Baltic Transport

bimonthly-daily companion

BLUE SUPPLY CHAINS

The hydrogen blueprint

Rivers reimagined

Where sea meets rail

MARITIME

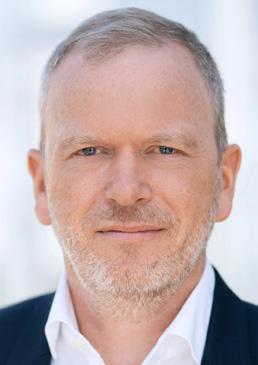

The twists and turns of fate. Interview with Kimmo Naski

Protecting subsea cables in the Baltic – and beyond

Safeguarding the maritime domain in the Baltic – militarily & commercially TECHNOLOGY

A call for rigorously scrutinising the green credentials of future fuels

The Port of Opportunities

The Port of HaminaKotka is a multipurpose seaport serving trade and industry. This major Finnish port is an important hub in Europe and in the Baltic Sea region.

Welcome to the Port of HaminaKotka!

Dear Readers,

Afew letters sponsor this autumn’s issue, manifestly M as in military. First, you’ll read about the security of subsea infrastructure (or rather the lack thereof…), a matter of national/regional/EU importance, hence an increasingly important task for the armed forces. As such, another article is about safeguarding the maritime domain in the Baltic (militarily & commercially); not with fighter planes sent to shoot down makeshift drones (which is highly effective but not sustainable, say, like squishing a mosquito with a shotgun blast…) but with un-crewed drones that can patrol our precious sea for months on end at the fraction of the cost of a destroyer. Be prepared to see more of these as you ferry across our region. Third, even the finished vehicle logistics is concerned with military issues, as was pronounced during the latest gathering of the industry in Amsterdam this October – markedly with the presence of NATO. Last, at this year’s Baltic Ports Conference (BPC), the agenda of which we had the satisfaction to craft, the letter M was also there – and double so as in military mobility, including the EU funds the transport & logistics business would like to tap into in order to help make Europe prepared in a better way (but first the block needs to kick the budget into high gear in this area). Though, when asked about their feelings on the prospect of gearing their premises with military stuff, ports and terminals were somewhat sceptical; they would rather prefer some kind of tech/digital means of neutralising hostile drones instead of projectiles flying over the head and littering the quays and yards with debris, unexploded shells, and whatnot. That sentiment is understandable, though it seems NATO has a lot of catching up to do in the hybrid warfare race. During the above BPC, the Ukrainian Sea Ports Administration shared footage and experiences of what it means to carry out port operations when one’s quays and yards turn into rubble with exploding ordnance…

In a more heartening manner, the remainder of the issue is composed with all your good ol’ Ses, Ts, and Ms. The Sustainability column puts the spotlight on offshore wind energy, warms you with a cuppa coffee (and what you, i.e. the transportation business, can do with used grounds to warm yourself even more – and help the planet, plus your ESG score, as a bonus), draws the critical limits to wind-assisted propulsion in the form of modern rotor sails likewise uncovers the emission-reduction potential of clean hulls, and more. Speaking of propulsion, Technology is big on nuclear ships, while also reasonably sceptical about the green credentials of future fuels (as they are marketed now).

MARITIME STARTS WITH THE END; THE END OF A LONG AND FRUITFUL CAREER OF ONE OF OUR DEAREST FRIENDS, THE PORT OF HAMINAKOTKA’S KIMMO NASKI, WHO WILL RETIRE BEFORE LONG. WE HAD THE PLEASURE OF PICKING KIMMO’S BRAINS ABOUT HIS POST-WORK PLANS, PLUS GETTING SEVERAL INSIGHTS INTO THE WORLD OF TRANSPORT & LOGISTICS. THANKS, KIMMO, IT HAS BEEN A GENUINE DELIGHT TO MEET YOU! SIR, YOU WILL BE SORELY MISSED! PLEASE WRITE THIS GOLDEN CHAPTER OF YOUR LIFE WITH NOTHING BUT TASTEFUL ADVENTURES – AT HOME AND ABROAD. KIPPIS!

Finally, a special column highlights the Blue Supply Chains project, featuring reads on making Umeå a hub for future energy carriers, e-revitalising the Lithuanian inland waterways for cargo, and (re)fitting Germany-Sweden rail ferries into the EU green landscape.

Baltic Transport Journal

Publisher

BALTIC PRESS SP. Z O.O. Address: Aleja Zwycięstwa 96/98 81-451 Gdynia, Poland office@baltictransportjournal.com

www.baltictransportjournal.com www.europeantransportmaps.com

President of the Board BOGDAN OŁDAKOWSKI

Managing Director

PRZEMYSŁAW OPŁOCKI

Editor-in-Chief

PRZEMYSŁAW MYSZKA przemek@baltictransportjournal.com

Roving Editor MAREK BŁUŚ marek@baltictransportjournal.com

Proofreading Editor EWA KOCHAŃSKA

Contributing Writers

KRISTĪNE CARJOVA, NICK COWLEY, MATTEO DI MAIO, IAIN GRAINGER, ALEXA IVY, BAHEZ KARIM, JANNE KOJO, AMIT KUMAR, MARKO MÄENPÄÄ, ROB MORTIMER, JOHN MUSTIN, NITESH RANVAH, MONIKA ROGO, IRENE ROSBERG, FITZWILLIAM SCOTT, JUKKA SUVANTO, ANDRZEJ URBAŚ

Art Director/DTP DANUTA SAWICKA

Head of Marketing & Sales PRZEMYSŁAW OPŁOCKI po@baltictransportjournal.com

If you wish to share your feedback or have information for us, do not hesitate to contact us at: editorial@baltictransportjournal.com

Contact us: PRZEMYSŁAW OPŁOCKI tel.: +48 603 520 020

Przemysław Myszka

3 REGULAR COLUMNS

3 Editorial

8 BTJ calendar of events

10 Safety news by TT Club

12 Market SMS

14 What’s new?

16 Map news

18 Venture forth

20 What’s in the Cabinet

21 Chart of the issue: Journey towards (ammonia & methanol) technology tipping point in shipping

64 Events: The new (car) world order?

– ECG Conference 2025, 16-17 October, Amsterdam by Przemysław Myszka

66 Who is who

22 BLUE SUPPLY CHAINS

22 The hydrogen blueprint

– Key takeaways from Blue Supply Chain’s Umeå Roadmap by Ewa Kochańska

24 Rivers reimagined

– Key takeaways from Blue Supply Chain’s Lithuanian Roadmap by Ewa Kochańska

26 Where sea meets rail

– Blue Supply Chains on the Rostock-Trelleborg shortcut to cleaner trade by Ewa Kochańska

28 SUSTAINABILITY

28 The 128-gigawatt tug – Insights from the Development of OWE in the Baltic Sea report by Andrzej Urbaś

30 A hot new life – From coffee to waste to burning logs by Bahez Karim

32 Critical limits –

Key takeaways from TalTech’s Economic Feasibility and Operational Performance of Rotor Sails in Maritime Transport by Kristīne Carjova

34 Clean hulls = clear gains

– Biofouling’s (untapped) decarbonisation potential by Nick Cowley

36 The (interwoven) propulsion crossroads

– Navigating the choices for ships of today and tomorrow by Nitesh Ranvah, and Amit Kumar

38 Turning the volume down

– How to lower underwater radiated noise (already at the ship design phase) by Jukka Suvanto

Big news. We’re getting bigger. And better. The Port of Oxelösund is growing. With expanded capacity for 10.5 million tons of goods every year, we are now growing to be Sweden’s largest port for bulk handling.

This marks new opportunities for our present and future clients. Higher capacity and smoother logistics from ship to shore. A new quay, expanded storage areas and modernized yards. Smarter systems and 24-hour operations. It’s all part of Oxchange, our transformation journey that’s redefining our role in Baltic logistics.

