How to design packaging that meets project goals

A world class team of designers and engineers in seven locations working across end markets, materials and process in the packaging industry

Masters in the development of bespoke packaging, specializing in high-level manufacturing processes, supply chain management, and product development

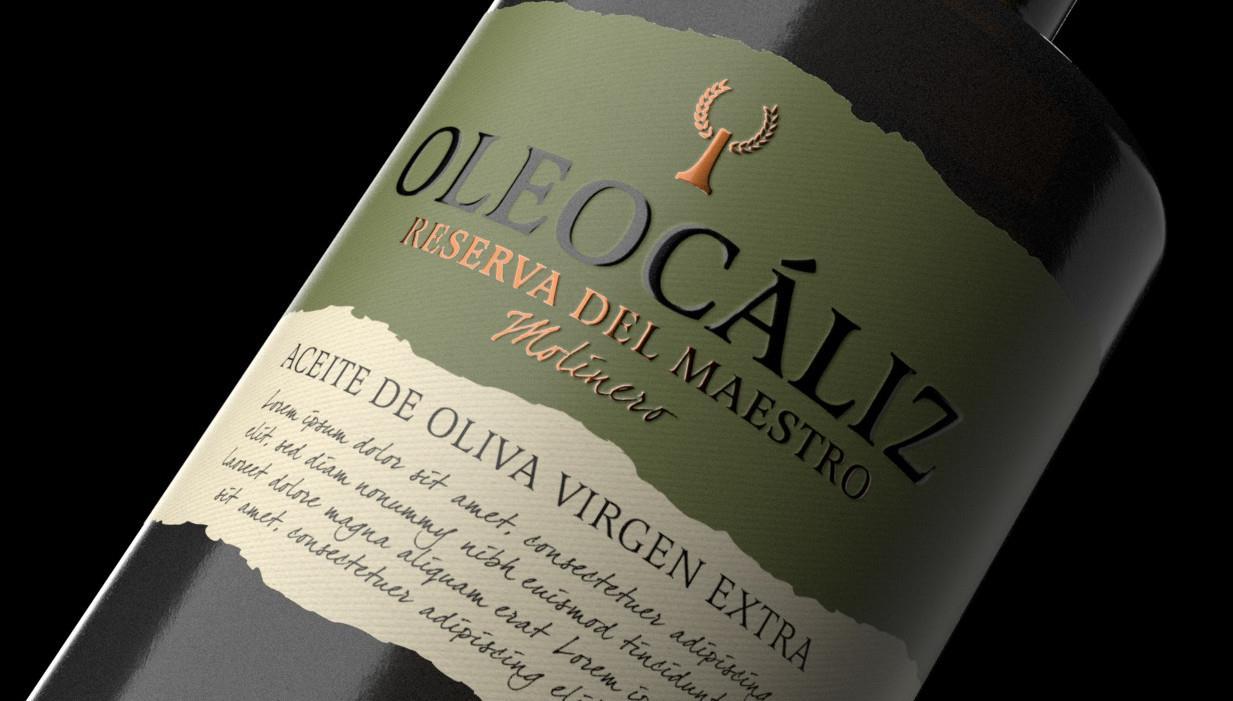

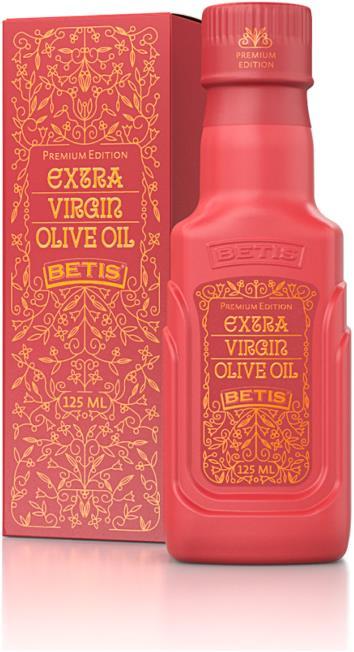

- SHELVE PRESENCE / VOLUME IMPRESSION

- COMMONALITY

- COMMUNICATION

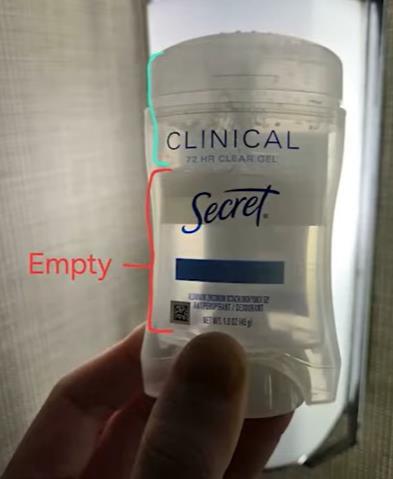

- CONTAMINATION RISK / AND EASE OF USE

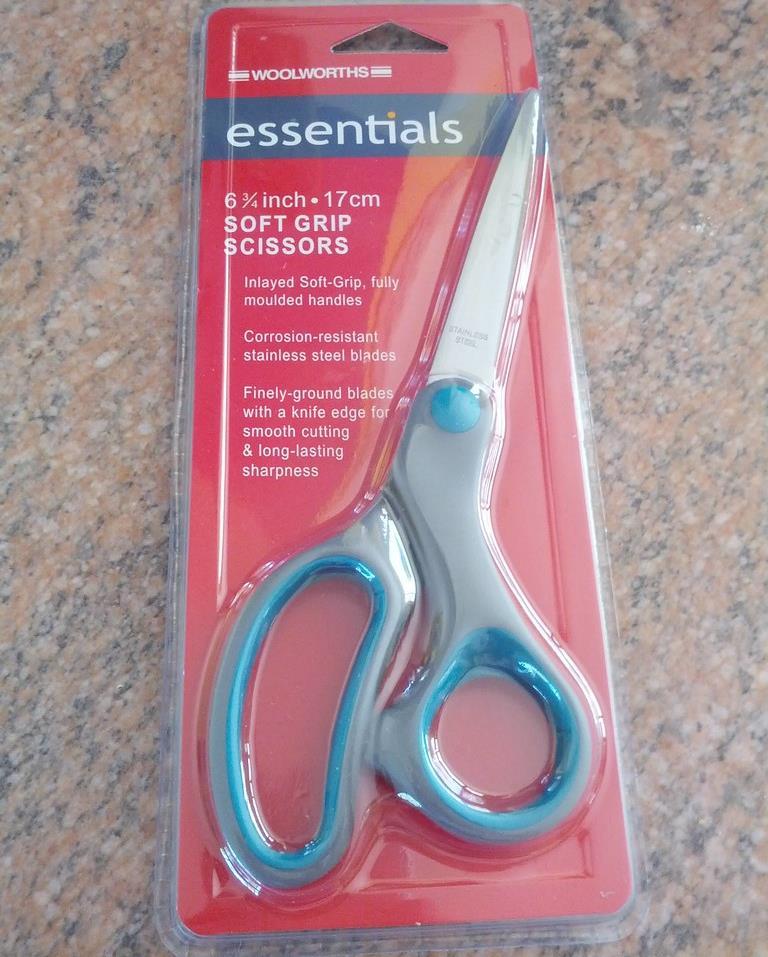

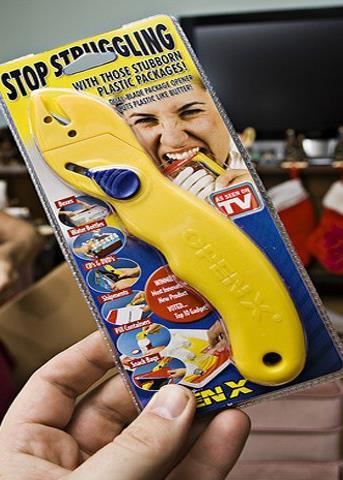

- TAMPER EVIDENT - INCONVENIENT TO OPEN

- COLOR USE/MESSAGING

- DIFFERENTIATION & CREATING SIMILARITY

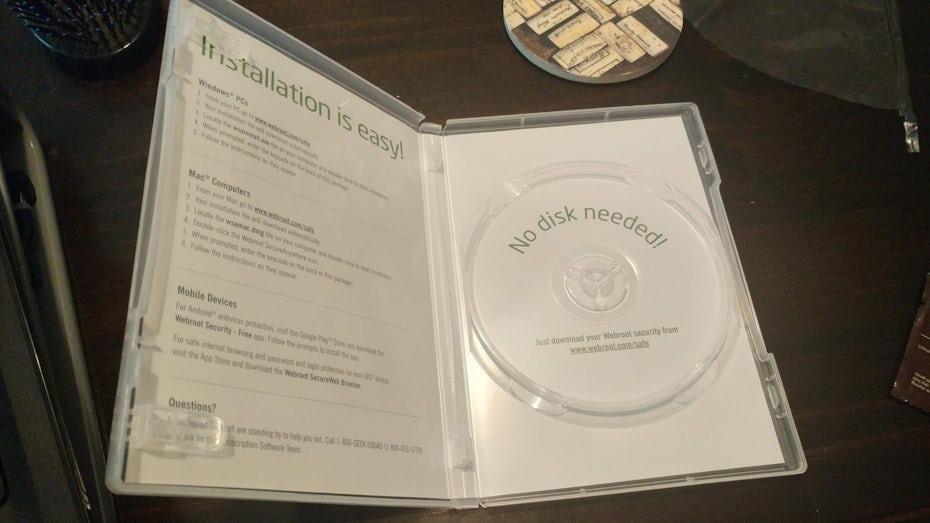

- COMPATIBILITY WITH CONTENT

- PACKAGING ARCHETYPES

- USE OF IMAGERY, TYPOGRAPHY

- CLAIMS

Topic

Overly complex visuals Too many fonts/colors, hard-to-read layout

Unclear messaging No clear product name, benefit/payoff, or usage

Inconsistent branding Style drift from logo, palette, or tone

Weak shelf presence Doesn’t stand out or attract attention

Topic What to Watch For

Hard to open/use Sharp edges, tightly sealed, unclear usage

Not resealable Especially critical for food or skincare

