8 minute read

Hydrolyzed Kluyveromyces fragilis: The all-in-one solution

Hydrolyzed Kluyveromyces fragilis: The all-in-one solution for fish and shrimp

Valentin Eckart, Biochem

Aquafeeds must meet high standards to meet the challenges of the modern aquaculture industry. Rising raw material prices are forcing feed manufacturers to use cheaper alternative protein sources to maintain the high nutritional value of their feeds without unduly driving up costs for farmers. These new feed formulations often have off-flavors that must be covered up with attractants. Speaking of farmers, emerging diseases, the effects of climate change and high stocking densities have raised awareness of the need for proper stress management in fish and shrimp. In short, modern aquafeed must be palatable, nutrient-rich, health-promoting and affordable in increasingly challenging times.

Fish prefer Kluyveromyces fragilis

To achieve this, Biochem has developed the product TechnoYeast, a hydrolyzed yeast based on Kluyveromyces fragilis (also known as K. marxianus). In its unhydrolyzed form, K. fragilis has already been shown to modulate the gut microbiota and counteract soy meal-induced enteritis in Atlantic salmon at 200 g/kg intake (Grammes et al., 2013). Other studies have found that K. fragilis can replace up to 40% of LT fishmeal in Atlantic salmon diets without affecting growth. No comparable results were found for the most commonly used yeast species Saccharomyces cerevisiae (Øverland et al., 2013). Accordingly, K. fragilis appears to possess some beneficial properties that could be even more effective after splitting into their functional components - by hydrolysis.