Discover how our port can become your platform for growth.

oxhamn.se

40 MARITIME

40 The twists and turns of fate

– Interview with Kimmo Naski, CEO & Satamaneuvos | Port Counsellor, the Port of HaminaKotka by Przemysław Myszka

43 A new chapter

– The new Port Reform Toolkit helps build resilience in uncertain times by Ewa Kochańska

46 The right blend

– Evolving maritime leadership in the Baltic Sea region by Irene Rosberg

48 A lot of joy

– How NemaX grabs gains for VLI – in productivity, maintenance, and safety by Fitzwilliam Scott

50 Tolerate uncertainty – go forward

– How changes in the operating environment have impacted the Finnish port sector by Janne Kojo, and Marko Mäenpää

52 Fragile lifelines

– Protecting subsea cables in the Baltic – and beyond by Iain Grainger

54 You cannot defend what you cannot see

– Safeguarding the maritime domain in the Baltic – militarily & commercially by John Mustin

56 Quality – wherever the work takes us

– Rethinking retrofit execution for high-demand vessels by Matteo Di Maio

58 Baltic ports gathered in Gdańsk to define the future of regional maritime cooperation by Monika Rogo

60 TECHNOLOGY

60 The (zero-emission) prize at the end of the (long) race – Tech & regulatory developments towards nuclear ship propulsion by Alexa Ivy

62 Cure worse than illness?

– A call for rigorously scrutinising the green credentials of future fuels by Rob Mortimer

TransLogistica Poland , 4-6/11/25, PL/Warsaw, translogistica.pl/en

TransLogistica Poland is a place where shippers and cargo owners can find comprehensive and highest quality logistics services for their goods. The exhibition is also perfect for showcasing a variety of telematics and fleet-management solutions to transport companies, including local and international carriers.

Baltic Ports for Climate Conference 2025, 19-20/11/25, PL/Gdynia, bpoports.com/baltic-ports-for-climate-conference-2025

The Baltic Ports Organization’s event, hosted by the Port of Gdynia, will tackle some of the most pressing environmental and sustainable development issues, including EU Port Strategy vs climate policies, green port strategies, investing in future energy, and decarbonisation of port operations & supply chains (featuring insights from the Blue Supply Chains project).

Offshore Energy Exhibition & Conference (OEEC), 25-26/11/25, NL/Amsterdam, oeec.biz

TOEEC is a leading international event in the offshore energy industry (wind, hydrogen, oil & gas and marine energy) held each year in Amsterdam that serves as an essential gathering point for professionals, experts, and companies active in the offshore energy sector and beyond.

SAFETY AND SHIPPING REVIEW 2025 – PUBLISHED

The fast-changing geopolitical landscape is creating additional risks and challenges for an industry already juggling the energy transition and the legacy of the coronavirus pandemic, according to Allianz Commercial ’s newest Safety and Shipping Review “The industry faces an increasingly volatile and complex operating environment, marked by attacks against shipping, vessel detentions, sanctions, as well as the fallout from incidents involving damage to critical sub-sea cables. Furthermore, the ripple effect of increasing protectionism and tariffs threatens to remake supply chains and shake up established trade relations,” the insurer underlined in a press brief. Fires, collisions, and groundings are still the primary drivers for total losses of large vessels. That said, whereas in the 1990s the global fleet was losing 200+ vessels a year, this total had halved 10 years ago and is now down to a record low of 27 as of the end of 2024 (from 35 in 2023). The Review also brings forth the shadow fleet. “Today, around 17% of the world tanker fleet is thought to belong to the shadow fleet: estimates indicate there are close to 600 tankers trading Russian oil alone. Shadow fleet vessels have been involved in tens of incidents around the world, including fires, collisions, and oil spills.” Next, “large vessel fires are still a major concern for hull and cargo insurers,” noted Allianz. There were seven total losses reported across all vessel types during 2024 (like the year before). The number of incidents overall was up year-on-year to a decade high of 250 (across all vessel types). Around 30% of these fire incidents occurred on either container, ro-ro, or other general cargo freighters (69). Altogether, over 100 total vessel losses have been caused by fires in the past decade. “Efforts to mitigate these risks are underway, with regulatory changes and technological advancements aimed at addressing mis-declared cargo, a primary contributor to such fires. This is critical as the electrification of the global economy poses further challenges given the growing number of lithium-ion batteries and battery energy storage systems being transported,” commented Allianz.

NEW LIGHT ON CONTAINER LOSSES AT SEA

The World Shipping Council reported in June this year that 576 containers were lost at sea in 2024 (out of the approximately 250 million). It was more than in 2023, when 221 boxes flew overboard, but still below the 10-year average of 1,274. A major driver for the 2024 rise in incidents was a 191% increase in container ship transits around the Cape of Good Hope, an area characterised by severe weather, such as many consecutive days with high waves, to avoid Red Sea attacks. According to a May 2025-published analysis (nine cases in 2011-22 involving the loss of 484 containers) by the International Maritime Organization (IMO), high waves and high winds were the prevailing external factors that led to the incidents. Commenting on the publication, TT Club highlighted in one of its TT Talks, “The analysis found that container loss or damage commonly occurred at ships’ sterns due to a combination of hydrodynamic forces, ship motion, and structural stresses. IMO said that structural flexing of the hull at the stern increases the stress on twist locks and lashings, which increases the likelihood of failure. Parametric rolling (a potentially violent combination of pitching and rolling), resonance effects, and sudden course changes also amplify these risks, making the stern particularly vulnerable to container losses in bad weather.” TT Club also brought forward the findings from the 3.5-year-long TopTier: Securing Container Safety project the insurer partook in. After analysing 44 incidents over the past two decades, involving the loss of nearly 10,000 containers, parametric rolling was found to be the most likely cause of large incidents. The TopTier report also found that single-bay losses often resulted from local failures and stack resonance. Surveys and interviews with 1,500+ sea and shore personnel revealed further challenges – in overseeing the container stowage plan execution and its validation, predicting vessel response to certain weather conditions, and the inconsistent use of navigation software tools. Key recommendations from the project include implementing operational guidance for proactive avoidance of off-design conditions such as parametric rolling; harmonising performance and functional standards for onboard lashing software; improving inspections of lashing gear and containers; recognising the use of onboard lashing software in rules and regulations; including multi-bay stack resonance effects in container securing computations; addressing uncertainty in container stowage positions; and improving the enforcement of verified gross mass requirements. “Each incident is a stark reminder to everyone in the transport and logistics sector of the need to take steps to prevent such losses, recognising that every lost container can have major environmental, financial, and reputational impacts for supply chain actors,” TT Club cautioned.

CARGO SAFETY PROGRAM – LAUNCHED

The World Shipping Council ( WSC ) has kicked off its Cargo Safety Program, an industry-led initiative to detect mis- and undeclared dangerous goods to prevent ship fires, as well as to protect crews, vessels, customers’ cargo, and the marine environment. A digital cargo screening tool powered by the National Cargo Bureau ’s technology sits at the solution’s heart. It scans millions of bookings in real time using keyword searches, trade pattern recognition, and AI-driven algorithms to identify potential risks. Alerts are reviewed by carriers and, when needed, verified through targeted physical inspections. The Program also establishes common inspection standards for verifying shipments and an incident feedback loop to ensure lessons from real-world cases strengthen prevention. At launch, carriers representing over 70% of global TEU capacity have joined the Program. “By working together and using the best available tools, we can identify risks early, act quickly, and prevent accidents before they happen,” Joe Kramek , President & CEO of WSC, said. “The Cargo Safety Program is a powerful new layer of protection, but it does not replace the fundamental obligation shippers have to declare dangerous goods accurately. That is the starting point for safety, and it is required under international law,” he added.

The Port of Gothenburg:

470 thousand TEUs handled in H1 2025 (+0.4% yoy)

Container rail traffic totalled 260k TEUs, up 4.4% on the H1 2024 result. “Repositioning empty containers between ports is necessary for the logistics system to function, but ideally it should be kept to a minimum. The fact that we are handling more loaded containers while managing fewer empties reflects greater efficiency across the entire logistics chain,” highlighted Claes Sundmark, Vice President Sales and Marketing at the Port of Gothenburg. The Swedish seaport also noted in a press release, “APM Terminals, which operates the port’s container terminal, reported its best month ever in July [2025] with 47,805 TEUs handled […]” Also, more ro-ro cargo units went through Gothenburg’s quays, up 0.7% year-on-year to 272,000. The finished vehicle logistics segment saw a decrease of 6.8% yoy to 124,000 new cars. Less liquid and dry bulk were taken care of, too, 9.4 million tonnes (-13.8% yoy) and 155 thousand tonnes (-43.2% yoy), respectively. On the other hand, passenger traffic grew by 126% yoy to 579 thousand ferry & cruise travellers.

The Port of Södertälje: 2,783 ro-ro cargo units handled in H1 2025 (+3,253% yoy)

Measured in tonnes, wheeled (ro-ro) cargo going via the Swedish seaport totted up to 57 thousand (+2,750% year-on-year) – of the total of 544kt handled (+15.5% yoy). Södertälje also saw 36,106 vehicles (+40.4% yoy; that’s 71kt, +47.9% yoy) and 4,272 TEUs (-10.5% yoy; 51kt, -5.6% yoy) going over its quays. Additionally, the Swedish port took care of 202kt of liquid bulk (+14.1% yoy), 116kt of forest products (-27.5% yoy), 27kt of dry bulk (-10% yoy), and 20kt of goods classified as ‘other’ (break-bulk; no handling in H1 2024).

