Knowledge means responsibility, and Artelia’s extremely skilled and committed employees work every day on making it easy for our clients to make more sustainable choices. This is how we make a difference –by creating solid solutions in cooperation with our clients.

Artelia Group entered the top 50 consulting engineering companies worldwide in 2023. Our aim is to combine our customer-centric culture, our ambition to positively impact the planet and the society, and to provide a genuinely fulfilling work environment for our staff.

Alex Fraenkel CEO Artelia Denmark

Alex Fraenkel CEO Artelia Denmark

Living Places Copenhagen – BoligVærkstedet The first prototype of the concept Living Places developed by VELUX, EFFEKT and Artelia. Contractor / Enemærke & Petersen © Adam Mørk

Benoît Clocheret CEO Artelia Group

Expertise translated into greener solutions

Artelia is in an interesting development where growth and ambitions to affect the green transition are focal points for our business.

We are part of Artelia Group – a worldwide multidisciplinary engineering group with more than 8,500 employees across the world. At group level, we share the ambition to make an active difference for future generations with our engineering skills.

Within the building area in Denmark, Artelia has contributed to showing how the CO₂ footprint can be decreased further, and we have left a significant mark on the debate on climate requirements to new buildings. We are among the leading consultants in the energy sector. Our specialists contribute to rolling out district heating, modernising the electricity network, building more climate-friendly production units and promoting new technologies such as power-to-X and carbon capture.

Within the industry area, we help many production companies with energy optimisation and environmental questions. Pharma and life science are becoming an increasing part of Artelia’s project portfolio, and we are among the largest companies in the market to cover the entire spectrum of consultancy to the pharmaceutical and biotech industry. Sustainability is also a strategic focal point for our consultancy in this area.

Within the infrastructure area, Artelia helps promote green transport modes, such as bicycling, optimise public transport and create better mobility solutions. Our contribution to the expansion of infrastructure ranges from airports and light rails to sewerage and climate adaptation.

We specialise in collecting and processing data, which form the basis for our consultancy. In this year's edition of our company profile, you can read about some of the many specific projects where we use data, expertise and an ambitious approach to making a difference for our clients, business partners and the climate.

Happy reading !

11 28

18

54

42

Contents Projects and qualifications 22 Climate-lowland projects 24 Development of Enghave Brygge Harbour

Transformation of Copenhagen Mall

Reconstruction of wood pellet silo

The great development of district heating 34 CO₂ reducing mobility plans

Biopharmaceutical production

Climate adjustment at a strategic level

Transformation of Musikhusparken

Maritime academy in Svendborg 50 Organisation and figures

Welcome to Artelia

Green transition of the building industry

Part of a global group Theme : A future built on data 11 Automatic mapping of material data in 3D 14 Digitalisation and sustainability in civil works 18 Analyses that promote bio-based buildings 56 14 24 34 6

26

30

32

38

42

44

46

3

6

8

Engineering knowledge – a corner stone in the green transition

The common understanding of and the shared responsibility for our planet has become more pronounced. Legislative climate requirements are continuously being tightened, while more and more of our clients choose to set the bar even higher than what is required under current legislation.

New North Zealand Hospital

On the 123,000 m² hospital construction, Artelia is responsible for DGNB auditing, sustainability management, indoor climate, daylight, environmental consultancy, climate adaptation, etc.

Owner / The Capital Region of Denmark Architect / Herzog & de Meuron and Vilhelm Lauritzen

Autodesk Forma Artelia started using the AI-based software for design analysis at an early stage. The tool can e.g. be used to investigate aspects that are of great importance to the consideration of sustainability.

TRÆ in Aarhus 20-floor office building in timber and recycled materials.

Owner / PFA Pension and Kilden & Hindby Architect / Lendager

New North Zealand Hospital

On the 123,000 m² hospital construction, Artelia is responsible for DGNB auditing, sustainability management, indoor climate, daylight, environmental consultancy, climate adaptation, etc.

Owner / The Capital Region of Denmark Architect / Herzog & de Meuron and Vilhelm Lauritzen

Autodesk Forma Artelia started using the AI-based software for design analysis at an early stage. The tool can e.g. be used to investigate aspects that are of great importance to the consideration of sustainability.

TRÆ in Aarhus 20-floor office building in timber and recycled materials.

Owner / PFA Pension and Kilden & Hindby Architect / Lendager

At Artelia, we strive to lead the way and take climate science seriously. Together with EFFEKT and Cebra, we initiated Reduction Roadmap, which translates the Paris Agreement into annual reduction targets for construction in Denmark. In 2023, version 2.0 was released with the clear message that the limit value for buildings' climate footprint should be set at 5.8 kg CO₂ eq./m²/year from 2025.

At the beginning of 2024, more than 560 companies and organisations across the industry had chosen to join the ambitious goal, which may also become a catalyst for even larger innovation. We believe that this will strengthen Denmark's position as a pioneer in a world where the demand for knowledge about sustainability will only increase.

Nationwide, we have over 50 skilled specialists working with energy, sustainability and indoor climate. They are complemented by our other specialists within everything from climate adaptation and nature to circular economy and waste management. We cover all relevant parameters within various certification

schemes and create holistic solutions as well as energy-efficient optimisations for both renovation and new constructions. In addition to our extensive experience with DGNB, we have qualifications within Nordic Swan Ecolabelling, WELL, BREEAM and LEED certification.

We are frontrunners in terms of putting timber construction on the agenda, we explore the use of recycled materials, we develop completely new tools for sustainability analyses, and we have extensive experience with energy-efficient solutions.

Sustainable from the beginning

It is a central part of Artelia's strategy to make it easy for our clients to make more sustainable choices. It is therefore important to include our sustainability experts as early as possible. This also applies in the idea phase, where the project has not yet been shaped in detail.

For instance within construction, Artelia's client consultants and sustainability specialists work closely together when helping an owner set strategic goals, set the right requirements in the tender or design a sustainability programme that is linked to the building programme.

Many choices cannot be made later in the process, and it will only be more expensive to change course later on. It is therefore also a matter of finances to get off to a good start, and it requires a solid knowledge base. At Artelia, we have an extensive data basis that plays a significant role in our sustainability consultancy.

Reduction Roadmap

Artelia, EFFEKT and Cebra are behind for Reduction Roadmap, which translates the climate goals set in the Paris Agreement into annual reduction goals for Danish constructions. The tool is supported by Realdania and VILLUM FONDEN.

Woodhub in Odense Denmark's largest timber construction, which will be an office hub for 1,600 government workspaces.

Owner / The Danish Building and Property Agency General contractor / NCC Architect / C.F. Møller Architects © NXT

Reduction Roadmap

Artelia, EFFEKT and Cebra are behind for Reduction Roadmap, which translates the climate goals set in the Paris Agreement into annual reduction goals for Danish constructions. The tool is supported by Realdania and VILLUM FONDEN.

Woodhub in Odense Denmark's largest timber construction, which will be an office hub for 1,600 government workspaces.

Owner / The Danish Building and Property Agency General contractor / NCC Architect / C.F. Møller Architects © NXT

Architect

A strong international cooperation

As part of a global group, we are able to attract more international projects and export our specialist knowledge and qualifications.

Grand Paris Express Metro Line 15

Globally, Artelia has extensive experience with metro constructions and other railway projects. Our colleagues in France have taken part in several significant expansions of the metro in Paris.

Owner / Société du Grand Paris

Nyhavna in Trondheim

The old industrial port in Norway's third largest city will be transformed into a completely new district. In the project, we work closely together with our Norwegian colleagues from Dr.techn. Olav Olsen.

Owner / Nyhavna Utvikling

Nyhavna in Trondheim

The old industrial port in Norway's third largest city will be transformed into a completely new district. In the project, we work closely together with our Norwegian colleagues from Dr.techn. Olav Olsen.

Owner / Nyhavna Utvikling

10

/ Cobe and Topic Arcitecture

For a number of years, we have experienced an increasing interest from international clients regarding our Danish expertise within airports and mobility. Recently, the demand has increased for other services where we in Denmark stand really strong. This applies, among other things, to climate adaptation, sustainability and digitalisation, but also noise management and cost management.

The cooperation with our foreign colleagues and business partners helps develop us as an organisation and gives us the opportunity to be part of even more large international projects.

