13 minute read

Celling the future

Hyzon fuel cell tractor units based on DAF truck platforms will be on New Zealand roads early next year.

By Colin Smith

This month we continue to look at hydrogen’s future role in the transport industry with a dive into New Zealand’s early adoption of fuel cell technology for trucks.

NEW ZEALAND’S LEARNING CURVE WITH HYDROGEN FUEL CELL

trucks is poised to take a rapid upward trajectory.

The second of Hyundai New Zealand’s XCIENT hydrogenpowered fuel cell electric trucks was scheduled to arrive in June, at about the same time the first unit begins its trial operation on Kiwi roads.

Since its arrival at the end of 2021, the first XCIENT FCEV (fuelcell electric vehicle) has been converted to right-hand-drive and its latest appointment is with a body builder who is repositioning the hydrogen tanks - from the delivery position at the rear of the chassis to stacked behind the cab for commercial use – and completing the body build.

Hyundai New Zealand says the first XCIENT FCEV is set to enter service with a New Zealand transport company in mid-2022. This will mark a significant development for the wider hydrogen economy and make carbon-neutral heavy transport a reality on Kiwi highways.

In total five XCIENT FCEVs will be involved in the trial and Hyundai says replacing a similar emissions-heavy diesel truck saves an estimated 50-tonnes of CO2 emissions per year.

New Zealand’s other significant FCEV pilot project is also gaining momentum, although it’s now running a little behind original schedules due to global supply chain issues.

The first of the DAF-based Hyzon 6x4 tractor units is now being built in the Netherlands with the initial batch of what is planned to be 20 trucks now destined to reach New Zealand in early 2023.

These trucks have been purchased through Southpac Trucks, are right-hand-drive and built to the same specification as conventionally powered DAFs already on New Zealand roads.

From early next year the Hyzon trucks will be leased to companies participating in the $50m trial which has funding support from the Covid-19 Response and Recovery Fund (CRFF) and the Energy Efficiency and Conservation Authority (EECA).

Waitomo Group will operate four hydrogen refuelling sites initially in Auckland, Hamilton, Tauranga and Palmerston North with more planned from 2023.

TR Group general manager Brendan King says global supply chain delays and lockdowns have slowed the build of the Hyzon trucks which had been expected to be on Kiwi roads this year.

King says the real-world experience that will be gained from

New Zealand’s first Hyundai XCIENT Fuel Cell arrived in December 2021 and is now ready for a pioneering trial.

the project has an important role in showing that hydrogen fuelcell technology will work for heavy transport in the New Zealand environment.

“If we want to make a difference on transport emissions, we have to make changes sooner rather than later,” King says.

“First of all, we have to show the gear works. And it’s not just showing that the trucks and the refuelling infrastructure stack up. We have to show the support network to service and repair the trucks is there as well.

“Starting out with 20 trucks is a tall order and so is starting with four refuelling stations.

“But we also have to show the OEMs that we are serious and there is a market in places like New Zealand. Otherwise, righthand-drive will be a lower priority for them, and we will not get carbon emission free trucks to NZ for many more years. We want to be at the front of the queue, not the back.”

King says there are cost issues to overcome – both capital costs and operating costs – that mean fuel-cell trucks don’t make economic sense at present until bigger volumes can be created.

“There is a cost issue with the whole thing. The only way to get that down is to create volume.”

One of the criticisms levelled at fuel cell vehicles is they are a less efficient use of energy than battery electric vehicles - when the energy required to create green hydrogen via electrolysis is taken into consideration.

“What they refer to is, if you take one unit of electricity and it can turn the wheels of a truck 100 times, the same unit of electricity will only turn those wheels 35 times,” King says.

“The lower efficiency is because it goes through two processes. Electricity is used to create the hydrogen that is stored until it is used to create electricity.”

King says there are other efficiencies that should be considered such as the 600km range and the 58-tonne GCM Hyzon units will offer.

“You would take a wider view of efficiency if you’re using your vehicle all of the time. And you can’t do that with electricity.”

