U-SOA Design & Make 2024

Digital Fabrication Workshop for a Full-scale Wood Pavilion

U-SOA Design & Make 2024

Hidden Forrest

Professor in Charge

Design Team

Yonghyun Yu, AIA, LEED AP, WELL AP

Sueon Lee

Sunggeun Bae

Jinwoo Yoo

Eunbi Kim

Construction Consultant

Carpentry Advisor

Dongwon Jeon (FINE ARCHITECTURE CO.)

Sookyu Kim

Dongseok Jeong

CNC Operator

Jinsoo Kim (M-BOX)

FOREWORD

Transformative Force in Architectural Education

INTRODUCTION

Pedagogical Model

The Site Competition Proposal

DESIGN DEVELOPMENT

Generative Algorithm

FOREWORD

Transformative Force in Architectural Education

In the realm of contemporary architectural education, design-build programs have emerged as a beacon of innovation, offering an unparalleled hands-on learning experience. These programs serve as a vital bridge, seamlessly connecting theoretical knowledge with practical application, and immersing students in the full spectrum of architectural practice, from conceptualization to construction.

Unlike traditional studio projects, design-build initiatives culminate in tangible structures, allowing students to witness the physical manifestation of their design decisions. This process not only unveils the challenges inherent in bringing a project to life but also reveals the profound rewards that accompany such endeavors.

This particular educational model, combined with contemporary technology, becomes the framework of the U-SOA Design & Make 2024 program. The possibilities of digital fabrication have been explored in a multi-dimensional way and helped students as future architects and designers to push the boundaries of traditional wood construction and perception of materiality.

During the fall semester of the 2024 academic year, I had the privilege of leading the program and mentoring students in the entire process of the U-SOA Design & Make, from design competition to full-scale experiments and realization. The structure and content of the 2024

program is carefully designed to provide students with a transformative experience that shapes the next generation of architects into skilled, socially responsible professionals ready to tackle the challenges of our built environment.

As we look to the future of architectural education, design-build programs stand out as a crucial component in preparing students for the complexities of professional practice. Within this perspective, the U-SOA Design & Make program serves as effective complements to our existing design studio curriculum.

This publication is intended to document the overall process of the U-SOA Design & Make 2024 program and the tremendous enthusiasm of the participating students demonstrated throughout this semester-long event. Without their hard work and dedication, this program would not have been such a success.

I extend my deepest appreciation and warmest congratulations to all the students who participated in this wonderful educational journey.

Yonghyun Yu, AIA, LEED AP, WELL AP Professor of Architecture University of Ulsan

INTRODUCTION

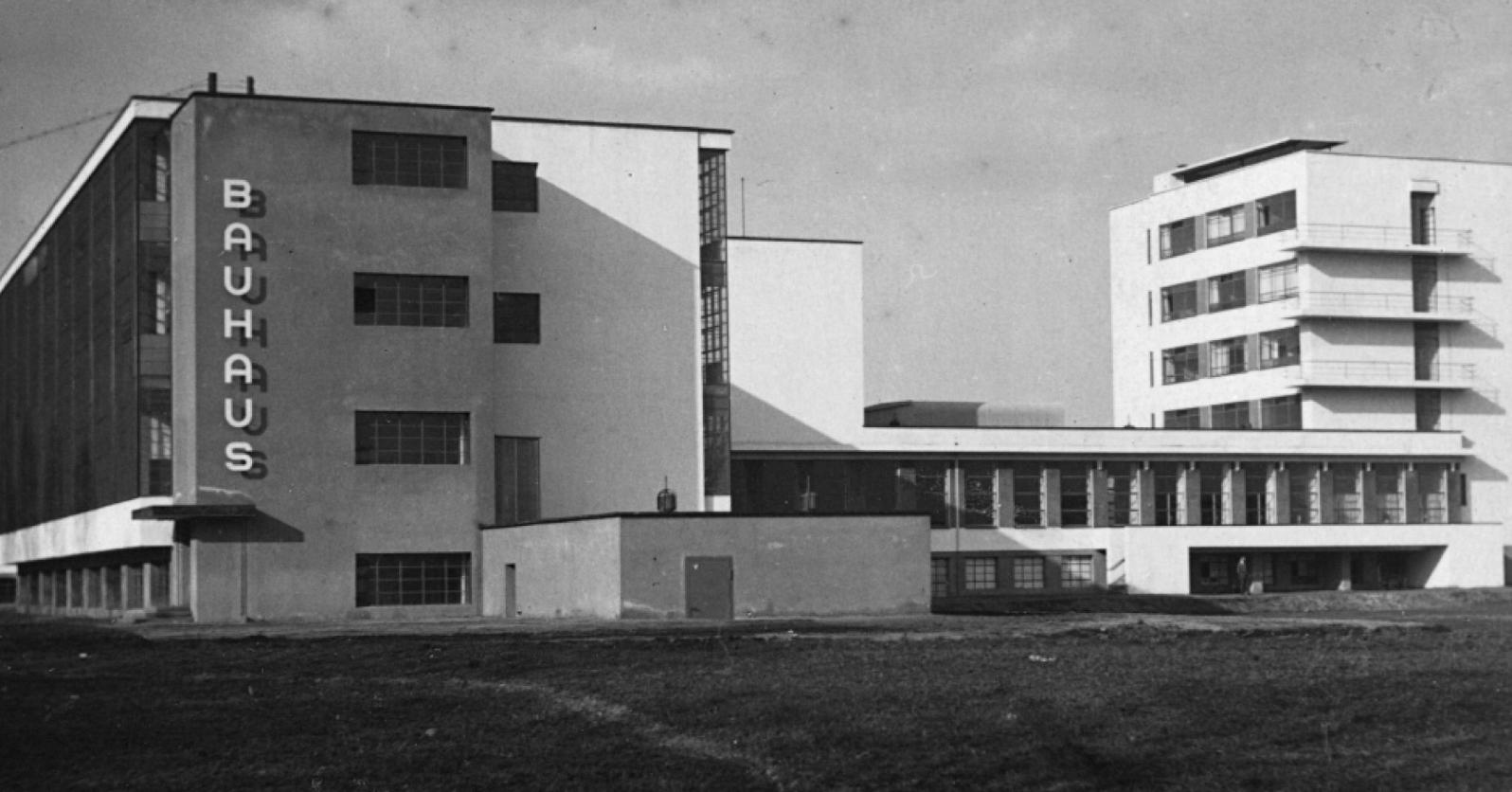

“Let us create a new guild of craftsmen, without the class distinctions, which raise an arrogant barrier between craftsman and artist. Together, let us conceive and create the new building of the future, which will embrace architecture, sculpture and painting in one unity and which will rise one day toward heaven from the hands of a million workers like the crystal symbol of a new faith.”

Walter Gropius - Proclamation Weimar Bauhaus, 1919

Hidden Forrest

Weimar Bauhaus Building and Curriculum Diagram

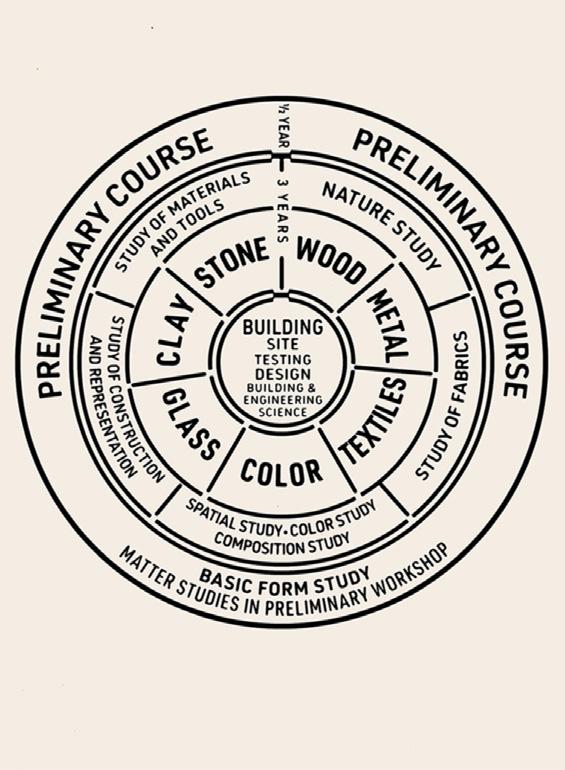

PEDAGOGICAL MODEL

The design-build pedagogical model in architectural education represents a return to the integrative approach that characterized the historical practice of architecture, where design and construction were inseparable. This model offers exceptional educational value and promotes excellence in architecture by providing a comprehensive, hands-on learning experience.

The success of design-build programs is evident in their global adoption. From Europe to North America, the Middle East and Asia, these programs are revolutionizing architectural education worldwide.

