www.www.facebook.com/agronfoodprocessing

www.twitter.com/BeveragesFood

www.linkedin.com/in/agronfoodprocessing

2

3

4

Our Reputation is on Your Trust

HI-TECH EQUIPMENTS (INDIA) PVT LTD TURNKEY PROJECTS OF ICE CREAM PLANT & DAIRY PROCESSING PLANT

HARVEST HI-TECH EQUIPMENTS (INDIA) PVT LTD

An ISO 9001 Certified Company 16-A, Sarathy Nagar - 1, Nandha Nagar Road, Singanallur, Coimbatore - 641 005, Tamilnadu, INDIA Phone: +91 422 - 2580835, 4348040 / 41, Telefax: +91 422 - 2580712, Mobile: +91 98430 57871. Grams: ‘HIPRESFLOW’ E-mail: harvestllp@gmail.com Website: www.homogenisers.net

Delhi Office Address: No.8-9, First Floor, Composit House, 170 -171, Prajapet Nagar, New Delhi - 110 049. Mobile: +91 9868899020, +91 9968281450.

5

CONTENTS

6 12

Launch of IDF World Dairy Summit 2018 Milk and dairy products are a sustainable food source for the next generation: Ban Ki Moon

Elanpro strengthens its solar portfolio with the launch of Mobile Freezer

28

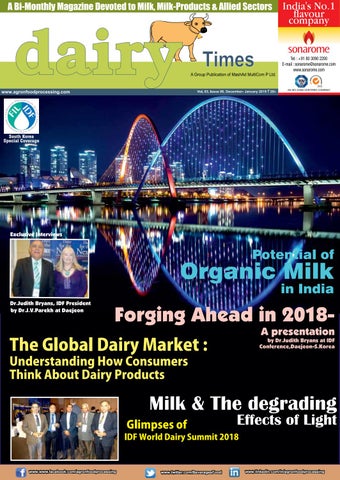

Forging Ahead In 2018

13

IDF driver of dairy sector growth and sustainability: Dr Judith Bryans

46

Global Cooperation of Codexand other international bodies such as IDF

Global platform for dialogue on dairy development: President of IDF Korea Dairy industry in the next decade

Kurien’s Dairy Economics Fodder for Cow Politics National Milk Day celebrated at ICAR-NDRI (SRS), Adugodi, Bengaluru

31

14

45

For a better study, three diverse Indian dairy systems compared 48

15

Glimpses of IDF world dairy summit, 2018 16

IDF at the forefront of dairy science through strong expertise and advocacy: Director General 18

38

FSSAI pushes dairy firms to start voluntary milk fortification ITC to Take on Amul, Coke with Milk-based Drinks Patanjali enters cow milk business; eyes Rs. 1,000 cr sales next fiscal

Potential of Organic Milk in India 50

39

Dakshina Kannada milk union to get third dairy by fiscal-end Centre keen to promote A2 cow milk to lift farmers’ income

Launch of IDF

the World Dairy Summit, Daejeon

40

Tedmag Training Academy Soon, BigBasket will deliver milk

23

The global dairy market: Understanding how consumers think about dairy products

41

Dairy firms’ profit margins to remain strong on low milk procurement prices ITC to enter paneer, milkshakes business in 2 months

53

42

Interview with Mr. Chang Buhm Lee-Chairman, South Korea IDF 26

Interview with Dr. Piercristiano Brazzale, Chair of the IDF SPCC

Amul world’s ninth-largest & fastest-growing dairy processor, says IFCN Major Focus on Increasing Milk Production by 2022- Agricultural Ministry

An Overview on PEF Technology: Scenario, Equipment and Applications

43

India has potential to be in top three in dairy sector by’ 22, says PM Nabard’s Rs.8,004-crore dairy fund takes off European Commission publishes draft to amend regulations on trans fats 44

AllOut cofounder to buy dairy tech startup Mr. Milkman

Dairy Times

55

MILK AND THE DEGRADING EFFECTS OF LIGHT

7

Since 1977

MEET US AT

47th DAIRY INDUSTRY CONFERENCE 2019 February 7th - 9th, Stall No: C4;C5;C6, Samrat Ashoka International Convention Centre, Patna, Bihar

Keeping the ecology in mind, SSP is willing to rectify all the existing spray dryers emitting more than desirable milk particle, No matter who has given the plant

GREEN QUOTIENT : THE ECONOMICS Powder 10 Plant Capacity (TPD)

15

30

40

50

60

300

400

500

600

60

90

120

150

180

140

210

280

350

420

Yearly 42 21 31 Powder Savings (300 Days /Year) Ton/Year

63

84

105

126

Powder Cost Per Kg in �

200

200

200

200

200

84

126

168

210

252

Others 100 150 200 Dryer Qty. at 1% Stack Loss (Kg/Day) SSP Dryer 30 45 Qty. at 0.3% Stack Loss (Kg/Day) Powder 70 Savings Per Day (Kg/Day)

200

105

200

Saving 42 63 Per Year (300 Days /Year) � in Lakhs

NOT ONLY SAVES

SSP PRIVATE LIMITED

20

13 Milestone, Mathura Road, Faridabad - 121003, Haryana (India) T: +91(0)129-4183700 F: +91(0)129-4183777 E: info@ssp.co.in W: www.sspindia.com

ECOLOGY BUT ITS ECONOMICAL TOO!

8

T

Editor In Chief Dr. J.V. Parekh Group Editor Firoz H. Naqvi firoz@advanceinfomedia.com Sales Executive S.H.Hasni hasan@advanceinfomedia.com Production Manager Syed Shahnawaz General Manager Gyanendra Trivedi Graphic Designer Naved H. Kazmi naved@advanceinfomedia.com Circulation Chandni chandni@advanceinfomedia.com Marketing & Circulation Office MashAd MultiCom P Ltd. 121, 1st floor, Rassaz Multiplex, Station Road, Mira Road (E), Dist. Thane- 401107 Telefax : +91-22-28555069, Tel.: +91-22-28115068 Mob.: +91-9867992299 E-mail: info@agronfoodprocessing.com sub@advanceinfomedia.com Vol. 03 Issue 06, December- January 2019 Annual Subscription Rs.1000/- By Courier Add Rs. 50/- For Outstation Charges Overseas $80 By Air Mail Email:sub@advanveinfomedia.com Single Copy Cost Rs. 100/Printed, Published & Owned by Firoz H. Naqvi RNI No. MAHENG13830

Regd. Office MashAd MultiCom P Ltd. 103, AmarJyot Apartments, Pooja Nagar, Mira Road (E) Dist.Thane-401107(Mumbai) Printed At Rolleract Press Services A-83, Ground Floor, Naraina Industrial Area Phase-1, New Delhi -110028

The views expressed in this issue are those of the contributors and are not necessarily those of the magazine. Though every care has been taken to ensure the accuracy and authenticity of the infomation,"Dairy Times" is however not responsible for damages caused by misinterpretation of information expressed and implied within the pages of this issue. All disputes are to be referred to Mumbai Jurisdiction.