Inefficient logistics Doesn’t ship, stack, or store efficiently

No real-world testing Not tested for drops, moisture, temp swings

Topic

Over-packaging Unnecessary layers, plastic trays, fillers

Non-recyclable materials Lack of compostable or recyclable options

Greenwashing Vague “eco” claims with no proof

Poor durability Packaging that crushes, leaks, or tears easily

Topic

Misaligned with audience Not designed for demographic habits or values

Unclear accessibility No thought to easy-grip, tactile cues, large text

No consumer feedback loop No surveys, unboxing videos, or reviews considered

Copycat design Too similar to competitors = confusion or lawsuits

“We spend a lot time designing the bridge, but not enough time thinking about the people who are crossing it.”

Prabhjot Singh

A product is a tool to reach a goal!

Requirements are created from that goal.

But requirements regarding packaging are often disconnected from the project goal.

Why is that?

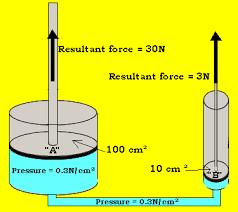

The functionality of packaging changes throughout the value chain.

Requirements made based on individually evaluated functions can cause a misalignment from the goal

Before creating requirements, we must analyze the packaging functions throughout the value chain and determine the importance of each of them towards the project goal.

Determine the most important packaging functions that enable reaching the project goal

First thing we do is identify what functions are driving the project and need to be "improved" to reach to project goal(s)

We find out by getting answers on in-depth and specifically formulated questions!

What is your current packaging and why?

What is your packaging process?

How will the consumer use the product?

Where do you see the packaging can add value to your product?

What are the positive and negative aspects of your current packaging?

What are the characteristics of the product to be packed?

Can you sketch your current product life cycle?

Which risks should your packaging reduce or eliminate?

What would be a reason to change?

What would your ideal packaging be?

Request the full questionnaire at studio111.nl@berlinpackaging.com

Getting those answers allows us to identify key improvement functions and formulate packaging requirements aligned to reach the project goals

WE MAKE SURE THE DEVELOPMENT APPROACH IS STRUCTURED

Analysis & Ideate

Evaluate & Select

Refine & Detail

• What is the project motive?

• What are the project goals?

• What is the project deadline?

• What are our limitations?

• What can we develop to reach our goals?

• What are our options?

• What do we have to adjust to move past limitations?