Summer Pavilion, Aalto University

Wander Wood Pavilion, University of British Columbia

Hidden Forrest

Re-Emerge Pavilion, Architectural Association School of Architecture

Temporary Plywood Pavilion, Waseda University

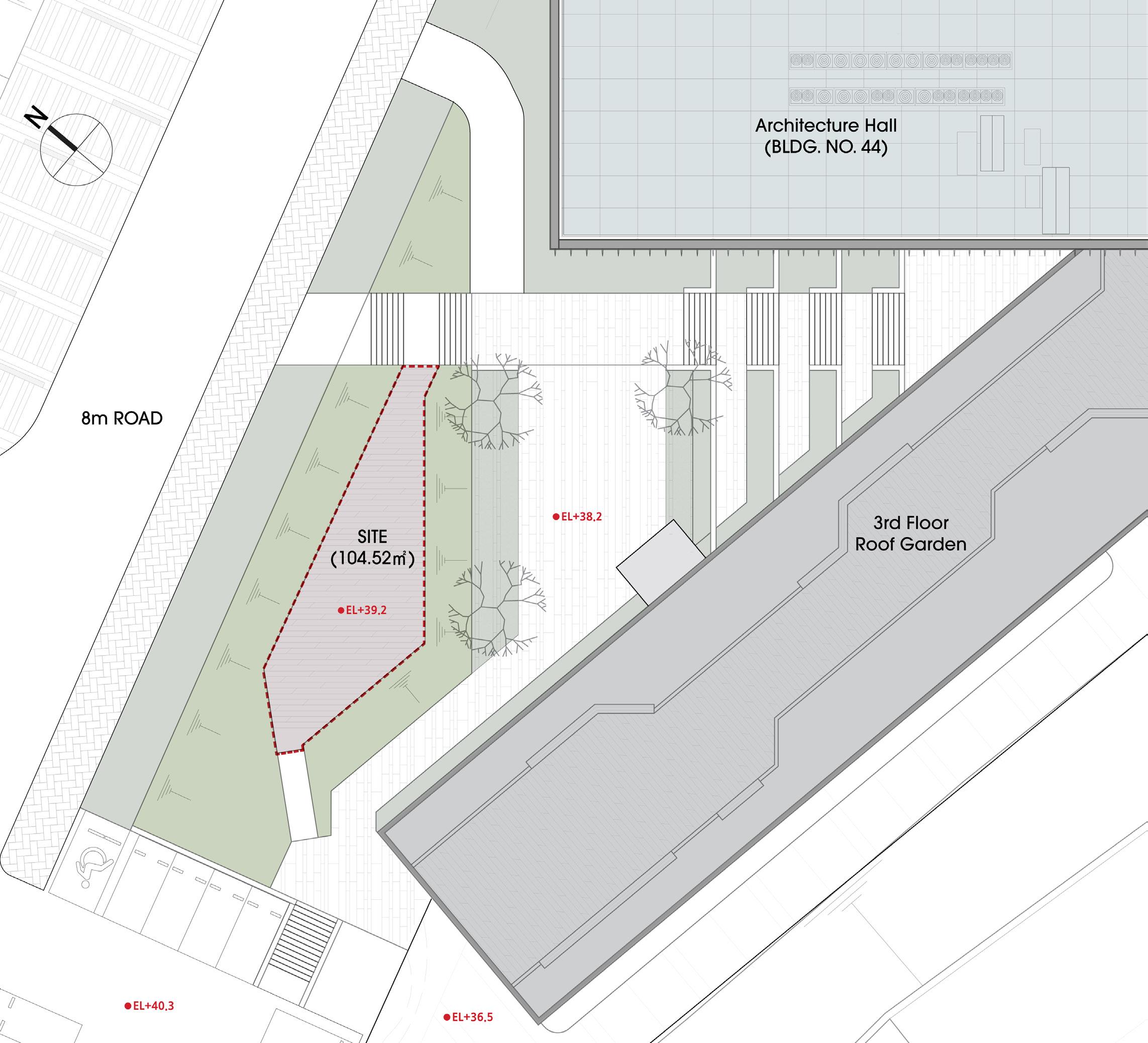

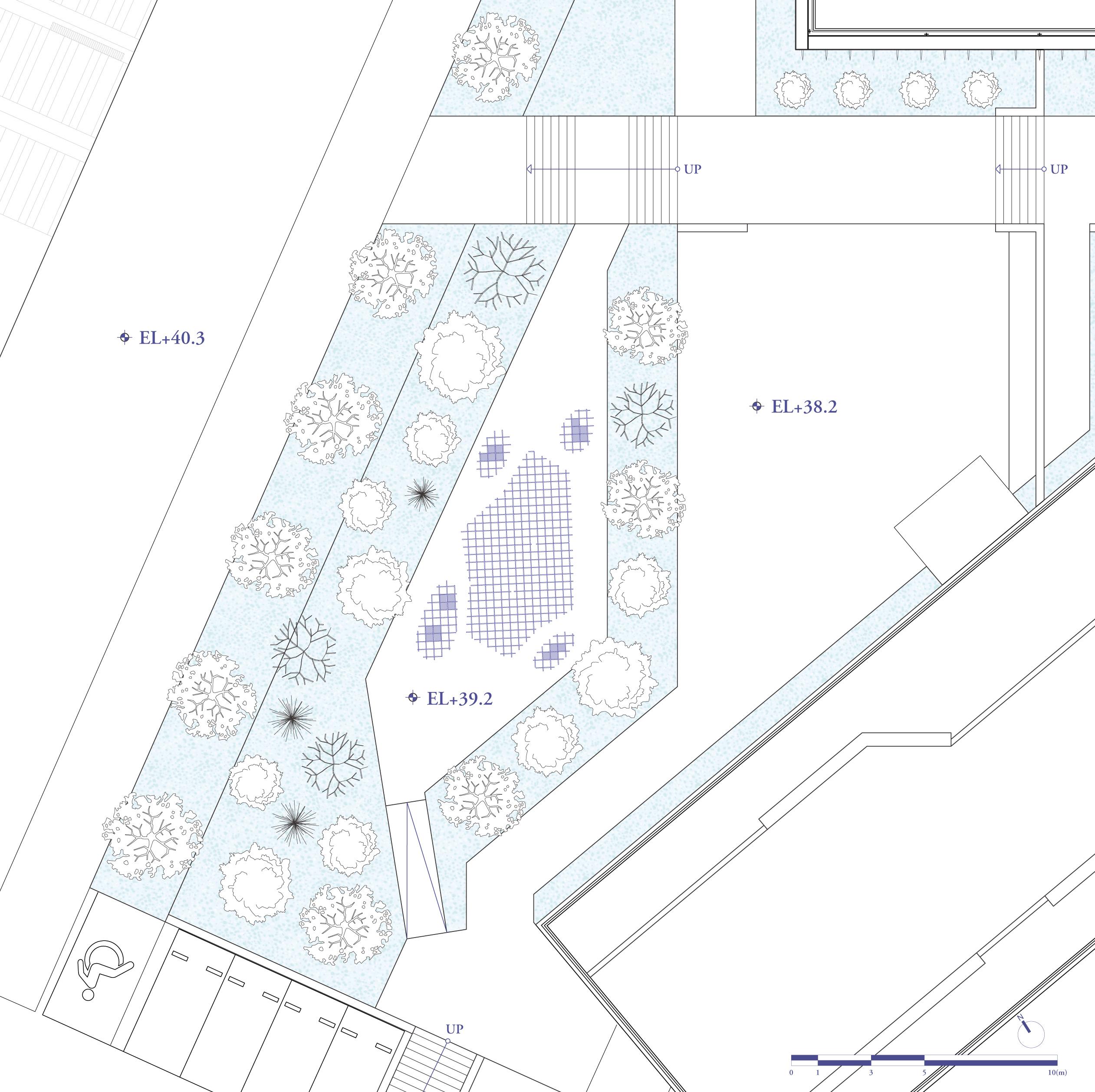

THE SITE

The abandoned exterior space around the Architecture Hall (Building No.44), with a total area of 104.52m2, was selected as the project site for the U-SOA Design & Make 2024 experiments.

Despite its proximity to a well-traveled student pathway, the site remained largely unnoticed and underutilized by passersby. However, the unique topography, landscape, and anomalous shape of the site presented numerous intriguing opportunities for architectural intervention.

These features offered the potential to transform the neglected space into a vibrant outdoor environment with a distinct sense of place.

Hidden Forrest

Hidden Forrest

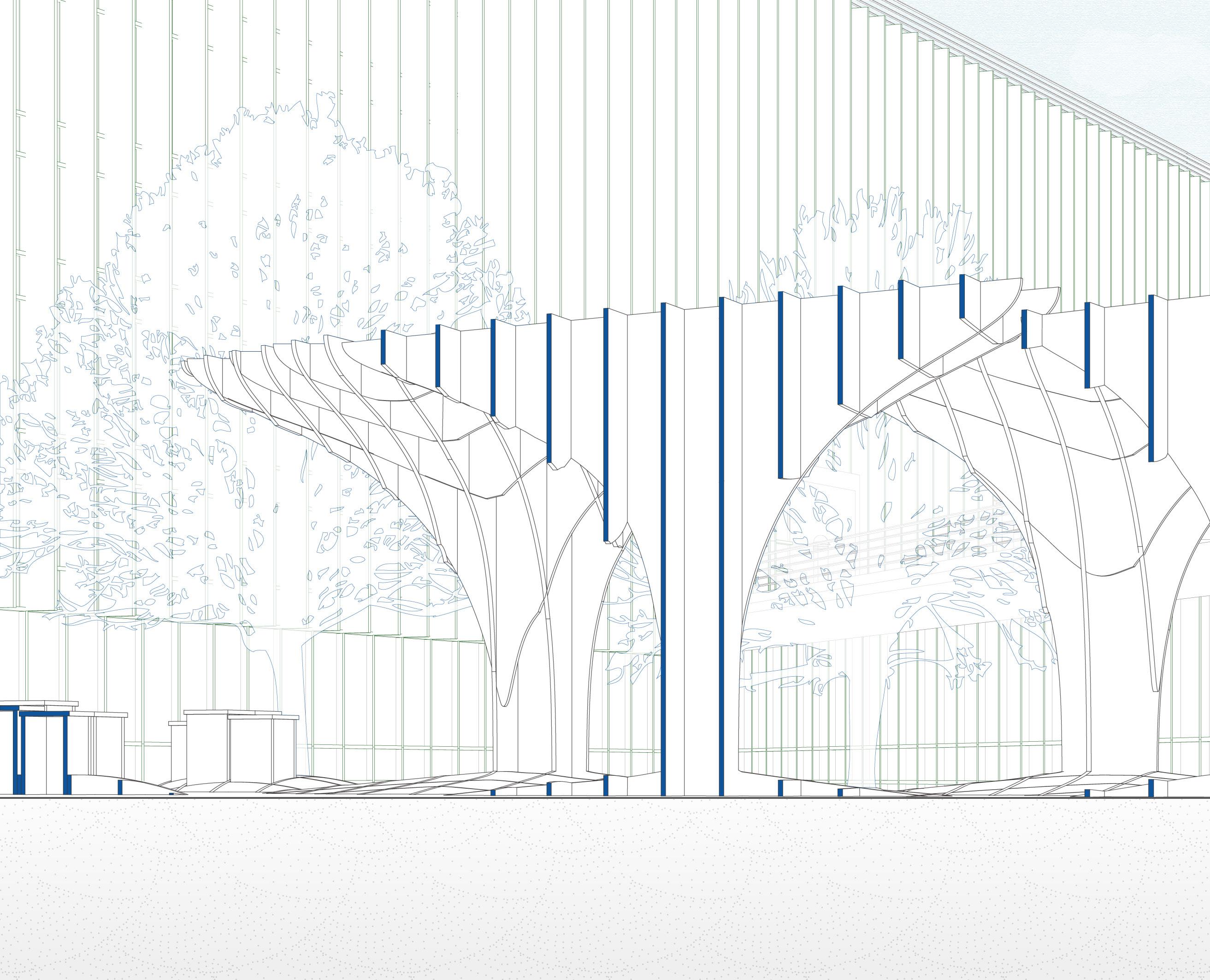

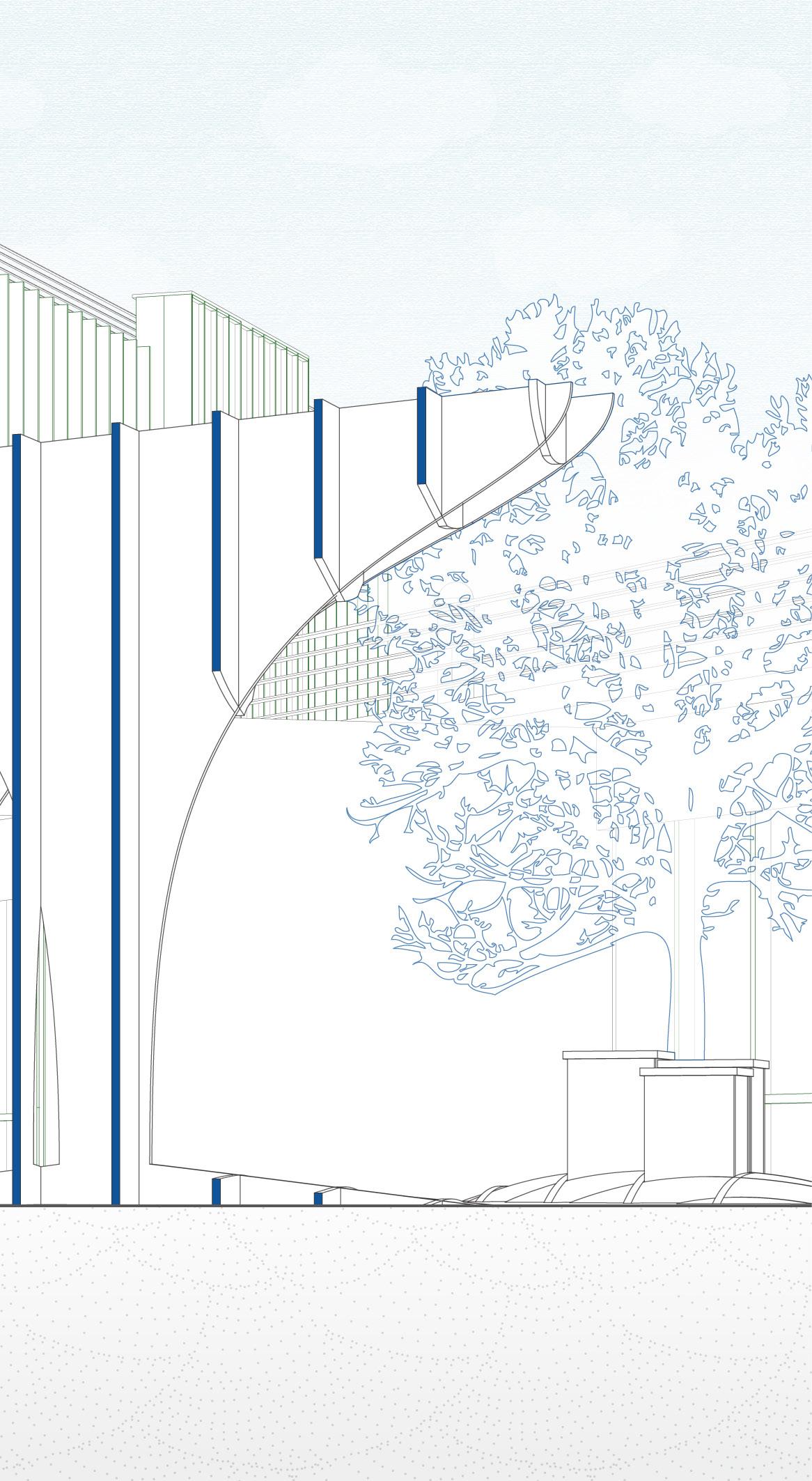

COMPETITION PROPOSAL

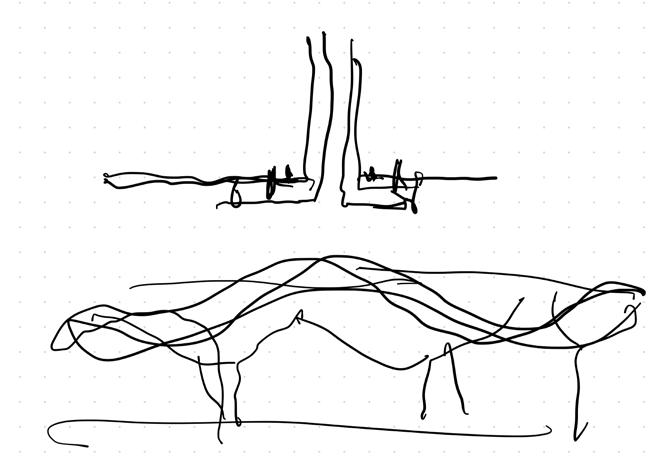

The winning design was selected from five submissions in the U-SOA Design & Make 2024 design competition. The winning team’s interpretation of the site as a “hidden courtyard” proved to be a pivotal element of their proposal.

