The flight path to digitalisation in aerospace manufacturing

The aerospace sector is incredibly important to the UK economy. It is the second largest in the world, after the United States. In 2023, the aerospace sector, including space and defence, added £38.2 billion to the UK economy, representing a 50% increase over the last 10 years. According to the trade association, ADS, businesses in these sectors saw a 40% increase in turnover during 2023, reaching £88.4 billion.

With the international aviation market recovering rapidly from the effects of the global pandemic, the target of ‘net zero’ flying by 2050 as outlined in the government’s Jet Zero strategy is, therefore, hugely challenging. At current rates, aviation is expected to become one of the largest emitting sectors by 2050. That said, the aerospace sector is seen as very much a part of the solution to managing the issues around climate change, rather than just being an isolated contributor of carbon emissions.

Whilst it is acknowledged that many of the technologies needed to decarbonise the sector are at an early stage of development, such as Synthetic Aviation Fuel (SAF) for example, aerospace manufacturers are also having to contend with existing market demands. According to the latest industry report from ADS, over 300 commercial aircraft were placed on order in Q1 of 2024, which was a 9% year-on-year improvement. Conversely, the impact of capacity challenges and delays across the supply chain is reflected in a 12% YoY decrease in aircraft deliveries. The backlog continues to reach record breaking numbers, with nearly 16,000 airframes still to produce, which is equivalent to nearly 13 years of production at the world’s leading two manufacturers.

In this context of global attention, public and market expectation, addressing these production challenges will mean significant change for the aerospace sector in the next few years.

At its foundation, ‘smart manufacturing’ represents a transition from conventional manufacturing practices to the seamless integration of digital technologies into every aspect of the production cycle. As highlighted by Atlas Copco in its own white paper on the subject, smart manufacturing goes beyond upgrading technology and instead approaches the entire production process and quality assurance in a whole new way, supported by the power of data. Embracing this transformative approach has the potential to not only propel aerospace manufacturers into the future but also to redefine the industry’s understanding of what is technically achievable. This can be further broken down, as follows:

Whilst automation is fundamental to smart manufacturing, its application within the aerospace environment is not straightforward (see chapter 2). Automated assembly lines have the capability to not only accelerate production but also ensure precision and consistency, mitigating the risk of errors associated with human processes. The manufacturing of aircraft, however, presents a unique set of challenges, not all of which can be overcome through automation.

Smart manufacturing doesn't replace jobs but instead creates new roles and requires workers to have higher skills. The collaboration between humans and machines (cobots) facilitates a new way of working, with skilled workers supervising and improving automated processes. Workforce development becomes essential to equip employees with the necessary skills to navigate this technological shift.

Smart manufacturing technologies take quality assurance and safety to a new level. AI-powered systems facilitate real-time monitoring of manufacturing processes, enabling immediate detection of any deviation from pre-defined parameters. This not only ensures the production of high-quality components but also enhances safety protocols by identifying potential hazards before they escalate.

Smart manufacturing allows data analytics and AI algorithms to extract actionable insights from the vast amount of data generated during production. This data-driven approach allows manufacturers to have full traceability of the assembly process, optimize production lines, identify bottlenecks, and thereby enhance overall operational efficiency. Real-time monitoring via smartphone apps and predictive analytics (see ALTURE below) enables quick and proactive decision-making, which not only reduces downtime but also improves resource utilization.

In the aerospace industry, supply chains are complex, and any delays or problems can cause significant issues. Smart manufacturing enhances supply chain resilience by providing end-to-end visibility into the production cycle. Manufacturers can adapt quickly to changes in demand, optimize inventory levels, and respond promptly to unforeseen challenges, ensuring a more agile and robust supply chain ecosystem.

Smart manufacturing boosts innovation in aerospace by encouraging collaboration among manufacturers, suppliers and other stakeholders. This leads to faster development and adoption of advanced solutions. This evolution extends beyond manufacturing processes to product design, materials science and other more sustainable practices, helping to keep the aerospace sector at the forefront of technological advancement.

Building a commercial aircraft is one of the most complex challenges in manufacturing. Involving significant physical geometries, one manufacturer likened the construction process as a task where employees need to be ‘gymnasts’ in order to work in very confined areas of the fuselage and wing structure.