Hydrogen offers the advantage of a longer range along with refuelling times comparable to diesel. Those two advantages would suggest the choices for future power sources for trucks tend to favour battery electric models for short-haul, metro and lighter loads with fuel cells favoured for line haul work and heavier loads.

King says it’s not quite so straightforward, and that time as well as distance should be considered.

“If you are using a vehicle close to 24 hours a day then the downtime needed for charging batteries isn’t an option. So hydrogen can also be an answer for smaller trucks working in a metro environment.”

While developing a hydrogen generation and refuelling infrastructure will be expensive, Kings says it needs to be considered alongside the cost of upgrading electric networks, so they are capable of charging a large number of vehicles.

“What some people haven’t fully realised is that it’s relatively easy to have one electric truck and be able to charge it. Maybe even two or three,” says King.

“But we have three small EV metro trucks at our Auckland [Penrose] branch. It costs about $150,000 to upgrade to an AC electricity supply so we could charge all three trucks at the same time.

“And if you look at it in a wider context, we have Owens over our back fence and Mainfreight, Mainstream and Toll are not very far away. If everyone is trying to charge multiple trucks the electricity infrastructure won’t handle it.

“One of the advantages of hydrogen is it allows you to move your electricity around.

You can think of hydrogen in the same way as a battery. It’s a way of storing energy for when and where you need it.”

King expects battery electric and fuel-cell electric will co-exist in the future with each being suited to different applications.

“It’s not one or the other. It’s like petrol and diesel – each has its advantages.”

One of the main productivity advantages of fuel cells is the same one that transport operators already fully versed in. Lower tare weights allow more payload to be moved.

“Fuel cell trucks will be lighter because they have a much smaller battery,’’ King says.

“Combine that with a range of about 600km and a 15-minute refuelling time and there are strong productivity arguments in favour of fuel-cell trucks.” T&D

Fuel cell monster

THE WORLD’S LARGEST ZERO-EMISSION MINE HAUL TRUCK

has been revealed in South Africa.

Set to work at Anglo American’s Mogalakwena open-cast platinum mine in South Africa, the ultra-class haul truck began life as a Komatsu 930E and previously burned thousands of gallons of diesel fuel per year. It’s been re-powered by a prototype hydrogen fuel cell and lithium-ion battery power system with regenerative capability.

As tall as a three-story building and weighing 181 tonnes empty, this truck can haul up to 263t of ore (444t total laden weight).

The zero-emission power source keeps 700 cars’ worth of carbon dioxide emissions out of the atmosphere. It’s estimated large trucks currently account for 70-80% of diesel fuel consumption at Anglo American’s mine sites.

The mining industry accounts for approximately 7% of global carbon dioxide emissions, with diesel haul trucks representing as much as 50% of total energy use at mine sites.

Mining is a key industry for the reduction of carbon emissions. According to the World Economic Forum, the transition to clean energy needed to avoid the worst effects of climate change could require as much as 3 billion tons of metals, for batteries, solar panels, wind turbines, and other devices.

The 2MW hydrogen-battery hybrid truck generates more power than its diesel predecessor and is part of Anglo American’s nuGen Zero Emission Haulage Solution (ZEHS) to reduce greenhouse gas emissions.

Hydrogen stored in pressurised tanks enters the fuel cell and mixes with oxygen to create water in a chemical reaction catalysed by platinum. This generates electricity that is used to power the motors that drive the wheels. The only emission from the vehicle is water vapour.

Anglo American says nuGen provides a fully integrated green hydrogen system, consisting of production, fuelling and haulage system, with green hydrogen to be produced at the mine site. It’s part of FutureSmart Mining, Anglo American’s innovationled approach to sustainable mining – which brings together technology and digitalisation to drive sustainability outcomes, including a commitment to carbon-neutral operations by 2040.

“The mining industry is playing a considerable role in helping the world decarbonise, both through our own emissions footprint and the metals and minerals that we produce that are critical to low carbon energy and transport systems,” says Duncan Wanblad, Chief Executive of Anglo American.