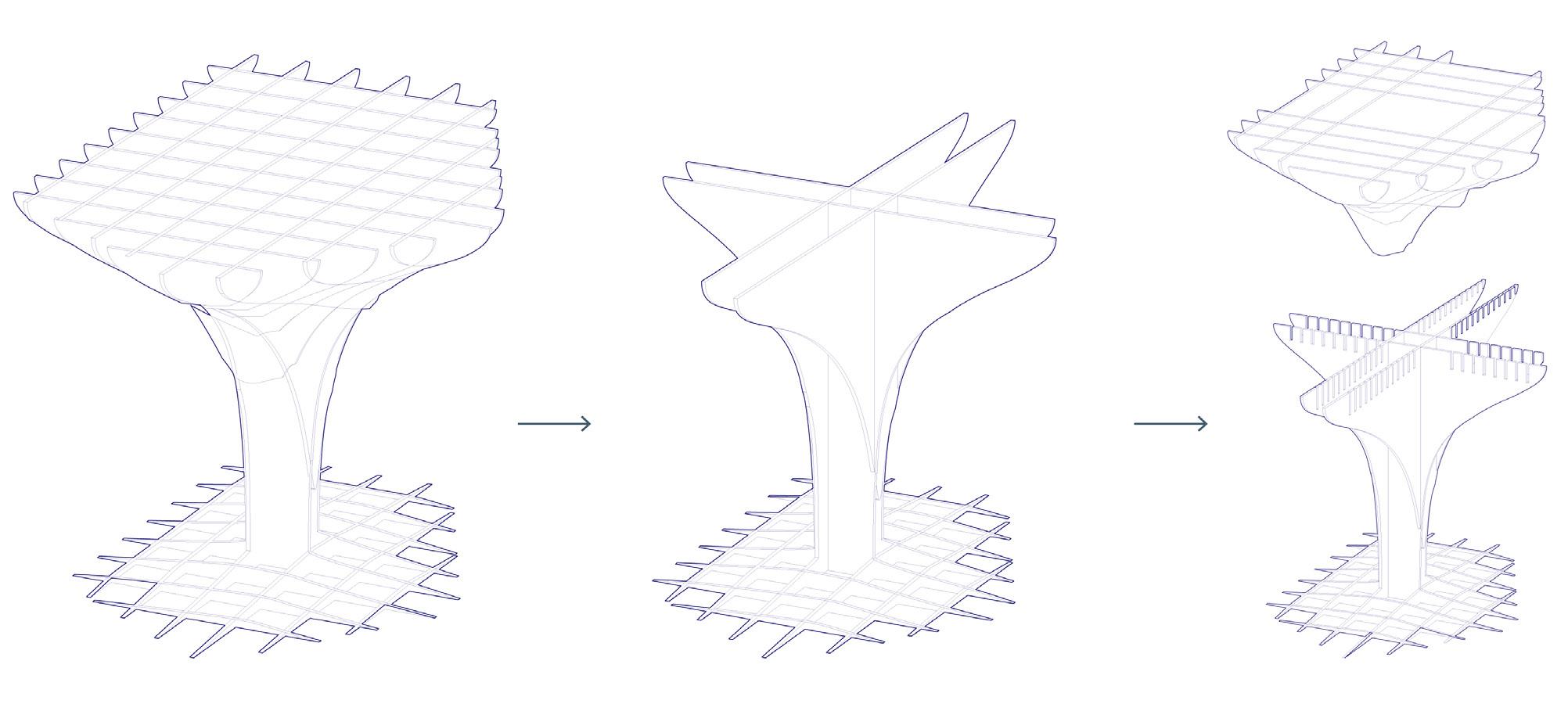

Their design featured a pavilion with a tree-like structure, crafted to envelop visitors in a warm and welcoming embrace upon discovering this hidden place. The concept aimed to transform the space into a cozy retreat, inviting those who passersby to experience a sense of place and seclusion within the campus landscape.

Hidden Forrest

AI Generated ‘Courtyard’ Image by the Winning Team, #Traditional / #Backyard / #Korean