The Port of Pietarsaari: 778.7 thousand tonnes handled in H1 2025 (+55.5% yoy)

Whereas domestic freight traffic lost 10.9% year-over-year, down to 20.2 thousand tonnes, international cargo trade going via the Finnish seaport gained 58.7% yoy to 758.5kt. Container traffic increased by 603% from 159 to 1,117 TEUs. Pietarsaari also saw more ro-ro cargo units, up 63.7% yoy to 902.

The Port of Hanko: 100,084 ro-ro cargo units handled in H1 2025 (+33.1% yoy)

The Finnish seaport also took care of more containers, up 4.8% yearon-year to 29,268 TEUs. The Port of Hanko altogether handled 2.73 million tonnes over this year’s first half (+32.1% yoy), of which international cargo traffic accounted for 2.64mt (+31.4% yoy) and domestic for the remaining 83.7kt (+58.1% yoy). The port also welcomed more passengers travelling by sea – 969 vs 58 in H1 2024.

The Port of Liepāja:

3.43 million tonnes handled in H1 2025 (-7.2% yoy)

The first half of this year proved to be a mixed bag for the Latvian seaport: while the turnover of liquid bulk advanced by 23.5% year-on-year to 160.3 thousand tonnes, the handling of dry bulk and general cargo both contracted. Dry bulk totalled 2.26mt (-7.6% yoy), including 1.38mt of grains & cereal products (-18% yoy), 393kt of building materials (+42.5% yoy), and 181.8kt of woodchips (-27.8% yoy). Turnover of general cargo totted up to 1.02mt (-10% yoy), comprising, among many, 811.6kt of wheeled (ferry) cargo (-7.8% yoy), 162.6kt of timber (-25.3% yoy), and 42.4kt of goods in containers (+61.8% yoy). With 39,658 ferry travellers, Liepāja’s passenger traffic was down 7.6% on the H1 2024 result.

The Port of Kaskinen: 341.2 thousand tonnes handled in H1 2025 (+12.6% yoy)

Apart from 337.4kt made in international cargo traffic (+11.3% year-onyear), the Finnish seaport also took care of 3.8kt in domestic seaborne trade. Kaskinen’s H1 2025 ro-ro traffic advanced by 412% vs the corresponding period last year to altogether 1,235 units.

The Port of Klaipėda:

692,159 TEUs handled in H1 2025 (+28.8% yoy)

Ro-ro traffic also advanced in the reported period – by 3.2% year-onyear to 125,046 cargo units. Overall, the Lithuanian seaport took care of 19.07 million tonnes over 2025’s first half, up 16.8% on the result from the corresponding period last year. Passenger traffic also noted an increase, +5.1% yoy to 172.5 thousand travellers, of which ferries brought 143.6k (-2.2% yoy) and cruisers 28.9k (+66.1% yoy). Also, ferries serving Klaipėda transported 43,862 private vehicles (+5.9% yoy).

The Port of Oxelösund:

2.5 million tonnes handled in H1 2025 (+7.6% yoy)

The growth noted by the Swedish seaport was driven by goods classified as other dry bulk, which totalled nearly 1.88 million tonnes over 2025’s first half (+14% year-on-year). Trade labelled as ‘other’ (break-bulk) also rose – to 60 thousand tonnes (no handling in H1 2024). Oxelösund also took care of 398kt of ores & steel products (-13.9% yoy), 93kt of wheeled (ro-ro) cargo (-13.1% yoy), 39kt of forest products (-20.4% yoy), 25kt of containerised freight (-52.8% yoy), and 9.0kt of liquid bulk (+50% yoy). The port’s container traffic totted up to 2,177 TEUs (-51.2% yoy), while ro-ro to 2,675 cargo units (-20.8% yoy).

Photo: VRT Finland

Photo: Port of Kaskinen

The Port of Aalborg: 1.21 million tonnes handled in H1 2025 (+10.4% yoy)

Whereas the handling of liquid bulk contracted by 4.1% year-on-year to 305 thousand tonnes, the turnover of dry bulk rose by 19.8% yoy to 749kt. The remaining 159kt (+1.9% yoy) comprised general cargo goods.

The Port of Aarhus: 4.85 million tonnes handled in H1 2025 (+5.3% yoy)

Whereas the handling of both liquid and dry bulk contracted, by 16.4% year-over-year to 510 thousand tonnes and by 6.5% yoy to 1.39 million tonnes, respectively, general cargo advanced by 17.6% yoy to 2.95mt. Out of the last one, containerised freight totalled 2.75mt (+19% yoy). On the passenger side, the Danish seaport served nearly 1.5 million ferry travellers (on the domestic routes with Odden and Sælvig), up 0.6% on the H1 2024 result. The services’ ferries also transported 637,305 private vehicles (+2.4% yoy) and 4,269 ro-ro cargo units (-2.1% yoy).

HHLA: 3.17 million TEUs handled by the company’s sea container terminals in H1 2025 (+7.9% yoy)

HHLA’s facilities in Hamburg took care of 3,006 thousand TEUs, an advance of 6.9% on the H1 2024 result, while its terminals outside Germany handled 165 thousand TEUs altogether (+28.7% year-on-year). HHLA’s intermodal business grew by 19.6% yoy to 997k TEUs, including 863k carried by rail (+20.2% yoy) and 133k by road (+16% yoy).

BTJ’s on issuu.

Photo: Port of Aarhus

Photo: Port of Aalborg

The Riga-based manufacturer of heavy-lifting equipment has installed a second rail-mounted gantry (RMG) for container operations at First Dry Port Terminal in Tashkent. Having a 10.8-metre cantilever length, 7.0 m of operating outreach and 17.1 m span between the legs, each sister RMG can lift up to 41 tonnes. The cranes are equipped with advanced control systems for maximum performance, reliability, and energy efficiency. “The development of the First Dry Port Terminal’s infrastructure, located on the historic Great Silk Road, holds strategic importance for regional economic development and enhanced trade connectivity between Asia and Europe. The terminal spans 22 hectares and features eight railway tracks with a total length of 5,300 meters, a covered customs warehouse, an open customs area, a customs control zone, and loading/ unloading platforms,” RIKON highlighted in a press brief.

Meyer Turku to build further Icons

BLG’s new mobile harbour crane

The Royal Caribbean Group has secured the right to construct vessels at the Finnish shipyard through 2036, confirming the order of Icon 5 plus an option for two other Icon-class cruise ships. Meyer Turku already delivered Icon of the Seas and Star of the Seas (364.75 by 48.47 metres, gross tonnage of nearly 249 thousand, room for 7,600 passengers), the world’s largest cruisers, with Legend of the Seas to follow next year. Icon 4 is in production, slated for delivery in 2027, with Icon 5 joining Royal’s fleet in 2028. “With the framework agreement now signed, we announce our common plan for the next decade in cooperation with the Royal Caribbean Group and other key partners to build more Icon-class ships and drive the future of shipbuilding over the next decade. I am extremely proud of the recognition that these orders bring to the skilled personnel at Meyer Turku and to the Finnish maritime industry expertise,” said Casimir Lindholm, CEO, Meyer Turku. Petteri Orpo, Prime Minister of Finland, also commented on the occasion, “This new framework agreement is excellent news for Finland. The longstanding collaboration between the Royal Caribbean Group and Meyer Turku will continue to have a significant positive impact on Finland’s economy, creating jobs across the country and energizing our unique maritime ecosystem.”

BCT Gdynia orders RTGs from Konecranes

The eight hybrid (battery/diesel) rubber-tyred gantry (RTG) cranes, manufactured in Poland, will come with several safety & performance features, such as stack collision prevention, auto-TOS reporting, and auto-steering. The European Union’s NextGenerationEU is funding the purchase as part of the National Recovery Plan in Poland. “We chose the Konecranes RTGs because they offer the best combination of performance and lower emissions. They met our requirements in terms of the technical solution, warranty, value for the investment, and delivery time. This investment fits perfectly with our goal of improving handling capacity while reducing our environmental footprint,” commented Maciej Maliszewski, Technical Director at Baltic Container Terminal (BCT) Gdynia. Heikki Kreku, Director of RTGs, Port Solutions, Konecranes, added, “More than 225 Konecranes hybrid RTGs are now in operation worldwide, with this latest order reflecting their growing popularity in Europe, too. The fact that our 3,000 th RTG will be built in Poland for BCT makes this delivery a milestone. Our manufacturing network in Poland has been a fundamental part of our global success with RTGs.”