“Over the next several years, we envisage converting or replacing our current fleet of diesel-powered trucks with this zeroemission haulage system, fuelled with green hydrogen. If this pilot is successful, we could remove up to 80% of diesel emissions at our open pit mines by rolling this technology across our global fleet.”

With a combination of abundant wind and solar renewable energy sources, and as the world’s largest producer of Platinum Group Metals (PGMs), hydrogen is a strategic priority for South Africa. It presents a significant opportunity for economic development, including the creation of new jobs and the development of the PGMs sector, while also contributing to South Africa’s decarbonisation objectives.

For the nuGen project, Anglo American has worked with some of the world’s leading creative engineering and technology companies, such as ENGIE, First Mode, Ballard and NPROXX.

The truck features a 1.2MWh battery pack and eight fuel cells that generate up to 800kW of power, combining to deliver a total of 2MW of power.

Other aspects of the project include the design and implement a software solution to safely manage power and energy between the fuel cells, batteries, and vehicle drivetrain.

The power management and battery systems are developed from the ground up and can be tailored to specific mine conditions to improve overall efficiency by designing in energy recovery as the haul trucks travel downhill through regenerative braking. A hydrogen production, storage, and refuelling complex at Mogalakwena, that incorporates the largest electrolyser in Africa and a solar plant, has been built to support the operation of the haul truck.

“The impact of our nuGen project goes far beyond our operations,” says Wanblad.

“We believe that the emerging hydrogen sector has the potential to dramatically improve the growth and development of many economies by creating new industrial value chains and economic generation opportunities. Growing the hydrogen economy will revolutionise not just Anglo American’s operations, but all mining and many other industries – and ultimately shape a better, cleaner world.”

There are plans to retro-fit the hybrid fuel-cell system to 40 mine haul trucks at Mogalakwena and then across 400 trucks in Anglo American’s global fleet. T&D

The Komatsu 930E has been repowered with a 2MW fuel cell and lithium-ion battery power system.

mills-tui.co.nz

mills-tui.co.nz

mills-tui.co.nz

Mills-Tui Log truck set up and F135 5 axle multi bolster trailer – Customer: R & L Beale Log Transport Ltd

COVID AIN'T STOPPING US!! KEEP ON TRUCKING

Mills-Tui Limited

16–38 Pururu Street, Managakakahi Mills-Tui Limited , Rotorua 3015 16–38 Pururu Street, Managakakahi, Rotorua 3015 P P 07 348 8039 T 0800 MILLS -TUI (645 578)07 348 8039 T 0800 MILLS -TUI (645 578)

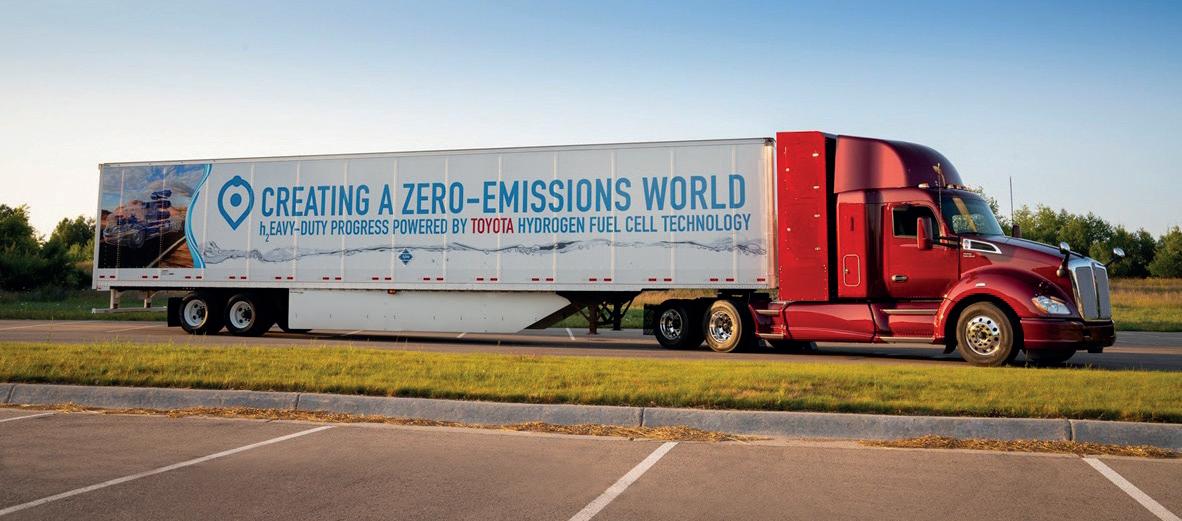

Kenworth has developed T680 fuel cell prototypes which use technology sourced from Toyota.