he country man and especially the dairymen of India should be delighted to learn that the IDF general assembly has approved India’s candidature to host WDS in 2022 World Dairy Summit in India. This was a long cherished desire of most of the dairy professionals, industry, researchers and dairy farmers of India that such an event should have been organized in India long time ago. The last World Dairy Congress was held in New Delhi during 1974. With India having attained the first place in milk production in the World several years ago, a strong Dr. J.V. Parekh need was felt that the nation must show case its achieveEditor in Chief ments to world community Indian dairy industry can learn from expert, policy makers, producers processors about policies and supply managements. India can play big role with IDF for dairy development in other parts of the world. The WDS 2018 attracted about two thousand global experts to deliberate upon the theme “Dairy for the Next Generation”. Around 120 speakers in 40 sessions outlined the contribution of dairying in the creation of employment and generation of income besides the role of milk in nutrition and health, food security and safety as well as sustainability. Former UN Secretary General Ban Ki Moon said that Milk and dairy products will serve as a critical, sustainable food source for the world’s 9 billion people by 2050 IDF President Dr. Judith Bryans said that IDF is shaping the environment in which dairy operates and driving the sector forward for well over a hundred years, IDF is at the forefront of dairy science through strong expertise and advocacy. IDF has played a pivotal role in promoting ISO standards among its members worldwide and has made useful contributions to the formulation of international standards and guidelines for the dairy sector. In a Special Conference on Dairy industry in the next decade, panelists from the UN Food and Agriculture Organization and OECD discussed dairy consumption patterns of the future, production capacity to meet population growth, change in consumption patterns and trade prospects. The conference on farm management focused on biodiversity, animal breeding and future farming. British farmer, David Cotton, stressed the importance of continuous learning to keep up with best practices and advancements in technology. He also projected that major processing will end up in fewer hands over time while climate change will bring other diseases from tropical climes to Europe. Marketing experts discussed product innovation, food trends and marketing strategies to develop the dairy sector. Dr. Gerrit Smit of Yili Innovation Centre Europe outlined dairy innovations in China aimed at driving market demand. He pointed out that the average milk consumption in China is about a fifth of that of Western countries and projected a continued growth of more than 10 per cent in the coming years. Other emerging markets, such as Latin America and Africa, were also discussed, as well as the overall trading environment for milk and dairy products.

Advisory Board Mr. R.P. Banerjee SSP Pvt. Ltd- Faridabad

Mr. B.M. Vyas Former M.D Amul Anand

Dr. G.S. Rajorhia Former Principal Scientist, NDRI, Karnal

Mr. V.K. Ghoda Sr. Consultant, Perfect Solution, Vadodarra Mr. Vijay Jailkhani Team Ldr, Schreiber Dynamix, Baramati

Dr. Mukund Naware Consultant, Mumbai

Dr. Harsev Singh Ms. Racheline Levi Chief Executive Officer Team Expert, Adepta France

Mr. Devendra Bhai Shah Chairman, Parag Milk Food, Mumbai Mr. Nitin Jain Aurum Equity Partners, Gurugram

Mr. H.R. Dave Deputy M.D Nabard, Mumbai

Dr. B.N. Mathur Former Director, NDRI, Karnal

Dr. K.R. Rao Former CGM, Nabard, Hyderabad

Mr. Subhash Vaidya CEO Dairy Tech Consultancy Serv Mumbai Mr. Dileep Dravid MD & Agro Dairy & Food CS Anand

Dairy Times

Dr. Satish Kulkarni Consultant,Bengaluru

Dr. J.B. Prajapati Principal & Dean, SMC Collage of Dairy Science, Anand

Dr. Ashok Patel Fr. Princ Scientist & Head, Dairy Technology NDRI Karnal Dr. Suresh B. Gokhale Director Research BAIF UruliKanchan, Pune

Mr. Vivek Nirmal MD Prabhat Dairy Mumbai

Dr. Trevor Tomkins President, Venture Dairy U.S.A

9

10

11

12

Launch of IDF World Dairy Summit 2018

culture, Food and Rural Affairs, Mr Lee Gae Ho, who encouraged delegates to seize the opportunity to meet counterparts from other parts of the world for indepth discussions on the future of dairy and to develop meaningful partnerships for growth.

A

spectacular grand opening was laid out for delegates at the IDF World Dairy Summit 2018 with a magnificent drum performance taking centre stage at the Daejeon Convention Centre on 15 October. The warm hospi-

tality of the Organizing Committee of the Summit comprising the leadership and members of the Korea National Committee made delegates feel very welcome to the Land of the Morning Calm. Gracing the event was Korea’s Minister of Agri-

“The Summit will serve as a foothold for the dairy industry to take off even further at the global level beyond Asia,” said Mr Lee. “The dairy farming business provides quality and decent food and nutrients to the entire world, while developing into an important industry.”

Milk and dairy products are a sustainable food source for the next generation: Ban Ki Moon population of more than 7 billion people. Scores of malnourished and food-insecure children across the world receive crucial nutrients from milk.” Mr Ban said milk is critical and essential for international efforts to combat poverty and hunger, stressing the importance of milk in providing essential nutrients for starved children. “Milk serves as an important nutritional food, as well as an essential staple for emergency relief. Providing milk is one of the simplest ways to help people in conflict areas and disasters.”

M

ilk and dairy products will serve as a critical, sustainable food source for the world’s 9 billion people by 2050, said former UN Secretary-General Ban Ki Moon. In a keynote speech delivered at the opening of the IDF World Dairy Summit 2018

in Daejeon, Korea, on 15 October, Mr Ban said: “This increase in population will naturally be followed by acute food shortage. I believe that milk will be one of the solutions to combat any food shortages that may occur.” Describing milk as a ‘complete food’, Mr Ban said: “Milk is a primary food staple for the world’s

Dairy Times

Mr Ban said he is heartened to note that the dairy industry is committed to sustainably providing nutritious dairy products to 9 billion people as the population grows, while also making efforts to preserve the environment. He cited the Dairy Declaration of Rotterdam, a joint initiative of the International Dairy Federation and the UN Food and Agriculture Organization launched in October 2016