With over 3 million safety-critical holes drilled in the fabrication of every single-aisle airliner, for example, it’s particularly difficult to automate drilling and sealing these holes. Experts suggest a best case scenario that robots could reach about two-thirds of them with existing technology.

According to one manufacturing specialist,

The primary reason why the aerospace industry has been slower to automate than the automotive sector is because the scale of production is much smaller. New models don’t get released very often, meaning there are fewer opportunities to introduce scalable technological improvements. Additionally, every aircraft is built to order, which demands a bespoke production process, not just to the families of jets offered by the two global manufacturers but also the model variants within those groups.

Our eye is toward finding the right balance of using human-assisted technology and automated technology. There is a path to deployment. Broadly speaking, however, full-scale robotics for airplane assembly is impractical.

Unlike the automotive industry, where car design has advanced significantly over the past few decades, airliner design has much less scope for radical change. For example, the Boeing 737 entered service in 1968. This aircraft was conceived and built without the benefit of Computer Aided Design (CAD). Although there have been several iterations of this iconic aircraft over the past 50 years, its fundamental design is the same.

According to one industry analyst,

the big challenge with automating production of an airframe such as the 737 is that you’re trying to replace what a human is doing with a machine but that machine has got to live in a design that was meant to be made by a person, as opposed to a design that was meant to be made by a machine.

Another key barrier to the advancement of automation within the aerospace industry is the financial viability. Current production volumes and indeed, scope of aircraft design, does not justify the capital investment needed to introduce automated technologies. That said, recent highly publicised issues around quality control within the sector have shone a spotlight on the need to improve safety. With this in mind, the role played by automated vision systems, for example, in pursuit of zero defect quality assurance cannot be underestimated. This is not just relevant to the assembly line but across the supply chain, in the manufacture of components, large and small. Ultimately, the goal of manufacturing is 100% precision products with 100% consistent repeatability, coupled with innovations in material science and data-driven processes will add value to the future of air transport.