AutoTerminal Bremerhaven saw the deployment of a Liebherr LHM 550, with a tower extension of 4.8 metres, reach of 54 m, and a loading capacity of 154 tonnes (in a two-rope configuration). “With 10 driven axles, it can be used flexibly on site and can be operated with shore power. The LHM 550 can therefore potentially make a contribution to low-emission port logistics and thus supports BLG’s goal of reducing emissions,” Liebherr-Rostock added in a press release. Before the end of 2025, another Liebherr mobile harbour crane will start supporting BLG LOGISTICS’ operations in Bremen (joining an LHM 320 and an LHM 550; there is also an LHM 400 in Bremerhaven). “The new LHM 550 takes us to a new level in heavy-duty cargo handling and is a clear commitment to the further development of the site,” commented Axel Krichel, Member of the Executive Board and COO of the BLG Group. Andreas Ritschel, General Manager Sales Mobile Harbour Cranes at LiebherrRostock, also said, “Delivering a crane to a terminal of this size [295 hectares] requires not only knowledge of the technical requirements but also of the entire logistical environment. This LHM 550 was developed to support Bremerhaven in its role as a high-volume, future-proof port.”

Langh Ship’s eco-feeder programme – completed

PaxOcean Zhoushan has delivered Martta , the last in the series of three 150 by 27 metres, 1A Ice Class, 1,200-TEU (290 reefer plugs) container ships for the shipping company from the Finnish Piikkiö. Each vessel is equipped with a hybrid scrubber system developed by the sister firm Langh Tech, which is also ready for installing an onboard carbon capture system (also made by Langh Tech and said to deliver proven CO2 -emission reduction of up to 50%). Martta ’s sisters, Ingrid and Lene, were delivered earlier this year. “By commissioning a full series with integrated scrubber and carbon capture systems, Langh Ship demonstrates how owners can move beyond compliance and take decisive steps toward net zero,” Langh Ship underscored in a press release. The company’s CEO, Laura LanghLagerlöf, added, “With this vessel series, we had a vision of pushing the energy efficiency and emission reduction further than before. PaxOcean Shipyard has been a valuable partner in achieving this, their shipbuilding expertise resulting in technologically advanced vessels that make an outstanding addition to our fleet. We are pleased to now have all three vessels soon in operation.”

Photo: RIKON

Rauanheimo enters Sweden via a steel-port deal

Stegra, whose green steel plant is under construction in the Swedish town of Boden, has entrusted the Finnish company with receiving & managing scrap in the Port of Umeå and with steel coil exports through the seaport in Skellefteå. “The Port of Skellefteå has for some time been working on an ambitious development plan that aligns well with an industrial investment such as Stegra. We value the customer-oriented and solution-driven commercial dialogue with the port in Skellefteå and the operator Rauanheimo, which has quickly led to this agreement securing the export of our steel products from Boden during the first years,” commented Jenny Marin, Head of Logistics at Stegra. Rauanheimo’s CEO, Tero Kosonen, also underscored, “We are very enthusiastic about the opportunity to expand our operations to Sweden. The agreement with Stegra is a historic milestone for us and an important step in our internationalization. We want to thank Stegra for the trust and the opportunity to be part of building the steel industry of the future. We look forward to collaborating with Stegra and the ports of Skellefteå and Umeå.” Stegra’s 270-hectare-big facility in Boden – said to be Europe’s first greenfield steel mill in 50 years – is expected to start production in 2026. “We will do things differently and produce green steel in a fully integrated production process, using end-to-end digitalization, electricity from renewable sources, and green hydrogen [from a 700-megawatt plant next to the mill]. By replacing coal with green hydrogen and electrifying the steelmaking process, we will be able to cut CO2 emissions by up to 95% compared to traditional steelmaking. Moving forward, we will continue to reduce emissions even more – getting closer and closer to zero – year by year,” reads Stegra’s website.

HES finalises its Gdynia grain investment

The Polish branch of HES International has commissioned three silos with a combined storage capacity of 21,000 tonnes, adding them to the May 2025-completed flat warehouse of 64,000 tonnes. The new facility, sitting on the Silesian Quay in the Port of Gdynia, offers 85,000 tonnes of automated grain intake and dispatch capacity, a fully integrated conveyor system connecting storage, handling and vessel loading operations, four separate compartments in the flat warehouse together with three vertical silos for simultaneous storage of different grain types, and truck and railcar loading/ discharge point stations with bottom-discharge technology. Capable of serving Panamax and Capesize vessels and offering now a total storage capacity of 240,000 tonnes, HES Gdynia’s throughput rose to 1.5 million tonnes of cereals per year.

Photo: HES Gdyni

Photo: Stegra

Stena Line takes over Terrabalt…

The Swedish ferry company will acquire all shares in the Liepāja-based port operator, becoming responsible for ro-ro, bulk, and other general cargo handling at Terrabalt’s terminal in the Latvian seaport. “Our investment in Liepāja means that we continue to be a long-term partner to Latvia and contribute to the further development of the country’s competitiveness and growth. We believe in a prosperous future for the Baltic Sea region, where investments in infrastructure and increased cooperation between the countries are key to strengthening trade and resilience throughout the region,” commented Niclas Mårtensson, CEO of Stena Line. The company’s COO Ports & Terminals and Head of Group Strategy, Carl-Johan Hellner, added, “Trade and supply chain resilience requires a long-term perspective, and in close partnership with the Latvian State, Liepāja Special Economic Zone, and not least our customers, we continue to build for the future.” The acquisition needs approval from the Latvian competition authority and other institutions. Until then, the current owners will continue running the business. Stena Line has been operating the Liepāja-Travemünde ferry service for a number of years, most recently with the sister ships Stena Flavia and Stena Livia (each offering room for 800 passengers and 2,255 lane metres for cargo). Since May 2023, the Swedish company has also been performing port operations in another Latvian seaport, Ventspils (from which it plies to and from Norvik in Sweden).

…signs a 50-year deal with Frederikshavn…

The Swedish ferry line and the Danish municipality have signed an agreement, thanks to which the former will operate the ferry part of the Port of Frederikshavn for the next half a century. “The new agreement expands Stena Line’s operating rights within the ferry port and establishes the company as the negotiating partner for other external customers requiring port services,” the shipping company said in a press release. Its COO Ports & Terminals and Head of Group Strategy, Carl-Johan Hellner, also highlighted, “Through an excellent dialogue with the Municipality and Port of Frederikshavn, we are continuing to build on our historically strong relationship to create a stable and prosperous future together. This long-term commitment enables us to establish infrastructure that supports sustainable trade, growth, and resilience.” Mayor Karsten Thomsen of Frederikshavn commented, “ I am delighted that we have reached a 50-year agreement with Stena Line. This creates security and long-term opportunities not only for the port but for the entire City of Frederikshavn. It sends a strong signal of trust and shared ambitions.” The Frederikshavn-Gothenburg crossing is served by Stena Line’s ferries Stena Danica (room for 2,274 passengers and 1,640 lane metres for cargo) and Stena Jutlandica (1,500 & 2,100), with three to four daily round trips.

…and wins Gdynia’s tender

The Swedish ferry line, present in the Polish seaport for 30 years now, has won a new contract that secures its operations at the Port of Gdynia’s Public Ferry Terminal in 2026-32. The deal will see Stena Line implementing several future-proof solutions, including 24/7 freight handling, automated drop & collect systems, and hybrid electrification of shipping. “The outcome of the tender secures the continuity of our strategic Gdynia-Karlskrona service, which is one of the most important ferry connections in the Baltic Sea. It also holds the status of a Motorway of the Sea within the EU transport network. This decision confirms the shared commitment of Stena Line and the Port of Gdynia to long-term development, investment stability, and sustainable shipping in our region,” Marek Kiersnowski, Trade Director for the Stena Line Gdynia-Karlskrona route, commented. The company’s CEO, Niclas Mårtensson, added, “Our uninterrupted presence at the Public Ferry Terminal in Gdynia means further developing its role as a modern, environmentally friendly, and integrated logistics hub. By continuing our cooperation with the Port of Gdynia, we reaffirm our long-term commitment to innovation, sustainability, and providing reliable services for both passengers and freight customers.” Stena Line has been calling to the new Public Ferry Terminal since June 2022. Over the past three decades, the company has served more than 12 million passengers and carried 2.5 million ro-ro cargo units between Gdynia and Karlskrona.

