin but must be well insulated. According to the regularity of supply of fish and type of operations envisaged, the capacity of the ice store can be easily estimated.

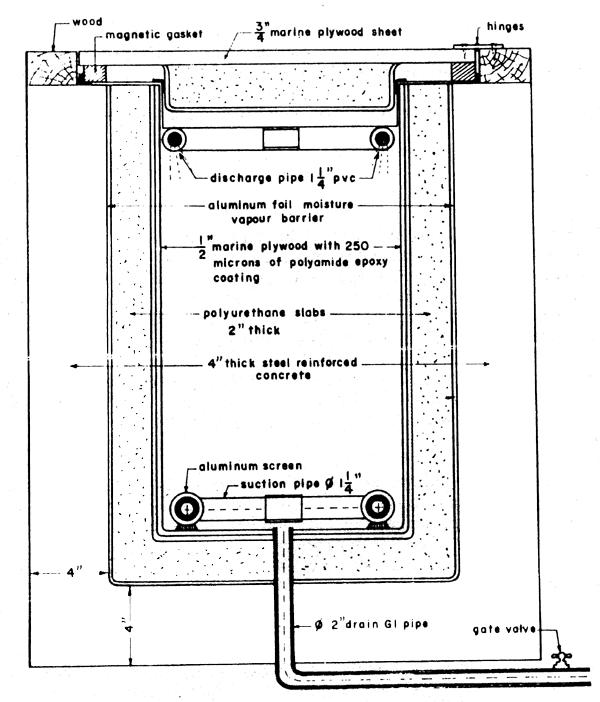

Refrigerated chill rooms are widely used in small and medium scale fish handling, distribution and marketing operations. A suitable choice is the pre-fabricated, walk-in, chillroom (well insulated for tropical conditions) with independent refrigeration equipment and, whenever possible, having a simple but reliable system of control, which can be easily understood and operated.

Chill rooms should be designed taking into consideration the expected total weight of the product to be stored, handling methods to be employed (preferably manual), ambient temperature of the product entering the chill room, availability and cost of electricity, water and labour, and spare parts, and service/repair personnel. Whenever possible, standby refrigeration equipment should be provided for, in the event of any serious breakdown of the main refrigeration system.

In small-scale fish landing and marketing facilities, other types of chill stores are also used; these include insulated rooms, chilled or refrigerated seawater containers, cargo containers, refrigerated cabinets and small insulated containers.

Figure 16 Cross section of the CSW tank Figure 17 View of the CSW tank

(vii) Gutting and filleting tables

There is a need for simple and easy to clean gutting and filleting tables in small landing and marketing facilities. These should be designed so as to provide ample working space, have offal chutes or bins located as close as possible to the working stations, have impervious and corrosion-resistant surfaces, and be provided with a good water supply and drainage facilities. Tables can be made of smooth concrete or stainless metal. Wooden working surfaces should be avoided since they tend to become water-logged and are very difficult to clean effectively. As an example, the specifications for a portable metal type, gutting, filleting, table could be:

Dimensions: 3 m long by 1.2 m wide, 85 m high

Materials: stainless steel 18/8 with fitted plastic cutting boards on each side of a central trough.

Tables should be designed to take into consideration the physical characteristics of the people who will work at them, providing a comfortable working space, and be of suitable height, to suit their body and reach characteristics. Various fish receiving facilities can be seen on Figures 18–23.

In order to meet the special needs of small-scale fisheries and to utilize more efficiently the fresh fish which they land at numerous and often scattered landing points, several fish collection methods have been attempted. These include, for example, the use of fish collection vessels, the use of road transport employing insulated trucks, or the use of modified bicycles.

The main requirements for fish collecting vessels are to have adequately insulated or refrigerated fish holds, for delivery of ice to the fish collecting beaches and the transport of the iced catch back to the main central fish depot. At the central fish depot or landing centre such vessels require adequate jetties for easy and fast unloading of fish and a supply of fuel, water, ice and fish boxes and food, as well as chill storage and transportation facilities for onward distribution of the fish to the markets. It is also necessary to have a reliable communication system in order to route collecting vessels, decide on quantity of ice and fuel to be supplied, and to obtain timely marketing information. As in all other commercial operations, fish collection schemes must be properly planned, the technical and economic feasibility evaluated and the schemes efficiently managed and operated.