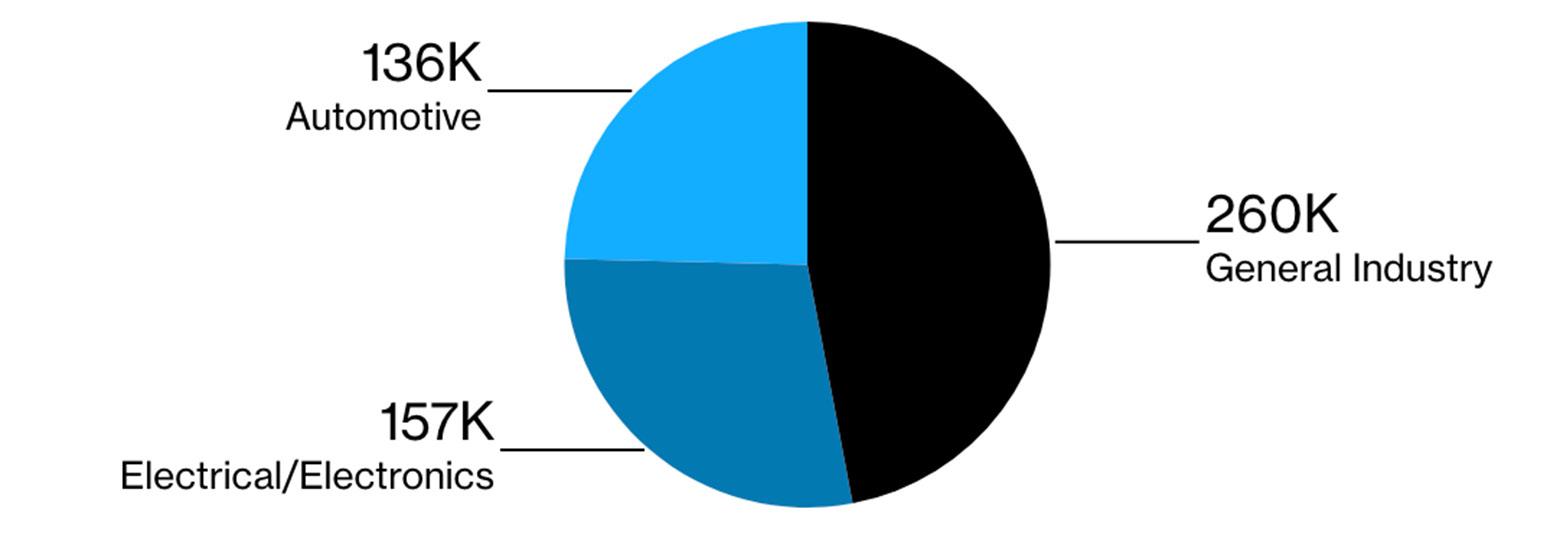

For context, the global automotive industry accounted for a quarter of the world’s industrial robot installations in 2022, while the electronics manufacturing sector made up about 28%, according to the International Federation of Robotics. Aerospace is grouped together with rail, marine and space vehicles, in the category of ‘general industry’, as highlighted in the chart below.

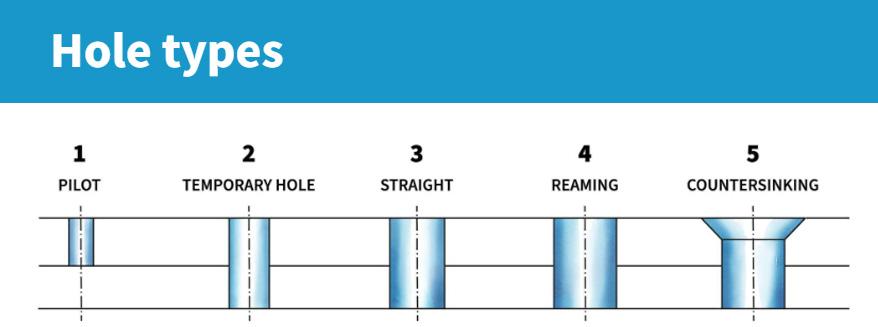

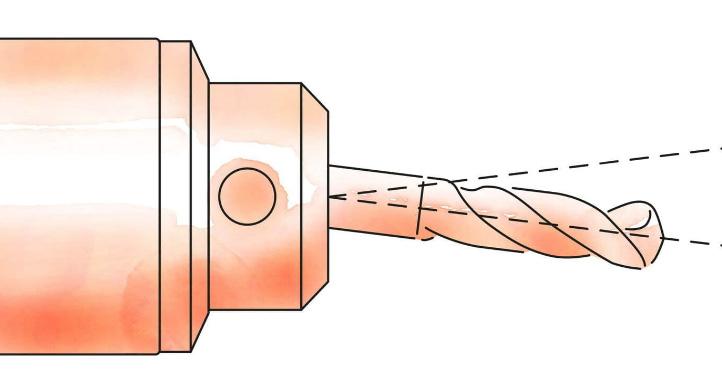

Drilling a hole for an application in the aerospace manufacturing industry is not easy. Instead, it is a critical and precise process where different materials, operational conditions and technical requirements come together. Even the smallest geometrical defect in a drilled hole can compromise the performance and safety of the aircraft.

