13 minute read

Thread chasing

from Auto Service Professional - November/December 2014

by EndeavorBusinessMedia-VehicleRepairGroup

Restoring male or female fastener threads

By Mike Mavrigian

Whenever you’re faced with dirty or slightly burred female threads (cylinder head threaded holes in a block, spark plug holes in a head, etc.), you may be tempted to grab an appropriate size cutting tap to clean up the threads. The correct choice is to use a “chaser” tap. A cutting tap is designed to create new threads, whereas a chaser tap is designed to clean, re-form and restore existing threads.

Chasing burred female threads

If you want to clean-up existing female threads (maybe the threaded hole has burrs or a bit of corrosion, etc.), it’s best to use a chaser, or follower tap instead of a common cutting tap. A chaser tap is designed to re-form the threads, as opposed to a cutting tap, which will cut its way through, possibly removing too much thread material. This is especially important when dealing with critical-torque-load threaded holes such as cylinder head bolt holes in an engine block’s deck. These taps that are designed specif cally for cleaning cylinder block threads are also called block clean out taps. Other dedicated restoration taps include those made specif cally for restoring spark plug threads in cylinder heads. Restoring cylinder head bolt holes in block decks and spark plug holes in heads are likely the two most common applications.

Chaser taps are specif cally designed to reform and clean existing threads. The spirals on a chaser tap are designed in such a way to follow an existing helical thread spiral path without removing material. While you may be able to accomplish the task by using a standard cutting tap, you run the risk of weakening the existing threads.

Chaser taps (male taps for cleaning female threads) are available in virtually all fractional and metric sizes, but only the most common sizes seem to be readily available. Fractional inch examples include 1/4x20, 5/16x18, 3/8x16, 7/16x14 and 1/2x20. Beyond that, we need to attempt sourcing from highly specialized tool makers.

Chasing male threads

In addition to cleaning and restoring female threads, thread chasers are available for addressing male threads. Common examples include spindle threads that have been damaged or deformed as a result of spindle removal from hubs and wheel hub studs.

An example of a professional grade thread chaser from Goodson Tools, designed for engine builders. High quality hardened steel and massive f utes designed to follow, straighten and restore female threads.

This Goodson example is size 7/16-14, a common size for cleaning/restoring cylinder head deck threaded holes on many V8 earlier-generation domestic engine blocks. Quality-wise, it just doesn’t get any better than this.

A variety of chaser tools are available for these applications, ranging from one-piece chaser dies, split dies and adjustable dies that feature a selection of thread chasing teeth and that adjust for thread diameter. Depending on the design of the chaser tool, restoring male threads will often require starting at the base and walking outward to the tip.

In order to aid in male thread cleanup,

Assuring clean and smooth-spiraling threads in an engine block head deck eliminates frictional variables during cylinder head bolt tightening, aiding greatly in achieving evenly distributed bolt torque.

An inexpensive set of chasers from Summit Racing. The set includes 1/4x20, 5/16x18, 3/8x16, 7/16x14, 1/2x13 and 9/16x12 sizes. Similar chaser sets also are available in f ne thread and in metric formats.