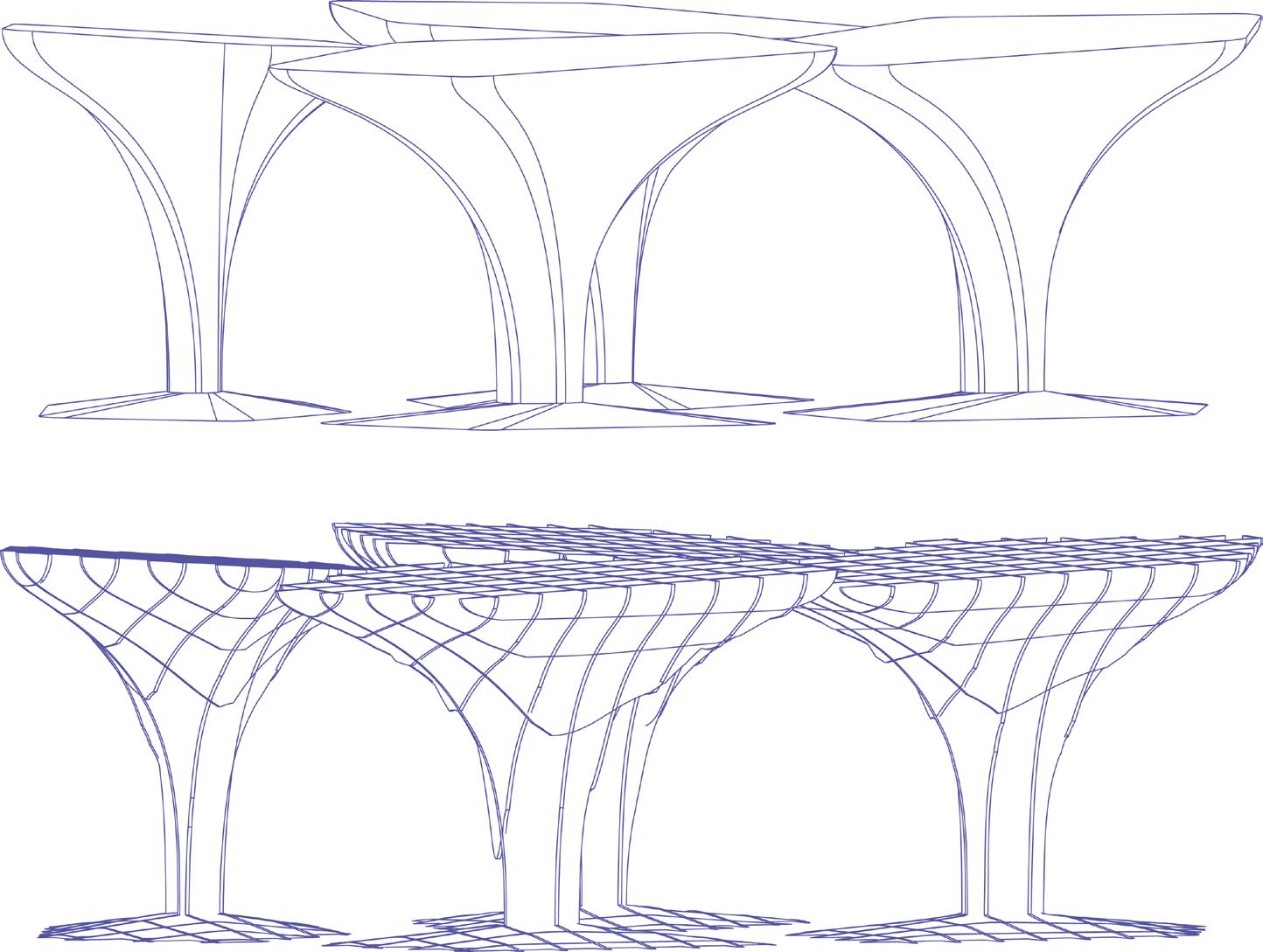

TREE STRUCTURE

STONE

STOOL

PAVING

Hidden Forrest

Hidden Forrest

SURFACES

DESIGN PROCESS

STRUCTURE & ASSEMBLY STRATEGY

Hidden Forrest

Hidden Forrest

DESIGN DEVELOPMENT

Hidden Forrest

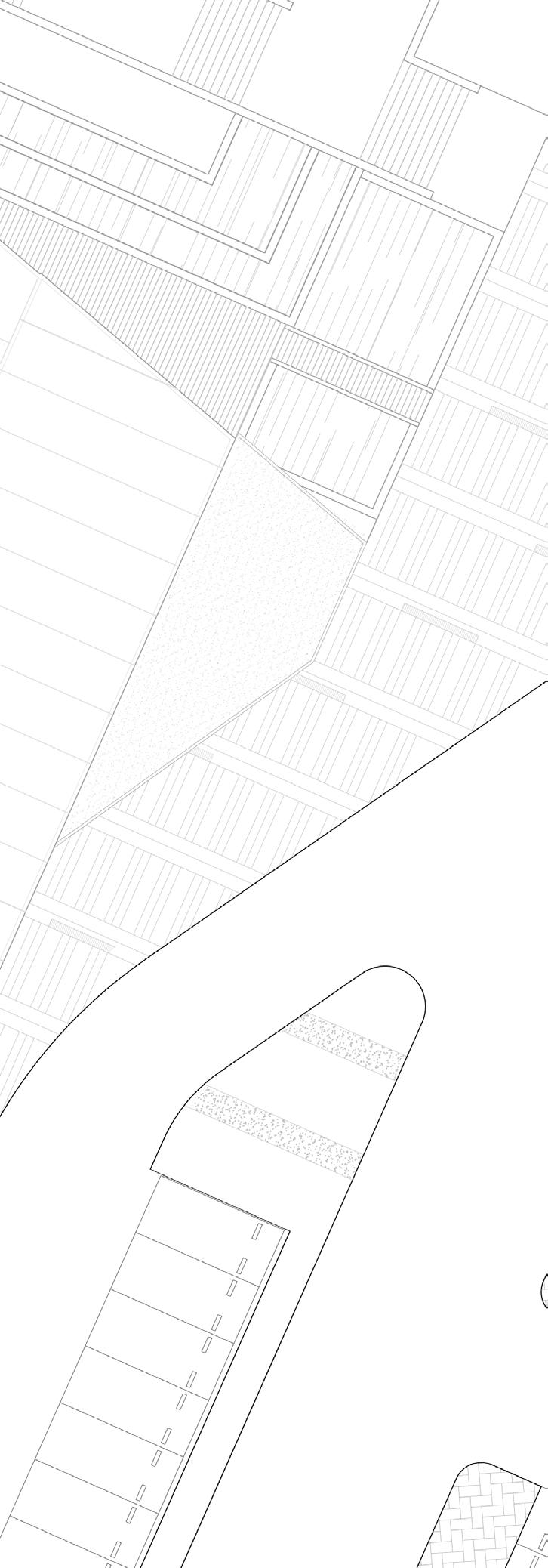

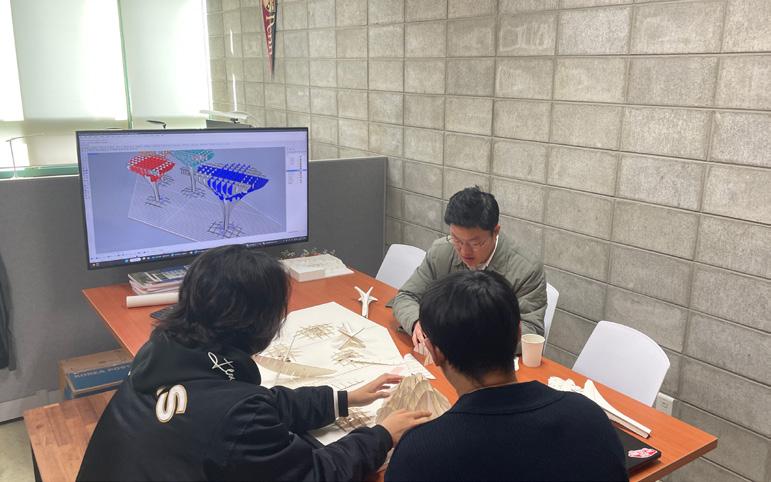

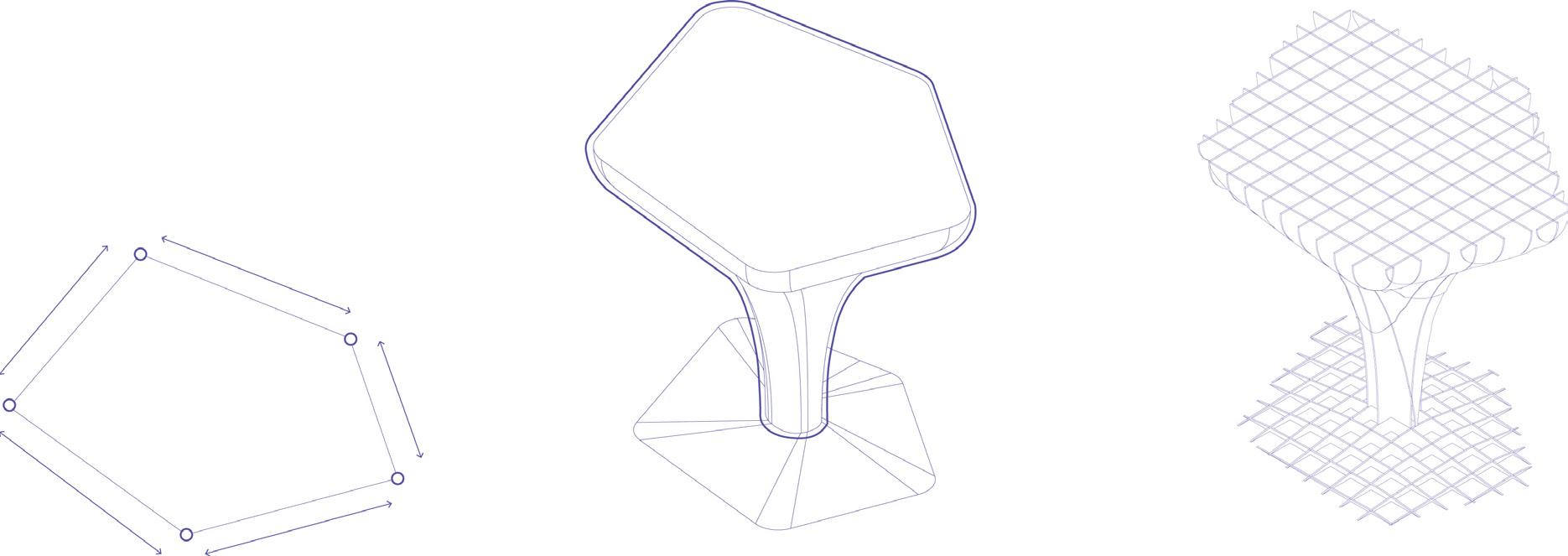

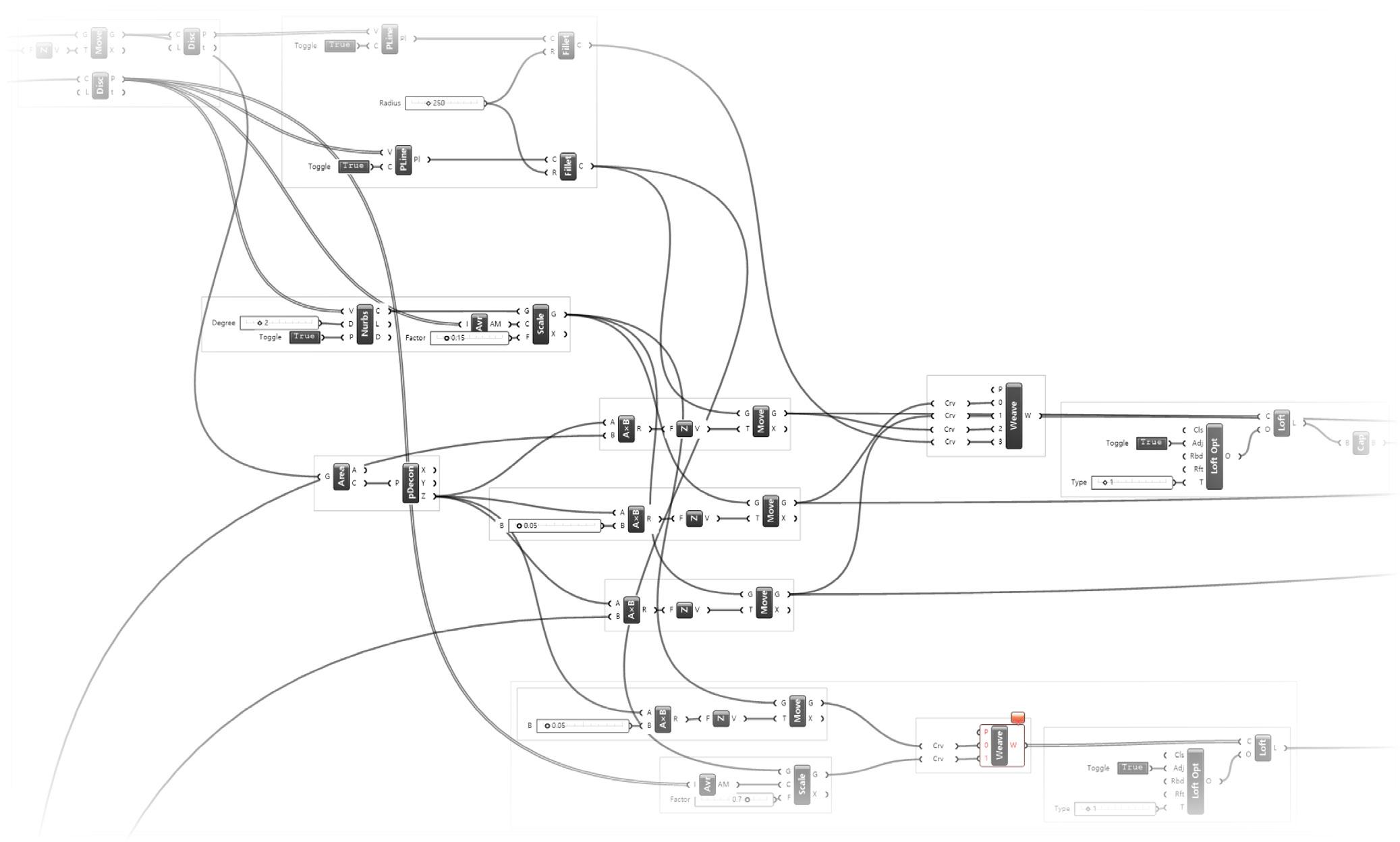