13

to promote dairy sustainability through responsible consumption and production. Mr. Ban said the dairy sector plays a leading role in international efforts to achieve the Sustainable Development Goals (SDGs) which are aimed at socio-economic transformation to eradicate poverty and hunger, and to construct a sustainable world where humanity can enjoy better education, healthcare, and equality. The SDGs were launched in 2015 during Mr Ban’s tenure at the UN and sustainability remains a key passion of his. He serves as Co-Chair of the Ban Ki-Moon Centre for Global Citizens in Vienna established in January 2018 within the framework of the Sustainable Development Goals to empower women and youth. Mr. Ban pointed out that the dairy sec-

tor plays an important role in helping to achieve many of the SDGs covering poverty eradication, banishment of hunger, good health and wellbeing and gender equality. Mr. Ban said the dairy sector creates employment through its value chain, generating the third-largest output and the largest trade volume among all agricultural industries. At the same time, he acknowledged that the dairy sector is promoting environmental protection by implementing initiatives to reduce global carbon and water footprints by striving to minimize greenhouse gas emissions, and water and soil pollution generated during the production and distribution of dairy products. “Unlike produce that is harvested once or twice a year, dairy products can be produced every day. This means that more cash can circulate through rural areas, injecting vitality into rural economies. As a result, the well-being of rural areas is improved, and the quality of living is enhanced.” Mr. Ban urged the dairy community to collectively prepare for the next century

by strengthening sustainability for the next generation. “Seven billion people around world today not only recognize milk as a healthy food, but also appreciate the value of the dairy industry for its contribution to humanity’s growth.” He called on the dairy sector to continue to strive through collective efforts to achieve the SDGs. “I hope the accomplishment of these goals can help construct a better environment for your industry to further prosper. I hope you can forge a robust global partnership that goes beyond the boundaries between countries, continents, and regions, and that you can work together to drive the development of humanity and society as global citizens. “I look forward to your industry being duly recognized not only for the nutritional values of its products, but also for its industrial values rooted in sustainability and responsibility. I truly believe this will further enable your industry to actively contribute to humanity’s happiness.”

IDF driver of dairy sector growth and sustainability: Dr. Judith Bryans

T

he International Dairy Federation (IDF) has been shaping the environment in which dairy operates and driving the sector forward for well over a hundred years, said IDF President Dr. Judith Bryans. Speaking at the opening of the annual IDF World Dairy Summit 2018 in Daejeon, Korea, on 15 October, Dr. Bryans said IDF has helped to define how dairy operates “by developing standards used all over the world which ensure the quality of dairy foods, which also helps to facilitate the free flow of trade.” “We have driven the environmental agenda forward, developing carbon and water foot printing methodologies, and through our commitment to the Dairy Declaration of Rotterdam signed together with the FAO,” said Dr. Bryans. “We are stewards of the land and want a healthy planet for

future generations. We’ve defended the nutritional integrity of dairy foods as nutrition is key to all age groups. We have also served as an advisor to Codex since it began, and promoted best practices in food safety, farm management and many more areas.” Dr. Bryans said one of IDF’s strengths is the unique way it works with its 41-member countries, allowing the organization which represents 75% of global milk supply to speak with true global consensus. When IDF speaks, she said it does so with the voice of the global dairy sector. “We will continue to shape the future operating environment for dairy and hope you

Dairy Times

will support us in our work,” said Dr. Bryans. She commended the Korean team for its organisation of the Summit and bringing the world of dairy to Korea to exchange knowledge on Dairy for the Next Generation.

14

Global platform for dialogue on dairy development: President of IDF Korea

T

he IDF World Dairy Summit 2018 is a forum that brings together international experts to share their knowledge and expertise, and exchange ideas on enhancing the dairy sector, said President of IDF Korea, Lee Chang Buhm. He said the annual Summit which was launched today by former UN Secretary-General Ban Ki Moon in Daejeon, Korea, will benefit delegates through the opportunities to interact with their counterparts from other countries and learn from their development experience. “Since we joined IDF in 2006, our dairy industry has grown,” said Mr Lee. “With the hosting of the Summit, we have the opportunity to promote Korean dairy products and to help internationalize our brands.” Mr Lee, who also Chairs the Organizing Com-

mittee of the World Dairy Summit 2018, said the Korean dairy sector can learn from experts, policy makers, academics, producers and processors about policies, supply management and value chains. “We hope to enhance our policies on pricing and milk supply to support the dairy sector in Korea by studying the impact of dairy policies in Europe and America. We are also keen to learn about new technologies to improve production as we expand our markets in China and Southeast Asia, targeting Thailand, Vietnam, Malaysia, the Philippines

and Singapore, before we find opportunities in Europe and America.” Korean exports to the region include ice cream, yoghurt, plain milk, liquid and milk powder, which is popular in China, said Mr Lee. He said Korean milk and dairy products are produced with high quality in food safety. He stated that processed milk powder, particularly infant formula, is sought after by Chinese consumers, which is encouraging to Korean exporters.

Dairy industry in the next decade

I

n a Special Conference on The Next Decade, panelists from the UN Food and Agriculture Organization, OECD, Seoul National University and University College, Cork discussed dairy consumption patterns of the future, production capacity to meet population growth, change in consumption patterns and trade prospects. Dean of Cork University Business School and Professor of Agri-Food Economics, Thia Hennessy, shared her views on food systems and market opportunities for dairy.

Dairy Times

15

Glimpses of IDF world dairy summit, 2018

16

Pricing Trends in Dairy Products: 2018 Domestic milk and milk products Price:

International milk and milk products Price:

Source: USDA Source: Market watch

Source: USDA

Source: Market watch

Source: USDA

Source: Market watch

Source: USDA

IDF at the forefront of dairy science through strong expertise and advocacy: Director General drove home this point to delegates at the World Dairy Summit 2018. She said IDF’s global advocacy for dairy development through interventions at international policy-making platforms and contributions in the drafting of standards, guidelines and policy reforms help to make a difference. She stated that the advisory role of the IDF at such fora has been strengthened by its strong foundation in science-based knowledge of dairy and insight on best practices.

A

dvancing the interests of the global dairy sector by being at the forefront of scientific knowledge and expertise on issues and challenges impacting on the growth and sus-

tainability of this major economic sector is the value the International Dairy Federation (IDF) brings to its members. IDF Director General Caroline Emond

Dairy Times

“IDFs activities from farm to fork help underpin the integrity of the dairy sector ensuring it is recognised as a responsible industry and continues to have a licence to operate, and to deliver safe and sustainable dairy products to consumers,” said Ms Emond. IDF has a worldwide network of 1,200 multidisciplinary experts working in 17 Standing Committees and 3 Task Forces

17 unsurpassed, stressed Ms. Emond. IDF, she said, is a trusted partner of international organisations in the setting of standards. She said the Codex Alimentarius Commission has requested IDF to review guidelines by the FAO/WHO Joint Expert Meetings on Nutrition (JEMNU) for the establishment of nitrogen to protein conversion factors for soy and milk proteins. IDF guide and publications, Ms. Emond said, serve as useful reference for the dairy sector as well as for international organisations.

providing science-based expertise and a wealth of knowledge and skills on tap. On the strength of this global talent pool, Ms. Emond said IDF is the leading voice of dairy to intergovernmental organizations, building global consensus and common ground. With 41-member countries representing two-thirds of global milk production, IDF is a force to be reckoned with, said Ms. Emond. “Milk is the top agricultural com-

modity in value terms, ranking third in the world by production tonnage,” said Ms. Emond. “Milk and dairy products account for 14% of global agricultural trade, contributing 10% to the global value-added from agriculture.” Contributions to the global economy by the dairy sector is significant, according to Ms. Emond, with dairy producing 27% to the global value-added from livestock. The global dairy expertise of the IDF is

Building on its reputation for over a century, the IDF Director-General said the organisation continues to grow from strength to strength, providing vital information impacting on dairy sector development and its prospects for growth. “In the era of fake news, heightened activism championing alternatives to dairy based on ignorance, it is all the more important to share your voice in IDF as we’re stronger together in championing the role of dairy in nourishing lives,” she concluded.