• What option will suit best to achieve our project goals?

• What are the individual items we need to develop?

• What are the characteristics of these items?

• What is the time needed for each item?

Validate & Implement First order & Reflection Production

• Is the development meeting expectations?

• How can we secure a uniform quality?

• Will is achieve our project goals?

• Approve development for production

• Initial production run of new development

• Evaluation of the first batch

• Market introduction

• Project evaluation

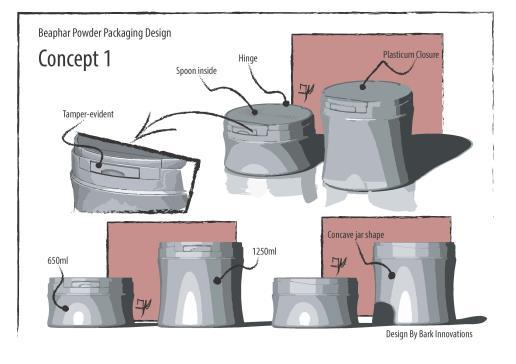

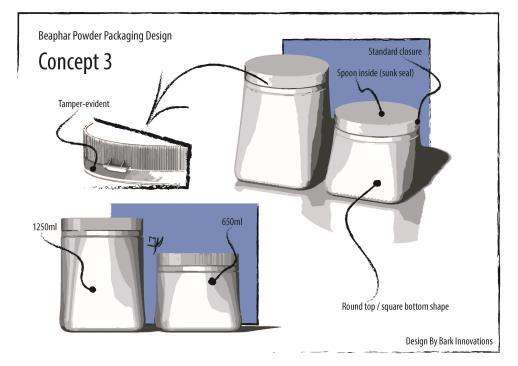

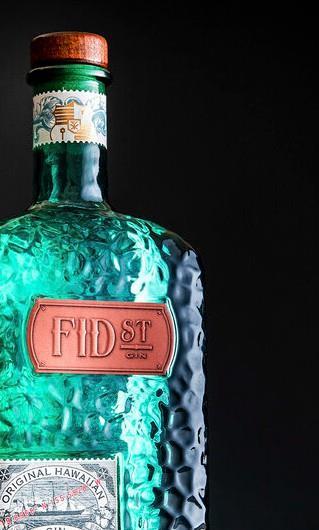

Design of a new packaging that elevates our Puppy Milk from the “generic” milk powder market and positions it in the market as a high end, and professional product with a medical look and feel

What are key functions to align our packaging requirements?

