2 minute read

IN PARLIAMENT

by apeauk

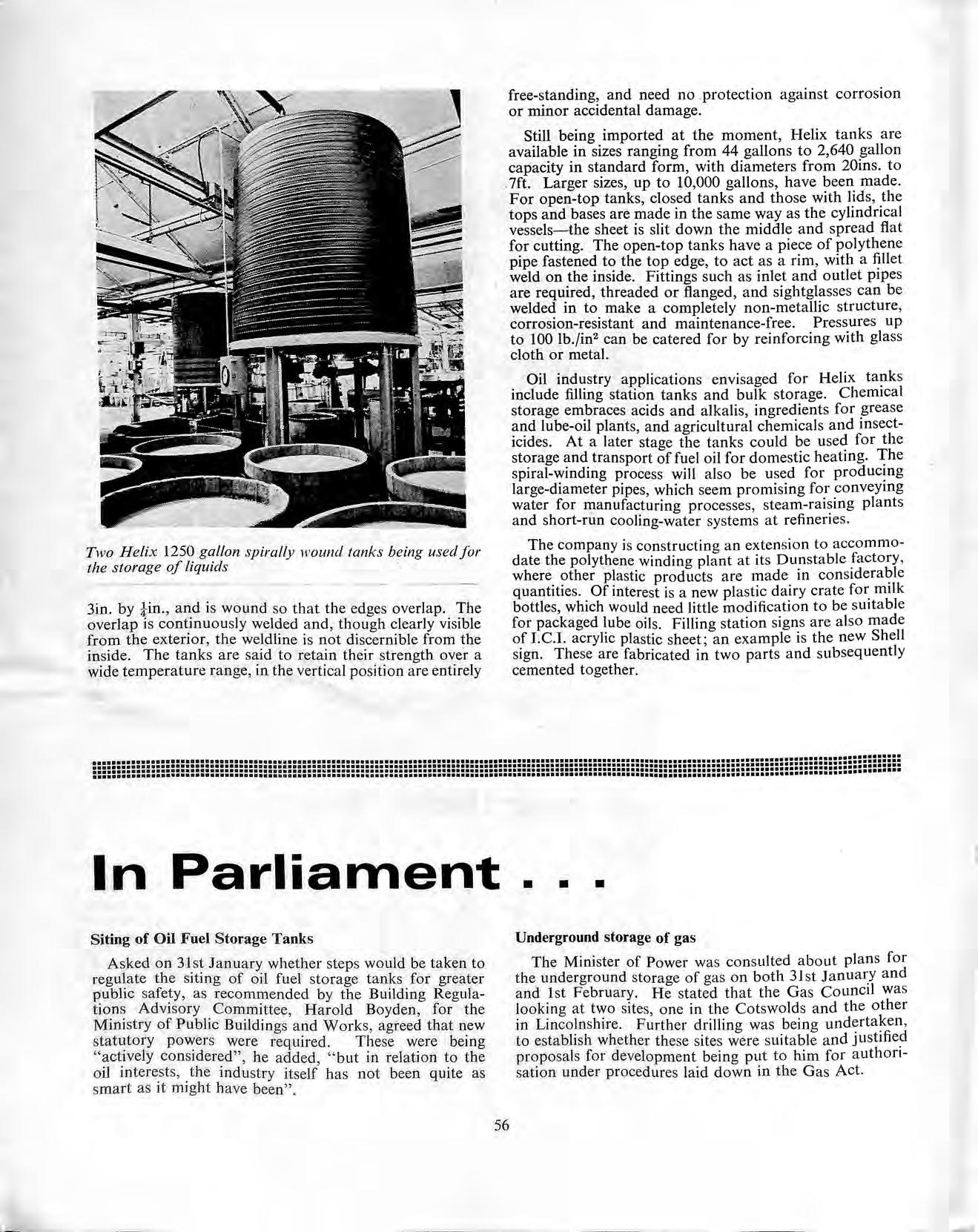

Two Helix 1250 gallon spirally wound tanks being used for the storage of liquids

3in. by ! in., and is wound so that the edges overlap. The overlap is continuously welded and, though clearly visible from the exterior, the weldline is not discernible from the inside. The tanks are said to retain their strength over a wide temperature range, in the vertical position are entirely free-standing, and need no _protection against corrosion or minor accidental damage.

Advertisement

Still being imported at the moment, Helix tanks are available in sizes ranging from 44 gallons to 2,640 gallon capacity in standard form, with diameters from 20ins. to 7ft. Larger sizes, up to 10,000 gallons, have been made. For open-top tanks, closed tanks and those with lids, the tops and bases are made in the same way as the cylindrical vessels-the sheet is slit down the middle and spread flat for cutting. The open-top tanks have a piece of polythene pipe fastened to the top edge, to act as a rim, with a fillet weld on the inside. Fittings such as inlet and outlet pipes are required, threaded or flanged, and sightglasses can be welded in to make a completely non-metallic structure, corrosion-resistant and maintenance-free. Pressures up to 100 lb./in2 can be catered for by reinforcing with glass cloth or metal.

Oil industry applications envisaged for Helix ta!1ks include filling station tanks and bulk storage. Chemical storage embraces acids and alkalis, ingredients for grease and lube-oil plants, and agricultural chemicals and insecticides. At a later stage the tanks could be used for the storage and transport of fuel oil for domestic heating. The spiral-winding process will also be used for producing large-diameter pipes, which seem promising for conveying water for f!!anufacturing processes, steam-raising plants and short-run cooling-water systems at refineries.

The company is constructing an extension to accommodate the polythene winding plant at its Dunstable factory, where other plastic products are made in considera'?le quantities. Of interest is a new plastic dairy crate for milk bottles, which would need little modification to be suitable for packaged lube oils. Filling station signs are also made of J.C.I. acrylic plastic sheet; an example is the new Shell sign. These are fabricated in two parts and subsequently cemented together.

Siting of Oil Fuel Storage Tanks

Asked on 31 st January whether steps would be taken to _ regulate the siting of oil fuel storage tanks for greater public safety, as recommended by the Building Regulations Advisory Committee, Harold Boyden, for the Ministry of Public Buildings and Works, agreed that new statutory powers were required. These were being "actively considered", he added, "but in relation to the oil interests, the industry itself has not been quite as smart as it might have been" . Underground storage of gas

The ,Minister of Power was consulted about plans for the underground storage of gas on both 31st January and and lst February. He stated that the Gas Council was looking at two sites, one in the Cotswolds and the other in Lincolnshire. Further drilling was being und~rta~en

, to establish whether these sites were suitable and JUSt1fied proposals for development being put to him for authorisation under procedures laid down in the Gas Act.

56