18

Launch of World Dairy Situation 2018 at the World Dairy Summit, Daejeon

T

he IDF World Dairy Situation 2018 report was launched at the World Dairy Summit in Daejeon, Korea, on 16 October. It was put together by IDF experts from dairy producing countries around the world under the scope of work by the IDF Standing Committee on Dairy Policies and Economics (SCDPE). “The IDF World Dairy Situation 2018 will further your understanding of the current macro supply and demand trends affecting the dairy sector,” said Gilles Froment, Chair of the IDF Standing Committee on Dairy Policies and Economics. “The publication contains a comprehensive set of dairy industry statistics and provides an insight on the

wide range of policies and economic factors which influence a world that is increasingly focused on food safety, quality, nutrition, sustainable development and global trade.” The 200-page flagship publication of the International Dairy Federation provides an overview of the dairy sector in over 50 countries around the world. The annual publication offers useful insight on macro supply and demand trends in the dairy sector with data on global milk production and processing,

MANUFACTURE OF HIGH PRESSURE WATER SPRAY STERILIZER

pricing, trade.

consumption

and

The main findings of the report are: * Milkfat-driven recovery of the market resulted in profitable milk prices throughout most of 2017, propelling above-average milk production growth last year. The strongest growth was recorded in India, Pakistan, Turkey, Australia, Poland and the United Kingdom. * There was greater import demand by China last year due to a shortfall in milk production. The East Asian country regained much of its strength as the No.1 dairy importer in the world after local stock positions normalised in 2016. The demand growth is in UHT milk, Mozzarella and cream cheese. * Key export regions like Oceania, the US and the EU will see their cheese production grow in years to come as they have to keep up with accelerating import demand in Asia, with Japan, the Republic of Korea and China being important destinations.

Retort/Sterilizer SUMPOT manufactures different types of Retort/Sterilizer including Static/Shaking/Rotary using Steam, Hot Water Spray, Hot Water Immersion to meet all different products and packages.

Standardized Sterilization High Safety Performance High Automation and Configuration Humanization Design

For all heat resistant and water proof package material Glass container: Glass bottle, Glass jar Metal can: Tin can, Aluminum can Plastic container: PP bottles, HDPE bottles Flexible pouch: Flexible Retort Pouch, Laminated bag, High Temperature cooking bag, Vacuum bag

Represented in India:

Parekh International Trading Corporation 125, The Summit Business Bay, Near W.E. Highway Metro Station, Andheri (East), Mumbai - 400093, India.

Email : info@parekhinternational.com Contact : +91-9819799776 / 22- 26836228 / 29 www.parekhinternational.com

Dairy Times

IDF Director General Caroline Emond said the World Dairy Situation 2018 provides an informative outlook on the dairy sector. “This publication presents data on the dairy sector in respective countries, not just at the farm level,” explained Ms Emond. “Useful information on national and global dairy production, consumption and trade flows are beneficial to producers and processors. The analysis of demand and supply trends help in decision-making and strategic planning to seize market opportunities.” The World Dairy Situation 2018 was produced by a team from ZuivelNL and CNIEL. The publication is available at the IDF booth at the World Dairy Summit 2018 in Daejeon, and online at IDF Store.

19

20

Interview with Dr. Judith Bryans, IDF President by Dr. J.V. Parekh at IDF WDS, Daejeon-South Korea

1. Why have you selected “Dairy for the Next Generation!” as the theme of this IDF-WDS 2018? Answer: Under the theme of ‘Dairy for the Next Generation!’ our summit has explored emerging issues and key aspects of the dairy industry, and offered inspiring prospects for the ever-changing world

of dairy. It has also provided a dynamic and interactive platform for participants to exchange best practice knowledge, and to identify a common agenda, besides developing shared solutions and improving dairy farming. 2. How will IDF play a role in helping participants to meet industry challenges and oppor-

tunities? Answer: In terms of the Summit, worldclass keynote and plenary speeches have been offered by renowned speakers from international organizations, industries and academia. More than 2,000 participants from 57 countries gave their time and effort to join us and all of you have made

MINI DAIRY PLANT

Costruzione macchine settore lattiero caseario Manufacturers of machines for dairies

MINI DAIRY CAPACITY 500L/H - SKID MOUNTED ON PLATFORM Consists Of: • Sanitary pump

Milk Pasteurizing Unit Complete Of:

• Powder milk recombination unit complete of mixing tank 500L, blender pump & control panel

• Balance tank

• Double in-line filter

• Sanitary centrifugal pump

• High pressure homogenizer

• Plate heat exchanger

• Insulated milk storage tank with pump

• Holding tube

• Form Fill Seal Machine for milk pouches

• Flow meter

• Compressor

• Flow deversion valve

• Boiler for hot water production / steam production in case of hot water preparation group

• Control panel

• Stainless steel base frame complete of all hydraulic & electrical connections

Represented in India:

Parekh International Trading Corporation

PAREKH

125, The Summit Business Bay, Near W.E. Highway Metro Station, Andheri (East), Mumbai - 400093, India.

Email : info@parekhinternational.com Contact : +91-9819799776 / 22- 26836228 / 29 www.parekhinternational.com

Dairy Times

IDF WDS Daejeon 2018 a success,and it was a great pleasure for us to have a networking opportunity with you all.We certainly hope that the summit has been all that you had expected, and that you have had an opportunity to make new friends, renew old acquaintances and extend your existing networks for your continued success.Beyond the Summit itself, IDF HO and its various committees will be weaving the discussions and learnings into our work to help push the sector forward in our priority areas. 3.What is the IDF’s role to promotedairy sector growth? Answer: The International Dairy Federation (IDF) has been shaping the environment in which dairy operates and driving the sector forward for well over 100 years. The IDF has helped to define how dairy operates by developing standards used all over the world which ensure the quality of dairy foods, which also helps to facilitate the free flow of trade. We have driven the environmental agenda forward, developing carbon and water foot printing methodologies, and through our commitment to the Dairy Declaration of Rotterdam signed together with the FAO in October 2016. We are stewards of the land and want a healthy planet for future generations. We’ve defended the nutritional integrity of dairy foods as nutrition is key to all age groups. We have also served as an advisor to Codex since it began, and promoted best practices in food safety, farm management and many more areas.One of IDF’s strengths is the unique way it works with its 41-member countries, allowing the organization which represents 75% of global milk supply to speak with true global consensus. IDF has a worldwide network of 1,200 multidisciplinary experts working in 17 Standing Committees and 3 Task Forces providing science-based expertise and a wealth of knowledge and skills on tap. On the strength of this global talent pool, IDF is the leading voice of dairy to intergovernmental organizations, building global consensus and common ground. 4. Anti-milk arguments are spreading by mass media. How are you addressing this? Answer: Liquid milk is becoming less popular in many countries although other products such as cheese and yogurt are