Kim Schwartzlose Executive Director Artelia Denmark Responsible for international development

Kim Schwartzlose Executive Director Artelia Denmark Responsible for international development

Large international projects include our contribution to designing Reykjavík's new state-of-the-art transport system with rapid buses, also called Bus Rapid Transit (BRT), and in several places in France, including in Le Mans and Paris, we have contributed with our specialist knowledge of cycle traffic.

In Norway, we contribute to the transformation of Trondheim's old industrial port into a new vibrant district together with our Norwegian colleagues from Dr.techn. Olav Olsen as well as Cobe Architects –one of our strong business partners. At the same time, we have several projects underway in Norway, Iceland, the Faroe Islands and Greenland.

In 2023, we submitted our proposal for the M5 metro line in Copenhagen. That is a good example of how we in Denmark can now draw on both skills and muscle when required for large projects. The proposal was a huge task that required close coordination and gathering of experience. We learned a lot from it, and even though we did not win, the process helped improve our international cooperation, says Kim.

After the metro M5 tender, clients now ask us directly to participate in other similarly large infrastructure projects in Denmark, for instance other metro tenders.

The increase in international activities have also contributed to our current organisational structure, where the responsibility for international tasks is distributed across our three business areas : construction, energy and industry as well as infrastructure.

We focus on how our Danish expertise can make a difference abroad, as well as how we can benefit from the specialised skills of our talented colleagues in the rest of the Artelia network. This includes areas such as maritime constructions, like ports and coastal protection, power-to-X, carbon capture and large infrastructure projects, such as metro constructions and railways.

Waste-to-energy facility in Nuuk and Sisimiut Project design of steel for two incineration plants, which help solve Greenland's significant waste challenges and at the same time produce district heating and hot water for the inhabitants in the two cities.

Waste-to-energy facility in Nuuk and Sisimiut Project design of steel for two incineration plants, which help solve Greenland's significant waste challenges and at the same time produce district heating and hot water for the inhabitants in the two cities.

11

Owner / ESANI Contractor / Babcock & Wilcox

A future built on data

Words take up a lot of space in the climate debate, but at the end of the day, only numbers matter. This is one of the many reasons why we emphasise structuring, processing and presenting data to create the greatest value possible. We develop our own new data sets and digital tools that make it easier to handle complex information, and we take part in several innovation projects that provide new data-driven insights for the entire industry.

12 Reinforcement level 2 % Material Insitu EPD number MD 22074 DA (EN15804 + A1) Type Concrete CO2-eq 752 kgCO2-eq DAT / DfD Mechanical coupling Exposure class XA1 Environmental impact Slightly aggressive chemical environment Material Bio Specification of material bio-based, mineral, metal EPD number MD 20007 EN Rev1 Specification of the material ’ s environmental label Type CLT Specification of material, e.g. CLT, glulam, NLT, DLT CO2-eq 301 kgCO2-eq Indication of climate footprint in stages A1-A3 + C3 DAT / DfD Mechanical coupling Possible to dismount and adapt Wood species larch, common spruce Describes wood species, spruce, larch, oak, etc. Remaining lifespan 15 years Description of the material ’ s remaining lifespan Reuse potential -3456 kgCO2-eq Description of reuse potiential EPD module D

13

14

15

16

17

18

19

21

22

23

Climate-lowland projects help support the goal to reduce Denmark’s emission of harmful greenhouse gasses by 70% towards 2030.

Protection Agency has set aside lowland projects in Denmark. This

which then results in the release of CO₂ into the atmosphere. The purpose of climate-lowland projects is to reduce greenhouse gas emissions from carbon-rich lowland soils that were previously used for agriculture. This is achieved by re-establishing natural hydrology. The water level in the lowland area will rise, which will give less oxygen to the soil and with that slower decomposition or complete termination of carbon decomposition.

In addition to CO₂ reduction, the climatelowland projects must support the purposes of nature and water environments and other climate purposes. This means that the subsidy scheme has a broad perspective and focuses on synergy with e.g. the Water Framework Directive, the Bird Protection Directive, the Habitat Directive, biodiversity, protected nature types, clean drinking water, outdoor life, organic agriculture and climate adaptation.

Mandatory feasibility studies

drained to enable agricultural cultivation. This practice resulted in oxygenation of the soil, which causes oxygen-consuming bacteria to start breaking down carbon,

Artelia can help prepare the necessary feasibility study, which forms the basis for the Danish Environmental Protection Agency's decision on whether a project is feasible or not. The feasibility study includes a description of the area and the extraction of soil samples, which are used to assess the potential for retention of CO₂ and nitrogen. The feasibility study must account for whether the project is expected to have sufficient effect for a justification of financial subsidy from the Danish Environmental Protection Agency.

We describe the area and take soil samples so that we can account for how much CO₂ and nutrients can be retained, design engineer Maja Kastbjerg Holm Poulsen explains.

It is not always profitable for the environment to re-establish the natural hydrology, as iron in the dry soil can bind phosphorus, which will be leached into the water environment under increasingly wet conditions. In addition, other and stronger greenhouse gases than CO₂, such as CH₄ (methane) and N₂O (laughing gas), may be emitted from water-saturated and oxygen-free soil. It is therefore crucial to analyse the composition of the soil in the area.

Productive cooperation at Simested Å

In Central Jutland, we are helping a plot owner with a feasibility study at the brook Simested Å.

It has been a bit of an adventure to collect soil samples, since a large part of the area has been under so much water that waders were necessary. It is a very exciting project, and the area is incredibly beautiful. The fieldwork has therefore been extra rewarding on this project, says Maja.

The feasibility study not only covers the results of a lot of soil samples, but also includes a description of how the project will affect nature and species under Annex IV of the European Habitats Directive (species that are strictly protected throughout the European Union), the water environment, surrounding areas, etc.

Both the plot owner at Simested Å and the Danish Environmental Protection Agency have expressed great satisfaction regarding the collaboration with Artelia on this project. The requirements set by the Danish Environmental Protection Agency have required ongoing dialogue between all three parties to ensure that the feasibility studies considered all requirements.

At Artelia, they have had good insight into the assignment and what it was about. At the same time, they have had ongoing dialogue with the Danish Environmental Protection Agency and me about the development of the studies, so I have felt that the project has been in good hands at all times.

Lars Jørgen Pedersen

Plot Owner

Fieldwork in waders.

Lars Jørgen Pedersen

Plot Owner

Fieldwork in waders.

In-depth analyses in Copenhagen Harbour

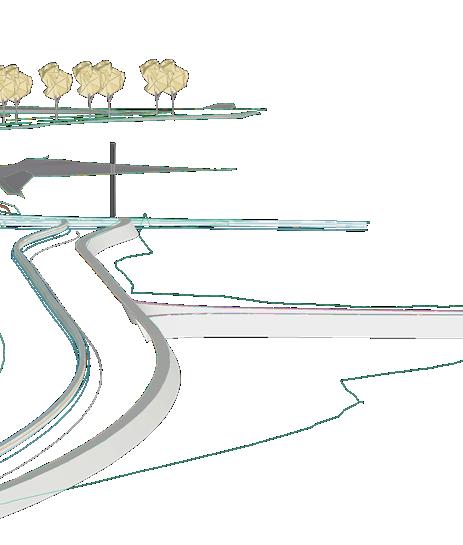

We help create a foundation for urban development that makes the best of the city's blue corridors and addresses the gradual increase of the water level.

Water is a defining element in the development and identity of Copenhagen. Only a few capitals can show off a harbour environment that is suitable for a swim, and the visual qualities help shape the city's architecture.

The desire to fulfil the potential is clearly seen in the neighbourhood Sydhavnen, where the blue landscape runs between the buildings on the inlets Sluseholmen and Teglholmen. For more than 20 years, Artelia has contributed to the development of the channel city, which is now growing even larger with the transformation of the quay Enghave Brygge, where the development company By & Havn is both site owner, project responsible and client. The former industrial area is to be transformed into a district with its own metro

station, which means that it will only take a few minutes to go to the city centre. The metro square will be a unifying urban space in the new residential and commercial district, where Artelia is responsible for all civil works services for the project designed by Juul Frost Architects. A project that covers an area of approx. 75,000 m² and embraces everything from utilities to roads, paths and open spaces.

In line with the style of the other islets, several channels will be established, which is another major part of our project along with three new road bridges. Enghave Brygge is already connected to Tegholmen with the bridge Alfred Nobels Bro, which we designed together with Cobe Architects some years back.