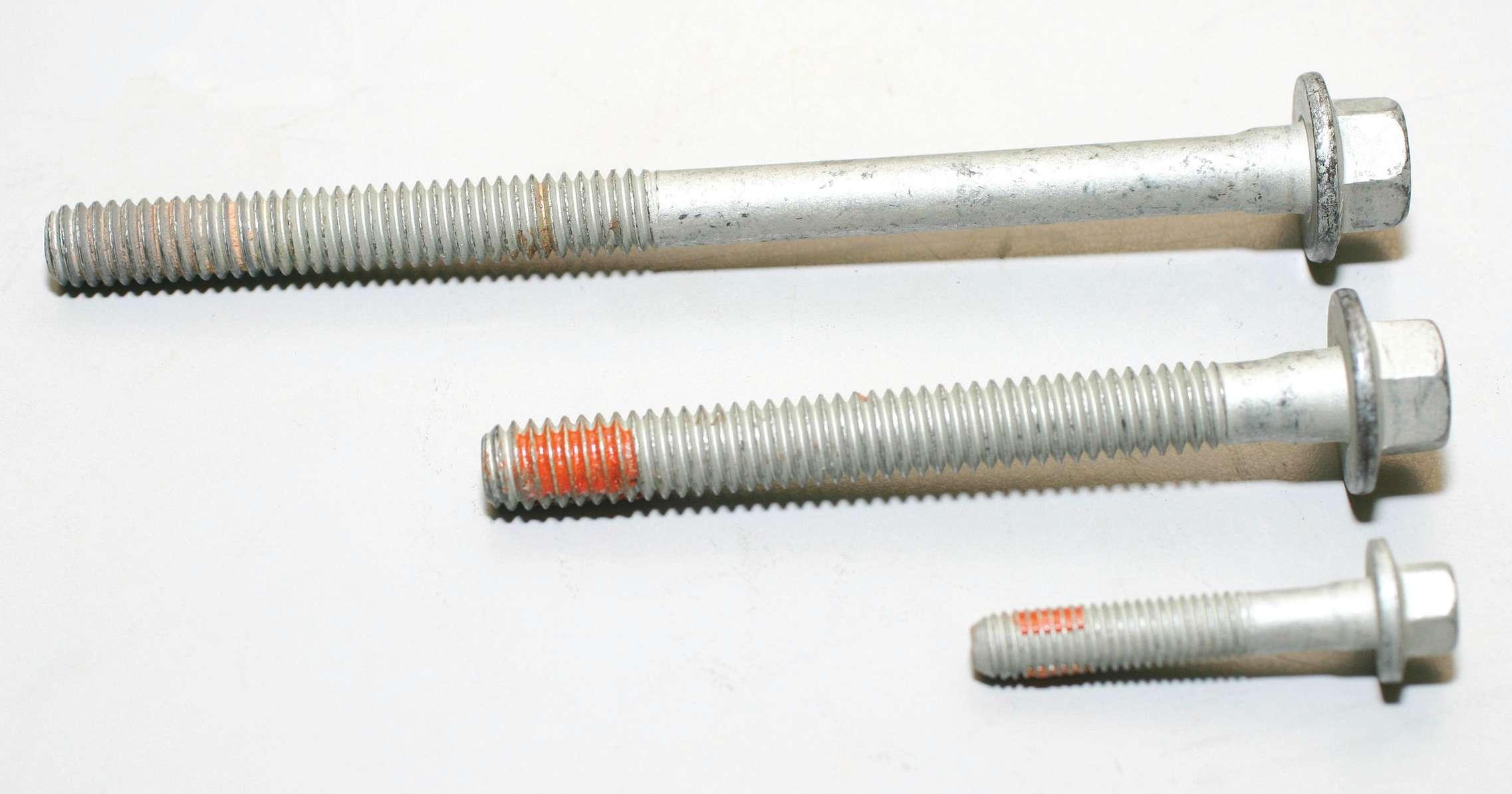

Pictured from the left: a tapered chamfer tap, a plug chamfer tap and a bottoming tap. Never guess at thread diameter. If in doubt, use a readily available checking card in order to identify thread bolt diameter. This example shows a 12 mm bolt diameter.

before using the chaser die, closely inspect the tip of the shank. If the tip is burred or very sharp, it may be wise to f rst slightly radius the tip (with the use of a f le or mini belt sander). Creating a slightly chamfered tip can make the eventual installation of the nut easier, helping to avoid initial cross-threading during assembly.

General tips

Prior to using a chaser tap or die, f rst clean the existing threads by removing any dirt, rust scale, grease or other contaminants to the best of your ability, using a solvent, bristle brush and compressed air. Quite often, these specialty re-forming tools can save an existing thread, avoiding potential component replacement.

If female threads are stripped out, with insuff cient thread material for the reforming process, the alternative is obvious: either replace the component (cylinder head, for example) or install a quality threaded insert.

Thread inserts are available in several designs, including helically wound stainless steel and solid inserts that are either locked into position by staking or with the use of an anaerobic locking compound. Regardless of the style of insert, the existing damaged hole must be drilled to a specif c diameter and tapped by creating new threads that will accept the insert. Be aware that most inserts require a specialized tap size that will match the outer threads of the insert.