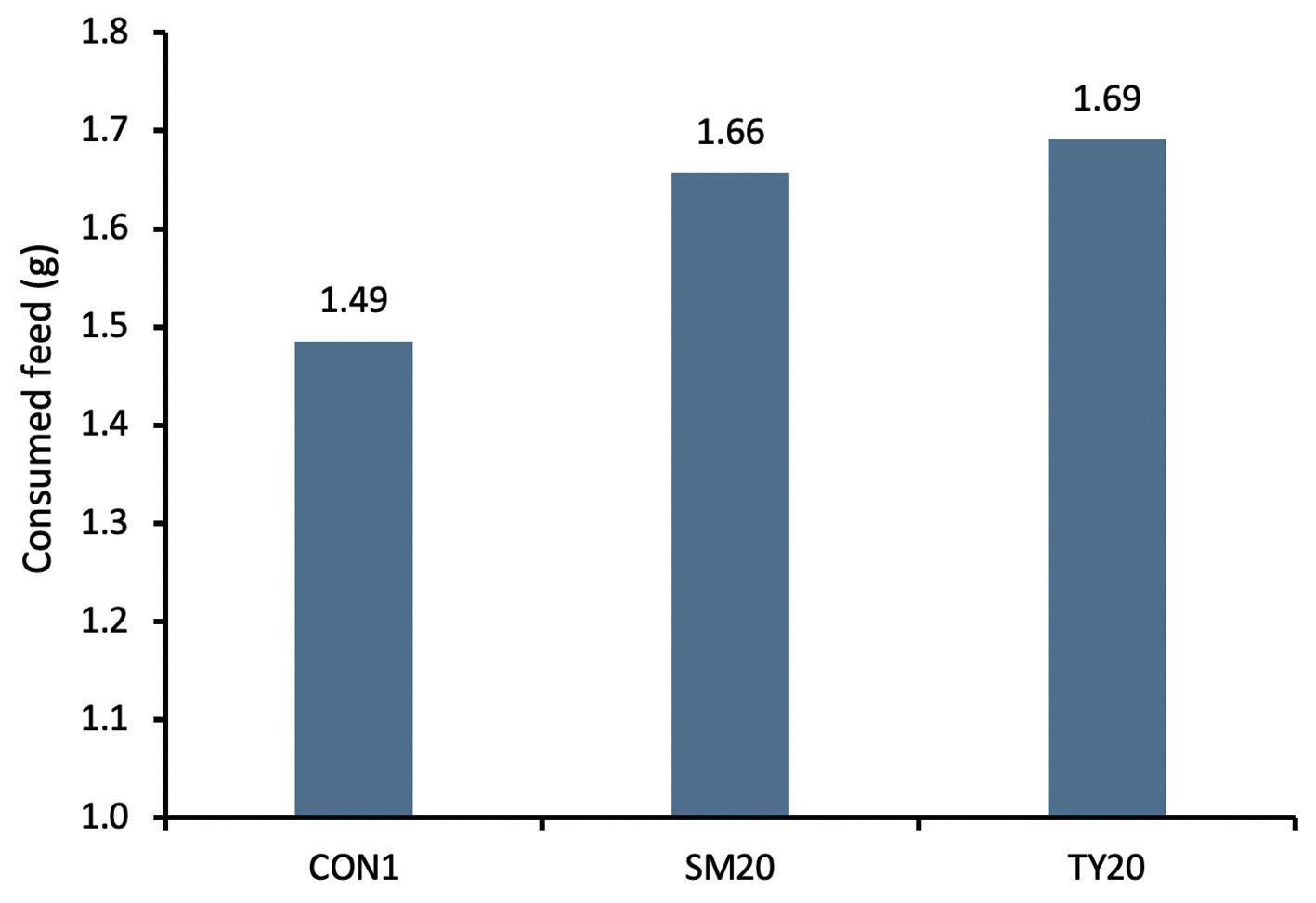

Figure 1. The average consumption of shrimp feed from the control diet (CON1), the 20 g/kg squid meal diet (SM20), and the 20 g/kg TechnoYeast diet (TY20) after 30 minutes. Due to the higher feed consumption of SM20 (+11%) and TY20 (+13%), the two feeds had a stronger attraction effect than CON1 (n=40).