▪ Scoop easily and “clean” accessible

▪ Scraper for scoop to correctly dose the needed amount

▪ Alu seal to protect and preserve content

▪ Label or Shrink sleeve to individualize packaging later in the chain

▪ One hand open and close

▪ Shaped packaging to move away from “cheap” pail design

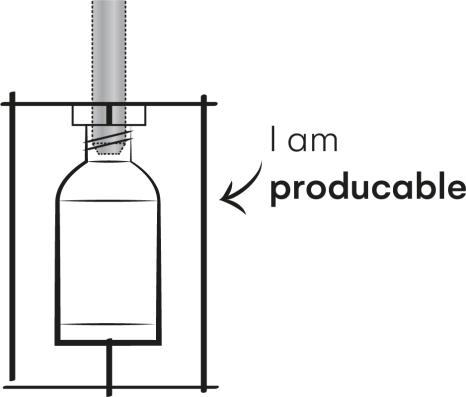

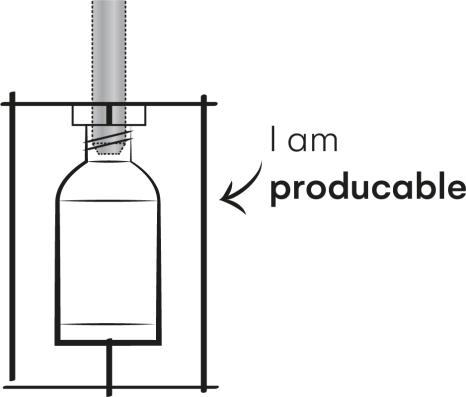

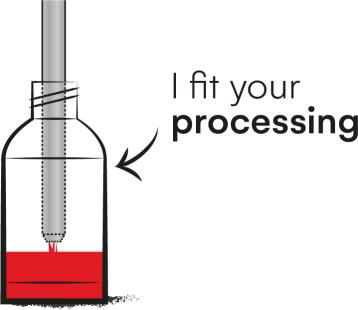

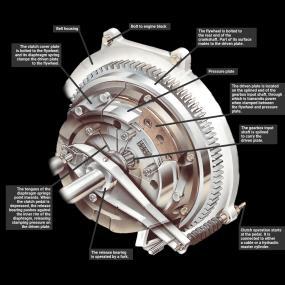

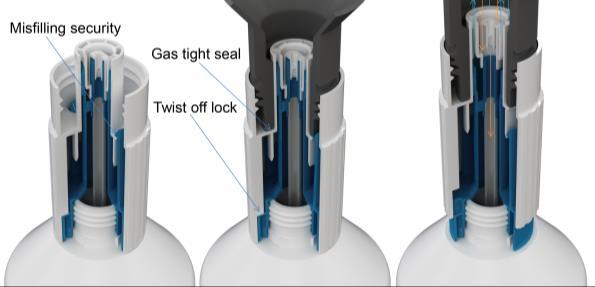

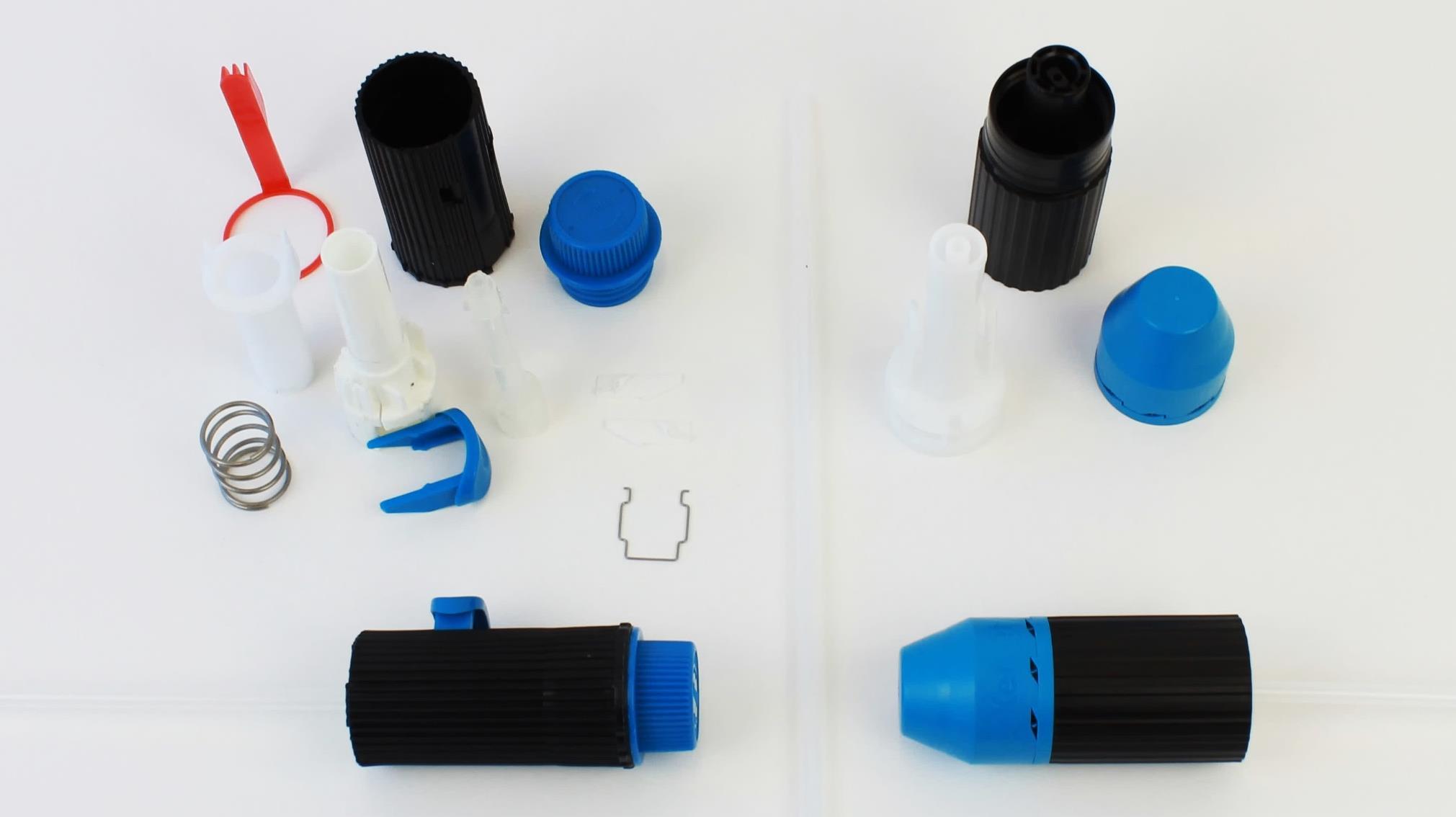

Develop a AdBlue adapter that is at least 25% more cost effective than the current adapter.

What are key functions to align our packaging requirements?

▪ Study ISO22241 norm

▪ Strip current adapter down to basic functions

▪ Brainstorm solutions for individual functions

▪ Construct concept for new adapter

▪ Test adapter using prototypes

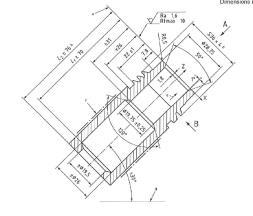

▪ Generate production drawings (2D + specifications)

▪ Product validation

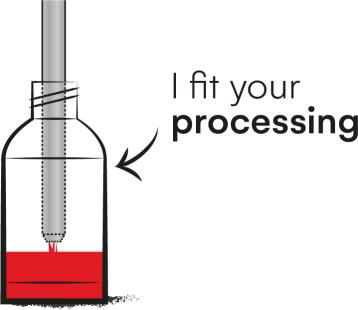

▪ Fit Adblue filler in car

▪ Fit 28mm bottle neck

▪ Only be able to open once correctly connected

▪ Outlet large enough to empty the bottle in 30 sec

▪ Vent the bottle during filling

▪ Auto stop when tank is full

Total cost: -30%

“IMPROVING HOW THE PACKAGING FULFILLS ITS FUNCTIONS WILL RESULT IN PRODUCTS

THAT NOT ONLY REACH PROJECT GOALS BUT PERFORM THROUGHOUT THE VALUE CHAIN”

Aligning the packaging functions towards your project goals

Analysis & Ideate

Evaluate & Select

Refine & Detail

• What is the project motive?