Lakeway Link upgrades its Gdynia-Södertälje ro-ro service

At the beginning of November 2025, Lakeway Express will be joined by her sister ship Mistral on the 22-hour route in question, enabling round-trip Monday-through-Friday departures. The 153-metre long Mistral, time-chartered from Godby Shipping, offers 1,624 lane metres for wheeled cargo, including high & heavy and project shipments. Godby Shipping shared that the charter will last until January 2026, after which “[…] Mistral will go to Remontowa shipyard in Poland for installation of new propeller blades, a new bulb, and some other routine dock jobs. The new blades and propeller are expected to give a fuel saving of at least 35% at speeds up to 13 knots.” Göran Söderdahl, CEO of Lakeway Link, also commented, “We are very pleased to meet our customers’ requests for daily sailings between Gdynia and Södertälje. The addition of Mistral strengthens our service offering and allows us to provide reliable, efficient ro-ro transport for both existing and new customers across the Baltic Sea.” He furthered, “This expansion represents an important step in our long-term strategy to develop sustainable short sea shipping. By increasing frequency and capacity, we can offer our customers greater flexibility while shifting more cargo from road to sea, reducing CO2 emissions and easing congestion on European highways.”

Albatros enters the Baltic

MSC has added Baltic Hub to the weekly service that links Northern Europe (Bremerhaven) with the US East Coast (Charleston & New York). The inaugural departure from the container terminal located in the Port of Gdańsk was made by MSC Berangere on 14 August 2025, a 366-metre-long and 51-m-wide carrier that offers room for 15,500 TEUs.

Photo: Baltic Hub

More runs on CLIP Intermodal’s Poland-Spain

rail link

Thanks to an extended co-op with Amazon, the company has increased the number of weekly round-trips on the Swarzędz-Barcelona Setemar Can Tunis route to four. According to CLIP, dispatching a trailer by rail over road between Swarzędz and Barcelona reduces CO2 emissions by up to 90%. The company also underlined that its rail connection is the first in Europe to serve Amazon’s intermodal units. “Expanding our cooperation with Amazon is an important moment for us as it shows that intermodality not only pays off but also genuinely supports our partners’ climate goals. We are thrilled to be building more responsible logistics together,” commented Marcin Uczciwek, Director of CLIP Group’s Sales Department.

BECAUSE TIME MATTERS

Port of Turku offers fast and frequent connections to Scandinavia and Central Europe, with sufficient capacity and a diverse fleet for all kinds of sea transport.

Regular liner services provide a shortcut for freight traffic to European markets and, through ocean lines, to more distant countries. These ensure flexibility in transport schedules, offering competitive and cost-effective solutions for import and export transportation for trade and industry.

In addition to unitised cargo, the port has expertise in handling project cargo that requires special attention. The transit time for cargo is short, allowing vehicles bringing and picking up cargo to get back on the road quickly.

www.portofturku.fi

Photo: CLIP Group

VIKING LINE UPS ITS BIOLNG GAME…

• This autumn, the ferry company increased its purchases of the bio version of liquefied natural gas (bioLNG) sixfold, from around 600 tonnes last year to 3,800. The bunker, delivered by Gasum and made from food and agricultural waste, powered the Viking Glory and Viking Grace cruise ferries on the Stockholm-Turku crossing (with standard LNG used as a complement). For an additional fee, passengers, conference guests, and cargo customers were able to make their journeys fossil-free. Viking Line expects the LNG-tobioLNG switch to axe its greenhouse gas emissions by 17,000 tonnes. “We have worked with others to create the market for biogas. Supply has now increased to a level that enables the use of renewable fuel to a significant extent. We have now been able to agree on our purchases through to October, and our goal is to continue at the same level. Moreover, the amount of bioLNG used will increase thanks to the fossil-free maritime journeys that our customers purchase,” commented Dani Lindberg, Head of Sustainability at Viking Line. He furthered, “In the 2025 survey for Finnish maritime transport, carried out by EPSI Rating, 45% of respondents indicated that they will make more sustainable choices in the future when

they travel. These alternatives will become a reality only through longterm development work, bold investments, and good collaboration. For example, the increased use of biofuel and the resulting decrease in total emissions have been made possible thanks to the company’s €450-million investment in Viking Glory and Viking Grace.” Jan Hanses, Viking Line’s CEO, also noted, “We want to be among the pioneers when Finnish maritime transport shows the way to a fossil-free future for the rest of the world. Major investments in sustainable solutions require predictability in operations and good collaboration both throughout the maritime cluster and with public sector actors.” Jacob Granqvist, Vice President Maritime at Gasum, said, “By running on biogas, Viking Line contributes to emission reductions in Gasum’s pooling service for FuelEU Maritime compliance, which is used by vessels that cannot use biofuel themselves. Viking Line thus helps the entire maritime transport sector to reduce emissions. Starting on 1 January 2025, vessels must reduce their emissions by 2.0%, but required reductions will increase all the way to 80% by 2050. We therefore need trailblazers like Viking Line, which can pave the way for others.” •

…SO DOES FURETANK…

• The Swedish tanker company will be operating its EU-based fleet on biogas, having secured a large-scale mass-balanced biomethane agreement with Cargill and Titan Clean Fuels. “Accessing biogas in large volumes has long been a bottleneck for Furetank and other shipping companies that chose gas propulsion as the fastest route towards renewable fuels,” the shipping line from Donsö said in a press brief. It added, “With the FuelEU Maritime Regulation, in force since the start of this year, it is now possible to account for mass-balanced biogas –meaning certified biogas can be injected into one end of the European gas grid and withdrawn at the other, just as has long been done with green electricity. Furetank has now signed an agreement securing all the biogas required to operate all wholly and partly owned gaspropelled vessels trading in the EU during 2025. Most vessels have now been bunkered, and the transition is taking place.” Viktoria Höglund, Sustainability Strategist at Furetank, also underscored, “This was our target when we converted our first vessel to gas propulsion in 2015. It is remarkable that we have finally reached the point we have worked for and talked about for so long. At last, the right incentives are in place to make the business case possible. We have found partners who can deliver the volume and quality of gas we have been looking for, with a very significant CO2 reduction.” The purchased biomethane provides a 150-200% reduction in greenhouse gas emissions on a well-to-wake basis. Biomethane produced from feedstock such as manure, “[…] prevents the potent greenhouse gas methane from being released into the atmosphere during natural decomposition of waste, while also replacing fossil fuels in vessel operations. In addition, residues from the biogas process return carbon to the soil as organic fertiliser, avoiding

emissions from the production of synthetic fertilisers,” Furetank explained. “What makes this agreement stand out is its scale. Furetank has secured significant volumes, becoming one of the first movers in this market. The FuelEU legislation is set to drive meaningful change, and we are only seeing the beginning of LBM [liquefied biomethane] in shipping as one of the most accessible compliance solutions for shipping, requiring no engine modifications in LNG-fuelled vessels,” said Willem Olde Kalter, responsible for Biogas and FuelEU at Cargill, which will produce the biogas from waste. Lana Sissing, Client Manager at Titan Clean Fuels, which will liquefy and deliver the end product, added, “This is a perfect demonstration of all players in the supply chain working together to make a pioneering deal happen. The security of this product, with end-to-end transparency, as the gas is produced in Europe, means the entire production chain can be verified and certified. The demand for bioLNG is accelerating quickly and will only keep increasing.” A small share of Furetank’s vessel operations, about 10% of total fuel consumption, cannot be powered by biomethane. Part of this is the small amount of pilot fuel (traditionally marine gas oil, MGO) injected into the gas engine to initiate combustion. As such, Furetank’s trialled replacing MGO with HVO100 renewable diesel (supplied by ScanOcean). The last part of propulsion involves operating the energy-intensive cargo pumps, which can now be operated via shore power connection on all Furetank vessels concerned (provided that ports offer the possibility). “This means we have done everything currently possible to enter the fossil-free era. In this way, we demonstrate that the 2050 targets are within reach in the immediate future, through the incentives put into force,” Höglund summed up. •

…AND WALLENIUS SOL

• A s of October 2025, the ro-ros Baltic Enabler and Botnia Enabler run on the bio instead of the traditional version of liquefied natural gas (LNG). The supplied bioLNG is produced from Nordic residual streams (agriculture and food production), certified under RED III, and traceable via ISCC. The switch is part of Wallenius SOL’s Climate Roadmap, a pathway to operate entirely on renewable fuels by 2035, towards no harmful environmental impact a decade later. “The transition from LNG to bioLNG is an important milestone for Wallenius SOL. It shows that renewable fuels are not a distant solution but something we can use here and now. Switching to bioLNG for the Enablers is clear proof that our Roadmap is delivering, and that we are investing in our customers’ climate goals,” underscored Rebecca Tagaeus, Sustainability Officer at Wallenius SOL. Gasum supplies the

bio-bunker under a pooling arrangement. “By aggregating demand from several customers, the arrangement helps scale up supply and build stability in the market. For Wallenius SOL, it provides access to consistent volumes of bioLNG and ensures that the fuel can be introduced in regular operations,” the Swedish shipping line added in a press brief. Gasum’s Vice President Maritime, Jacob Granqvist, also commented, “We are very excited that Wallenius SOL has decided to join our FuelEU Maritime pool, as this collaboration enables us to open even more regulation surplus to shipowners. The window for securing compliance for 2025 is closing rapidly, and the available capacity may run out before the year’s end. Pooling is a brilliant and easy opportunity for all maritime actors to join forces in lowering emissions from the industry together.” •