Unless you’re already stocked with a specif c thread insert brand’s installation tools, it’s best to purchase an insert kit that will include not only the required inserts but all installation tools (and instructions) as well.

Chaser taps vs. cutting taps

Taps and dies allow you to create threads. Taps are male cutting tools that create threads in a female hole. Dies are female cutting tools that create threads on a male rod or shank.

NOTE: The vast majority of taps are designed for creating female threaded locations. By their nature, these tools cut the parent metal in order to create the threads. When you need to “restore” or clean-up “boogered” threads in a critical engine component, such as the cylinder head threaded holes in an engine block, avoid using a normal cutting tap. Instead, use a “forming” or “chaser” tap that is specif cally designed to chase and re-form the existing threads instead of cutting thread material away.

By using a regular cutting tap in a block’s cylinder head bolt holes, you could easily remove too much thread material, weakening the threads and possibly resulting in cylinder head gasket failure down the road (along with a resulting warped head, oil/ coolant cross-contamination, etc.).

Chaser taps will commonly feature very large f utes (open grooves intersecting the chaser threads), which promote thread cleaning during insertion.

A few don’t’s of thread cutting and repairing • If a bolt or stud’s threads are stripped, galled or otherwise mangled, replace the bolt or stud. If the bolt or stud doesn’t feature enough material to provide full-depth threads, you’ll waste your time. • Never be in a hurry when running a tap or a die. Cutting threads is a precise process. Rushing the job will only cause problems. • Never guess or eyeball the size of the drill required to create a threaded hole. Take the time to look at a reference chart to

Spark plug hole chasers can save the day when dealing with a slightly damaged spark plug female thread in a cylinder head. This double-ended chaser from Lisle (P/N 20200) features both a 14 mm and an 18 mm spark plug thread chaser. A standard 13/16-inch deepwell spark plug socket wrench is required for driving this chaser. Note the three f utes on each end, which aid in evacuating any debris. This also eases the force required to follow the threads. A center O-ring secures the tool inside the socket wrench.

If an NPT (tapered pipe) thread requires a cleanup, I’m not aware of any specialty NPT chaser taps, so a conventional NPT tap will suff ce. Just don’t get carried away by tightening the tap into the hole too deeply. You don’t want to cut new and deeper threads. Only run the tap to the existing thread depth. Since the hole is tapered, by cutting deeper you run the risk of the NPT plug seating too deep relative to the outer component surface.

determine the correct size drill for a given hole. • If you’re dealing with a shallow blind hole, you must use a bottoming tap in order to create threads as close to the bottom as possible. However, start the threads with a chamfered tap, following up with a bottoming tap. • Handle and store your taps and dies

Always use a thread gauge to identify the thread pitch. Using the wrong thread pitch chaser (or cutter) tap will destroy thread integrity, forcing you to repair the hole with a thread insert.

carefully. Always clean them when you’re done, and store them away from moisture. Before using a tap or die, check and clean the threads. • Remember that conventional taps and dies are designed for cutting and creating threads. Whenever possible, use a following, or forming, tap or die to clean or repair existing threads, in an effort to remove as little metal as possible from existing threads.

Cheap alternative

If you’re in a pinch and don’t have the proper chaser tap on hand, and faced with aluminum or steel threaded holes that are only slightly damaged (burrs, etc.), you may be able to clean and re-form those threads by lightly lubricating a high-grade (hard) bolt (grade 8 or 9) with cutting tap oil, and running the bolt into and out of the hole several times, making sure to clean the hole and the bolt of all debris every time the bolt is removed. The bolt’s metal will be harder than the parent material, and will often restore damaged threads. This avoids the use of a cutting tap where too much metal might be removed from the threads.

To be clear: I am not recommending this procedure. I am simply pointing out that in an emergency, this may be suff cient to get the job done, although it’s certainly not the correct method.

Photo courtesy Snap-on.