• What are the project goals?

• What is the project deadline?

• What are our limitations?

• What can we develop to reach our goals?

• What are our options?

• What do we have to adjust to move past limitations?

• What option will suit best to achieve our project goals?

• What are the individual items we need to develop?

• What are the characteristics of these items?

• What is the time needed for each item?

Validate & Implement First order & Reflection Production

• Is the development meeting expectations?

• How can we secure a uniform quality?

• Will is achieve our project goals?

• Approve development for production

• Initial production run of new development

• Evaluation of the first batch

• Market introduction

• Project evaluation

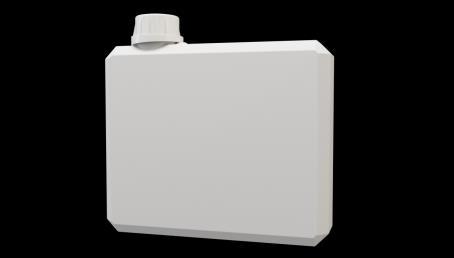

What packaging are we going to analyze?

Creating a packaging repositioning the product in a higher/luxury segment product & is PPWR

‘compliant’ (improve sustainability)

Before creating requirements, we must analyze the packaging functions throughout the value chain and determine the importance of each of them towards the

What packaging function(s) drive the development to reach its goals

No transport of water → lower impact

Can be used with various products Various mixing ratios possible

Recyclable & Recycled Aluminum

Packaging minimization: Refill is low impact, high impact components are re-used

Unique shape

High quality sprayer and materials can be used with various products (refills)

High quality sprayer, materials and shape

Big opening for addition of water / base product