ESTONIA & FINLAND KICK OFF DIGIMARIS

• The €2.9-million project, funded by the EU Interreg Central Baltic Programme, will see the development of smart surface vessels equipped with pollution detection sensors. These small units, designed to operate in the Gulf of Finland, will “[…] eventually be able to operate autonomously or support larger pollution response operations, improving monitoring capabilities and response speed,” the Estonian State Fleet said in a press brief. Its Director of the Development Service, Hannes Ojangu, detailed, “In the project’s first phase, existing pollution detection technologies will be mapped, and the most suitable solutions selected for the project. New equipment will be tested in a trial basin in Finland and then in Estonian waters to verify their performance in real conditions.” He furthered, “The project will also create a unified service concept and data processing platform that enables real-time

monitoring and effective cooperation between different parties.” Ojangu also underlined, “This is a significant step in cross-border environmental cooperation between Estonia and Finland and a contribution to strengthening pollution response capabilities across the Baltic Sea region. At the end of the project, guidelines and technical documentation will be produced to enable the developed solutions to be used elsewhere.” The partner team of DIGIMARIS includes the Kotka Maritime Research Centre (lead partner), the Estonian State Fleet, SouthEastern Finland University of Applied Sciences (Xamk), Kymenlaakso Rescue Services, and TalTech’s Estonian Maritime Academy. Additionally, the Estonian Navy and the Estonian Rescue Services Agency’s experts will guide pollution control. The September 2025-started project will last for 30 months, concluding in the spring of 2028. •

OMOQO GOES ONLINE IN LÜBECK

• In the start-up’s first commercial development partnership, its terminal operating system, designed for small and mid-sized terminals, has been implemented at Lehmann Group’s Cargo-Terminal Lehmann (CTL) in the Port of Lübeck. The cloud-based, modular platform (comprising Terminal Operating Modules, TOM) is used by CTL for digitalising core operational workflows in daily container activities.

“The implementation at CTL was completed within eight weeks.

The company reported that onboarding and training caused minimal disruption, and early results showed measurable improvements in data quality and process visibility. The stated objective is to gradually replace manual tasks and fragmented tools with TOM,”

omoqo underscored in a press release. Alexander Berg, CTL’s Head of Operations, commented, “We were looking for a solution that wouldn’t require a massive system overhaul but could still deliver real operational impact. With TOM, we’ve been able to improve transparency and reduce manual workload without disrupting our day-to-day business.” To this, Niko Kaufmann, Managing Director of omoqo, added, “With TOM, we aren’t offering a finished product. We’re building a new standard together with the industry. Cargo-Terminal Lehmann is our first commercial development partner. Alongside CTL, there are further co-creators helping us shape a solution that is intuitive, transparent, and ready to grow with their needs.” •

Photo: Lehmann Group

WHAT’S IN THE CABINET

Guidelines on Cooperation between Customs and Port Authorities – updated

The International Association of Ports and Harbors and the World Customs Organization (WCO) have released the updated version of the Guidelines in question, including input from the World Shipping Council (WSC). Launched in 2023, the set of guides serves as a practical tool to foster closer collaboration, better data sharing, and enhanced risk management between customs and port authorities. Key WSC recommendations include establishing robust consultation mechanisms with port stakeholders when introducing new data or regulatory frameworks, ensuring that business realities are considered. Shipping lines also emphasise the importance of timely, accurate data exchange – covering vessel, crew, and cargo information – in alignment with international standards (such as IMO FAL.14(46)). The new section also recommends and supports the adoption of single window environments to simplify and harmonise data submission, reducing duplication while enhancing security and compliance. The contribution also highlights the need for trusted public-private partnerships to tackle illicit trade, drawing on lessons from cross-border, multi-stakeholder global operations (like Operation TIN CAN that resulted in 43 arrests and 158 drug seizures of nearly 100 tonnes of narcotics in 2022). Finally, WSC calls for clear international practices to address abandoned and uncleared containers, which pose both safety and security risks. “This joint document reflects evolving priorities, including digitalization, coordinated risk management, and joint enforcement efforts. The guidance it contains reaffirms our commitment to strengthening collaboration at the border in an increasingly complex and data-driven trade environment,” commented Ian Saunders, WCO’s Secretary General.

BPO on the next MFF

The European Commission’s proposal for the EU Multiannual Financial Framework (MFF) 2028-34 includes the European Competitiveness Fund (€409 billion; €451b with the Innovation Fund), among which also sits the Connecting Europe Facility in its third edition (€81.4b, of which €51.5b for transport and military mobility). “While CEF III is vastly ‘bigger’ than its predecessors, it does not automatically mean that maritime transport-related projects will finally enjoy increased success in being accepted for funding. Questions remain over whether port-related infrastructure projects are automatically classified as ‘cross-border,’ a matter requiring clarification. Furthermore, the European Maritime Space and TEN-T Ports have been listed as one entry in the ‘Indicative list of projects of common interest with cross-border dimension,’ the significance of which is as of now unclear and will also require further clarification,” the Baltic Ports Organization (BPO) said in a press brief. The Organization furthered, “Climate-related investments must be implemented without undermining the overall competitiveness of the EU maritime transport sector. Ports operate in a global environment where international competition is fierce, and the EU budget should ensure that environmental ambitions are pursued in parallel with measures safeguarding efficiency, affordability, and competitiveness.” BPO’s Secretary General, Bogdan Ołdakowski, also commented, “The strategic importance of ports as essential nodes of trade, energy transition, and security for the EU needs to be understood and considered at every step and reflected in access to sufficient financing support. The budgetary decision-making process should be as transparent as possible. We hope that the recently proposed EU Ports Strategy will be taken into consideration during the planning of the budget.”

IMO NZF – delayed

The much-awaited Extraordinary Session of the International Maritime Organization’s (IMO) Marine Environment Protection Committee (MEPC) in mid-October 2025 ended without adopting the Net Zero Framework (NZF) policy measures agreed upon in principle in April 2025 (essentially, the world’s first legally binding global carbon price for any sector and a fund for distributing revenues). A vote called by Saudi Arabia to adjourn the meeting for one year resulted in 57 countries accepting the motion, forming a majority of those present and voting, and the meeting was subsequently put off. “A number of countries changed their positions relative to that vote, providing evidence that well-publicised threats from the United States, including tariffs and reprisals for any country that supported the Framework, and related pressure, were effective at changing positions,” wrote the UCL Shipping and Oceans Research Group in a commentary. Its Professor of Energy and Transport, Dr Tristan Smith, commented, “This is catastrophic for confidence, and therefore also for the equitable and ambitious decarbonisation we need. We will now have to double down on other means to drive shipping GHG [greenhouse gas] reduction and energy transition. Climate science tells us that the challenge of decarbonisation does not go away; it gets harder. This delay, therefore, means those with the means must step up and lead more than ever, until this multilateral process can regain its composure.” UCL also stressed that the postponement does not override or change the foundation of the GHG Reduction Strategy that was adopted at MEPC 80 in 2023 (GHG emission reduction of 20-30% in 2030 and 70-80% in 2040 towards net-zero emissions by/around 2050). “As long as that is the stated strategy, the IMO should, in theory, make progress toward adopting regulations in line with it. However, the outcome at IMO means further work on regional and national regulation of international shipping has now been vindicated, making current regulations such as those in the EU likely to be prolonged. We could now see more regions taking similar action.” Work on the underpinning NZF guidelines can continue, UCL underlines, to specify definitions, calculations, and methods for determining how the policy incentivises and evaluates different technology and fuel options needed for decarbonisation, how the fund will be set up and run, and how its key parameters will be revised on an ongoing basis.