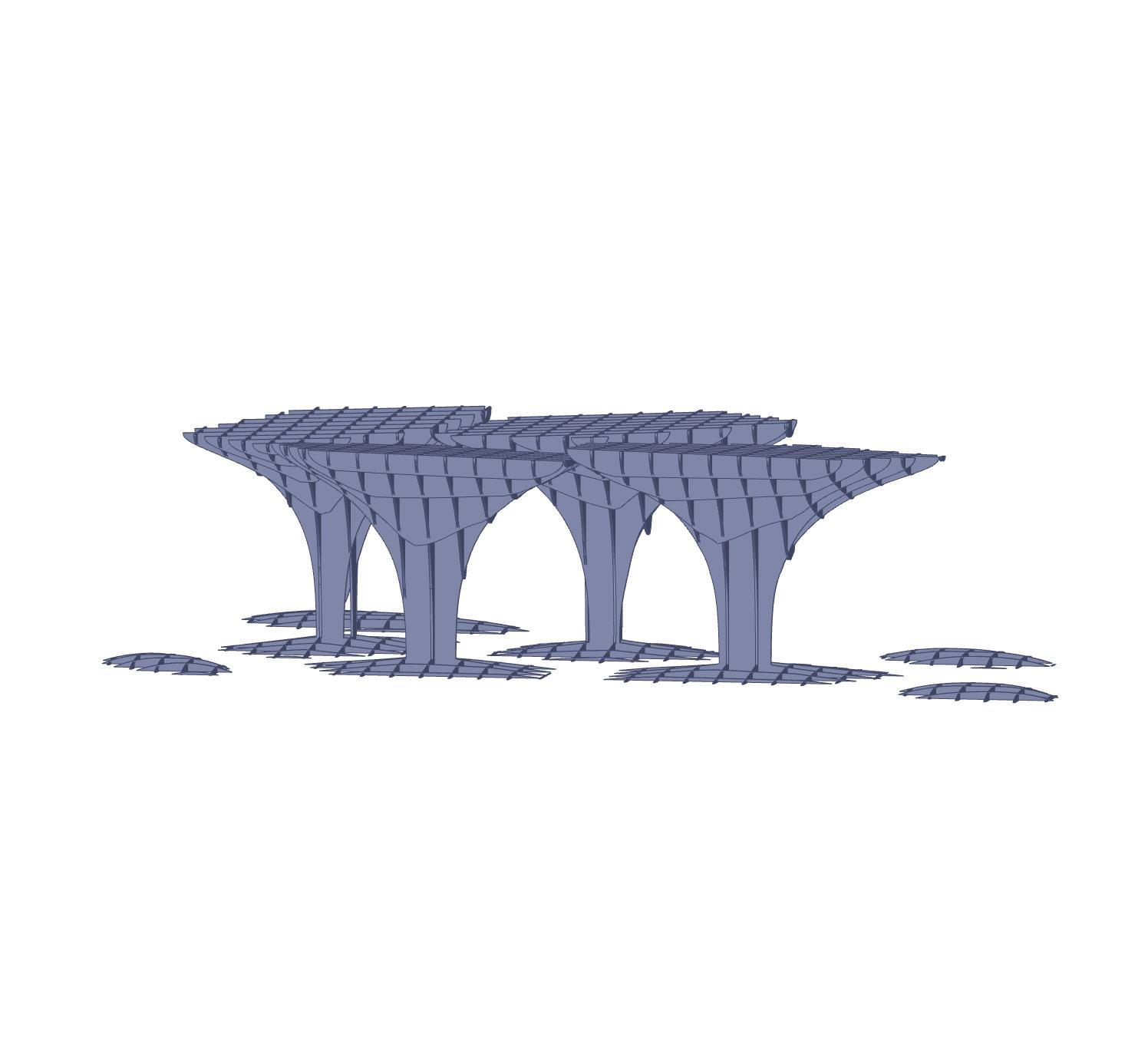

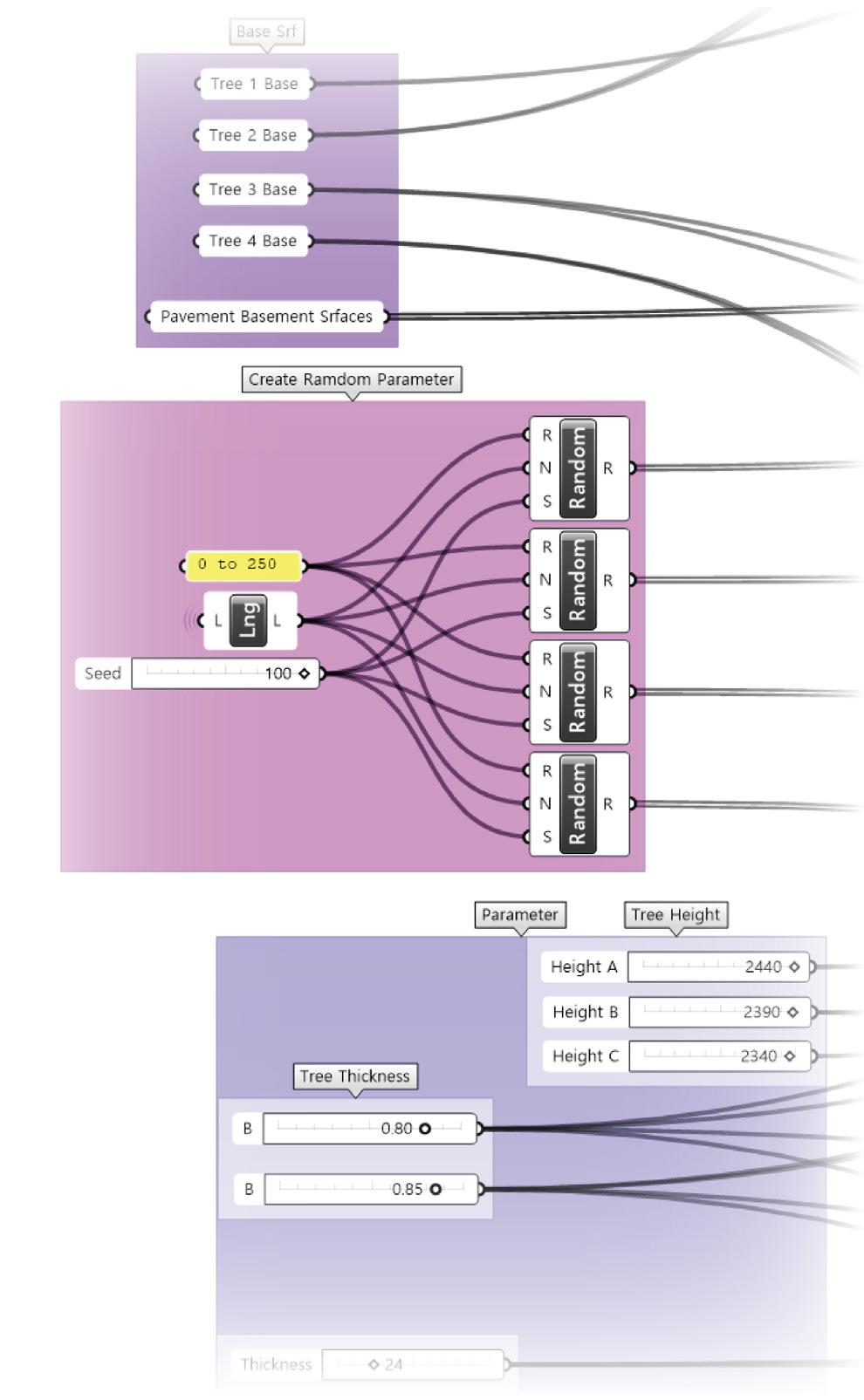

GENERATIVE ALGORITHM

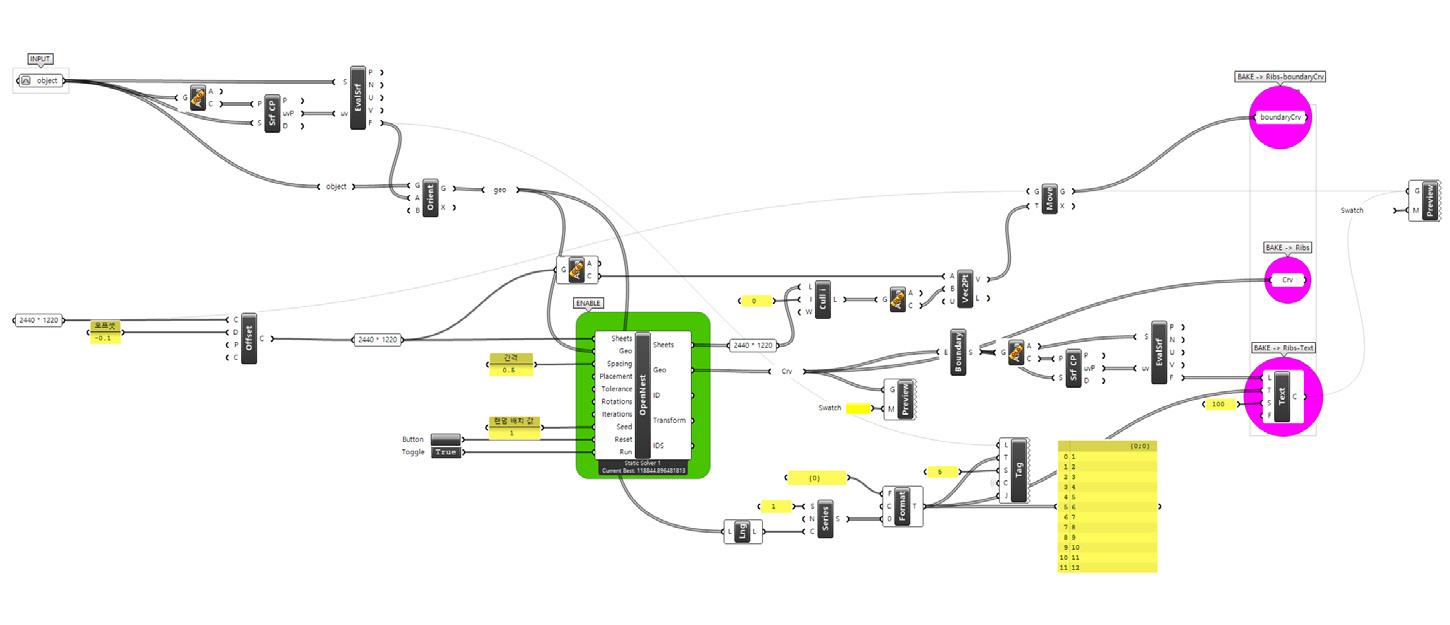

Grasshopper’s generative algorithms allow architects and designers to explore a wide range of design possibilities quickly and efficiently. Using these parametric tools, students can generate numerous iterations and variations of their concepts.