Figure 18 Windmill water pump Figure 19 Concrete fish display tables

Figure 22 Insulated ice storage container Figure 23 Water tower

A detailed fish marketing plan, including a realistic estimate of the sales and daily demand, should provide basic information for the planning stages. Fish marketing trials on a modest scale will also be required in order to assess in practice all aspects of the fish collection and distribution schemes being considered. In order to keep operational costs realistic, attempts should be made to provide for return cargo (for trucks or carrier vessels), and to work out an optimum size of the carrier vessels or trucks, keeping in mind the quantity of cargo available, the duration of the trips, fuel consumption, and maintenance.

Management

Basic decision making skills and supervisory capacity are vital for good management. Training in technical and organizational methods will often be required to upgrade staff skills to enable them to successfully overcome daily fish marketing problems.

A detailed plan of operations should be prepared during the planning stages and used to establish clearly, each staff member's functions. This plan should also establish detailed procedures for the systematic collection, handling, storage and distribution of landings, method of payment, issue of receipts, weighing system, daily sales and marketing expenses recording system, and the preparation of monthly financial reports. In the case of fish landing centres with fuel and oil service stations, gear and engine workshops, ice plants, supplies stores, etc., a detailed plan of operations and procedures for each component should also be prepared (see Figure 24).

In Southeast Asian countries such as China, Hong Kong, Indonesia, Philippines and also the Bahamas, in the Caribbean, the live marine and freshwater fish trade, originating, predominantly, from coral reefs areas and fish ponds is an economically viable practice.

These live fish are stored on board vessels in live-fish holding tanks which are constructed so as to provide for a constant exchange of water in which the vessel sails. On arrival at the landing centres the live fish are sold to wholesalers or retailed directly to the consumers (Bahamas). In these landing centres handling space is required for the storage and marketing of the live fish. For this purpose, watertight concrete tanks with a water circulation system, which also provides adequate aeration by the spraying action of the incoming water, should be considered. For example, a live-fish collecting station and market (330 × 40 m) designed to handle 2 500 t/year was proposed for Java (Magnusson).

It included 24 concrete tanks (2 × 3 × 0.6 m each) for live-fish storage, an elevated water tank (45 m3 capacity) and a water pump.

However, mortalities due to post-harvest handling of live marine fish have been reported to be around 50%, due mainly to injuries incured during capture and transportation (inflicted by the fishing gear or excessive agitation of the water). An improved water circulation system on board has been proposed to lower this mortality rate (Leung, 1978).

Water used for the transportation and holding of live fish should be clean, well oxygenated, uncontaminated, and unchlorinated (small quantities of chlorine can kill fish). To hold live fish for sale (market) storage rates of 5–8 kg of live fish/100 litres of water is a practical approach for design purposes and provides a few days holding. For live fish retail shops, simple tanks provided with biological filters (gravel/sand) and aerated by small electrically driven air pumps can be a good alternative.