JOURNEY TOWARDS (AMMONIA & METHANOL) TECHNOLOGY TIPPING POINT IN SHIPPING

Key takeaways from Blue Supply Chain’s Umeå Roadmap

The hydrogen blueprint

by Ewa Kochańska

The Roadmap of Local Green Hydrogen-Based Fuels in the Umeå Region, report of the EU-backed Blue Supply Chains project, outlines an ambitious yet balanced strategy to decarbonise port and industrial activities. Led by the goal of achieving climate neutrality by 2040, the Roadmap details a framework for developing a localised electro-fuel production framework centred on green hydrogen. The proposed multifaceted approach – infrastructure readiness, fuel compatibility, environmental regulations, and financial responsibility – provides a flexible methodology that other port regions in the Baltic can, too, utilise.

The shipping industry is under pressure to reduce its heavy reliance on fossil fuels, which still account for almost all of its energy use –far behind other sectors in decarbonisation efforts. As global shipping is still responsible for nearly 3% of all greenhouse gas (GHG) emissions, this lag could seriously undermine international climate targets. Ports have a vital role to play in this shift – not just as logistics hubs but as key drivers of change by supporting the adoption of alternative fuels and green technologies across the maritime sector.

The Umeå region is particularly wellpositioned to become a northern European epicentre for green hydrogen-derived fuels. Substantial, dependable supplies of renewable electricity, particularly hydropower, dominate the area’s energy profile. In addition, Umeå has access to clean water for electrolysis, bio-based carbon dioxide suitable for synthetic fuel production, and a welldeveloped industrial base. Designated as the primary site for fuel production in the region is the Dåva Eco-Industrial Park. Equipped with district heating infrastructure and situated near robust rail & road networks, Dåva’s location makes it convenient for both domestic use and export opportunities. Umeå has already been taking an active

role in renewable energy projects (e-methanol), showing its consistent resolve to environmental sustainability.

Becoming climate neutral in six steps

The foundation of the Umeå Roadmap is a six-step methodology. First, define the objective and timeframe; second, map the present; third, assess the future; fourth, understand technological developments; fifth, explore pathways, actors, and measures; finally, plan for realisation, followup, and evaluation.

The process begins with picking strategic goals – such as that by 2040 Umeå aims to produce enough green electro-fuels for maritime and port activities to cut GHG emissions throughout the logistics chain. Next, the report takes a snapshot of the current situation, including strengths and weaknesses in Umeå’s energy, transport, and industrial infrastructure. For example, the Port of Umeå currently hosts over 800 ship calls annually and supports significant freight operations but lacks the refuelling and support systems necessary for hydrogen-based fuels. Still, the presence of industrial emitters producing biogenic CO2 and a stable energy grid form a solid foundation to continue with the next steps.

Central to the goal of Umeå being climate neutral before long are the future fuel supply and demand projections. The Roadmap estimates the Dåva site could support the production of up to 110,000 tonnes of e-methanol annually. This fuel, alongside hydrogen and ammonia, has emerged as a leading candidate for maritime decarbonisation due to its energy density and growing market availability. The transitional pathway described in the Roadmap illustrates milestones such as constructing hydrogen infrastructure, implementing carbon capture, and retrofitting port operations and vessels with fuel-flexible or zero-emission tech solutions.

Technology-wise, the Roadmap emphasises that there’s no single one-size-fits-all fuel or technology. Instead, a diverse mix – including hydrogen, methanol, ammonia, batteries, and wind-assisted propulsion – must be deployed concurrently. This is because of the complexity of the maritime sector, where different vessel types and travel routes demand different energy solutions. In terms of the economics of alternative fuels, the report offers detailed comparative cost analyses. At the moment, hydrogen, methanol, and ammonia are more expensive to produce and distribute

– largely because electrolysis requires heavy investment while supply chains are still developing. That said, falling costs in electrolyser technology, increasing system efficiencies, and the expanding carbon pricing regimes in the EU are projected to significantly close the gap by 2030-40. Green hydrogen costs, currently estimated at $4.0-9.0 per kg, are expected to decline to $1.0-3.0/kg through technological advancement and economies of scale.

Collaborative & cross-sectoral

The report also stresses the role of EU policies (FuelEU Maritime and the Alternative Fuels Infrastructure Regulation) that incentivise/mandate the use of renewable fuels in shipping and port operations. Sweden’s national policy is also moving towards aligning with the block’s climate targets, although not without some regulatory uncertainty – particularly around hydrogen storage, fuel classification, and CO2 capture and storage permits. The Roadmap identifies these gaps and calls for harmonised standards to facilitate market development.

The governance structure proposed in the Roadmap is collaborative and crosssectoral, bringing together municipal bodies, energy providers, port authorities, private companies, and logistics operators.

The Municipality of Umeå and the Port of Umeå are tasked with steering coordination efforts supported by commercial stakeholders, including Umeå Energy, Liquid Wind, and INAB. Implementation is tracked through a dedicated oversight system that includes performance indicators, pilot project evaluations, and adaptive strategy reviews. This governance model ensures that institutional momentum is maintained over the long timeframe required for full transition while allowing flexibility to incorporate new technologies or policy changes.

Blueprint for a green future

The Roadmap of Local Green HydrogenBased Fuels in the Umeå Region also outlines an integrated system that leverages existing infrastructure whilst preparing for new investment. The Dåva facility is envisioned as a production and distribution hub, using excess renewable electricity for electrolysis, captured biogenic CO2 from local industries, and thermal integration with the district heating grid to increase overall energy efficiency.

Green hydrogen is expected to serve both as a direct fuel and a feedstock for methanol synthesis, with planned port storage and bunkering facilities. Additional seaport upgrades – such as shore power systems, ammonia-compatible fuelling stations, and

rail-port connectors – will align with the broader digital and environmental modernisation of logistics systems.

Additionally, ‘trickle-down’ economic and regional benefits are forecasted. The development of green hydrogen and e-fuel capacity is expected to spur job creation, innovation, and regional competitiveness. Synergies with other future-oriented industries in northern Sweden – like battery production and green steel manufacturing – enhance the region’s appeal as a centre for sustainable industrial growth. The export potential of e-fuels, particularly as global shipping regulations tighten, positions Umeå as a strategic player in the international maritime decarbonisation sector.

The charted Roadmap represents a comprehensive blueprint for transforming Umeå into a model region for green hydrogen-based fuel production and utilisation. Through detailed analysis of economic, technical, policy, and governance dimensions, the report outlines a clear path towards a zero-emission maritime future. By capitalising on local strengths – renewable energy, industrial readiness, and political will – Umeå is set to lead Sweden and the wider Baltic region in implementing a sustainable and economically viable energy transition.

Photo: Belatchew

Key takeaways from Blue Supply Chain’s Lithuanian Roadmap

Rivers reimagined

by Ewa Kochańska

The Greening Lithuania’s Transport Chain report, by the EU-supported Blue Supply Chains project , reviewed the Baltic State’s ongoing project tasked with shifting road traffic onto inland waterways – along the Nemunas River. At the core of the initiative is the electrification of pushboats operating between Klaipėda and Kaunas, supported by a public tender that has attracted domestic and international stakeholders. The project not only advances the country’s environmental agenda but also establishes Lithuania as a test site for green transport solutions.

Lithuania’s road-to-river strategy is consistent with broader maritime aims in the EU. Because the shipping sector still relies almost entirely on fossil fuels for energy (and contributes nearly 3% of worldwide greenhouse gas emissions), (sea & river) ports that quickly develop low-carbon solutions and infrastructure can gain a lasting competitive advantage. Further, the EU’s Fit for 55 package, which extends carbon pricing to shipping and sets binding targets for alternative fuels, makes early action particularly valuable.

Taking advantage of Europe’s sustainability push, Lithuania is positioning its rivers at the centre of a modern logistics strategy. By utilising inland waterways, the state intends to reduce road congestion, lower emissions, and enhance sustainable transport.

The revival

What had begun under the Project EMMA developed into a flagship programme of the Lithuania Inland Waterways Authority (LIWA) to revive the Nemunas and the E41 waterway as viable commercial routes. Between 2019 and 2023, €27 million was invested to restore the latter (plus some €300,000 spent on light and GPS-equipped buoys). The first field test in 2021 showcased the potential of the project when a barge carried a 164.5-tonne General Electric transformer from Klaipėda to Kaunas. By 2022, over 200t of freight had been transported, showing that it is both practical and sustainable to move goods from highways to rivers.

Modernisation and infrastructure development around the Nemunas River have been necessary to ensure that this early success could continue. Over 550 groynes were built to regulate water flow and manage sedimentation and erosion. As part of the EU TEN-T upgrades, these improvements guaranteed the Nemunas is fit for commercial navigation. Moreover, E41 was upgraded to ensure year-round operation to transport at least 100,000t/year. In the second half of 2023, regular deliveries were underway on the Nemunas River, and from 2024, LIWA started bulk cargo transports (grain and rubble). Each barge trip replaces about 106 trucks, reducing CO2 emissions by 21t.