21 increasing in popularity. The anti-milk arguments spreading via the mass media over the past 20 years, as well as the rise of plant-based alternatives, could have a significant impact on consumption. Our challenge as a dairy sector is to: (1) continue to innovate to meet consumer expectations and spread the word about our new products to as many consumers as possible, (2) continue to make simple essential products that everyone can afford and find in stores and, (3) use sustainable nutrition as a driverto remind everyone about the benefits of dairy and their role in peoples diets and livelihoods. 5.How can sustainability be improved at the dairy farming, processing and retail levels? Answer: Unlike produce that is harvested once or twice a year, dairy products can be produced every day. This means that more cash can circulate through rural areas, injecting vitality into rural economies. As a result, the well-being of rural areas is improved, and the quality of living is enhanced. Seven billion people around world today not only recognize milk as a healthy food, but also appreciate the value of the dairy industry for its contribution to humanity’s growth. The dairy sector plays a leading role in international efforts to achieve the Sustainable Development Goals (SDGs) which are aimed at socio-economic transformation to eradicate poverty and hunger, and to construct a sustainable world where humanity can enjoy better education, healthcare, and equality. 6. As a nutritionist, what do you think can be done to improve health and nutrition as well as livelihoods? Answer: Milk and dairy products will serve as a critical, sustainable food source for the world’s 9 billion people by 2050. If we have an increased population, we have to have a way to feed those people. Milk, dairy foods and dairy ingredients are already a primary food staple for the world’s population of more than 7 billion people and will be needed for growing populations. Scores of malnourished and food-insecure children across the world receive crucial nutrients from milk. Milk is critical and essential for international efforts to combat poverty and hunger. Milk

serves as an important nutritional food, as well as an essential staple for emergency relief. Providing milk is one of the simplest ways to help people in conflict areas

Dairy Times

and disasters. I am heartened to note that the dairy industry is committed to sustainably providing nutritious dairy products to 9 billion people as the population grows, while also making efforts to preserve the environment. 7. How can the dairy footprint be reduced? Answer: Ms. Anne Mottet from the Livestock Team at (FAO) gave an excellent overview of livestock’s role in climate change, livelihoods and resilience. She talked about the lack of understanding on the multiple benefits that investments in

22 livestock can generate, and the fact that although climate change is a challenge for the livestock sector, it’s also a development opportunity. The dairy sector is already looking carefully at how it can continuously improve in the environmental arena and use of technology can help with that. 8. What role does the IDF play in the promotion of ISO standards? Answer: IDF has played a pivotal role in promoting ISO standards among its members world wide and has made useful contributions to the formulation of international standards and guidelines for the dairy sector. This strong collaboration between the IDF and ISO continues through the development of joint standards for methods of analysis and sampling for dairy products, which brings together dairy expertise and standardization to enhance compliance in food safety and quality. 9. What do you see as global dairy trends? Answer: Milk fat-driven recovery of the market resulted in profitable milk prices throughout most of 2017, propelling above-average milk production growth last year. The strongest growth was re-

corded in India, Pakistan, Turkey, Australia, Poland and the United Kingdom. There was greater import demand by China last year due to a shortfall in milk production. The East Asian country regained much of its strength as the No.1 dairy importer in the world after local stock positions normalised in 2016. The demand growth is in UHT milk, Mozzarella and cream cheese. Key export regions like Oceania, the US and the EU will see their cheese production grow in years to come as they have to keep up with accelerating import demand in Asia, with Japan, the Republic of Korea and China being important destinations. 10. Could you please tell me something about World School Milk Day? Answer: Every year, World School Milk Day is celebrated all over the world on the last Wednesday of September to raise awareness on the benefits and success of school milk programmes. In addition to providing milk and/or dairy products, school milk programmes include food education. It helps to foster a better understanding of dairy products, including where they come from, how dairy products are made, their nutritional composition, and how they fit into the overall diet.

Dairy Times

Globally, School Milk programmes play a key role in ensuring that young children have access to nutritious foods. This is vital given the role nutrition plays in longterm growth and development. The IDF members around the world participate in these celebrations through different activities, such as a milk lunch party, school activities, media activities or a visit to dairy farms. 11. How can India benefit by hosting IDFWDS in 2022? Answer: I am delighted to inform you that the IDF general assembly has approved India’s candidature to host WDS in 2022 on 14 October, 2018. India can show its achievements to the world community after a gap of more than 4 decades. The Indian dairy industry can learn from experts, policy makers, producers and processors about policies, supply management and benefit from valuable exchanges with international experts to share their knowledge and expertise to enhance the Indian dairy sector. We can also learn a lot from India and look forward to the role India can play in IDF in the coming years to promote dairy development in other parts of the world.

23

Interview with Mr. Chang Buhm Lee -Chairman, South Korea IDF Committee by Dr. J.V. Parekh IDF WDS, Daejeon 1. Why did you host IDF WDS Daejeon 2018 in South Korea? The IDF World Dairy Summit 2018 is a forum that brings together international experts to share their knowledge and expertise, and exchange ideas on enhancing the dairy sector. WDS will benefit delegates through the opportunities to interact with their counterparts from other countries and learn from their development experience. Since we joined IDF in 2006, our dairy industry has grown.

ternational dairy sector. We are now producing over 2 million tones of milk every year with the average growth of 4.5%. the consumption per person is approximately 76.4 kg annually. 3. What are the challenges Korean dairy industry is facing? As in many other countries, Korea’s dairy sector faces challenges such as increasing productivity, improving supply-demand management systems, innovating dis-

With the hosting of the Summit, we have the opportunity to promote Korean dairy products and to help internationalize our brands. The Korean dairy sector can learn from experts, policy makers, academics, producers and processors about policies, supply management and value chains. 2. How Korea is a new dairy powerhouse that is leading the emerging market in Asia? We are able to produce high quality milk thanks to an excellent natural environment that includes superb weather conditions. We continue to expand dairy production through the cooperative efforts of dairy farmers, companies and government agencies. That includes strengthening the industry’s foundations and capabilities through ongoing R&D and investment. Meanwhile, consumption of dairy products is rising steadily due to lifestyle changes as more people begin to incorporate dairy into the country’s traditional food culture. Dairy farming in Korea has great potential for further growth. Building on our role as a leader in Asia’s dairy market, we are ready to contribute to the progress and development of the in-

Dairy Times

tribution structures, and increasing consumption. To successfully navigate such challenges, companies are investing in R&D and dairy farmers are paying greater attention to milk quality, eco-friendly practices, and animal welfare. Government efforts also contribute to improving

24

the dairy sector by focusing on collaborations and support. 4. What problems are faced with current issues by the Korean dairy industry? We have Low birth rate, increased consumption of alternative drinks. Also decreased consumption of liquid milk, increased import of dairy products. Also increased consumption of cheese, butter, etc. We need to expand domestic investment in dairy products. Decreased numbers of dairy farmers, also excessive initial investment costs. and also difficult for new farmers getting into the industry. 5. What are the dairy products Korea is exporting & importing? Korean exports to the region include ice cream, yoghurt, plain milk, liquid and milk powder, which is popular in China. Korean milk and dairy products are produced with high quality in food safety. The processed milk powder, particularly infant formula, is sought after by Chinese consumers, which is encouraging to Korean exporters. We are importing approximately 50% cheese, table butter & SMP in our country.