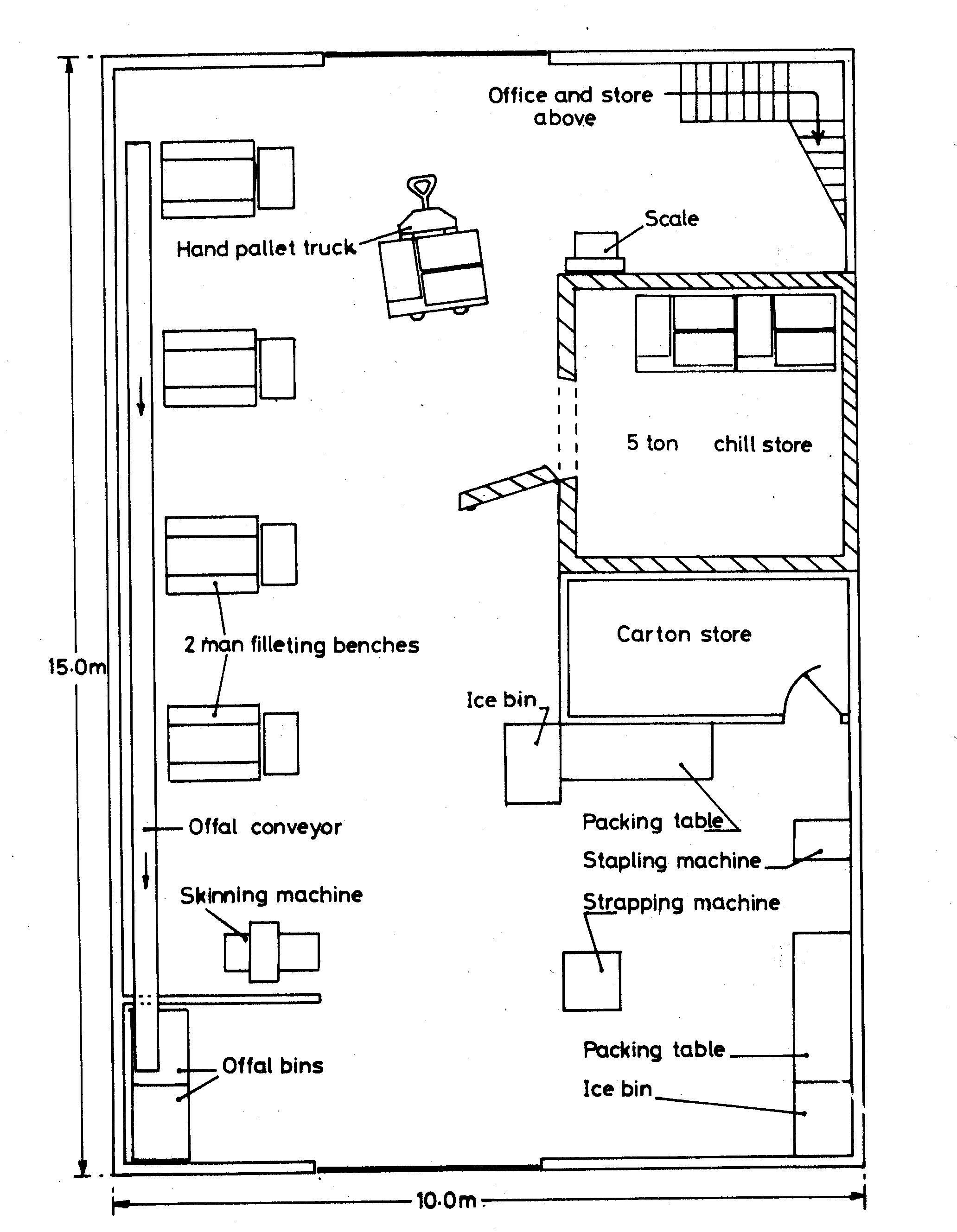

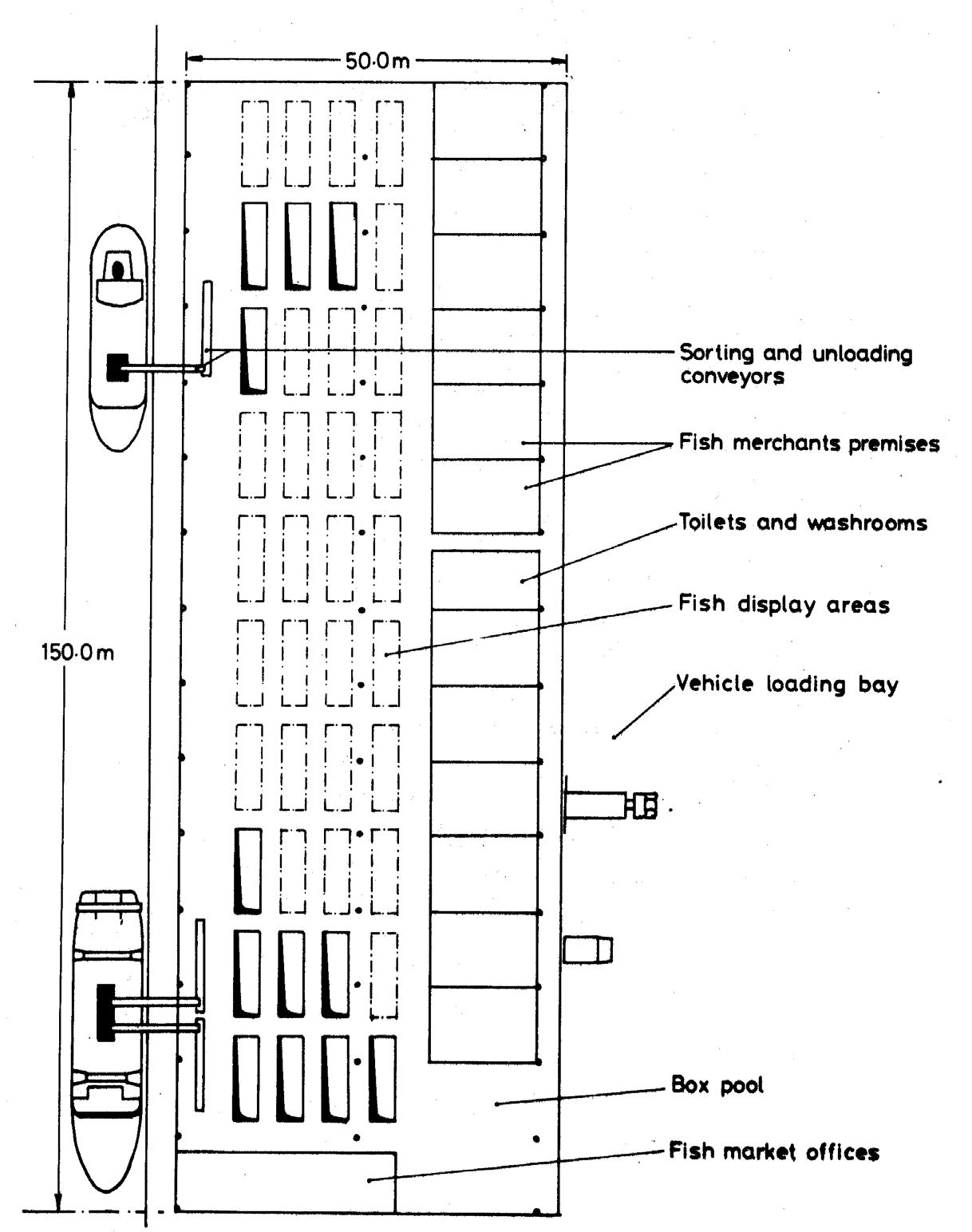

The floor area requirements for fish handling operations depend on the throughput, the nature of the operation and methods of handling and storage. Within the building adequate space must be left for access and movement of fish, offal, ice, packaging materials, etc. Area requirements for ice and chill stores are given in Sections 5 and 7 and fish box dimensions and capacities in Section 8. Careful consideration should also be given in the planning stage as to the requirements of access to the building and parking in its vicinity particularly in the case of fish markets. As an example, Figure 41 shows the plan of a wet fish (filleting) operation designed for a maximum throughput of 5t (whole gutted fish input) per day. It is typical of many small concerns operating on or near wholesale fish markets supplying a wet fish trade. It is assumed in this cage that centralised facilities of canteen, toilets, etc.,are available to staff.

The second example shown in Figure is of a wholesale fish market designed for a maximum landing (mostly by vessel) of 200 t per day. The design assumes that a11 fish is laid out for display and that only one auction round is conducted each day. A boxed display is assumed with no stacking of boxes. The design makes allowance for storage of unloading and grading equipment, box cleaning and storage, and washroom facilities. Other facilities such as canteen, ice supply, banking and other offices are assumed to be available.