Channel and harbour structures

Our qualifications within marine and geotechnical engineering have played an important role in the creation of Enghave Brygge. For the future channels and harbour structures, we were responsible for the project design of sheet pilings, bulwarks and other measures such as stone pitching, where this is necessary.

At the same time, we have helped assess how best to use the necessary extra land for the new building plot and ensure an optimal construction pace for the infill. As part of the project, a temporary construction pit will be established at a depth of 10 metres, where the utility company HOFOR will carry out a major re-routing of district heating pipelines to prepare for the new buildings.

26

The pit must be kept completely dry but is only separated from the water by sheet piles. It requires several safety measures such as extreme groundwater lowering for water not to seep up from the limestone.

Climate proofing

Resistance to climate change is another important component in the design of Enghave Brygge, and the expected sea level rise is an important part of the equation. The same applies one kilometre to the north, where another example is found of our work with climate protection in the harbour Inderhavnen.

As part of the BREEAM certification of Fisketorvet – Copenhagen Mall, we have analysed how the waterfront and the mall

itself can remain robust against future water masses and storm events. Here, we have obtained and interpreted public statistics on the water level and hydraulic models for storm surge events in different climate scenarios. At the same time, that knowledge is combined with forecasts for future water level rises.

Geotechnician and marine engineer Meesha Olesen contributed to the analysis, which also includes wave impact and current conditions. As Meesha explains, Fisketorvet is not the only example of Artelia providing maritime inputs via the use of international certification :

We have considerable experience with BREEAM analyses of both quay areas and coastal areas. Therefore, we have a solid grasp of how to best uncover all conditions related to climate protection.

Meesha

Meesha

Olesen

Senior Design Engineer Maritime & Geotechnics Copenhagen

Owner / By & Havn Architect / Juul Frost Arkitekter

27

A taste of everything

A four-storey food universe with 39 places to eat and outdoor seating right next to the water. This is the recipe for the latest phase in Fisketorvet – Copenhagen Mall's transformation, which Artelia is taking part in on several levels.

Fisketorvet's new food universe and meeting place will contribute to life by the water with both street food, bars and traditional restaurants that face the mall's popular harbour bath. For that reason, the project was named KAJEN – which means the quay. The major transformation of the centre’s restaurant area will result in dining experiences in four floors spread over approx. 6,500 m². There will literally be a taste of everything, as visitors can look forward to 39 new eateries and a much more varied selection than before. At the top, there is a publicly accessible roof terrace with a view of the harbour and the Copenhagen skyline.

Interaction with the local area

This project is a great example of how shopping centres change character in these years, says Lars Beier, who works with development projects for Fisketorvet :

Traditionally, many shopping centres were built inside out in the sense that all user-oriented elements are located in the middle, while technology and administration are located along the facade, generally with a closed look. But now, there is a tendency for centres to become transparent instead, so that they can interact better with their surroundings and live up to today's demands for daylight.

There is no doubt that the ambient surroundings have become more vibrant since Fisketorvet opened in 2000. The harbour bath was established in 2003, and today, the area is not only frequented by the many visitors who enjoy the waterfront during the summer months. It has

also become a busy traffic artery for pedestrians and bike riders due to the bicycle bridge Cykelslangen, the bridge Bryggebroen and other urban development. It therefore makes even more sense that much of what the mall has to offer will be accessible from the outside on the ground floor.

Retail in change

The new addition is part of a large vision with a new district plan that Artelia helped prepare. The plan opens for possibilities for expanding the centre with other types of commercial buildings and housing. As Lars points out, this shows yet another new tendency with much more emphasis on experiences, where the centres to a greater extent are combined with buildings for other purposes :

Lars Beier Senior Project Director Retail & Mixed Use Copenhagen

New consumption patterns have created a need to redefine what a retail building must be able to provide, and we therefore see a movement from shopping centres to multi-use purposes. Continues on the next page

28

Owner / Unibail-Rodamco-Westfield Architect / Schmidt Hammer Lassen

The plans for the other projects are not 100% fixed, but as part of the idea development, Lars and our cost management specialists have helped create business cases for different scenarios. In relation to the overall planning of Fisketorvet's development and with that the realisation of the possibilities in the district plan, there is a large context to consider. Lars therefore works closely together with Artelia's traffic planners and many other specialists.

The area is in every way a hub, and not just in terms of traffic. If we dig a little deeper, we will reach one of HOFOR's mains in the ground and a large metro construction that requires a lot of coordination, Lars explains and is supported by Helle Korndal, who represents the owner :

It is an extensive project with many aspects. It is therefore important for us to have a consultant who both understands the retail industry and can help clarify the many questions.

Helle Korndal Head of Commercial Management Denmark Unibail-Rodamco-Westfield

39 new leases

The complexity was also a characteristic of the new food universe, where Artelia was responsible for all engineering services, design management, construction management as well as health and safety coordination (P). The process required careful planning and consideration for the rest of the operation.