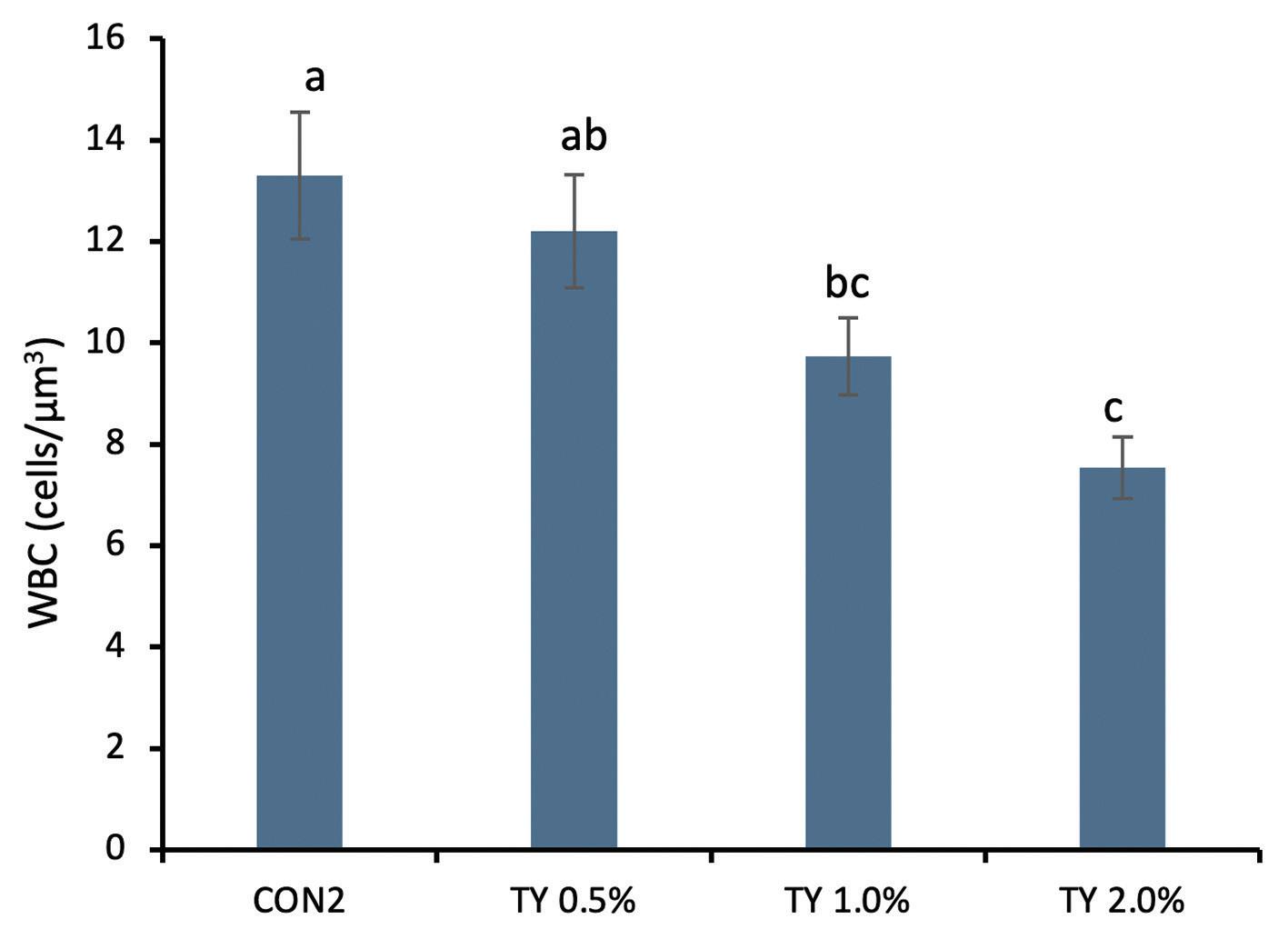

Figure 2. White blood cell (WBC) density in blood. Fish fed increasing levels of TechnoYeast (TY 0.5%, TY 1.0%, TY 2.0%) had lower WBC counts – an indicator for reduced pathogenic pressure. Different letters accompanying bars denote significant differences (P < 0.001; n=3).

Table 1. Data on fish weight, weight gain (WG), specific growth rate (SGR), feed conversion ratio (FCR) and survival. Values are the means. Different letters in a row indicate significant differences (P < 0.001) (± standard deviation, n=30).

CON2 TY 0.5% TY 1.0% TY 2.0%

Initial weight (g) Final weight (g) WG (g) SGR (%BW/day) FCR

17.2b ± 0.5 17.8b ± 0.7 81.4a ± 2.0 91.2b ± 4.6 64.2a ± 1.5 73.5b ± 5.0

17.1b ± 1.2 12.9a ± 2.5 94.6b ± 6.5 102.9c ± 5.3 77.5b ± 7.0 90.0c ± 7.3 1.73a ± 0.01 1.82a ± 0.08 1.90a ± 0.12 2.31b ± 0.24

0.79a ± 0.01 0.73a ± 0.04 0.69a ± 0.05 0.61a ± 0.05

Survival (%)

99.98a 99.33a 99.67a 99.98a

Increase feed intake of plant-based diets

Nowadays, attractants are very common in state-ofthe-art feed formulations with reduced fishmeal content and high content of plant material. For example, it was recently reported that ingredients such as krill meal and fishmeal hydrolyzate in soybeanbased diets accelerate and increase feed intake of shrimp (Soares et al., 2021).

To test whether these effects were also observed when hydrolyzed K. fragilis was used, three isonitrogenous shrimp diets were formulated - one with no attractants (CON1), one with 20 g/kg squid meal (SM20), and one with 20 g/kg TechnoYeast (TY20). Five grams of each of these diets were randomly placed in the center of the marked feeding areas in a tank containing 100 Pacific white shrimp (size 8-10 g). After 5, 15, and 30 min, the number of shrimp within the marked area and next to the feeds was counted to determine shrimp feeding preference. Then, the remaining feed was removed, dried, weighed and compensated for leaching loss to calculate feed consumption. The experiment was repeated 40 times at different feeding sites.

There was a clear preference for the two feeds with attractants compared to the control. Finally, measurement of the consumed feed confirmed that hydrolyzed K. fragilis provided at least the same attractiveness as other commercial shrimp attractants such as squid meal (Fig. 1).