This approach also facilitates easy adjustments and modifications throughout the design development process. As the design progresses and new constraints emerge, construction details can be developed in a way that rapidly responds to new requirements and addresses various buildability issues.

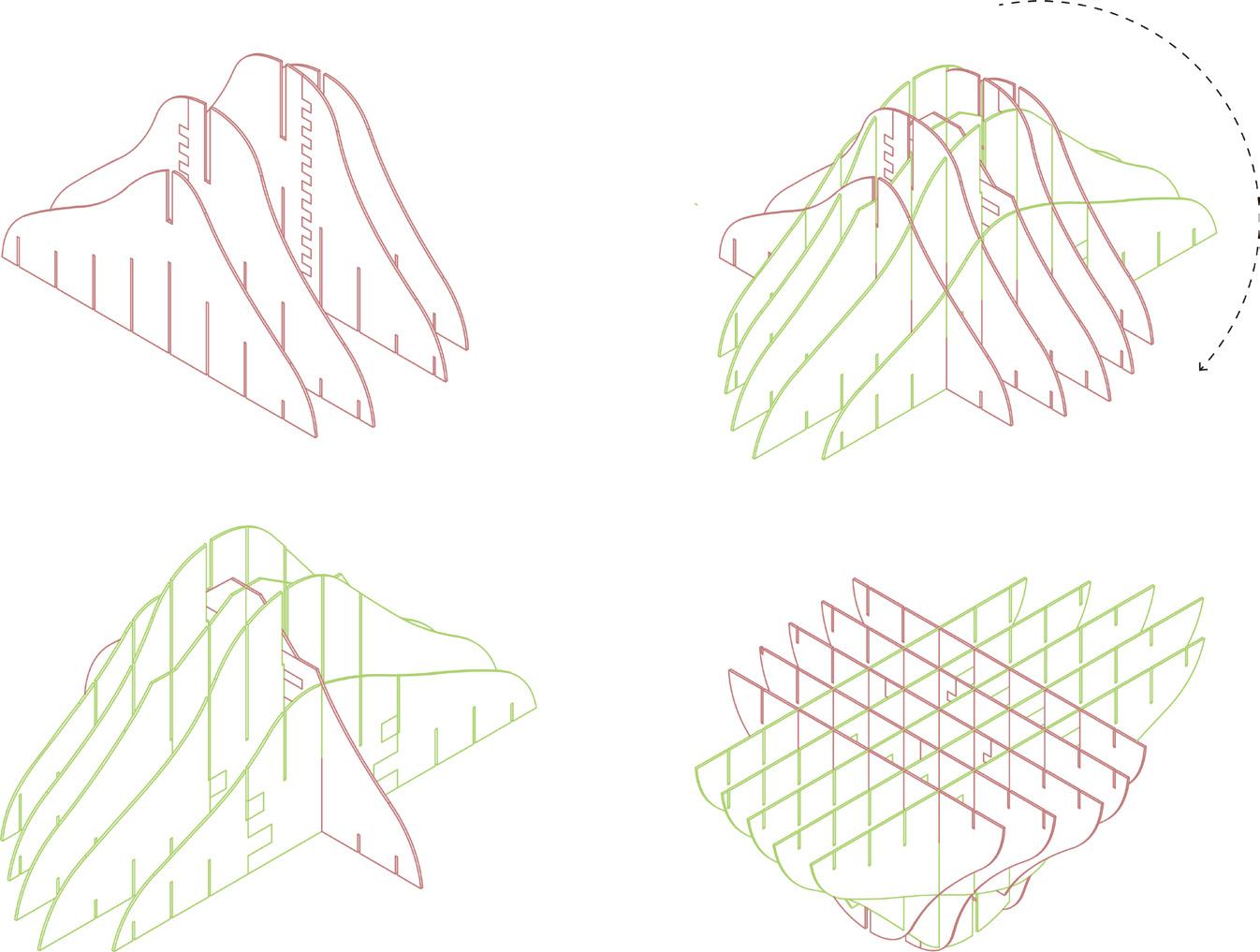

BASIC SURFACE

ORGANIC FORM WAFFLE STRUCTURE

GENERATIVE ALGORITHM & DESIGN SCRIPT

Hidden Forrest

Hidden Forrest

DESIGN VARIATION STUDIES

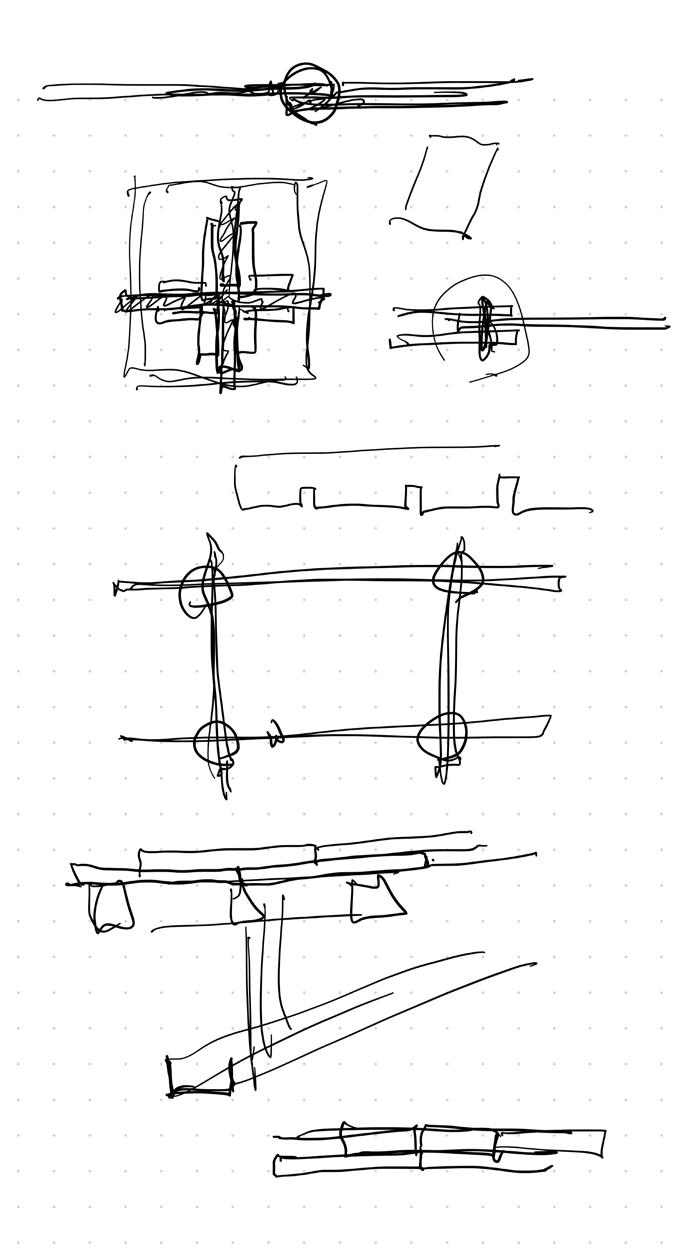

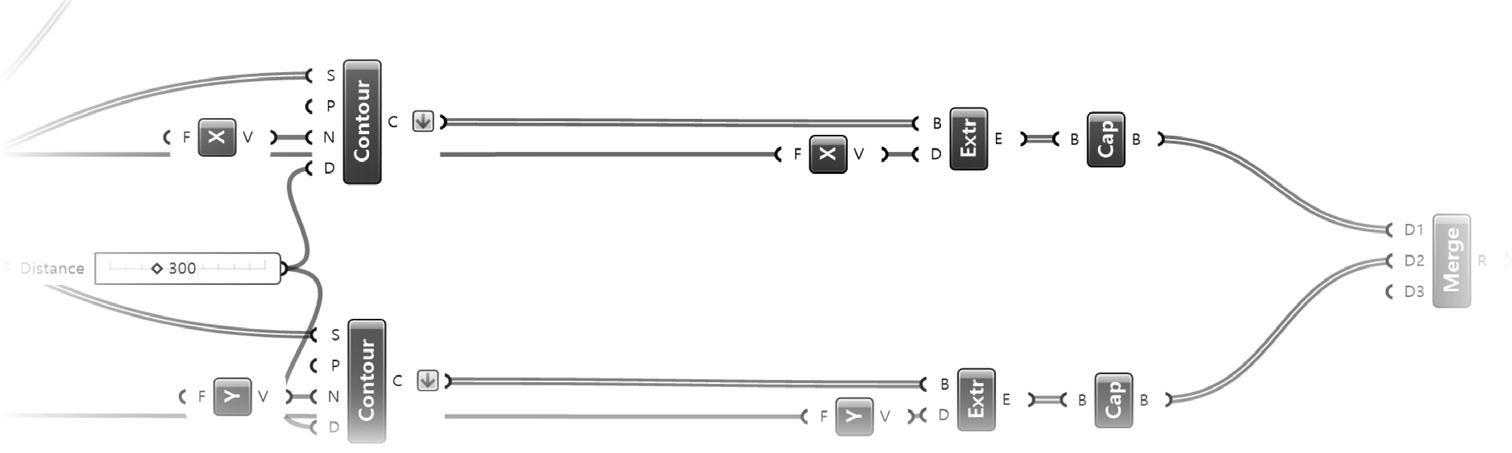

STRUCTURAL LOGIC - CONTOUR ON X·Y PLANE

Hidden Forrest DESIGN PARAMETERS

DETAIL DESIGN

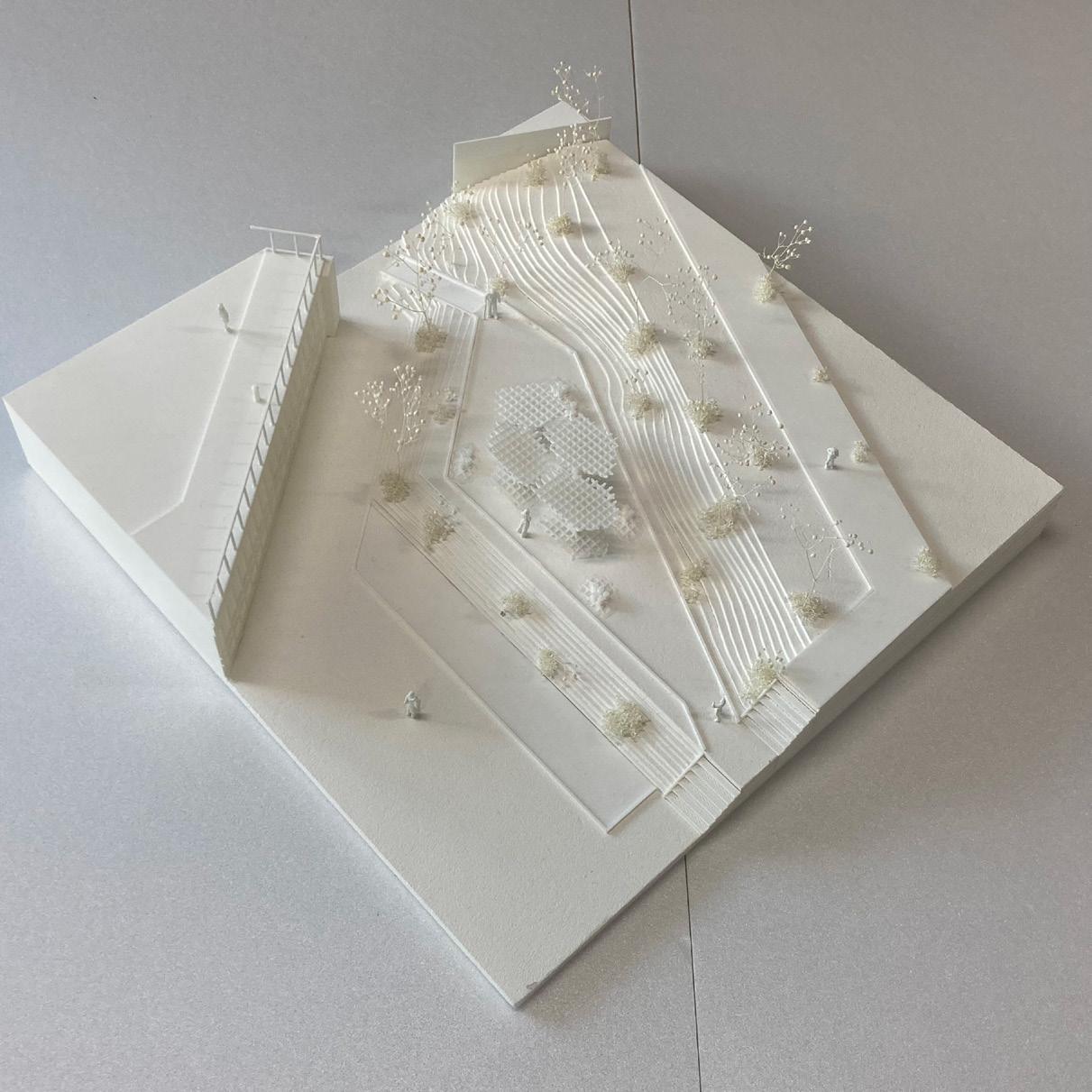

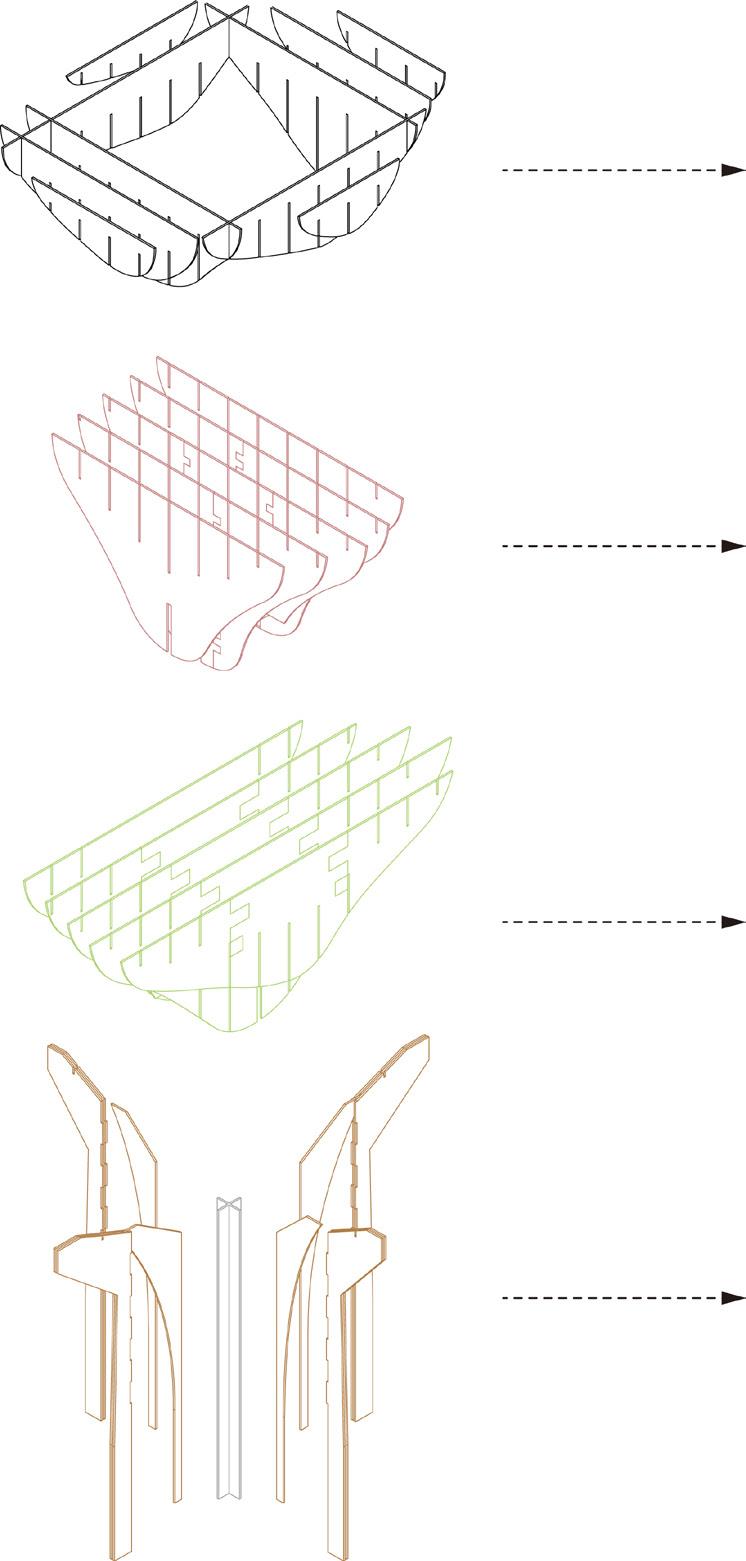

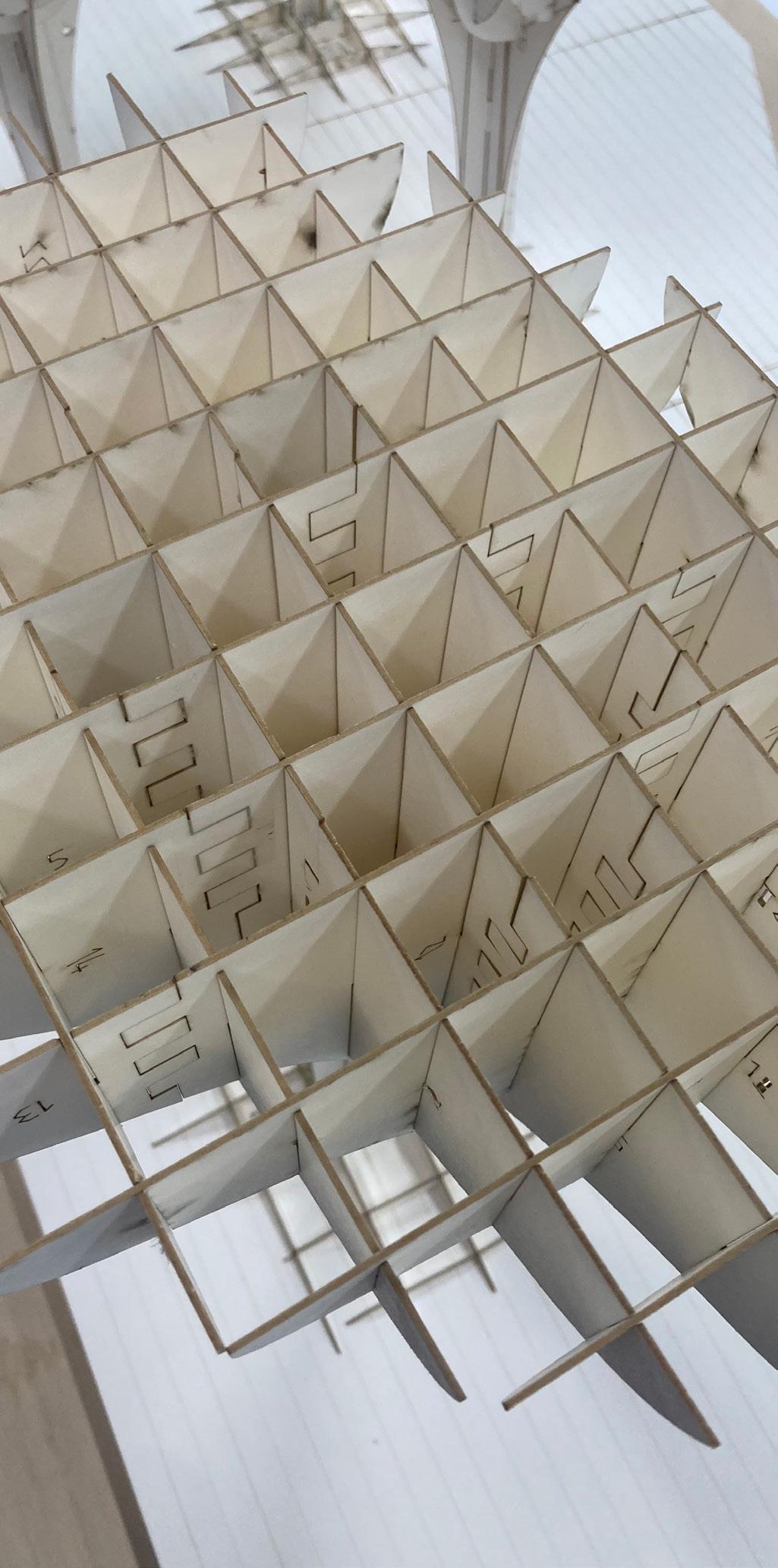

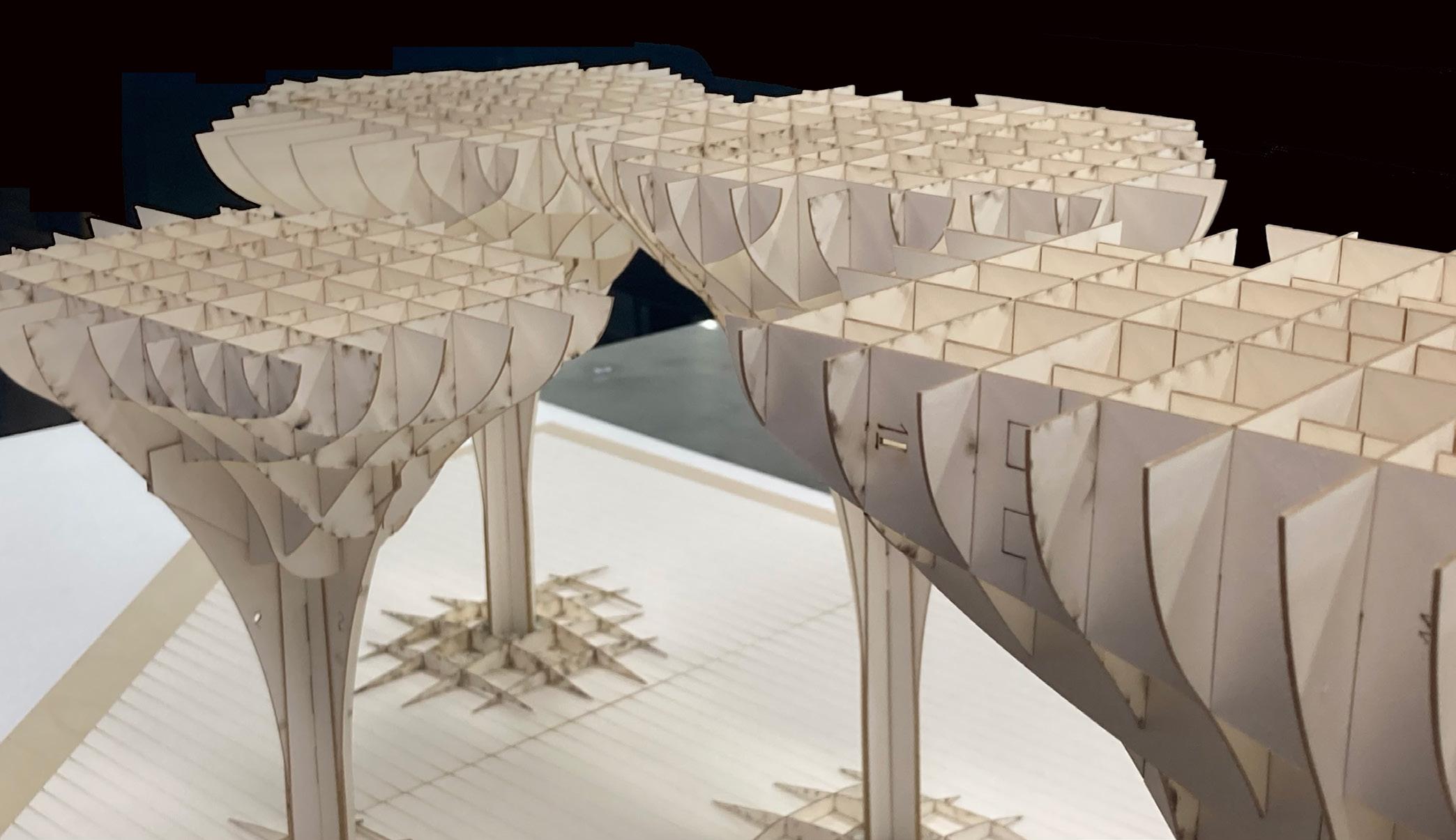

The pavilion structure is composed entirely of CNC cut wooden components. During the development of the construction details, careful attention was devoted to the tolerances of the connections and joints. The construction sequence was also meticulously planned to ensure that the design was seamlessly translated from concept to reality.

