SPECIAL FOCUS ←

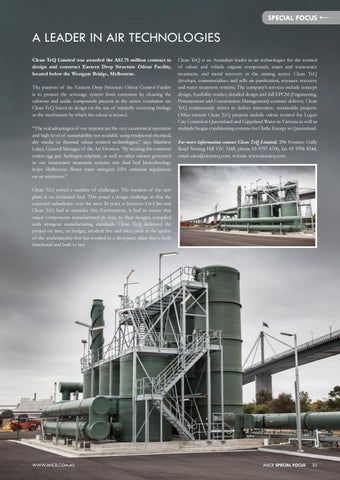

a leader in air technologies Clean TeQ Limited was awarded the A$2.75 million contract to design and construct Eastern Drop Structure Odour Facility, located below the Westgate Bridge, Melbourne. The purpose of the Eastern Drop Structure Odour Control Facility is to protect the sewerage system from corrosion by cleaning the odorous and acidic compounds present in the sewer ventilation air. Clean TeQ based its design on the use of naturally occurring biology as the mechanism by which the odour is treated. “The real advantages of our systems are the very economical operation and high level of sustainability not available using traditional chemical, dry media or thermal odour control technologies,” says Matthew Lakey, General Manager of the Air Division. “By treating the common rotten egg gas, hydrogen sulphide, as well as other odours generated in our wastewater treatment systems our dual bed biotechnology helps Melbourne Water meet stringent EPA emission regulations on air emissions.”

Clean TeQ is an Australian leader in air technologies for the control of odour and volatile organic compounds, water and wastewater treatment, and metal recovery in the mining sector. Clean TeQ develops, commercialises and sells air purification, resource recovery and water treatment systems. The company’s services include concept design, feasibility studies, detailed design and full EPCM (Engineering, Procurement and Construction Management) contract delivery. Clean TeQ continuously strives to deliver innovative, sustainable projects. Other current Clean TeQ projects include odour control for Logan City Council in Queensland and Gippsland Water in Victoria as well as multiple biogas conditioning systems for Clarke Energy in Queensland. For more information contact Clean TeQ Limited, 296 Ferntree Gully Road Notting Hill VIC 3168, phone 03 9797 6700, fax 03 9706 8344, email sales@cleanteq.com, website www.cleanteq.com

Clean TeQ solved a number of challenges. The location of the new plant is on reclaimed land. This posed a design challenge in that the expected subsidence over the next 20 years is between 1.0-1.5m and Clean TeQ had to consider this. Furthermore, it had to ensure that major components manufactured in Asia, to their designs, complied with stringent manufacturing standards. Clean TeQ delivered the project on time, on budget, incident free and takes pride in the quality of the workmanship that has resulted in a showpiece plant that is both functional and built to last.

WWW.ANCR.COM.AU

ANCR SPECIAL FOCUS

33