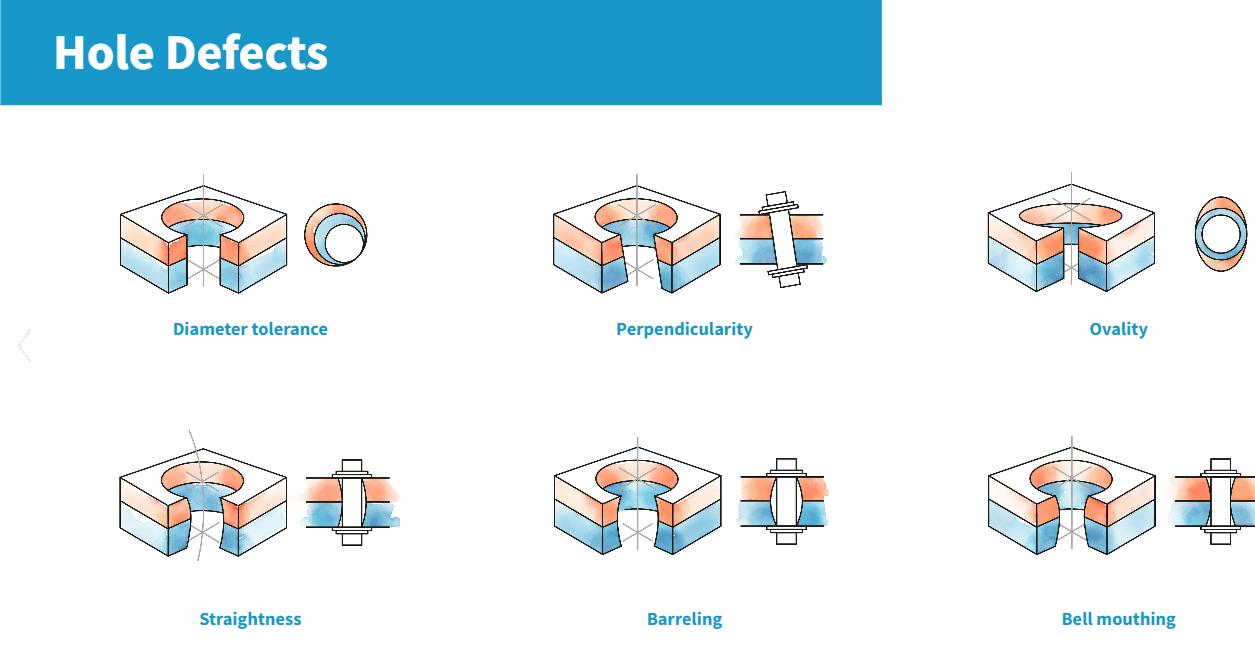

The quality service department plays an important role in upholding the quality of drilled holes during the process of manufacturing an aircraft. It is responsible for ensuring that the tolerance is within stipulated criteria. This may vary depending on the materials used and encompass essential factors such as the minimum and maximum hole diameter and overall quality. The latter includes considerations such as roughness, burn marks affecting material properties, scratches, material deficiencies, straightness, barrelling, and delamination of carbon fibre.

One significant issue that can arise during drilling is ‘runout’. This causes ovality in holes when the drill bit deviates from a perfectly straight rotation around its axis. Eliminating this defect completely is challenging, but minimizing it is crucial to achieve the desired hole characteristics and quality. There are various factors that can influence runout, such as the quality of the drill bit, the chuck or collet used, the condition of the drill tool itself and ultimately, the expertise of the operator.

Despite best efforts, mistakes do occur when drilling. When this does happen there are a multitude of remedial actions necessary, depending on the severity of the issue. The range of possible repair options varies from simple and cost-effective solutions to more extensive efforts which will require additional time and cost.

In all cases, hole defects are meticulously recorded in the aircraft’s technical log, which accompanies it throughout its service lifespan.

Until such time that robotics plays a bigger part in the assembly process, humanled manufacturing will benefit from the advancement of digital smart tooling and ergonomics. This improves efficiency and productivity and crucially, enhances quality through automatic traceability, providing a complete audit trail. Linked with errorproofing smart tooling and advanced vision inspection systems, assembly processes and deviation checks can be part or fully automated to the point where the achievement of zero defects is attainable.

Atlas Copco has supported the UKʼs aerospace industry for a number of years with advanced assembly technology supporting commercial aircraft manufacture, engines, rotary-wing, defence and even space projects. Leading manufacturers within the sector trust Atlas Copco to deliver the highest levels of accuracy and quality, where safety is mission-critical in every application, from the manufacture of wings to engines. The companyʼs comprehensive range of products for the aerospace industry includes solutions for assembly, material removal and quality assurance.

Growth in demand for latest generation airframes has meant that the leading players in the UK have invested significantly in the addition of new production lines. Furthermore, in line with Atlas Copcoʼs strategic partnership philosophy, its research and development is driven by the needs of customers. Factors such as size, ergonomics, single-handed operation and torque range are all accounted for in Atlas Copcoʼs design of sector-specific smart tools, which ultimately enables operators to work in areas of the aircraft wing structure, fuselage and engine, where access is restrictive.