Pushing feed efficiency to the limits

The COVID-19 pandemic has shown how fragile the world market can be. There have been shortages of feed raw materials and a drop in the price of harvested

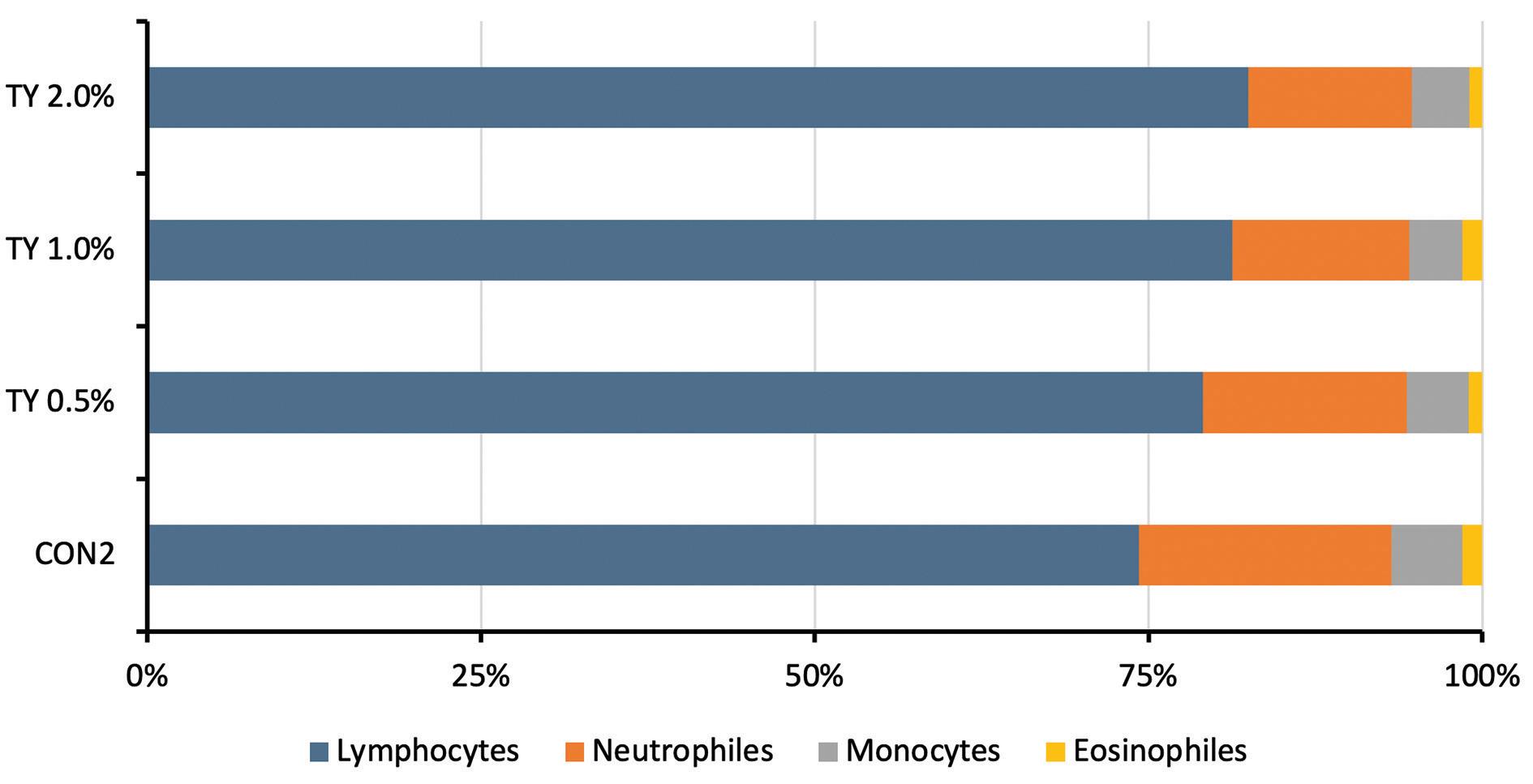

Figure 3. Composition of white blood cells (WBC). A WBC composition with increased neutrophils may be a sign of acute inflammation (min. sig. level compared to CON2: lymphocytes P < 0.05; neutrophiles P < 0.001; No significance for monocytes & eosinophiles; n=3).