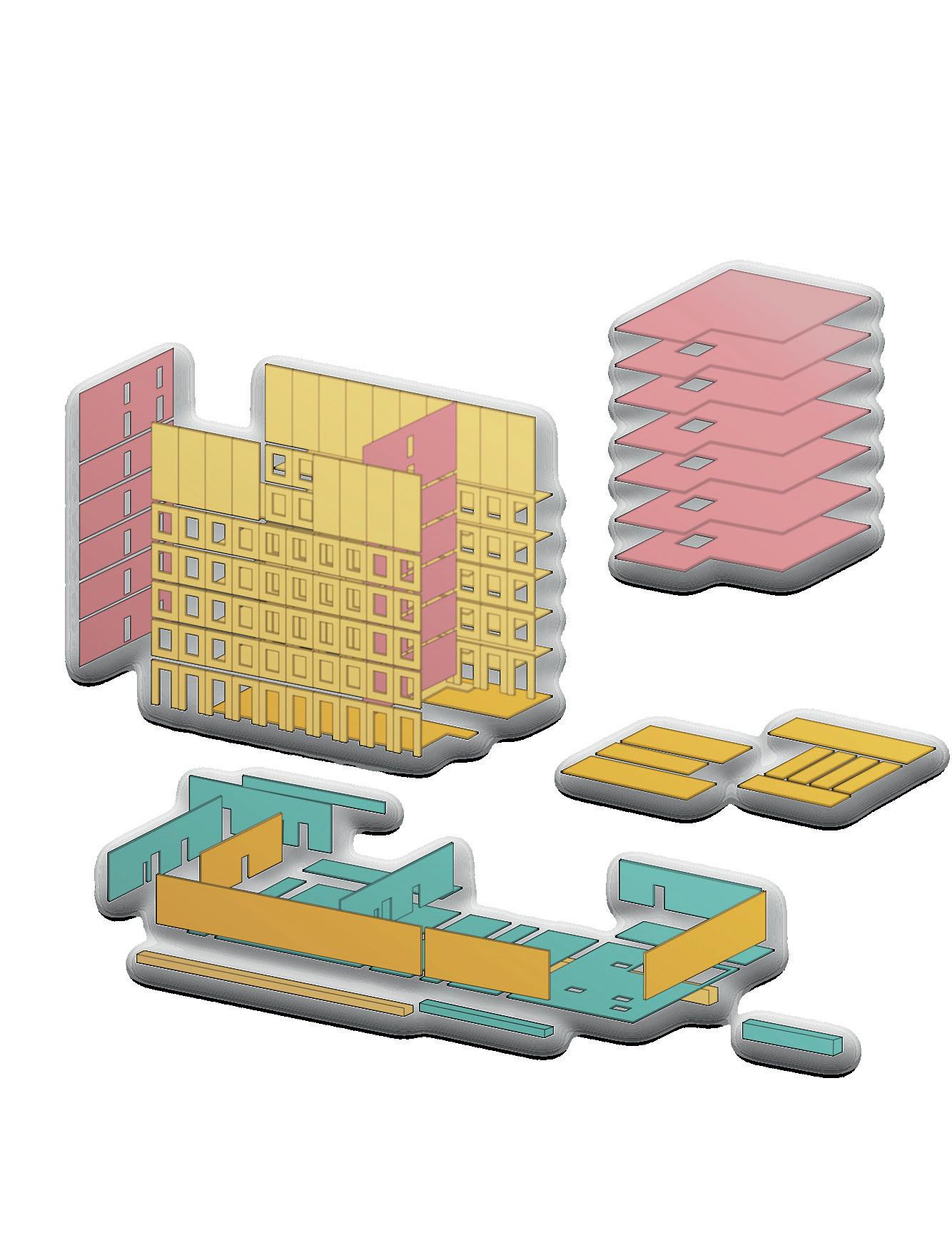

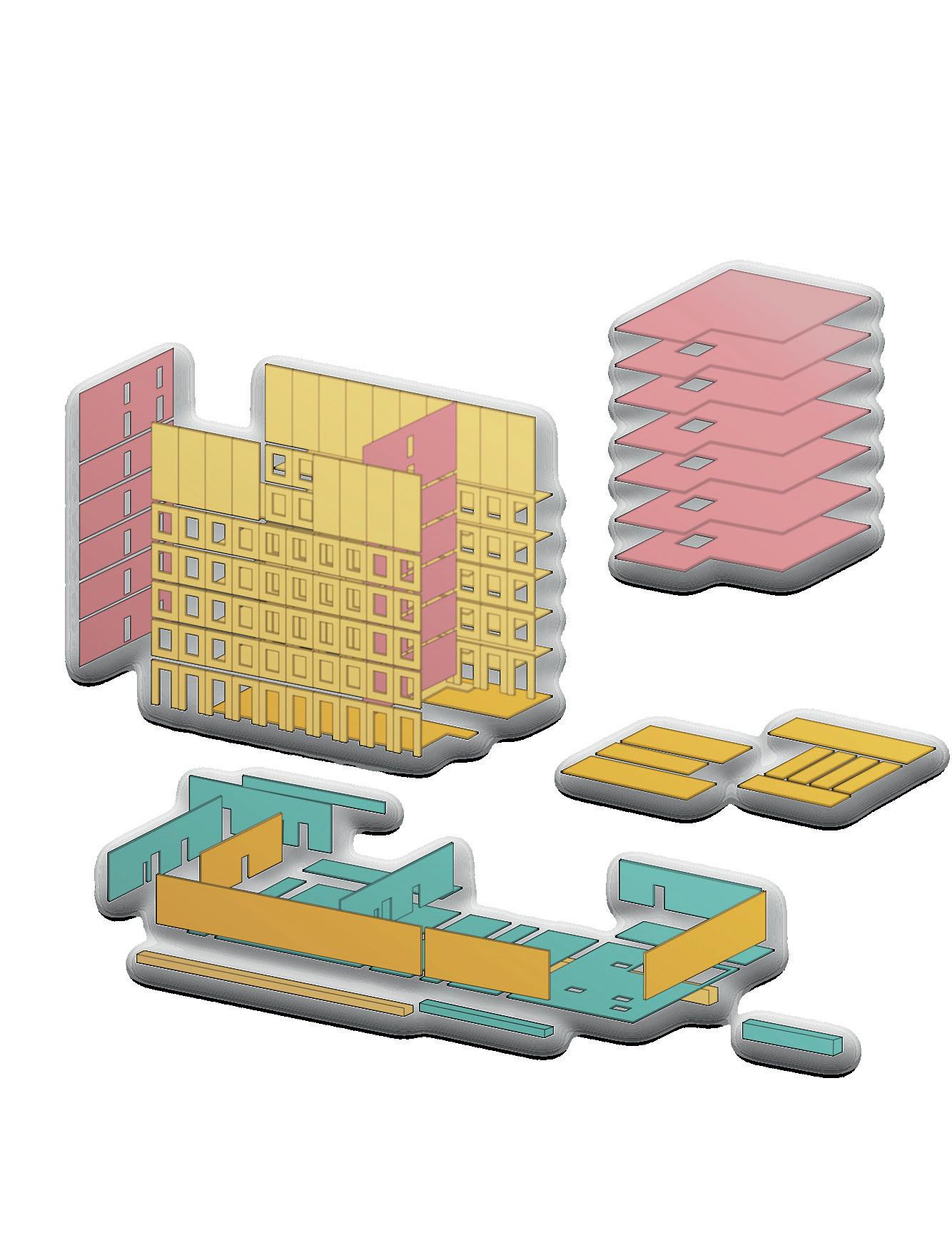

Mall constructions are also characterised by the need for flexibility to easily adapt to different needs. The tenants each have their own unique wishes, which we have also helped meet as consultants to the tenants. Edda Maria Vignisdottir was responsible for that task, and she looks back on a creative process where a digital taste of the future layout formed the basis for dialogue. Each leased retail space was designed in 3D by Unibail-RodamcoWestfields own design studio, Concept Studio, who at the same time helped many of the tenants create or refine the aesthetic expression for the individual eatery. Artelia's more technical models, on the other hand, had a different function, says Edda :

Eateries in particular have a number of installations that influence the design, and it is much easier to review with the tenants in a 3D model.

Edda Maria Vignisdottir Senior Project Director Retail & Mixed Use Copenhagen

3D versus 2D

For almost five years, Edda has been a regular at Fisketorvet, where she helps with several projects in relation to the ongoing operation and design of leased retail space for new purposes. A good example is Denmark's largest Sport 24 store, which moved into the centre in 2023. Therefore, she also knows quite a bit about the contrast between digital models of new buildings and the existing centre’s old 2D drawings, which present challenges that are in no way unique to Fisketorvet

As-built material from the analogue age is rarely accurate enough. It is a technical problem when renovating, but also when the municipality has to have all the documentation that is now mandatory in order to get an occupancy permit. The difference becomes even clearer when compared to a fully modelled new building, where data extraction is easy, says Edda.

:

30

Asset management

For the same reason, Fisketorvet works continuously to digitalise the operational tasks. For this, they get help from our department for asset and facilities management, who are helping to implement DKV plans (operation, control and maintenance plans) for the fire technical systems in the centre's facilities management system (Dalux FM). In connection with the new expansion, they were responsible for facilitation and quality control of the digital delivery to ensure a valid and adequate basis for operation and maintenance, which will be of value to the future operation, says Aziz Hüdai Idil :

All building component cards are transferred to the owner's FM system and can be picked directly at the component's location. This means that we have a lot of important information gathered on one platform.

Aziz Hüdai Idil Senior Consultant Asset and Facilities Management Copenhagen

Aziz Hüdai Idil Senior Consultant Asset and Facilities Management Copenhagen

The information could be product data, drawings, service intervals and the reports that are added on an ongoing basis. As Aziz points out, the model is not only a gain in relation to asset management at an operational level. The easy access to data can also be used on a tactical and strategic level.

A retail centre is a perfect example of a property where it makes very good sense to have the exact distribution of all areas. Here, you can very easily see what exactly belongs to the individual leased retail space, and which areas are shared. Since you can map all surfaces of a certain type, it can also be used for tendering of services like cleaning or window cleaning, says Aziz and is supported by Edda, who highlights a final perspective :

Fisketorvet is certified with BREEAM, and this requires a lot of documentation. Since all new additions must comply with relevant requirements, we have gone through the same process with the food universe. In this case, we saw that the work was a lot easier when everything is digital.

31

Comeback to fire-damaged silo in a top-safe version

The CHP plant Studstrupværket's enormous wood pellet silo is facing a reconstruction with several significant upgrades to prevent future fires. Artelia helps establish the new initiatives, which include a nitrogen factory, a water mist system and a fire detection system.

On 22 September 2022, Studstrupsværket's silo for certified wood pellets, which is used in the plant's unit 3, caught fire. In this block, heat is produced equivalent to the consumption of 106,000 households and electricity corresponding to the consumption of 230,000 households. The silo therefore plays a significant role, and even though the heat supply was initially unaffected, the owner Ørsted immediately started cleaning up and investigating, while planning the reconstruction. A project that Artelia is now taking part in, as we are consultants on the construction project and provide machine and process-related services.

The nitrogen factory

Damp comprises a sort of fire hazard and probably initiated the fire in 2022. Just a little bit of increased damp in the wood pellets can start a biological process that generates heat that can escalate quickly if not released. This may be close to impossible if the process takes place in the middle of a stack of 56,000 tons of wood pellets.

This results in high temperatures, which is extra risky when very large quantities of fuel are within reach. The phenomenon is also known from piles of compost that combust spontaneously.