www.agronfoodprocessing.com

Dairy Times

25

26

Interview with Dr. Piercristiano Brazzale, Chair of the IDF

SPCC by Dr. J.V. Parekh IDF WDS, Daejeon

T

he Italian national, who is a Board member of the Dairy processor Brazzale Spa, was nominated as the New Chair of the IDF Science and Programme Coordination Committee (SPCC) at the General Assembly held on 14 October 2018 on the eve of the World Dairy Summit 2018 in Daejeon, Korea. He also now represents the SPCC on the IDF Board of Directors. Through the strength of his experience in the past three years representing the Standing Committee on Environment (SCENV), Dr. Brazzale aims to promote the essential role of dairy in a nutritious, healthy and sustainable diet. He spoke to Dr. Parekh about his views. 1. Importance of milk in our Diet. Milk is a primary food staple for the

world’s population of more than 7 billion people. The malnourished and food-insecure children across the world receive crucial nutrients from milk. The increase in population will naturally be followed by acute food shortage. I believe that milk will be one of the solutions to combat any food shortages that may occur. The dairy industry is committed to sustainably providing nutritious dairy products to 9 billion people as the population grows, while also making efforts to preserve the environment. The dairy sector plays an important role in helping to achieve many of the Sustainable Development Goals (SDGs) covering poverty eradication, banishment of hunger, good health and wellbeing and gender equality. The dairy sector creates employment

ONE INDUSTRY, ONE SHOW!

13-14-15

7

TH

DECEMBER 2018

REFRIGERATION & COLD CHAIN EXHIBITION IS IN MUMBAI Meet 200+ exhibiting companies from India & abroad

FREE

VISITROYR !

45+ Product launches during the exhibition

ENT

82+ First time exhibitors to showcase their latest solutions International Pavilions Holland & China Industry related Workshops on Startup & Subsidy for cold chain Dec 14, 2018 Timing: 03:30 PM onwards at BEC Mumbai Packaging Zone providing cold chain packaging & labeling solutions Food & Pharma Cold Chain Conference from Dec 13-14, 2018 | Contact: +91 9871628542

Network with 8000+ Senior decision makers

VIP Buyer Programme GoConnect the Business match making platform to prefix meetings Gold Partner

Silver Partners

Bronze Partner

Cold Chain Partner

Food & Beverages

Registration Partner

Dairy & Icecream

Conference Partner savE ® Advanced PCM Technology

Lanyard Partner

Turnkey Solutions Partner

Visitor Badges Partner

Presenting Partners

Media Partner

Organised By

Pharma

Logistics & Retail

FOR MORE DETAILS, CONTACT

+91-9654181043 +91-9654489143

www.IndiaColdChainShow.com

Dairy Times

through its value chain, generating the third-largest output and the largest trade volume among all agricultural industries. 2. How do you promote the essential role of dairy in a nutritious, healthy and sustainable diet? We know that not all nutritionists know about sustainability, and not all sustainability experts know about nutrition, and yet these topics walk hand-in-hand. The dairy sector has suffered from the fact that some published studies use poor methodologies when trying to link environment and nutrition. Many of the methodologies used to link the environment and diet are misleading consumers because the science behind them is not transparent. IDF is working to link nutrition and sustainability with science based methodologies to have finally a clear and positive message for the consumers. 3. How do you see effect of dairy diet on the environment? Data showing that it is possible to reduce greenhouse gas (GHG) emissions by 60% and still maintain dairy in the diet at its current level. However, it does require the reduction in consumption of meat, fish and eggs. He added that an optimal diet produces 3.67 kgs of carbon emissions daily while a dairy-free diet produces 3.53 kgs of carbon emissions, which is a negligible amount. The diet with dairy products, as well as having an environmental impact similar than a diet dairy free, guarantee an apport of essentials nutrients for the human health. As a sector, we know our consumers are not reading studies but they are being influenced by what they see and hear around them.

27

28

Forging Ahead In 2018

T

here is an old saying that time flies and it certainly feels that way. It’s been almost eight months since we were together as Dr. Judith Bryans, IDF family at the IDF President 2017 World Dairy Summit. Many things have happened at IDF over those months and I wanted to take this opportunity to highlight just a few of them to you. You will of course know by now that our new Director General, Caroline Emond, is in place. My thanks to all of you who have contacted her and made her feel welcome. Caroline has been doing excellent work since she took over as DG at IDF. She has been strengthening relationships with some of the intergovernmental bodies that are so important to IDF’s work, as well as building new relationships and contacts. Caroline has also been modernising the way the IDF team works, and is preparing to implement significant

changes to IDF communications, including bringing on board a new Communications Director. We said goodbye to our old DG this year, thanking Nico for his service to the IDF community at a dinner held during the first IDF Head Office event on Nutrition and Sustainability in Seville. For those of you who couldn’t join us for that event, I wanted to take a little bit of time to share some thoughts and learnings from the event since it was the first run by the IDF Head Office. There is no doubt that the importance of nutrition and sustainability as an area of focus came over really well from our very strong line up of speakers who came from the FAO, the USDA, EFSA, academic institutions and the dairy sector. This event had a workshop feel about it giving delegates a lot of opportunity to network with the speakers and have all of their questions answered. Over two days, we covered a broad range of topics under the nutrition and sustainability umbrella, from environment to consumer perceptions to nutrition.

Dairy Times

The sustainable diet topic was beautifully covered during the event by three great speakers: Nicole Darmon from INRA, Brad Ridoutt from CSIRO and Olivier Jolliet from the University of Michigan. Nicole presented data showing that it is possible to reduce greenhouse gas (GHG) emissions by 60% and still maintain dairy in the diet at its current level. However, it does require the reduction in consumption of meat, fish and eggs. Brad explained why water scarcity is so important when considering a water footprint because local conditions at the point of water loss or contamination determine the degree to which ecosystems and human health are impacted (and in all of those with potential for a high degree of variability). Olivier explained the challenges of assessing nutritional and environmental impacts, and benefits of food. While there has been considerable effort to understand the environmental impact of a food or diet, nutritional effects are not usually included in food-related life cycle assessment (LCA). We know that not all nutritionists know about sustainability, and not all sustainability experts know about nutrition, and yet these topics walk hand-in-hand. The dairy sector has suffered from the fact that some published

29 studies use poor methodologies when trying to link environment and nutrition. As a sector, we know our consumers are not reading studies but they are being influenced by what they see and hear around them. Laurent Damiens, from CNIEL, gave the audience a great overview on consumer perceptions of dairy across 27 countries. He told delegates that over the last five years, largely positive food market trends have been seen as a result of (1) economic trends such as a rise in purchasing power and economic upturn in many countries, (2) product offerings that were meeting consumer expectations, (3) a dynamic agri-food industry which offers consumers a constantly changing product selection, and (4) demographic trends such as global population growth and middle-class expansion. Liquid milk is becoming less popular in many countries although other products such as cheese and yogurt are increasing in popularity. He cautioned that anti-milk arguments spreading via the mass media over the past 20 years, as well as the rise of plant-based alternatives could have a significant impact on consumption.