CORE STRUCTURE ASSEMBLY WORKFLOW

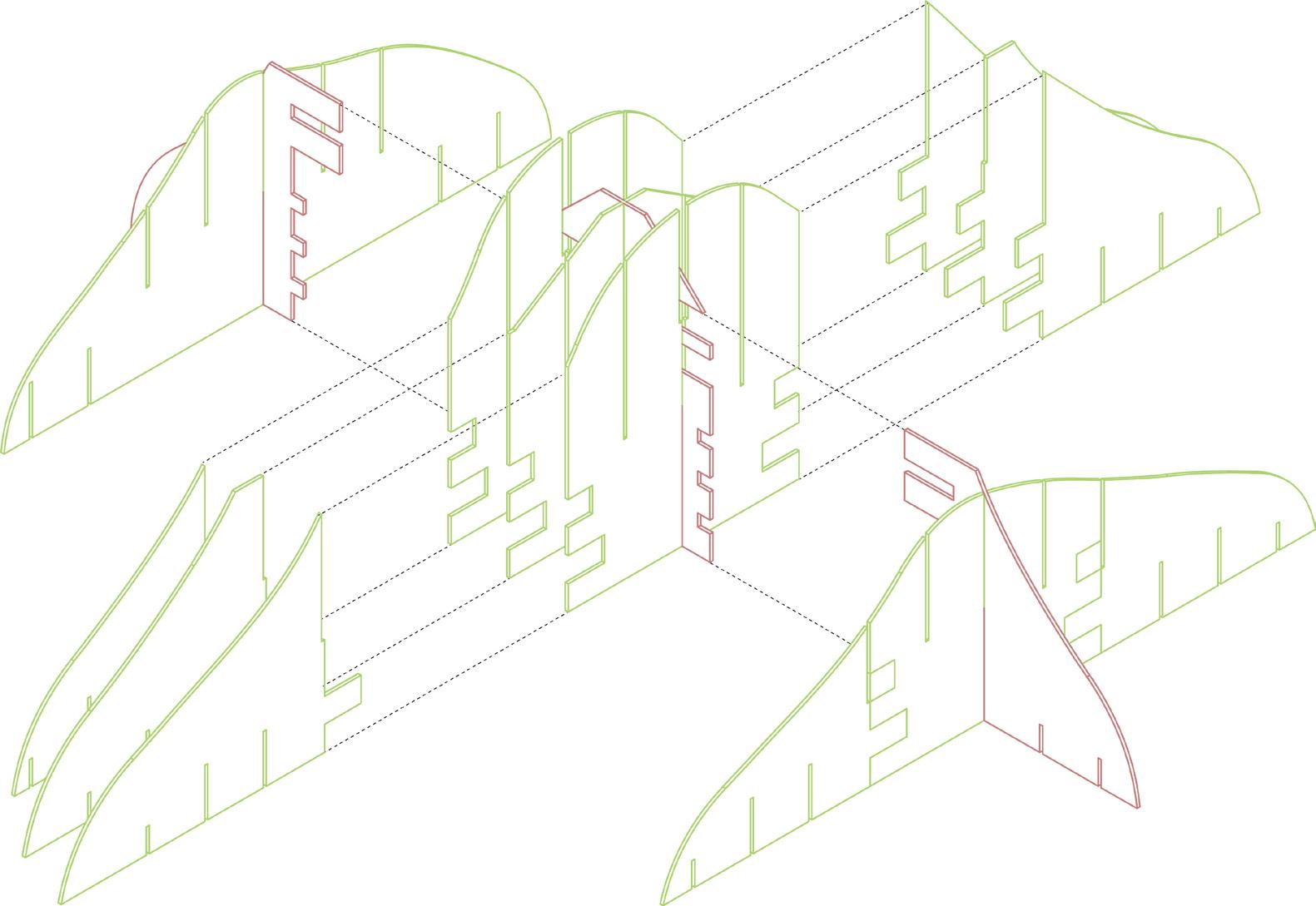

EXPLODED AXONOMETRIC

WAFFLE COMPONENTS for structural integrity

X-RIB CNC-cut wood panel with grooves in the top direction

Y-RIB CNC-cut wood panel with grooves in the bottom direction

BASE STRUCTURE with Steel Plate

Hidden Forrest

CONNECTION & ASSEMBLY SEQUENCE

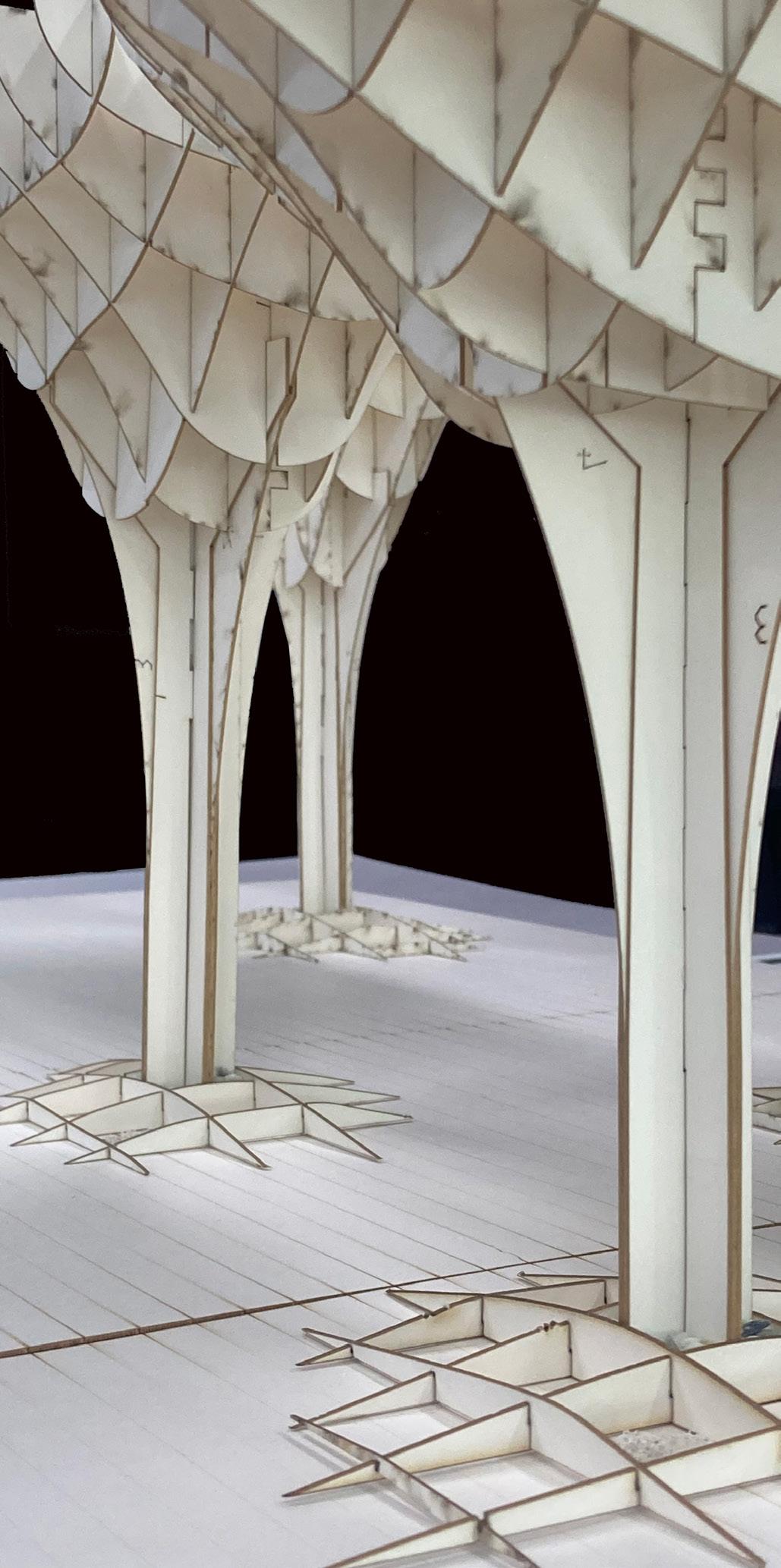

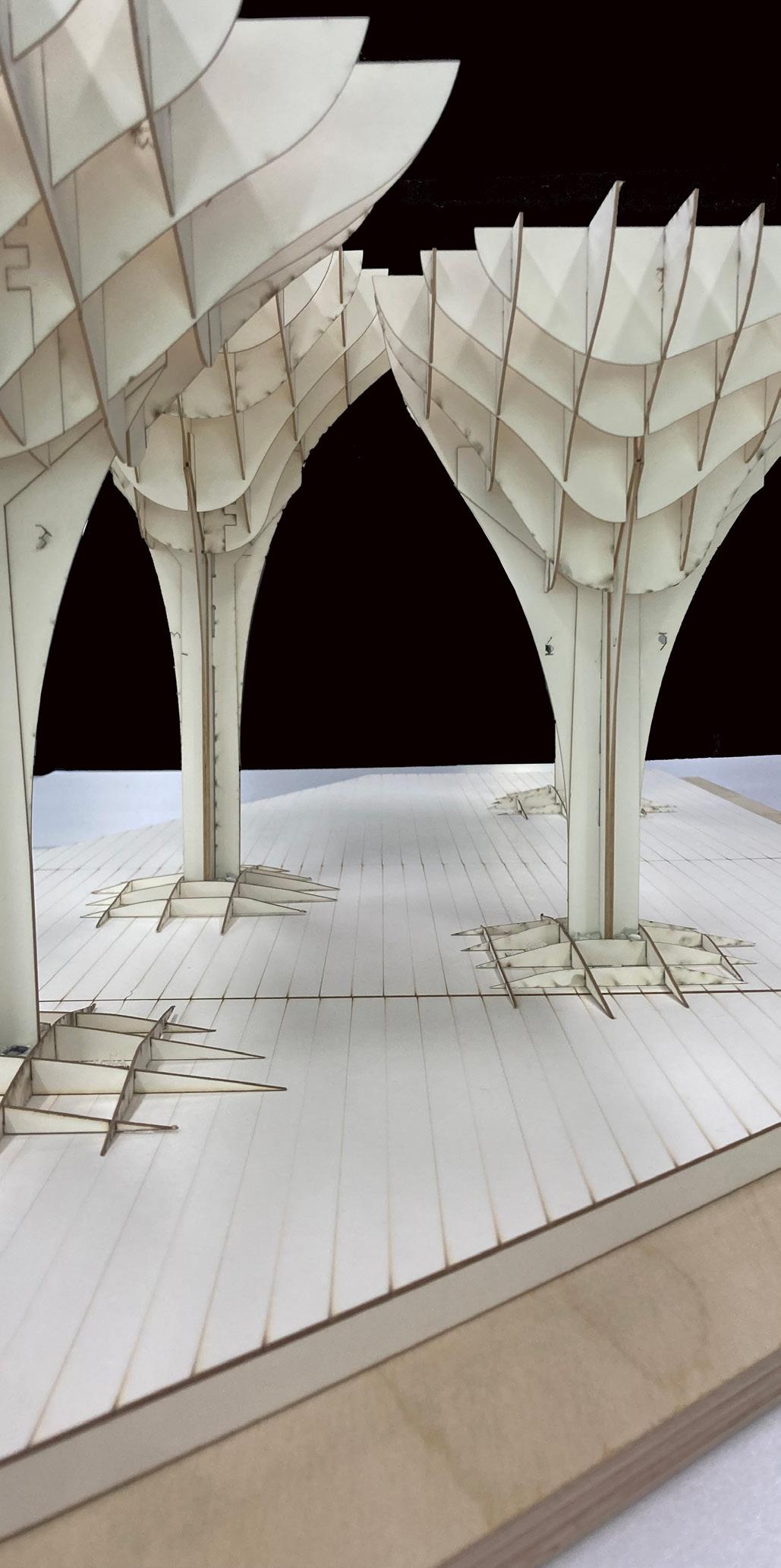

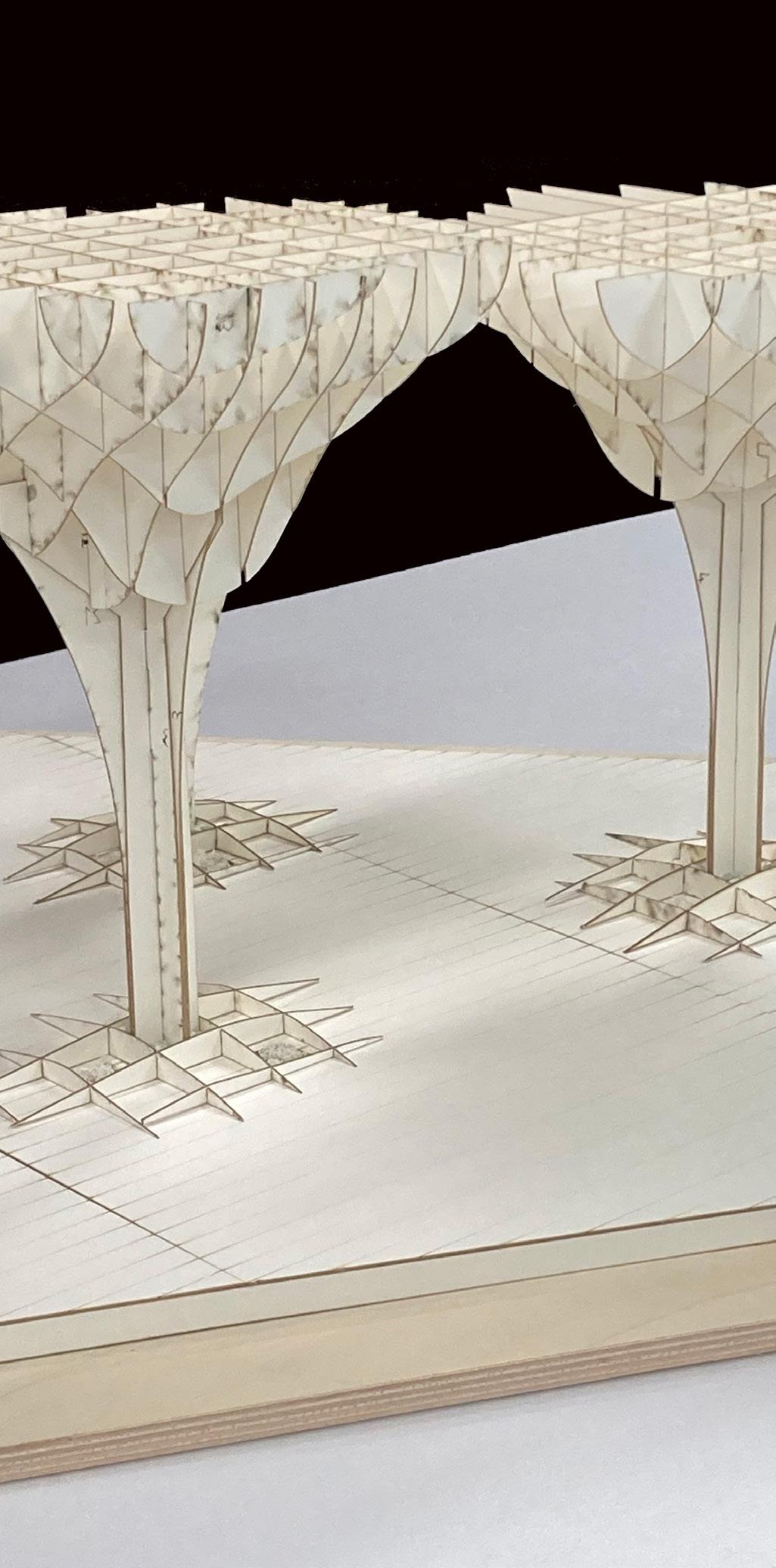

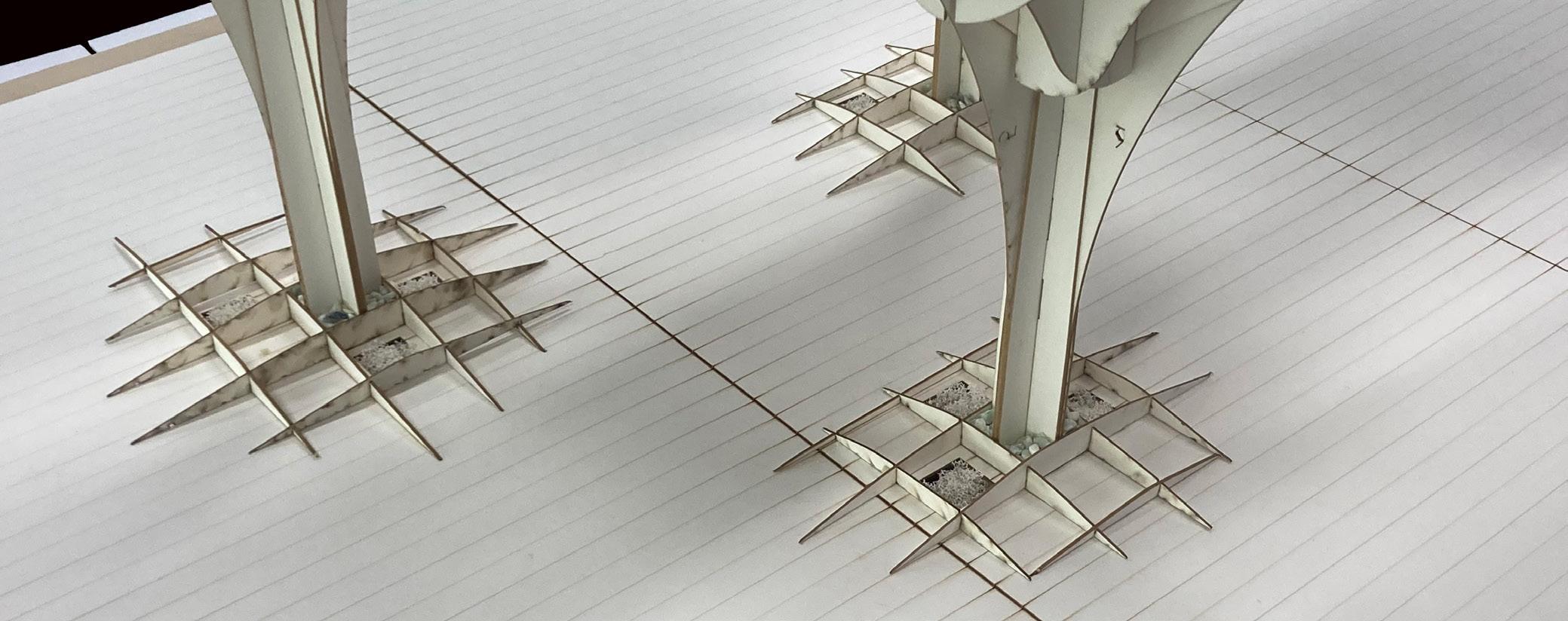

SCALE MODEL

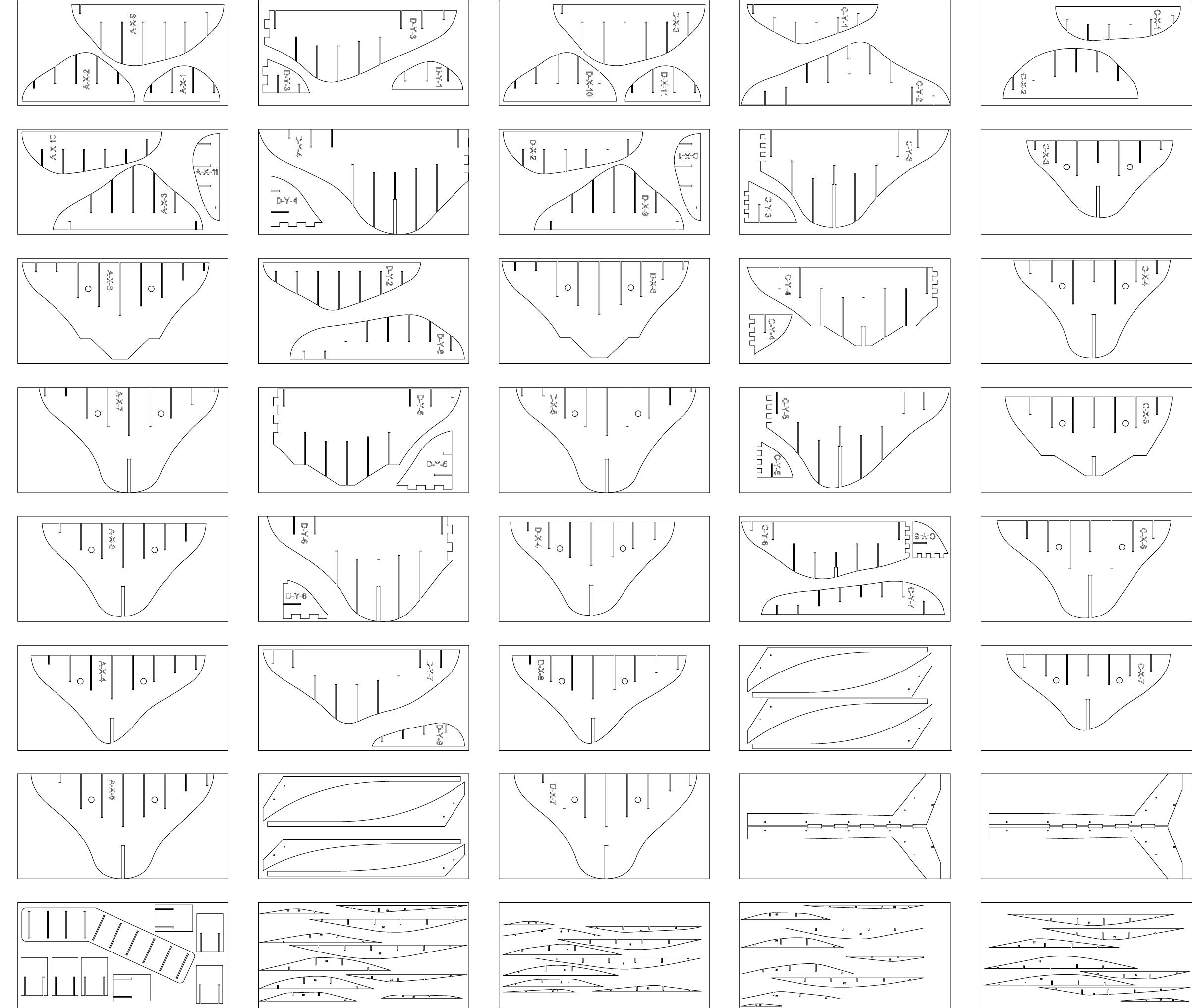

A final 1:10 scale pavilion model was constructed from laser-cut cardboard sheets to verify the assembly sequence and constructability. This process also informed the preparation of CNC cut files that could be efficiently laid out on the sheets to facilitate the overall workflow.

Hidden Forrest

Hidden Forrest

Hidden Forrest

FABRICATION

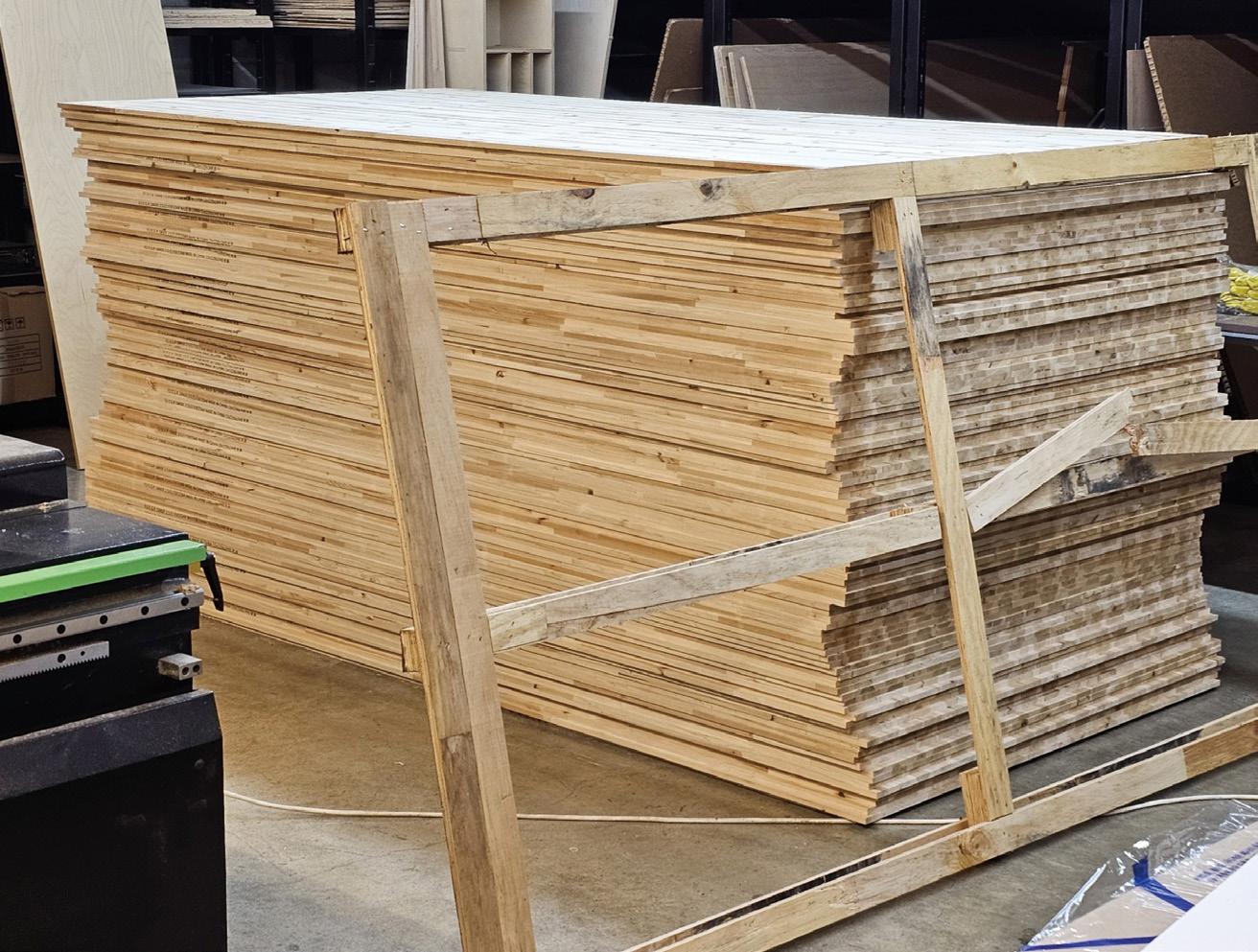

CNC PROCESS

Digital fabrication drawings were created from the Rhino parametric model, and the final components were cut using a CNC routing machine.