A major preventive measure at Studstrupsværket is a new nitrogen factory, which will remove oxygen from the silo's wood pellets and atmosphere. This means challenging conditions for organic processes, and more importantly, it can prevent fire development. The nitrogen factory works in such a way that normal atmospheric compressed air is sent through special filters and containers that absorb the oxygen and allow the air's remaining nitrogen to pass.

For all the new initiatives, we are responsible for descriptions and tenders of the technical facilities, which must be manufactured specially for the purpose, says Jens Schaltz Bertelsen, who is project manager for the machine and process part :

We provide fairly detailed descriptions of the desired functions and help clarify all technical issues. In certain cases, we define the choice of material and ATEX-related aspects. At the same time, there is a task in designing all necessary piping, which connects the nitrogen factory to the silo.

The water mist system

If worst comes to worst, another new installation will come into effect, says Jens :

The nitrogen factory is part of plan A, while plan B is a water mist plant at the top of the silo. Once a fire is impossible to stop, the system can produce a large cooling cloud that will protect the roof structure.

Jens Schaltz Bertelsen Project Director Energy Plants Copenhagen

Jens Schaltz Bertelsen Project Director Energy Plants Copenhagen

As Jens points out, the nitrogen plant is one of several new installations that will come into play before plan B becomes effective, since the use of water has complications as mentioned and therefore is a last resort.

2,000 temperature measurements

Another assignment is a new fire detection system. From top to bottom of the silo, approx. 65 cables will be placed carefully with small temperature gauges attached for every metre all the way down through the wood pellet stack. This will give a total of approx. 2,000 temperature measurements. This way, the operating organisation can observe any kind of heat development in the sea of wood pellets and intervene in time by e.g. adding extra nitrogen. Here we have mapped the length and location of cables and defined the required number of measurements.

We have also made a presentation on how the system can be programmed and implemented in the plant's control system. In reality, we have enough temperature measurements to create a 3D model if desired, Jens elaborates.

The reconstruction

Our engineers in Aarhus are responsible for the structural aspects, and they model all structures in Tekla, which contains the project's master model. For this, the installation design is imported from Revit together with models from the programme Plant, which our specialists in machine and process use. The digital platform must be used in particular to coordinate the many interfaces. Large parts of both the silo and the transport facility survived the fire, and Ørsted mapped how much can be reused and what must be thrown away. Existing structures, installations and equipment must thus be combined with new parts, which makes this part of the project special, Jens concludes :

A contractor will probably find it easier to build a new facility from scratch using own well-known methods. But since we must ensure the greatest possible reuse of the materials, it will be our job to provide a solid knowledge base regarding the existing material, since the alternative will be too many unknown factors. It is not just about describing what is already there, but also how it can be connected to something new.

© Colourbox, Kenneth Bagge Jørgensen

The golden age of district heating

A thorough transition of Danish heat supply has gained renewed strength with the desire to become free of fossil energy. Planning is well under way, new district heating networks are being rolled out, and facilities for renewable energy sources are being established.

An impressive 1.8 kg CO₂e/m²/year. That is how much by which we are able to reduce the climate footprint for buildings that are supplied with district heating when making LCA assessments with the new emission factors that will apply from 2025. The updated factors are presented in a report that Artelia prepared for the Danish Authority of Social Services and Housing with data from the Danish Energy Agency. The prognoses show that climate impact from district heating will also decrease by approx. 80% from the period 20252075. The reason is the increasing use of renewable energy sources, which are used among other things with the help of the heat pumps we are helping to establish across the country.

The figures show clearly that district heating is already playing an important role, and that the expected development will become a central step in the green transition. After a number of years in which the area has not changed significantly, the attitude has turned 180 degrees, which is something we experience very much at Artelia with projects of different characters.

Planning in North Zealand

Once the decision has been made to roll out district heating to new areas, and an overall heating plan has been drawn up, more detailed planning is one of the next steps. Artelia is assisting Norfors with this process in four of the utility company's five owner municipalities.

A large part of the assignment is to examine the possibilities for establishing new facilities that operate on renewable energy. Several solutions are assessed carefully, including air-to-water heat pumps of 30 MW. Norfors has an ambitious plan to double its production capacity by approx. 130 MW district heating, which corresponds to a doubling of the current system and will supply many consumers with district heating instead of gas.

Based on the company's own suggestions for possible locations, we have examined nine different scenarios, where we have screened factors such as heat pump technology, environment, geotechnics and planning aspects. We have now entered the next phase, which is to prepare a project proposal that will be even more detailed regarding technique and will include calculations of company, social and user economy to assess the profitability of the project. With the help of the programme EnergyPro, we will also analyse how tomorrow's energy facilities can interact in the future network the best way possible.

The district heating network itself must be dimensioned at the same time, and here we use Termis for hydraulic analyses of both the future extension, the existing system and the coupling between them.

Client consultancy for Vestforbænding

A similar plan for the massive roll-out of district heating is a bit further ahead at the waste and energy company Vestforbrænding, which is going to establish district heating for 40,000 new consumers in the period 2023-2030.

Artelia is client consultant to the company in both phases of the large expansion, which includes distribution networks, branch lines and installations for the new district heating customers. The first phase consists of three programmes covering seven municipalities and will be executed by two turnkey contractors.

As client consultant, we will help coordinate the contracts, handle dialogue with authorities, hold meetings with the client, perform peer review and not least keep track of time and finances.

Detailed design in Nyråd and Ørslev Consultancy and calculations at the most detailed level characterise yet another large part of our numerous district heating projects. Two good examples can be found in South Zealand, where we assist the utility company Vordingborg Forsyning in converting supply in the two towns of Nyråd and Ørslev from gas to district heating. Here, we have detailed designed the new pipeline networks and put the assignment out to EU tender. We are now construction manager in the construction phase, which is well underway.

In addition, the two towns will be connected to the district heating network via two new transmission pipelines, which will connect to a much larger pipeline already familiar to us. Because in the past, we designed the transmission line which leads to the actual production facility on Masnedø and crosses under the strait Masnedsund. The pipeline was therefore established via directional drilling with assistance from our geotechnicians, who used field investigations on water to analyse soil conditions. The projects in Nyråd and Ørslev naturally extend from our previous efforts and years of experience in the district heating sector.

© Colourbox, #220

5 MW water-to-air heat pump in Vildbjerg Artelia was responsible for project proposal, authorities management, tender and application for financial support from the Danish Energy Agency. Owner / Vildbjerg Tekniske Værker

35

A greener road from A to B

Our cities are growing – both in population and in the number of daily users with errands in the city centres. That makes increasing demands on the cities’ infrastructure and transport offers which, at the same time, are important pieces in the municipalities’ climate and health goals.

36

We can all agree that it has to be easy, efficient and comfortable to move around in the city. At the same time, it has to be attractive to choose a mode of transport that promotes health and sustainability. In order to achieve these goals, Artelia cooperates with several municipalities to develop green mobility plans where options and solutions are examined to meet the mobility challenges of the future.

The green footprint

The mobility plans are based on a holistic approach, where it is important to achieve an optimal interaction between the different modes of transport in order to cover all relevant needs. The green element weighs heavily and is expressed by promoting climate-friendly modes of transport that encourage physical activity such as walking and cycling as well as public transport rather than car traffic :

The climate is definitely on the agenda, but so is health. We therefore work with a mobility hierarchy, where there is extra focus on the modes of transport that support physical activity and are the least harmful to the climate.

Jakob Høj Technical Director Mobility Copenhagen

The green mobility plans that Jakob and his colleagues contribute to are typically prepared in collaboration with other firms from the architecture or engineering industries that specialise in urban planning. This applies to Brøndby Municipality where Artelia, together with Urban Creators, is going to prepare a green mobility plan that plays into the municipality's climate policy.

We will start by uncovering the current conditions – the basic situation. Which junctions are important for the area, what are the travel times for cars and public transportation, and are there places with poor accessibility? We will then identify the challenges that arise in relation to achieving the goals and which tools are available in order to find possible solutions. It will all be gathered in a plan with scenarios and projects that the municipality's politicians can use in the further work, Jakob explains.

At Artelia, we are experts in data-driven analyses, while the work related to e.g. campaigns and graphic communication or the process with the municipality, involvement of focus groups, etc., will be handled by our business partners.