Study compares carbon emissions

NEW RESEARCH FROM THE US SUGGESTS BATTERY ELECTRIC

heavy vehicles might not be as green across their full life-cycle as they are often proclaimed to be.

The American Transportation Research Institute (ATRI) has released a new report that analyses the environmental impacts of zero-emission trucks (ZET).

This analysis, a 2021 top priority of ATRI’s Research Advisory Committee, utilised federal and industry-sourced data to identify and compare full life-cycle CO2 emissions for a range of truck types, including a baseline diesel truck, battery electric trucks and hydrogen fuel cell trucks.

The study found that while electric trucks have no direct tailpipe emissions, CO2 production associated with vehicle, battery and electricity production would only result in a 30% decrease in CO2 emissions when compared to a standard diesel truck.

The marginal environmental benefits of electric trucks are due, in large part, to lithium-ion battery production – which generates more than six times the carbon of diesel truck production.

The research, which utilised outputs from the Argonne National Lab’s GREET (The Greenhouse Gases, Regulated Emissions, and Energy Use in Technologies) model, also incorporates CO2 emissions that generate from the US electrical grid – which still relies primarily on fossil fuels.

ATRI’s research concludes that hydrogen fuel cell trucks are ultimately the most environmentally friendly truck type, although it says the technology is not presently feasible for long-haul operations.

The report concludes by identifying additional strategies that can reduce CO2 truck emissions for all three energy sources – diesel, electricity and hydrogen.

For example, renewable diesel could decrease CO2 emissions to only 32.7 percent of a standard diesel engine without requiring new infrastructure or truck equipment. Hydrogen, if sourced from solarpower electricity, could enable hydrogen fuel cell trucks to emit only 8.8 percent of the baseline diesel CO2.

The ATRI is a not-for-profit research organisation. It is engaged in critical research relating to a safe, secure, and efficient freight transportation system.

A copy of the full report is available from the ATRI website: www. truckingresearch.org T&D

Cummins and Daimler collaborate

CUMMINS AND DAIMLER TRUCK NORTH AMERICA (DTNA) ARE partnering on a hydrogen fuel cell version of the Freightliner Cascadia.

The project will upfit and validate Freightliner Cascadia trucks with a Cummins fourth generation hydrogen fuel cell powertrain for use in North America.

Cummins says its fourth generation fuel cell powertrain provides improved power density, efficiency and durability.

The joint effort will support both organisations’ goals to reduce emissions across product offerings and operations. Upon successful validation, the companies intend to have initial units available in 2024 for selected customers.

“Cummins and Daimler Truck have a strong history of partnership, and this next step into fuel cell electric vehicles is an exciting development for zero-emissions transport,” said Amy Davis, Vice President and President of New Power at Cummins.

Hydrogen fuel cells are a promising solution for the demanding requirements of heavy-duty trucking.

“CO2-neutral commercial transportation must not only be technically feasible, but also economically viable for our valued customers,” says Rakesh Aneja, Vice President and Chief of eMobility at DTNA.

“Depending on the customer application and energy infrastructure considerations, hydrogen-powered vehicles can absolutely complement battery-powered electric vehicles in accelerating our carbon-neutral journey.

“We are pleased to expand our partnership with Cummins to include hydrogen-powered fuel cell electric vehicles in our future portfolio. We remain focused on serving our customers by providing them with a choice of propulsion-technologies, ultimately resulting in solutions that best suit their business needs,” says Aneja. T&D