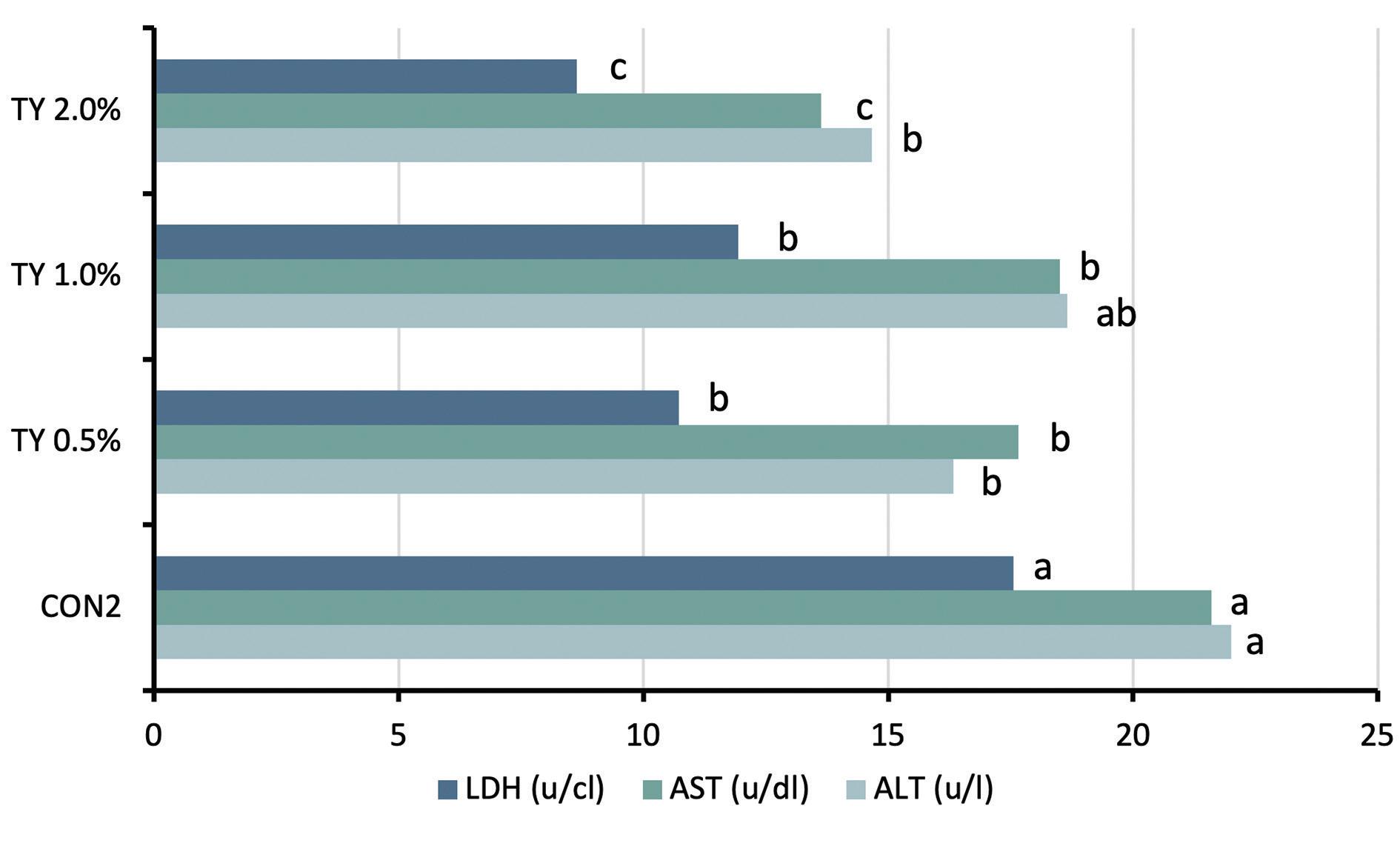

Figure 4. Liver enzyme analysis of lactate dehydrogenase (LDH), aspartate transaminase (AST) and alanine transaminase (ALT). Elevated values are an indicator of bad liver condition and tissue damage. Different letters accompanying bars denote significant differences (P < 0.01; n=3).

fish and shrimp. As aquafeed is still the biggest cost factor for farmers, high feed efficiency is important to maintain competitiveness. In this context, TechnoYeast was tested in a dose-response trial with rainbow trout (Oncorhynchus mykiss). Over a 90-day period, 4 groups of 200 fish (initial weight 16.3 g) were fed a commercial trout diet (CON2) with different doses of TechnoYeast - 0.5% (TY 0.5%), 1.0% (TY 1.0%) and 2.0% (TY 2.0%) - with 3 replicates each.