Continues on the next page

Walking, cycling and other climate-friendly modes of transport Electrical bicycles and other mainly climate-friendly modes of transport Public transportation Car-pooling and shared cars Electrical vehicles Fuel and diesel vehicles

37

Data show the way

To a great extent, mobility planning is about common sense and about creating options. Data helps us understand needs and options.

One of the primary data sources is the Danish National Travel Survey made by the Technical University of Denmark, which is based on ongoing interviews about Danes' traffic behaviours. We also use accessibility analyses in the model TPRejsetid, which can calculate and visualise travel times with public transport and car traffic between selected destinations. The different national, regional, municipal or urban traffic models are also important tools to predict the effect of the measures that are used in the mobility plans.

New does not necessarily mean better

One of the fundamental ideas is to focus on mobility needs rather than transport needs. This means that the primary focus is on how to move people from A to B instead of on the modes of transport themselves, which paves the way for coordinating across modes of transport. When we prioritise the tools available to achieve mobility goals, we work with a 4-stage model :

It is, for example, preferable to get commuters to park their cars in the outskirts of the city and take public transport to the centre instead of expanding the road network. It makes sense both in an economic and sustainability context, explains Jakob.

International demands

Outside the borders of Denmark, there is also a demand for greener solutions to mobility challenges. Artelia contributes with our qualifications within mobility planning, e.g. in Norway as part of the development of the new climate-neutral district Nyhavna in Trondheim as well as in Riga, where we have prepared a mobility strategy in collaboration with the architects from Gehl.

Impact on the need for traffic and choice of transport mode Efficient use of existing infrastructure Improvement of existing infrastructure Establishment of new infrastructure 1 2 3 4

From plan to reality

The joy of mobility in Odense Odense Municipality aims for Odense to be a vibrant city with clean air and less noise. The city and city centre must still be accessible by car to ensure a well-functioning city with an active and attractive business life. This is reflected in the city's green mobility plan with ambitions to influence citizens' transport habits towards cycling or public transport, where Odense Light Rail plays an important role. A high proportion of electric cars and lower speed on roads will help reduce private and business transportation and emit less noise and particles.

Among other things, the goals must be achieved by changing deeply rooted traffic habits through physical planning and creating new climate-friendly urban spaces. Joy of mobility must be created among the city's users, and it must be easy and obvious to make the right choice when it comes to modes of transport.

The team behind the green mobility plan for Odense is led by Urban Creators and in addition to Artelia, it consists of Gehl and EY. The team won the task in a parallel assignment and will in the coming years work with the realisation of projects and initiatives in the mobility plan.

CO₂ reduction in Copenhagen

It is the ambition of Copenhagen to be the world's first CO₂-neutral capital, and traffic obviously plays an important role if the goal is to be achieved. Within the next few years, new transport options will become available with the light rail and new metro lines, but with an expected increase in both population and car ownership, there is also a need to look at other solutions.

Together with Urban Creators and EY, Artelia is carrying out a transverse analysis of the mobility in the capital area for the City of Copenhagen, the Capital Region of Copenhagen and KKR Hovedstaden (Capital Region Regional Council) up to 2035. The analysis will shed light on which measures to take in order to strengthen interconnected mobility, increase accessibility and create more climate-friendly transport across the capital area.

A significant part of the knowledge base and mapping of the traffic challenges in today's situation and for the development up to 2035 is illustrated on the basis of traffic model calculations with the City of Copenhagen's Compass model, which was developed by Artelia.

39

A dynamic environment where new medical products take shape

For 10 years, Artelia has assisted AGC Biologics who handles important steps in the comprehensive innovation process that characterises product development in the biopharmaceutical field.

© AGC Biologics 40

In the process of developing new medical products, it is a long way from when the first innovative idea is born in a research laboratory to a new medical product reaches the market. The process consists of several stages, and AGC Biologics specialises in helping pharmaceutical manufacturers in a number of the stages where the potential of new ideas must be explored and tested.

Globally, the company is a leading biopharmaceutical CDMO (Contract Development and Manufacturing Organisation). This means that AGC Biologics can also handle the actual production for the customers.

Over the years, this has led to the production of over 200 biological products for preclinical studies and commercial approval. Protein, gene and cell therapy are among the core qualifications of the company, which has facilities several places in Copenhagen and is rooted in a company that was founded in Denmark.

In 2024, Artelia has been a consultant to AGC Biologics for 10 years, and we have solved many tasks with one special common feature, says business manager Morten Gravgaard, who is overall responsible for the client relationship :

Since AGC Biologics produces and develops for other players, they have to be adaptable, which of course affects our work. It is a good example of the great flexibility you must have as a consultant in an industry with constant innovation.

Morten Gravgaard Business Manager Project Execution – Pharma Copenhagen

Design on the users’ terms

As Morten points out, the tasks illustrate the width of the qualifications in our Pharma & Life Science division. We are usually involved right from the early idea development and conceptual design to the implementation of the technical facilities.

This can be seen in one of our latest projects, which involved setting up a downstream laboratory in existing office premises. At an early stage, our process architects helped design the facilities and production flow right down to the individual work station in close collaboration with laboratory technicians and researchers.

Based on user input, several suggestions were drawn up for the future layout, and that gave great value, says Pernille Susgaard, who is department manager for Process Architecture :

Our inspiration comes directly from the users themselves, but we also have good experience with using that knowledge to set up several alternatives. They are often positively surprised to see how we can accommodate their needs even better in a completely different way than what they had originally imagined. It is layout on the users’ terms, but at the same time, we must use our expertise to offer a new perspective. Therefore, both the fourth and fifth user meetings are valuable.

As Pernille explains, the user experience must also be combined with the consideration for an efficient work flow and the many requirements that the biopharmaceutical field is subject to, including cGMP (Current Good Manufacturing Practice).

Scan to BIM

The conversion to laboratories required an upgrade of the ventilation system, which meant significant changes to a densely packed technical floor that supplies several parts of the building. At the same time, it was therefore necessary to establish a temporary supply facility that could uphold the operation of a critical production area while the other measures were implemented.

For several reasons, it was an advantage to carry out a 3D scan of the entire technical floor. The facilities were laser scanned in combination with a 360° photo registration to get a precise picture of the work area as a point cloud, which formed the basis for modelling both the current and future installations in Revit. By using the programme Revizto, both model and point cloud could be taken on the go, which made it easy to scrutinise the details on the site.

Continues on the next page

41

An intensive summer shutdown

The 3D model was one of the tools we used when planning an efficient construction process, which had to be carried out in 18 days during a summer holiday, during which operations were disrupted as little as possible. Shutdown is a discipline in itself, as everything must be organised in detail. It requires careful planning, an understanding of the mechanical processes and insight into the industry's workflows, which our pharma specialists have.

Just establishing a construction site alone is a challenge, as all work routes must be placed in a way that does not in any way compromise the requirements to cleanness in other areas. It requires very precise plans for how materials and craftsmen must enter and leave the building, Pernille explains.

Clean production environments

In the same property, Artelia has helped establish the actual production facilities. This comprises a so-called 6-pack unit with six bioreactors, made for single-use technology, which is replaced each time AGC Biologics has to produce a new product for a customer.

Production takes place in cleanrooms, which we have designed based on all the common regulations such as cleanability of the highest standards and a downward air flow, which means that the ventilation is established as floor suction. The ventilation qualification is also essential in our design of locks and changing facilities for the clean environments. Here, there is either positive air pressure or negative air pressure in the different rooms to eliminate the risk of particle contamination and cross-contamination.

The entire layout is of course covered by the cGMP requirements that apply in all geographic markets that AGC Biologics operates in.

The complexity of the technique

The machines in the production machinery are another one of our core qualifications. The process facility normally consists of custom-made deliveries with

special requirements, and our machine specialists’ job is, among other things, to design the many necessary supplies such as heating, cooling, electricity and water. During implementation, they help with testing, commissioning and, not least, qualification, which is the process by which it is confirmed and documented that the equipment comply with the requirements for pharmaceutical production.

In construction projects, the technical equipment is an important variable in a large picture, where factors change constantly due to the dynamics that characterise the activities of AGC Biologics and the pharmaceutical industry in general.

As a client consultant, I have helped assess the purchase of equipment, and it is obvious how the needs change constantly during the process. Our starting point must be that the design is not fixed until the construction is actually completed.