Within the production environment itself, aerospace manufacturers are under pressure to reduce carbon emissions, whilst improving quality. The transition to electrification, from a pneumatic-driven manufacturing process, that is reliant on compressed air tools, is very much underway. Many of Atlas Copcoʼs largest customers are switching to DC-based, cordless tooling solutions. Not only does this improve the safety of the factory floor due to the removal of air lines, but also reduces the carbon footprint from the improved energy efficiency of the latest generation tools.

Driving production efficiency is a key pillar of Atlas Copcoʼs approach and to that end, the company is involved in a Government-backed, collaborative research project to identify and realise methods of improving manufacturing cycle times for UK wing manufacture, whilst lowering recurring costs. Utilising digital technologies, Atlas Copco is part of the three-year ʻDELTA Projectʼ, funded by Innovate UK through the Aerospace Technology Institute (ATI), which involves Airbus and other leading aerospace and academic partners.

Central to Atlas Copcoʼs Smart Integrated Assembly philosophy is the formation of strategic partnerships with customers to deliver a smart manufacturing ecosystem that can seamlessly integrate into existing manufacturing and assembly processes. This harnesses real-time data insights to improve production efficiencies, eliminate costly rework and material wastage that create more sustainable manufacturing.

Traceability in aerospace manufacturing is not just desirable, it is now an absolute necessity. As manufacturers strive to meet increasing market demand for new aircraft, the need for rigorous quality control and accountability to safeguard against risks related to inconsistency, omissions and errors has never been greater. Traceability ensures that every part, material and process involved in manufacturing is meticulously documented and traceable back to its origin.

With traceability systems in place, manufacturers can conduct thorough investigations in the event of a process defect or part failure, tracing the problem back to its source and taking action to prevent similar issues from re-occurring. This level of oversight is essential for ensuring compliance with regulatory requirements and industry standards, as well as confirming that all components meet the necessary specifications for performance and safety. Traceability and oversight are also central to the brand reputations of both manufacturers and endusers and ultimately passenger sentiment.

Historically, the aerospace industry has been reliant on manual tooling for assembly processes, which depend on the operator to manually record torque values and related quality information. In addition, the current practice of using physical, hard copy Standard Operating Procedures (SOPs) presents a number of management challenges, such as ensuring that updates are implemented and that

the appropriate personnel are reading and following SOPs correctly.

It is also important to recognise that manual SOPs only provide evidence of a person signing or initialling a specific document. As a result, they do not confirm that a particular process was followed properly, or that any targets were achieved.

Introducing process control technology provides manufacturers with a starting point for automating traceability and ensuring adherence to SOPs with a digital audit trail, alongside the capability to track production in real time, enabling a detailed insight into the production process.

Atlas Copco’s Smart Integrated Assembly concept is designed to wirelessly connect all electric tools throughout the factory, utilising

the latest 5G connectivity (where available) on selected tool models. Connecting tools via 5G provides more reliable communication and allows for much wider bandwidth for faster communication between devices. In addition, tools with 5G connectivity feature unique SIM cards, to ensure secure and stable connectivity to the Manufacturing Execution System (MES). Greater bandwidth removes bottlenecks, enabling production data to flow seamlessly to provide instant traceability and information on what is occurring across production in the assembly plant.

Electric tools within Atlas Copco’s Smart Integrated Assembly ecosystem communicate via barcode scanning or sending data or PLC signals to inform the tool controller which part of the aircraft assembly or component is being worked on and the corresponding assembly process to be followed.

The use of smart electric tools allow variantspecific programmes to be configured, enabling the same device to be utilised on multiple assembly processes. In addition, smart connected technology enables the tool to report results against a unique product ID, for traceability and analysis purposes.

Atlas Copco’s customisable ToolsControl software removes the need for separate controllers for each tool in the production line by creating a single environment for connecting every tool in the factory to the MES, enabling significant reductions in hardware costs and floor space.

ToolsControl is a centralised server-based controller solution, that assigns a specific assembly tool to a virtual station. This is achieved by using dedicated channels to establish connections between a specific tool and a controller.

Installing ToolsControl on a server greatly simplifies the installation process compared to traditional controller hardware. With a server installation, the initial setup is done once with a single IP address. This eliminates the need for installation on individual controllers and significantly reduces the time required to implement new processes.