Results showed that fish performance was significantly better with increasing doses of TechnoYeast (Table 1). The average FCR was reduced from 0.79 to 0.61, and the final weight was improved by up to 26%. Hydrolyzed K. fragilis is rich in free amino acids, dipeptides, tripeptides, and nucleotides, but also contains decent amounts of prebiotic components such as mannanoligosaccharides (MOS) and β-1,3-1,6-glucans. According to the above-mentioned modulation of the

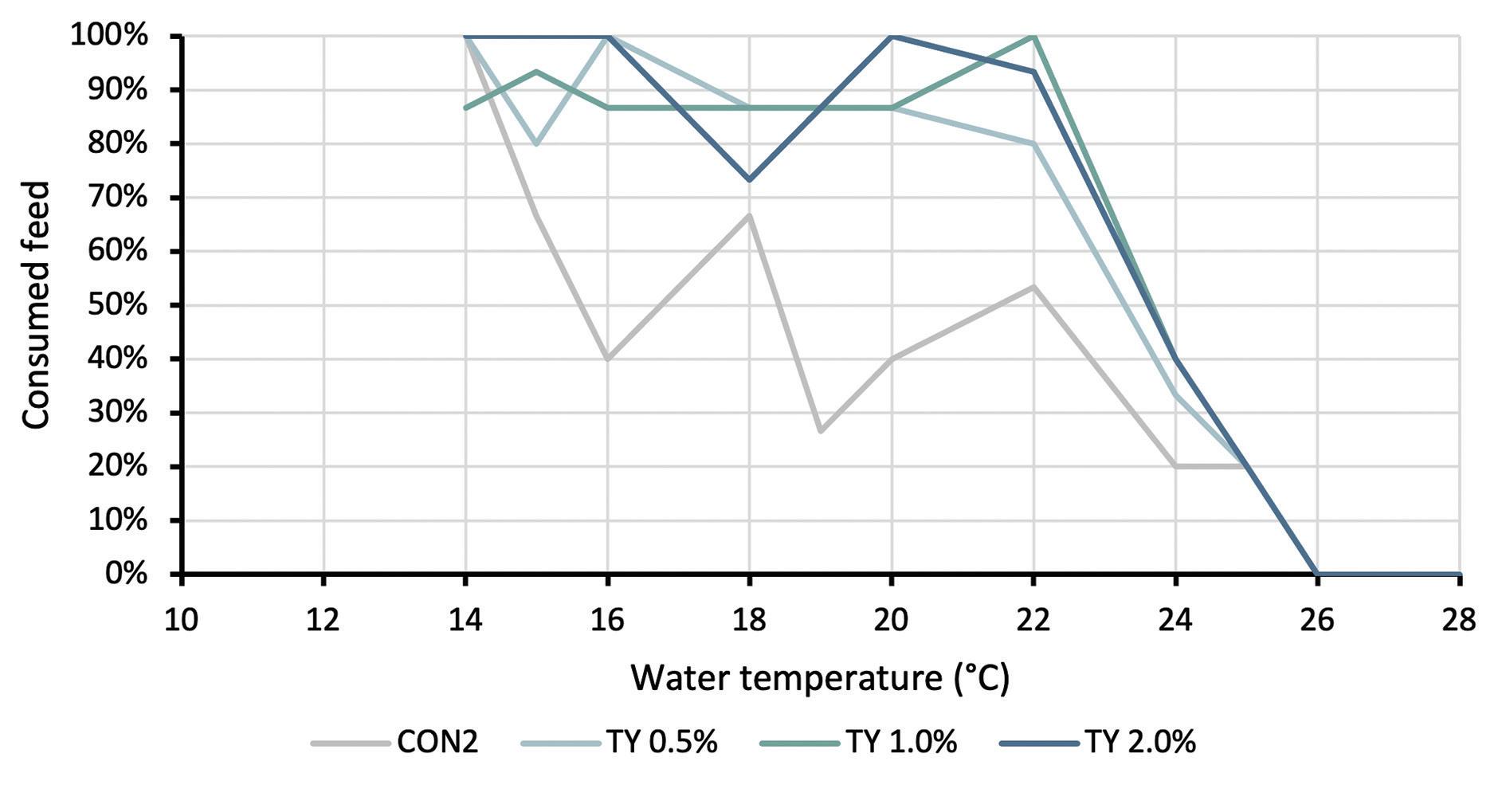

Figure 5. Consumed feed from standard feeding regime during thermal challenge. Feeding was started on the second day at 14°C water temperature. TechnoYeast treated groups (TY 0.5%, TY 1.0%, TY 2.0%) continued feeding at high rates even at temperatures above 20°C. The negative control (not shown) was normally feeding at a constant temperature of 10°C (n=3).