Pernille Susgaard Head of Department Process Architecture – Pharma Copenhagen

Pernille Susgaard Head of Department Process Architecture – Pharma Copenhagen

Pernille is supported by Morten : The prerequisites change all the time, and we therefore have to be very clear about the professional considerations behind each and every decision, so that we can go back and argue professionally for the choices that have been made. By having control of every link in the decision-making chain, we can better assess the exact consequences that a new change will entail. So, in addition to flexibility, the dynamics require a very high level of structure.

42

43

The art of climate adjustment

an = advanc3d 3quat1on

Climate-proofing is expensive, but so is damage caused by flood, which is why several economic considerations are at stake when assessing the level needed of climate-proofing against flooding.

A lot is at stake when complex challenges are to be solved. On one hand, finances must add up and on the other side, citizens and nature must be taken into account. There is no doubt that further climateproofing is imperative, but the question of where and how much is inevitable, seeing that climate changes are increasing.

A well-balanced solution

Artelia has helped Middelfart Municipality find the optimal balance.

First, we had to simulate flood from cloudburst in the entire municipality in order for the results to be applicable for pointing out risk areas in the climate-proofing plan that was released in 2022, says Lasse Bo Brinch, design engineer in Drainage & Civil Works.

In cases where cloudbursts pose a risk of flood, the sewerage works Middelfart Spildevand A/S was asked to assess how the sewer system may be optimised in order to secure the areas. Artelia was hired as consultant once again.

Together with Middelfart Spildevand A/S, we based our work on service level regulation 2276 and the accompanying guidance that contain a method to be used for calculating which solutions have fewest costs when determining the service level for handling rain water in a certain area. This means that costs for establishing and operating the initiatives throughout their lifespan will be assessed in relation to the damage that floods may cause in the same period depending on the efficiency of the solutions.

Specific suggested solutions

In order to determine the most balanced level for climate-proofing, specific suggested solutions must be prepared for

several different service levels in the risk area. Suggested solutions are then modelled and dimensioned in a hydrodynamic modelling programme where Artelia has used MIKE+. Based on that, construction and operation costs can be calculated. At the same time, potential costs for damage must be calculated based on the rainfall events that will exceed the service level in the entire lifespan of the facility in question. It is therefore necessary to calculate damage caused by several rainfall events for each of the service levels that are included in the analysis. That will result in a great deal of calculations.

In order to have the best basis for evaluating how to prioritise, we have provided more than 25 suggested solutions and conducted 100 flood calculations in MIKE+ in relation to the assignment in Middelfart

Lasse Bo Brinch Design Engineer Drainage Fredericia

The method used for the analysis of the service level for handling rainwater in a given area can also be used for potential flooding from e.g. storm surge or freshwater.

© Colourbox, Knud Erik Christensen

Flooding map 45

Culture in centre

When the transformation of the park Musikhusparken in Aarhus is completed, it will be an attractive green breathing space which will create a link between cultural institutions and strengthen the traffic connections in the city.

In cooperation with landscape architects Schønherr, biodiversity consultants Habitats and sculptor Morten Stræde, Artelia participates in the upcoming transformation of Musikhusparken which will form a vibrant gathering point for all inhabitants and guests of the city.

The interesting fusion between unique art, culture and urban development makes this urban space project very special.

Peter Hoy Head of Department Roads & Traffic Aalborg

Peter Hoy Head of Department Roads & Traffic Aalborg

The vision must be seen in relation to the future expansion of the art museum ARoS, The Next Level, which will include a new underground gallery and the creation Skydome made by the American artist James Turrell.

The art installation plays a central role in the consultancy team’s winning proposal where a large elliptical park originates from the green dome of Skydome. This main theme is called the Ring and will function as a unifying unit which will unite the cultural beacons by facing ARoS, the music house Musikhuset Aarhus, the dance theatre Bora Bora, the Officers' building with the music school Aarhus Musikskole and the building Ridehuset Aarhus. A park which will be ideal for both small and large concerts and events –including the annual Aarhus Festival Week.

Between ARoS and Musikhuset, ARoS Gardens will be established and consist of beds and small isotopes and will have room for stay and play. In connection with the Ring and the protected gardens by the city hall, a large, contiguous green area will be created.

Concerts, ice skating and water play Musikhusparken will form a busy gathering point for the entire city which is why traffic and accessibility are important parts of our services to ensure that all users of the area will have the best and safest experience – during the construction phase as well as when the project is finished. The project also includes project design of paths, open spaces and civil works.

Rainwater management is another one of Artelia’s qualifications that will help ensure that the selected solutions will withstand rainfall. Water will also be integrated as a natural part of the visual expression. Along the Ring, a stream runs and flows into the water artwork Vandkunsten¸ where people can play during the summer months, and during the winter months, a brand new skating rink can be used in the southern part of the Ring. The skating rink was realised based on a donation of DKK 20 million from the Salling foundations. This donation will also cover the establishment of a brand new playground and the completion of the park.

Both the skating rink, Vandkunsten and the need for holding concerts and events means that Artelia’s electrical engineers will incorporate the necessary power supply and install this in the most appropriate places.

Schønherr is general contractor on the project and handles the architectural part as well as the primary project management. Artelia is sub-consultant which means delivery of all engineering services, including project management, tender management, construction management, technical supervision as well as health and safety coordination.

The project is expected to be completed during 2025.

46

Owner / Aarhus Municipality funded by Realdania and the Salling foundations Team / Schønherr, Habitats and Morten Stræde © Schønherr

48

When The New SIMAC opened in September 2023, Svendborg got a new maritime landmark.

SIMAC is short for Svendborg International Maritime Academy. The educational building is established on the quay Nordre Kaj in Svendborg Harbour and forms an innovative and inspiring frame for approx. 900 students and their educators. Here, the ship’s officers, master mariners and marine engineers of tomorrow will be educated, and more experienced candidates are able to strengthen their qualifications via the academy’s further training programmes.

The building includes classrooms, two auditoriums, common areas, workshops, administration, technical room, etc. In addition, a new and advanced simulator centre will be established with a full-scale engine room and a bridge where projectors create a visual and realistic experience of being at sea.

The many functions in the building must operate and work together, and even though work is done on noisy machinery in the workshops or engine

rooms, it must still be quiet in the rooms where the theoretical training takes place. This made special demands on the technical solutions, and the process included a lot of user involvement to ensure a good acoustic environment for all users of the building.

Unhiding the hidden

Artelia was engineer on the construction which was designed by C.F. Møller Architects and EFFEKT. It was a clear ambition that the building had to reflect its purpose by referring to the maritime environment. The structure of the building is inspired by the cross section of a ship hull, and the raw concrete elements refer to the industrial buildings and ship masts in the area. In June 2023, the building won the concrete element award Betonelement Prisen for its trim structure design, which gives an open and transparent building that interacts with the surrounding maritime environment.

Continues on the next page

It required great accuracy in both the project design and the execution phases to achieve an elegant finish on things that would normally be hidden away behind walls and ceilings.

Sidsel Juhlin Head of Department Structures Copenhagen

49

The inspiration from the industrial and maritime environment is also seen in the way that all elements that are normally wrapped and hidden are now made visible. The installations are fully visible, and the concrete columns in raw concrete steal the spotlight both outside and inside the building. Both the architect, engineer and contractor have therefore had extra focus on aesthetics, including the appearance and hidden joints of the concrete, says design manager for structures, Sidsel Juhlin, who has nothing but praise for the parties to the project :

It required great accuracy both in the project design and the execution phases to achieve an elegant finish on things that would normally be hidden away behind walls and ceilings in a completed construction but are fully visible in this project. Everyone has made a huge effort to achieve the impressive result.

Technical challenges and local attention

The challenge with designing parts of the load-bearing structure on the outside of the facade is that some of the structure is cold while the rest is placed inside where it is hot. This may result in thermal bridges with the risk of creating condensation and damp. It required close cooperation between the structural engineer and the energy engineer to create a solution that would meet all needs.

The building consists primarily of regular modules, but several of the rooms are in double height to create visual variation in the building design and to contain the functions in the house that require high ceiling. The rooms in double height are staggered for each floor which means that none of the floors are alike, which also made extraordinary demands on the engineers’ calculations, Sidsel explains :

For a structural engineer, it was a challenging project because it was so unusual, but it was also exciting to think outside the box. We experienced that the project was known all over the city, and many people were curious and followed the development of the construction.