Here is an external thread chaser. This type (Snap-on TR20) is adjustable for thread diameter and features a set of chaser bits. Available in both fractional and metric formats. Good for cleaning up studs or bolts. This is a different style internal thread chaser. Instead of a dedicated thread-size chaser bit, this thread chaser features a driver and a set of chaser heads in a variety of sizes (which are available in fractional and metric). Shown here is Snap-on Equipment’s TR25M.

Split-die chasers are designed for restoring wheel stud threads. Kits include all popular fractional and metric sizes.

Spark plug holes

Also, for spark plug hole thread repair, a special thread chaser is available that will clean and re-form the existing spark plug hole threads without cutting (so no metal chips will be dropped inside the cylinder). An example is the 14 mm spark plug thread chaser offered by Goodson Shop Supplies as P/N SPB-14. Some cheap, bargain-basement

The split die is placed onto the base of the stud, with the f at hex end seated against the hub face. A socket wrench captures the halves together. The die is then rotated outward toward the stud tip. Thread inserts require the use of a special driver tool. Various designs are available depending on the brand. The insert threads onto the driver and is engaged at the insert’s bottom tang. The tang exists strictly for installation purposes, and is removed once the insert has been fully installed.

spark plug chasers may be nothing more than glorif ed taps that might remove too much thread material.

Types of taps

While this article focuses on thread chasing as opposed to cutting, be aware that several styles of cutting taps are available, not all of which will be available at your local hardware or discount builder supply store.

Spiral point taps are also referred to as gun taps because of the angular point that shears and shoots chips out ahead of the tap. This minimizes the chance of the f utes being clogged with chips, which in turn reduces the chance of tap breakage. This type of tap can be run faster, with less power required. To be used only for through-holes or holes which are at least two diameters deeper than the required thread length. For instance, if you’re using a 1/2-inch diameter tap (cutting, say 1/2x20 threads), if the hole is blind, you’ll need at least 1 inch of extra depth where threads are not required.

Hand taps feature straight f utes. Hand taps can be used either by hand or by machine (for example, on a lathe).

Spiral f ute taps feature spiral f utes (also called helical f utes), and are best

Photo courtesy Snap-on.

A spindle thread chaser set (Snap-on RD8), applicable to most domestic and import front wheel drive spindle threads, which can be used on-car or off-car.

Tap chamfer styles

used on soft materials such as aluminum, brass, copper or magnesium. The f ute spiral offers a lifting action that removes stringy chips that form when tapping soft metals. Good for deep holes, blind holes and holes that feature a keyway or a gap.

Pipe taps, as the name implies, are designed to create the specif c diameter and pitch required for pipe threads. Note that not all pipe taps are tapered.

Three basic styles of tap tips are available based on the tip’s chamfer. These include tapered chamfer, plug chamfer and bottoming chamfer. Tapered chamfer taps feature a noticeable taper, or chamfer at the tip, featuring about seven to 10 threads in this tapered area. This eases tap entry and alignment. Plug chamfer taps feature only about three to f ve chamfered threads at the tip area. Both tapered and plug chamfer taps are OK to use in through holes.

Bottoming chamfer taps allow you to “bottom” the threads in a blind hole (creating threads as close to the bottom of the hole as possible). Bottoming chamfer taps feature one to two chamfered threads (the slight chamfer offering initial entry into the hole).

Pay attention to the type of tap chamfer. When tapping a through-hole, any of these types will do. However, when tapping in a blind hole, if it’s critical to use up all of the hole, you’ll need a bottoming tap. And if you need to tap all the way to the bottom, it’s best to use all three types in progression. Start with the taper chamfer tap, followed by the plug chamfer tap, and

A helically wound thread insert must be installed slightly below the top surface. If the upper end of the wound insert is too close or above the surface, the upper end of the winding may pop out, which creates a host of problems including poor retention, preventing bolt entry and obstruction.

f nishing with the bottoming tap. ●

Solid/one-piece thread inserts are available in various designs, but are an alternative to a spherically wound insert. While a wound insert retains its position via installed tension, a solid insert requires another means of retention. The example shown here features small stakes that are hammered or pressed f ush with the top surface.