Powering the progress

The next phase of the programme focuses on innovation. In partnership with the European Investment Bank, LIWA completed a feasibility study for electrifying its fleet. The research looked at market demand, vessel needs, river conditions, port infrastructure, and alternative energy systems (including hydrogen, methanol-electric, and battery-electric options). The results show that battery-electric vessels are most viable at the moment. Supported by €14.6m in grants, the initiative includes ordering six pushers, 12 barges, and 27 battery containers to be introduced over six years. The transition to rivers enabled by these assets could replace around 49,000 truck journeys annually.

A resilient charging network is essential to provide enough power for this brand-new

tonnage. The initial grid connections provided only 350kW, insufficient for pushboats, so a dual-link system was introduced, raising capacity to 750kW per vessel. But more is needed, thus charging points are being set up at three key locations: Klaipėda (as the hub), Jurbarkas (mid-route charging and battery exchange stop), and at the Kaunas Marvelė Port (multi-purpose energy centre supporting both vessels and heavy-duty trucks). The last offers specific advantages, including direct access to a nearby high-capacity transformer. Under a long-term agreement, the Lithuanian government has pledged €500,000 to enhance the grid, while the port operator will cover 10% of the expenses and set the electricity rate at €3.0/kW.

Peeling the layers of complexity

Another key finding from the report is that while electrification is moving along swiftly in road transport, the same cannot be said about maritime, where charging infrastructure is scarce. Only a few European ports are able to provide a large-scale alternative energy supply. Establishing hubs like Klaipėda and Kaunas with long-term, stable grid connections is instrumental in enabling the maritime sector to decarbonise.

However, deploying high-power charging technology is still a tall order. The commercially available solutions at the required scale are insufficient. Thus, a phased method has been adopted in the Lithuania project to allow for infrastructure improvements as new systems become available.

There are also constraints on energy supply within urban areas, e.g., at Marvelė, on-site renewable generation is restricted, so the port must rely on the national grid. Here, long-term planning and fixed-rate contracts with energy providers are critical to ensure a stable, cost-effective supply.

Battery logistics adds another layer of complexity. Each container weighs about 30t, which requires strong docks, special cranes, and improved storage areas to manage safe and efficient exchanges. A second charging point in the Port of Klaipėda is also being considered to meet growing demand, which involves talks with local operators and energy suppliers to get both power and space.

That said, to enhance operational flexibility even further, floating ‘battery barges’ are being considered as mobile power units to keep vessels running without interruption. Also, fixed-rate energy contracts will help control electricity costs, while close coordination between government, industry, and energy providers is helping develop the E41 into a scalable, zero-emission inland waterway system.

With infrastructure plans in place, the focus has shifted to vessel design. A blueprint for electric pushers has been completed, tailored to the Nemunas River and fit to work with high-capacity batteries. Trials with diesel-electric hybrids, methanol-electric systems, hydrogen fuel cells, and battery-electric vessels have already provided important data that shapes the final specifications.

The project is currently in the implementation stage, with standards of production, regulatory approvals, and procurement underway. A 2024 public tender invited international building companies and technology providers to deliver the pushboats to the needed performance and sustainability criteria. At the same time, the Kaunas Marvelė Port is expanding its capacity to 2.5MW, which will enable three battery containers to charge at 750kW each.

Charge up!

Clearly, the success of Lithuania’s inland waterway electrification depends on a robust charging network. With the dual-connection system, which delivers the necessary 750kW/ vessel, the network fits into the European

combined charging system standard but remains demand-scalable. Kaunas’s proximity to a high-capacity transformer reduces grid extension costs, while a public-private financing model ensures stable pricing. Yet, challenges remain – from the limited availability of ultra-high-power charging equipment to reliance on the national grid due to zoning restrictions, as well as the need for heavy-duty cranes and reinforced docks to handle 30t battery modules.

To overcome these obstacles, solutions such as battery barges and fixed-rate energy contracts have been under discussion. Meanwhile, improvements to the infrastructure at the Kaunas Marvelė Port and the public tender for e-pushboats highlight Lithuania’s capacity for extensive implementation. Thanks to robust collaboration among the government, the private sector, and the EU, the project is progressing despite market volatility and competition from road transport. The initiative’s benefits go beyond logistics, reinforcing environmental targets, supporting economic growth, and positioning Lithuania as a regional leader in sustainable (inland) shipping.

Photo: Lithuania Inland Waterways

Blue Supply Chains on the Rostock-Trelleborg shortcut to cleaner trade

Where sea meets rail

by Ewa Kochańska

Decarbonising freight transport across Europe requires not only cleaner and smarter technologies but also an innovative use of existing corridors. The reports Role of port authorities in the set-up of green transport chains , Set-up of Green Transport Chains Rail Ferry Case Rostock-Trelleborg, and Improved green transport chains through demonstrated cooperation between port authority and operator, from the Blue Supply Chains project, analysed the Rostock-Trelleborg rail ferry link as an example of how ports can support the creation of greener supply chains by combining sea and rail. This type of solution eases congestion on the roads and diversifies access between countries and cities. The analysis showed that the Rostock-Trelleborg service has long-term potential to support both climate targets and resilience strategies as long as investments in rail capacity, digitalisation, and alternative fuels keep pace with demand.

Besides new fuels and innovative digital tools, decarbonisation of freight transport across Europe also demands a rethinking of how existing corridors are utilised. The Rostock-Trelleborg rail ferry, the last train ferry connection between Germany and Sweden and a vital link in the ScandinavianMediterranean (ScanMed) TEN-T Core Corridor, serves as a perfect example of this. Once seen simply as a niche service, it is now being repositioned as a model for green logistics, with security and geopolitical implications, at the centre of Europe’s transport network.

From polluters to pioneers

Ports have long been the engines of trade, just as they have long been major polluters. As Europe accelerates its Green Deal ambitions, seaports are under pressure not only to cut

their own emissions but also to lead the energy transition, helping the entire transport sector decarbonise. The Rostock-Trelleborg partnership demonstrates how ports can assume this role: by modernising facilities, investing in alternative fuels infrastructure, and supporting sea-rail solutions that reduce truck traffic and diversify supply chains.

Trelleborg, Sweden’s busiest ro-ro port, is already consolidating intermodal operations to reduce internal driving distances, renewing equipment with electric tug masters and hydrogen shunting locomotives, and expanding shore power connections for ferries. Meanwhile, Rostock is building up its combined transport terminal with new storage, additional 680-metre tracks, and is testing e-tug masters to cut emissions from port operations.

Stena Line operates the rail ferry between the two. The company’s existing vessels, about

26-28 years old (expected to run for up to four decades), are being retrofitted with silicone hull coatings (one ferry so far), upgraded propellers, and AI-assisted navigation tools to reduce drag and optimise routes. Additionally, terminal time is being optimised to reduce fuel burn, and vessel machinery is being renewed to prepare for biofuels. Methanol conversion and hybrid propulsion are being explored, following Stena Line’s earlier introduction of the world’s first methanol-powered ferry. The strategy is twofold: extend the life of the current fleet while laying the foundation for fossil-free operations in the coming decades.

In terms of digitalisation, the KV4.0 Data Hub is a new machine-to-machine data exchange system, able to provide realtime visibility across intermodal terminals, allowing users to track shipments, optimise truck arrivals, and better allocate resources. This level of transparency

reduces congestion and makes combined transport more attractive, particularly for smaller operators who previously found intermodal logistics too complex.

The strategic shortcut

The Rostock-Trelleborg link also plays a strategic role in Europe’s economy and security. It provides an alternative to infrastructure such as the Öresund Bridge when congestion, pandemics, or political upheaval threaten supply chains. Past disruptions have shown how fragile a singlecorridor system can be, and policymakers in Germany and Sweden now emphasise a ‘two-corridor strategy’ as a security issue.

Geopolitical developments have only reinforced this point. The Russian aggression against Ukraine as well as Sweden and Finland’s NATO accession highlight the corridor’s importance for civil protection and military mobility. The ferries can carry entire trains, locomotives, and heavy equipment unsuited for roads due to axle load and clearance limits, and and is approved for the transport of dangerous and critical goods, underlining the link’s twofold role in trade and defence logistics.

Demand is expected to climb steadily for the connection. Northern Sweden’s industrial plans in areas of green steel, batteries, and raw materials will create new freight flows southwards; yet, inland rail remains congested. In the country’s south, the Skåne network is already stretched, and while upgrades, such as the Lund-Hässleholm double track, will certainly help, they will not meet