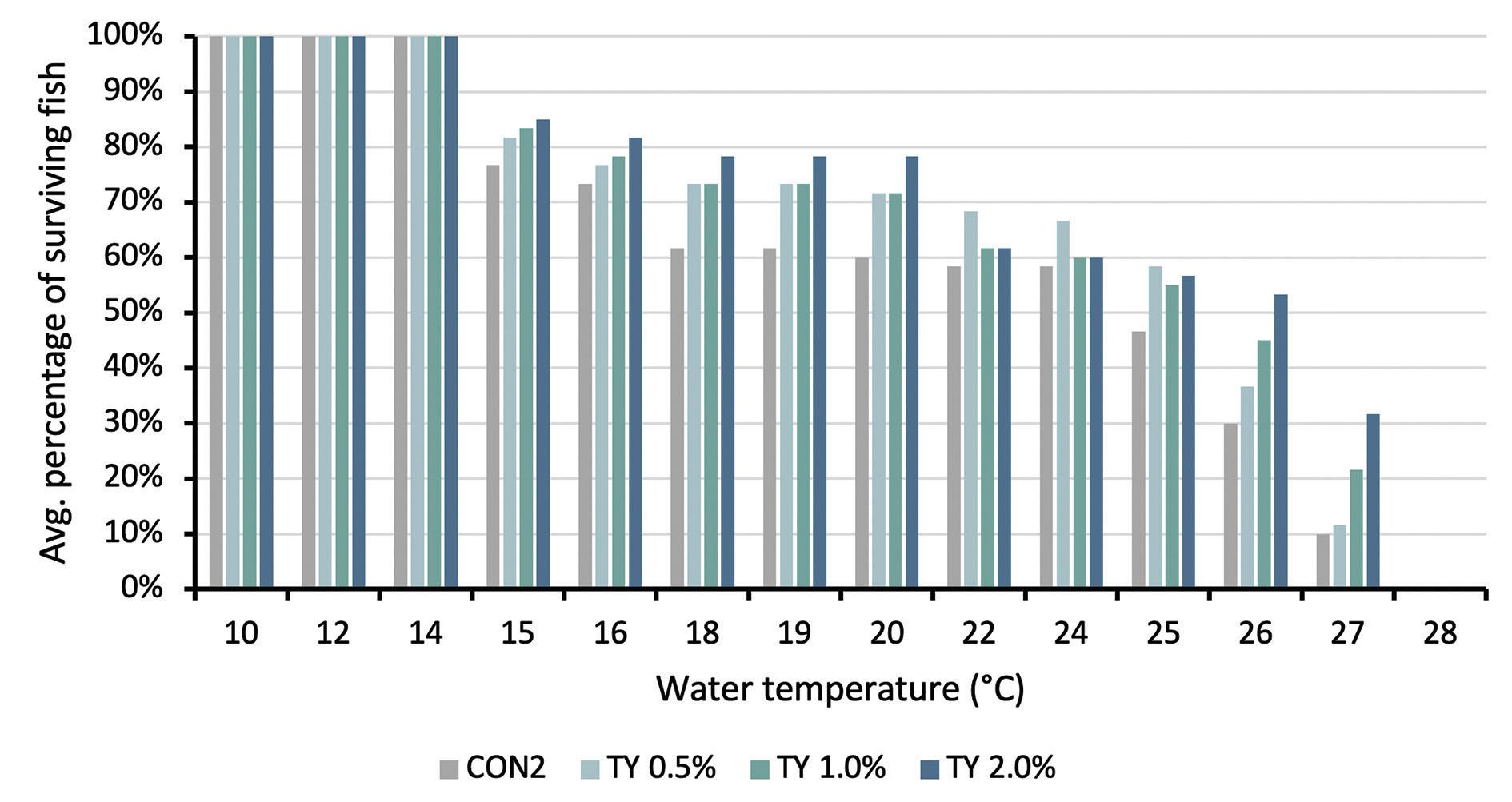

Figure 6. Survival of fish during a 7-day thermal challenge. The temperature was increased by about 2.5°C every day. Treatment groups, which were fed TechnoYeast at 1% and 2% inclusion (TY 1.0% & TY 2.0%) had about 10-20% lower mortality at different temperature levels compared to the control group (CON2). There was no mortality observed in the negative control group at constant 10°C water temperature (n=3).

gut microbiota and the demonstrated attractant effect, this combination of functional components must be the reason for the improved performance and feed efficiency shown here.

Reduce stress for better growth

There are many types of stress in the life of an aquacultured fish, such as handling stress, suboptimal temperature, low oxygen, pathogens, or high stocking densities. Blood analyses are often used to get an idea of the current immune status of animals, such as by the number and composition of white blood cells (WBC) as part of the innate immune system. Peters and Schwarzer (1985) described the relationship between elevated levels of WBC with a dominant abundance of neutrophils in the blood of rainbow trout and exposure to various types of stress.

Blood analysis of rainbow trout fed TechnoYeast showed a significant reduction in the total number of WBCs and a significantly lower abundance of neutrophils compared to untreated fish (Fig. 2, 3). Despite the same production environment, these fish appeared to be less stressed. These observations were confirmed by analysis of liver enzymes such as lactate dehydrogenase (LDH), aspartate transaminase (AST) and alanine transaminase (ALT) (Fig. 4). LDH, AST, and ALT are commonly used as indicators for assessing liver health in relation to intoxication and tissue damage (Bury et al., 2003, Parveen et al., 2017). Good to know, but what is the benefit to the fish farmer? If a fish has to spend less effort on strengthening its immune system, it can use the saved energy for growth - as shown in the previous section.

Break the limits: Improve stress tolerance