A total of 107 sheets of 12mm-thick cedar laminated board, measuring 1220 x 2440 mm, were cut in this process.

Hidden Forrest

Hidden Forrest

SURFACE TREATMENT

As a post-CNC cutting process, wood surface treatment methods such as sanding and varnishing are applied to all CNC-cut parts.

This procedure significantly improves the surface quality by removing any roughness or imperfections left over from the CNC cutting process and protects the wood from a number of external factors to enhance its functional properties.

Hidden Forrest

Hidden Forrest

ASSEMBLY & INSTALLATION

COLLABORATIVE CONSTRUCTION

Hidden Forrest

Hidden Forrest

Hidden Forrest

THE PAVILION

Hidden Forrest

Hidden Forrest

Hidden Forrest

PROJECT CREDITS

U-SOA Design & Make 2024

지도교수

디자인

유용현

이수언

배성근

유진우 김은비

시공 자문

목공 지원

전동원 (파인건축 대표)

김수규

정동석

CNC 가공

제작 및 설치

김진수 (M-BOX)

김민재, 김민정, 김민지, 김은서

김채현, 김태완, 박정우, 서현규

신동원, 신재훈, 우예림, 이상혁

이시원, 정선우, 홍인화

설계기간

시공기간

2024년 9월 19일 - 11월 30일

2024년 12월10일 - 12월 16일

울산대학교 건축학부 건축학전공

Hidden Forrest