say they are planning to eat less dairy to be healthier. Millennials often have negative perceptions around dairy. However, millennials who are thinking about having children or have young children are open to learning about nutrition, as well as loving the taste of dairy, so there is an opportunity for us to re-establish the forgotten relevance of dairy and its core values. Emily Meredith, from the National Milk Producers Federation (NMPF), spoke about consumer perceptions in the USA. She told the audience that consumers in the US now seek “sustainably sourced” and/or “responsibly produced” dairy. Investment firms are considering animal welfare when choosing whether or not to invest. The NMPF has a voluntary quality assurance programme named FARM: Farmers Assuring Responsible Management based on the ISO Standard on Animal Welfare. FARM offers a continuous improvement process to ensure a high level of on-farm

Our challenge as a dairy sector is to: (1) continue to innovate to meet consumer expectations and spread the word about these new products to as many consumers as possible, (2) continue to make simple essential products that everyone can afford and find in stores and, (3) use sustainable nutrition as a driver. The session on consumer perceptions continued with Professor Wim Verbeke from the University of Ghent presenting a survey done in five European countries. Although consumers associated health more with plant-based than animal-based foods, within animal-based foods, dairy is strongly accepted as a good source of protein. Ialso presented in this session. In my case, I talked about consumer perceptions and dairy promotion in the UK. In the UK, dairy alternatives are using dairy values to promote themselves and 28% of UK consumers

Dairy Times

animal care and sets the highest standards that encourages dairy farmers to continually improve. Professor Ian Givens, University of Reading, suggested that of all of the products in the dairy portfolio, yogurt appeared to have the strongest positive effect on diabetes. He also said that more attention is needed on the effects of foods, not nutrients and that so-called sustainable diets must be assessed for functionality. Silvia Valtueña Martínez from EFSA talked to the delegates about health claims, but there was nothing new on dairy. Regarding the socioeconomic impact of dairy, Eric Grande, talked about the GRI Sustainability Reporting Standards. These are to be used by organisations to report about their impacts on the economy, the environment, and/or society. He stressed that for dairy companies, IDF remains the core scientific expertise body

30 a development opportunity. Anne’s talk was followed by Jorgen Eivind Olesen explaining how the dairy sector can adapt to climate change – mostly by the extension of current technologies to adapt to climatic variability.

with valued publications such as bulletins on carbon footprint, water footprint, and biodiversity assessments. He also mentioned the European Dairy Association project on the Product Environmental Footprint Category Rules and communication guidance on the environmental footprint of different dairy products. Piercristiano Brazzale, talked about sustainability from the perspective of a child. He argued that many of the methodologies used to link the environment and diet are misleading consumers because the science behind them is not transparent. Torsten Hemme from IFCN expressed his concern about milk prices. His view was that price is a driver for sustainability since for a dairy farmer economics comes first. I would say we also have to look on the other side of that coin as there is data to show that environmentally friendly farmers tend to be more efficient and benefit financially. Dacia Whitsett-Morrow from USDEC talked about the positive role milk pro-

tein could play in terms of improving lean body mass, reducing obesity risk, reducing chronic diseases risk later in life and preserving muscle mass as we age. She stressed the need for the dairy sector to communicate the beneficial impact of dairy proteins to policy makers. The IDF President has a seat on the Governors Board of the Dairy Sustainability Framework (DSF) and also chairs the Advisory Council of the DSF. During the Seville event, I addressed the audience about the role of DSF in continuing to enhance sustainable development of the dairy sector. I touched on the 11 sustainability criteria and how it connects members and reporting criteria. Anne Mottet from the Livestock Team at the Food and Agriculture Organisation (FAO) gave an excellent overview of livestock’s role in the climate change, livelihoods and resilience. She talked about the lack of understanding of the multiple benefits that investments in livestock can generate, and the fact that although climate change is a challenge for the livestock sector, it’s also

The final speech of the two-day event was given by Mary Beth Hall of the USDA who gave a wonderful and very meaningful explanation of why removal of all livestock from the US would result in nutrient deficiencies and more caloric intake, based on work she had conducted. My overall reflection on the two-day event is that it opened a door to future events of this type, and that we need to be bolder and broaden the types of speakers we bring to include our dairy farmers and maybe an NGO or consumer group for a more rounded discussion. Beyond the event in Seville, there have been lots of other things happening in IDF around a potential new MOU with the FAO, and possible new partnerships with other organisations. I have also now been trained as a dairy ambassador, and have had the opportunity to engage in a session at the UN in New York. The training was done thanks to our colleagues at GDP, where the IDF President has a seat on the Board. I look forward to attending the UN HLPE in July and taking on some meetings to get across global dairy nutrition and sustainability messages. But before then, I will represent IDF at the Food2030 in Plovdiv, Bulgaria. More info on all the items mentioned in this paragraph will come in future blogs and IDF meetings. We also had the privilege of celebrating World Milk Day on 1 June with our South Korean colleagues. I hope, like us, you enjoyed one of your favourite dairy products on World Milk Day.

Dairy Times

31

Global Cooperation of Codex and other international bodies such as IDF 1. Food, glorious food! We all rely on food. Food is fragile. We need it to be available, safe, nutritious and tasty. Beyond keeping us Dr. Tom Heilandt alive, food is an Codex Secretary important element of our culture and society. Milk and milk products are an excellent example of this. They are nutritious and part of our culture. In some countries so much that President De Gaulle of France once said: “How can you govern a country, which has 246 varieties of cheese?” Peace and prosperity depend on the availability of food. Food is a commodity like no other and needs to be treated like specially. Only the close cooperation of all actors in the food supply chain whether public, private and consumer will achieve our common goal of safe, good food in every home all. 2. History The first item in the summary of the Codex Alimentarius history on the Codex website is 1903, the year in which the International Dairy Federation was founded. IDF was an important catalyst in the creation of Codex. The fact that the IDF was founded before any other major organization still existing today shows the importance of milk and milk products. In fact, the IDF dates from an era when food safety was still at the beginning. In those days the use of unsafe food additives (especially preservatives) was still common practice in many parts of the world. Cold chains were by far not as developed as today and many homes did not have a refrigerator thus the possibilities that chemistry offered were quickly embraced by industry in order to deal with one problem and unwittingly creating others. As it became apparent that the chemicals used did not only have beneficial effects, it

became also clear that research and regulation was needed. Many national and international initiatives followed and 53 years later in 1956 the two major United Nations organizations FAO and WHO created the Joint Expert Committee on Contaminants and Food Additives (JECFA) to scientifically examine the safety of food additives and the impact of contaminants in all foods. 1957 saw the creation of the Government Experts on the Code of Principles on Milk and Milk Products which in 1963 became a committee of the new Codex Alimentarius Commission marking also the beginning of a unique cooperation.

sions with which it is essential to comply. However, the reference made to science based Codex food safety standards in the World Trade Organization’s Agreement on Sanitary and Phytosanitary measures (SPS Agreement) means that Codex has far reaching implications for resolving trade disputes. WTO members that wish to apply stricter food safety measures than those set by Codex may be required to justify these measures scientifically. Since its foundation, the Codex system has evolved in an open, transparent and inclusive way to meet emerging challenges. Image 1 shows how the Codex membership has grown over the years together with the food export value. Codex today has 188 member countries and one member organization (EU) and over 220 observers of which IDF is one of the most active.