Alternatively, an energy reserve can be used as a buffer to cope with stressful situations. For example, instead of producing WBC, the organism may produce relevant enzymes, such as superoxide dismutase (SOD), to compensate for stress-induced production of radical oxygen species (ROS) (Slaninova et al., 2009). According to this hypothesis, fish fed hydrolyzed K. fragilis should have higher stress tolerance.

To see if this was true, trout from the dose-response experiment were exposed to various challenges after the 90-day feeding period. To make a long story short: TechnoYeast-treated fish showed higher survival and vitality under all five stresses - high and low water pH, low oxygen, thermal stress and bacterial stress (Aeromonas hydrophila). The thermal stress results were particularly interesting because warm water is a seasonal threat to many trout farms. Due to the

relatively long observation period of one week with increasing temperatures (10 to 28°C in 7 days), the feeding regime was continued. Although trout prefer temperatures well below 20°C, fish fed hydrolyzed K. fragilis continued to consume feed at high rates above 20°C, whereas fish in the control group radically reduced their feed intake (Fig. 5). In addition, the survival rate of TechnoYeast-treated fish was 10% to 20% higher than that of the control group at each temperature level (Fig. 6). Thus, the original hypothesis was confirmed.

Conclusion

The initial statement “modern aquafeed must be palatable, nutrient-rich, health-promoting and affordable in increasingly challenging times” applies perfectly to a functional feed material based on hydrolyzed K. fragilis, like TechnoYeast. The last aspect regarding the cost can be answered considering the wide range of benefits derived from the use of this product. The addition of 2% hydrolyzed K. fragilis is a source of highly digestible proteins that accelerates the production cycle, increases feed efficiency and feed intake even in stressful situations, and reduces the risk of excessive losses due to various types of stress.

Acknowledgements:

Many thanks to the researchers from the Iranian Fisheries Research Organization (IFRO), Iran, and CreveTec, Belgium, who conducted these trials.

References available on request.

More information: Valentin Eckart

Product Manager Aqua Applications Biochem E: veckart@biochem.net