ToolsControl constantly monitors the status of each individual virtual controller. As soon as a fault is detected, ToolsControl activates a selfhealing function, resolving the problem within seconds without operator involvement. The data collected via ToolsControl also enables the use of data driven services for maintenance, quality and process improvement (see chapter 6).

Inspection technology such as Atlas Copco’s ISRA vision systems can also be employed in the production process to ensure traceability and quality assurance. For example, the efficient SMASH inline inspection system enables sheet materials such as composites to be inspected in real time with any defects detected and classified to ensure material quality.

Traditionally, the aerospace industry has been reliant on pneumatic tooling and manual torque wrenches to ensure joint integrity. In the drive towards decarbonisation and traceable, sustainable operations, a phased transition to electric and battery-powered smart tooling for high-torque, joint fastening applications, delivers a compelling proposition. Atlas Copco’s advanced electric assembly technology removes the need for multiple tools by providing a joint integrity check and data collection for a specific assembly process.

Although the needs of a specific application determine the optimum tooling solution,

there are a number advantages of using electric and battery tools over legacy pneumatic ones.

Atlas Copco’s new XCB and XTB electric assembly tools have been developed to provide manufacturers with a starting point in the journey towards transformation. The clutch-based XCB model provides the entry point to smart tooling, while a transducerised XTB version offers the next step up with the addition of data collection functionality.

Atlas Copco’s Tensor ICB cordless smart tool range is based around a compact, one-handed tool, specifically designed for cramped area applications such as wing sections. Tensor ICB tools offer a number of features including a built-in EHMI display and a rotating angle head and trigger.

As part of Atlas Copco’s Tensor IXB smart tool family, which share an integrated controller platform, Tensor ICB models have full controller functionality inside the tool. This enables direct integration with station accessories and the MES without the need for an intermediate physical controller.

Alongside traceability, error-proofing is a core focus in aviation manufacturing and requires all processes to be designed to ensure zero-fault production. To support manufacturers, Atlas Copco’s Seven Steps to Securing Product Quality provides a scalable and flexible roadmap of process error-proofing steps that can be implanted incrementally to suit specific needs.

Error-proofing applies to all manufacturing processes and aims to reduce human error by introducing process control and automation, as well as securing errors by providing the operator with clear and immediate feedback on where the error occurred, so it can be corrected straightaway. Further measures include the use of tool interlock and line control functions on smart tools to prevent tools being used on the wrong application.

To support the need for a ‘right first time’ approach, error-proofing software for assembly processes, such as Atlas Copco’s Scalable Quality Solution 3, SQS3, can be integrated into the production process. SQS3 is a comprehensive software solution that drives quality,

process reliability and transparency to reduce errors in assembly. The software connects directly to the MES, allowing the seamless communication of build and result data.