The New SIMAC was constructed by the private commercial foundation Fonden Svendborg Maritime Uddannelsescenter (SMUC) and was made possible thanks to a significant donation from, among others, the foundation Den A.P. Møllerske Støttefond. In addition, a large donation will be granted by Dampskibsselskabet Orient’s Fond as well as additional donations from, among others, Den Danske Maritime Fond, Lauritzen Fonden, Sydfyns Elforsynings Almennyttige Fond and Sydfyenske Dampskibsselskabs Fond.

50

Architect / C.F. Møller Architects General contractor / MT Højgaard Danmark © Rasmus Hjortshøj

Organisation and figures

Key figures for Artelia Denmark

Artelia Group

We are a part of an international multidisciplinary consultancy, engineering and project management group specialising in the sectors of building construction, infrastructure, water, energy and industry with over 8,500 employees. Artelia Group is organised in 10 business units and has offices in more than 40 countries.

Operating profit margin

Solvency ratio

Average number of full-time employees

EcoVadis – Eco-label for the entire Artelia Group

Artelia has been awarded a Platinum EcoVadis, which is the highest level of recognition within the EcoVadis rating system. This rank puts Artelia among the top 1% of more than 100,000 evaluated companies in 175 countries.

Ecovadis is the leading global supplier of sustainability evaluations for companies. Their evaluation system covers 21 CSR indicators distributed between four main themes : environment, work and human rights, ethics and sustainable procurement.

Austria, Czech Republic, Germany, Italy, the Netherlands, Portugal, Spain, Switzerland, United Kingdom Australia, Cambodia, Indonesia, Malaisia, Mexico, Philippines, Singapore, Thailand, Vietnam PRINCIPIA – SHER – SPRETEC Algeria, Ivory Coast, Egypt, Emirates, Guinea, India, Madagascar, Morocco, Oman, Rwanda, Saudi Arabia QUADRIC – SECOA Belgium, Switzerland PCSI – RFR Monaco – GANTHA Denmark, Norway DR. TECHN. OLAV OLSEN Asia Pacific Europe & Retail Nordics Buildings, French Regions & Equipment Buildings, Greater Paris Region Industrial Facilities Urban & Regional Development, France Mobility & Infrastructure Water, Energy, Environment & Africa, Middle East Canada FNX-Innov

Revenue

0 150,000 300,000 450,000 600,000 750,000 900,000 1,050,000 1,200,000 t. DKK 2020 2021 2022 2023 0.00 1.25 2.50 3.75 5.00 6.25 7.50 8.75 10.00 % 2020 2021 2022 2023 0 5 10 15 20 25 30 35 40 % 2020 2021 2022 2023 0 150 300 450 600 750 900 1,050 1,200 2020 2021 2022 2023

Buildings

Business areas

Energy & Industry

Infrastructure

Artelia Denmark We are geographically organised in 11 divisions. The three business areas Buildings, Energy & Industry and Infrastructure are represented in all geographical units, and we exchange knowledge and qualifications across all offices.

Board of Directors

Executive Board

Finance, IT, R&D, HR, Education, Legal, Communications

Division Aarhus Division Aalborg Division Zealand Division Pharma Division Southern Denmark

QHSE

Client Project Manager

Project Team

Project organisation

Artelia has a simple and clear project organisation. Individual projects are handled by a project manager leading a project team. The project manager is overall responsible for the contact with the client and reports to the project owner.

Project Owner

Copenhagen Division Transport Division Civil Works & Environment Division Consultancy & Specialist Services Division Energy & Industry Division Technology & Design Division Sustainability & Design

Copenhagen Buddingevej 272

2860 Søborg +45 4457 6000

Vipperød Skimmedevej 10

4390 Vipperød +45 5911 0077

Næstved Marskvej 29

4700 Næstved +45 5572 0907

Vordingborg

Næstvedvej 1

4760 Vordingborg +45 5537 1600

Odense

Wichmandsgade 5D, 1. tv. 5000 Odense C +45 7593 5030

Fredericia Bødkervej 7A

7000 Fredericia +45 7593 5030

Aarhus

Mariane Thomsens Gade 1C

8000 Aarhus C +45 8750 8700

Aalborg

Østre Havnegade 18, 1. th.

9000 Aalborg +45 9812 1911

Alex Fraenkel CEO Artelia Denmark

Alex Fraenkel CEO Artelia Denmark

New North Zealand Hospital

On the 123,000 m² hospital construction, Artelia is responsible for DGNB auditing, sustainability management, indoor climate, daylight, environmental consultancy, climate adaptation, etc.

Owner / The Capital Region of Denmark Architect / Herzog & de Meuron and Vilhelm Lauritzen

Autodesk Forma Artelia started using the AI-based software for design analysis at an early stage. The tool can e.g. be used to investigate aspects that are of great importance to the consideration of sustainability.

TRÆ in Aarhus 20-floor office building in timber and recycled materials.

Owner / PFA Pension and Kilden & Hindby Architect / Lendager

New North Zealand Hospital

On the 123,000 m² hospital construction, Artelia is responsible for DGNB auditing, sustainability management, indoor climate, daylight, environmental consultancy, climate adaptation, etc.

Owner / The Capital Region of Denmark Architect / Herzog & de Meuron and Vilhelm Lauritzen

Autodesk Forma Artelia started using the AI-based software for design analysis at an early stage. The tool can e.g. be used to investigate aspects that are of great importance to the consideration of sustainability.

TRÆ in Aarhus 20-floor office building in timber and recycled materials.

Owner / PFA Pension and Kilden & Hindby Architect / Lendager

Reduction Roadmap

Artelia, EFFEKT and Cebra are behind for Reduction Roadmap, which translates the climate goals set in the Paris Agreement into annual reduction goals for Danish constructions. The tool is supported by Realdania and VILLUM FONDEN.

Woodhub in Odense Denmark's largest timber construction, which will be an office hub for 1,600 government workspaces.

Owner / The Danish Building and Property Agency General contractor / NCC Architect / C.F. Møller Architects © NXT

Reduction Roadmap

Artelia, EFFEKT and Cebra are behind for Reduction Roadmap, which translates the climate goals set in the Paris Agreement into annual reduction goals for Danish constructions. The tool is supported by Realdania and VILLUM FONDEN.

Woodhub in Odense Denmark's largest timber construction, which will be an office hub for 1,600 government workspaces.

Owner / The Danish Building and Property Agency General contractor / NCC Architect / C.F. Møller Architects © NXT

Nyhavna in Trondheim

The old industrial port in Norway's third largest city will be transformed into a completely new district. In the project, we work closely together with our Norwegian colleagues from Dr.techn. Olav Olsen.

Owner / Nyhavna Utvikling

Nyhavna in Trondheim

The old industrial port in Norway's third largest city will be transformed into a completely new district. In the project, we work closely together with our Norwegian colleagues from Dr.techn. Olav Olsen.

Owner / Nyhavna Utvikling

Kim Schwartzlose Executive Director Artelia Denmark Responsible for international development

Kim Schwartzlose Executive Director Artelia Denmark Responsible for international development

Waste-to-energy facility in Nuuk and Sisimiut Project design of steel for two incineration plants, which help solve Greenland's significant waste challenges and at the same time produce district heating and hot water for the inhabitants in the two cities.

Waste-to-energy facility in Nuuk and Sisimiut Project design of steel for two incineration plants, which help solve Greenland's significant waste challenges and at the same time produce district heating and hot water for the inhabitants in the two cities.

Lars Jørgen Pedersen

Plot Owner

Fieldwork in waders.

Lars Jørgen Pedersen

Plot Owner

Fieldwork in waders.

Meesha

Meesha

Aziz Hüdai Idil Senior Consultant Asset and Facilities Management Copenhagen

Aziz Hüdai Idil Senior Consultant Asset and Facilities Management Copenhagen

Jens Schaltz Bertelsen Project Director Energy Plants Copenhagen

Jens Schaltz Bertelsen Project Director Energy Plants Copenhagen

Pernille Susgaard Head of Department Process Architecture – Pharma Copenhagen

Pernille Susgaard Head of Department Process Architecture – Pharma Copenhagen

Peter Hoy Head of Department Roads & Traffic Aalborg

Peter Hoy Head of Department Roads & Traffic Aalborg