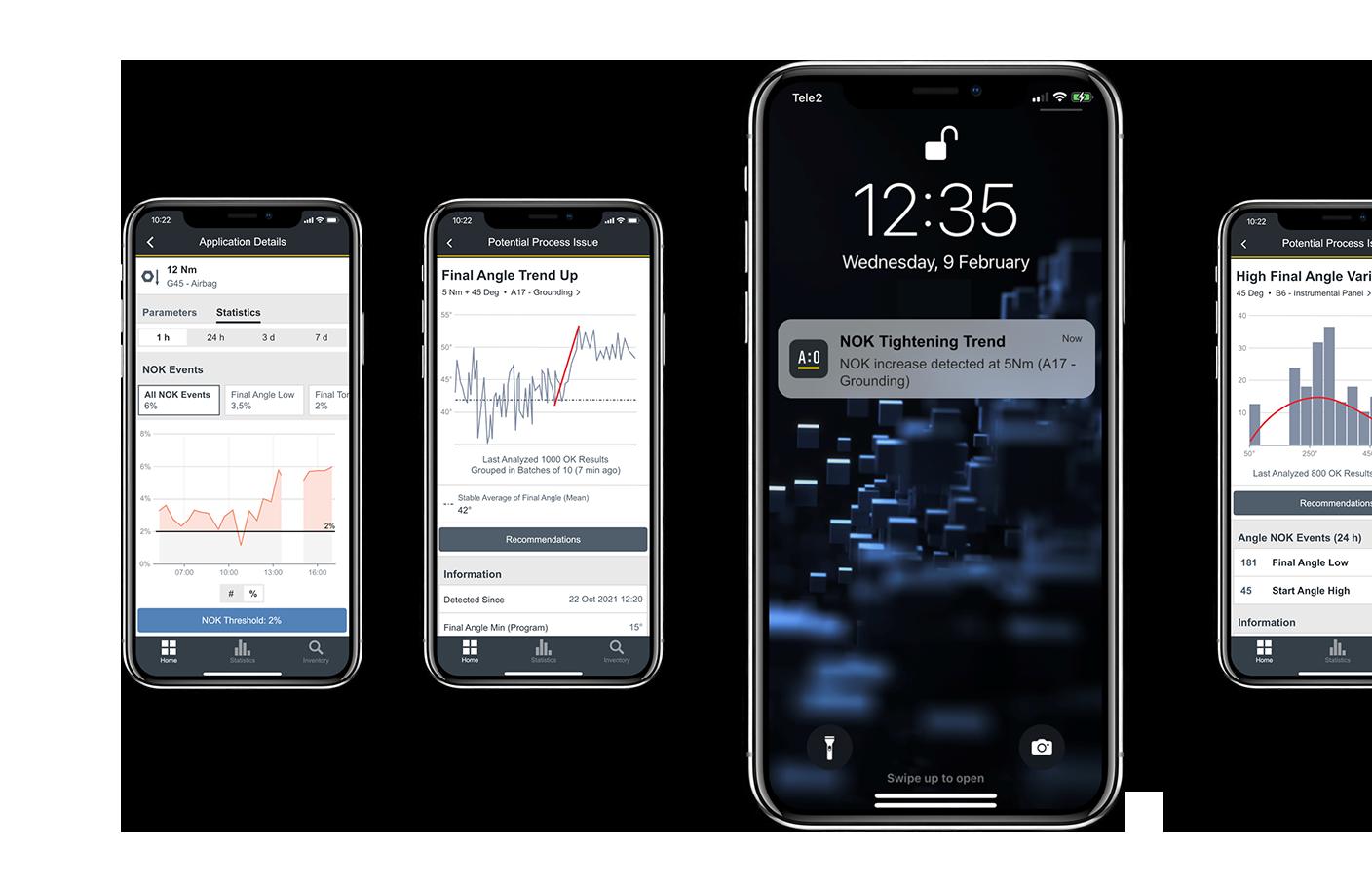

Atlas Copco has introduced a pioneering application which accelerates the value from data-driven manufacturing by harnessing artificial intelligence (AI) and machine learning to identify risks in production before they occur. The ALTURE (ALTernate futURE) smartphone app uses raw data captured from smart tooling and integrated controllers and analyses this information using AI and an algorithm within the app. This enables ALTURE to provides users with real-time manufacturing performance notifications, as well as any ‘Not OK’ (NOK) tightening trends and recommendations for process improvement.

Feedback from over 50 of Atlas Copco’s global customers during a 12-month trial confirmed that the ALTURE app was the simplest and fastest means of delivering real-time information, enabling personnel on the shop floor to counterstrike any emerging issues.

The development of data driven services for maintenance, quality and process optimisation has reached a level where, as demonstrated by applications such as ALTURE, failures can be predicted well before a problem arises and potential quality issues detected even though the process has been performing within specification.

As the aerospace industry evolves towards digitalization and the implementation of smart factories and data-driven assembly, the transformation from legacy tooling to smart-enabled equipment will deliver a significant positive impact on the journey to decarbonising aviation. Atlas Copco provides a holistic approach to client partnerships, which add value to the customer and de facto, the industry

Supporting the transition of the aerospace industry from traditional assembly and maintenance tooling and processes into the age of smart manufacturing with 100%

traceability, is a priority for Atlas Copco, which is evolving traditional Tier 1 supply chain relationships into long term strategic business partnerships. Our long-term success depends on sustainability throughout the value chain. It’s about managing operations, natural resources and people in a responsible and ethical way.

The adoption of smart manufacturing reverberates across various dimensions, bringing about tangible benefits and fostering a culture of continuous improvement. Such technologies will bring a fresh approach to quality assurance and safety in aerospace.