2. Codex: an international tool 2.1 Purpose

Image 2: Codex Alimentarius Commission Session in Rome

International food trade has existed for thousands of years but until not too long ago food was mainly produced, sold and consumed locally. Over the last century the amount of food traded internationally has grown exponentially, and a larger quantity and variety of food never before travels the globe today. The codex alimentarius international food standards, guidelines and codes of practice contribute to the safety, quality and fairness of this international food trade. Consumers can trust the safety and quality of the food products they buy, and importers can trust that the food they ordered will be in accordance with their specifications.

Image 3: Codex Alimentarius Commission Session Rome 2.2 Work methods Codex prides itself to be open, transparent and inclusive. All information about Codex work is publicly available for free on the Codex website (www.codexalimentarius.org) the work is member driven and strives even in the most difficult cases to take decisions by consensus.

Codex standards and related texts are not a substitute for, or alternative to national legislation. Every country’s laws and administrative procedures contain provi-

The Commission itself is the ultimate decision body meeting annually in Rome or Geneva and usually attended by more than 600 delegates from over 100 coun-

Dairy Times

32 tries. It is supported by an Executive Committee consisting of elected members and regional coordinators. The technical work is done in horizontal and vertical committees or task forces, each of which is hosted and chaired by a member country that is also responsible for the costs of interpretation and translation. In addition, FAO/WHO coordinating committees for each of the six Codex regions make sure that specific regional aspects are addressed by Codex. In some cases, these committees develop standards for regional products. The structure differentiates between horizontal committees (dealing with all foods) and vertical committees (dealing with a specific food group). Task forces are formed to deal with specific problems and are dissolved once they have achieved their work. Presently one task force is active dealing with the challenges of Antimicrobial resistance.

Image 5: Codex Committee Structure in 2018 The Codex standard setting process depicted in Image 6 has 8 steps consisting of: An initial reflection on which new work is needed (discussion paper) Agreement of new work (Step 1) Drafting (Step 2)

Circulation of the draft for comments to all members and observers (Step 3) Discussion in the technical committee or task force (Step 4) Intermediary adoption by the Commission (Step 5) Circulation for comments (Step 6) Discussion in the technical committee or task force (Step 7) Adoption as a Codex standard (Step 8) The process is designed to allow sufficient input from all stakeholders to achieve a consensus. Steps 6 and 7 may be omitted and the overall process can be finished within one year or take longer depending on the complexity of the issue.The process also allows for input received from the FAO/WHO scientific advice provided by standing committees (JECFA – food additives, contaminants and veterinary drugs; JMPR – pesticides; JEMRA – microbiological risks and JEMNU – nutrition). Image 6: Codex standard setting process 2.3 Achievements Since 1963 Codex has set Commodity standards for all major food commodities (221 texts) as well as 78 Guidelines dealing with general issues such as food import and export inspection and certification systems and 52 Codes of Practice dealing for examplewith guidance on preventing contamination (chemical, physical or microbiological) of food products. 106 maximum levels have been set for contaminants, 4130 food additives provisions, 5231 pesticide residue levels and 623 veterinary drugs residue levels. 2.4 Codex and the Sustainable development goals Codex work has a clear connection to the six following 6 goals for safer, better food for everyone, everywhere. SDG1: “No Poverty”.

Dairy Times

33 If a country adopts global food safety standards such as Codex standards into national legislation, then local traders can access new markets and increase their trade. They do business and create employment. Reaching this goal would mean an end to poverty in the agriculture sector. SDG2: “Zero Hunger” The first target of this goal is (by 2030) to “end hunger and ensure access by all people, in particular the poor and people in vulnerable situations, including infants, to safe, nutritious and sufficient food all year round”. There is strong link between Codex work on food safety and the positive outcome of food security. This goal also deals with trade and states the need to correct and prevent trade restrictions - another central aspect of the Codex mandate. Codex is advocating

this goal in a positive wayby contributing to making it possibly to bring safe and nutritious food to every home.

ductive employment and decent work for all”. Trade is a vital opportunity for growth in this area and the Codex standards promote fair practices in food trade by eliminating trade restrictions and barriers to trade.

SDG3: “Good Health and well-being”. When developing and transition economies engage in the development of Codex standards and then use those standards as the basis for national standards, they are protecting consumer health both within and outside their national borders. Strengthening food safety systems will enable countries to take measures to reduce the burden of foodborne disease.

SDG12: Food waste and management of chemicals. One of the targets of goal 12 is “halving per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains”. Codex work on accurate and reliable food labelling links directly to this goal.

SDG8: “Decent Work and Economic Growth” The targets of this goal are linked primarily to growth, productivity and employment. Engaging in Codex, rather as for Goal 1, will help countries work towards achieving “full and pro-

Dairy Times

The goal also calls for sound management of chemicals. Chemicals in food are a worldwide health concern and are a leading cause of trade obstacles. The expert advice provided to Codex by FAO and WHO ensures that correct exposure levels are set in Codex standards to protect consumer health. SDG17: Partnerships for the SDGs. Partnerships: working together will ensure that no one is left behind in the drive to reach the 2030 Sustainable Development Goals. Codex itself is one of the finest and longest standing examples of part-

34 nership within the United Nations system. Codex, together with OIE and IPPC, is also part of another strong partnership when working on global issues such as antimicrobial resistance or when called upon as the benchmark for standards in WTO trade disputes. Codex also believes in the value of partnerships with all its stakeholders, both

members and observers, industry and consumers. In the longstanding partnership with the International Dairy Federation, Codex created standards, guidelines and Codes of Practice for milk and milk products. Codex measures itself against organisations such as ISO and GFSI to ensure that the standards produced in Codex are the best, most robust science-based standards possible.

Manufacturer of Disposal Plastic Cups and Food Packaging Containers with Multicolor printing

SHRI VIGNESHWARA POLY PRODUCT Beach Road, Koteshwara, Kundapura - 576222, Karnataka, India Phone: +91-8254-261746, +91-8254-325006 Fax : +91-8254-262746 Mobile: +91-9448462746 Web Site: www.shrivigneshwara.com

When Goal 17 describes a “universal, rules-based, open, non-discriminatory and equitable multilateral trading system” it is pointing directly at the mandate, goals and daily work of the Codex Alimentarius. 3. IDF and Codex – a unique relation For over 55 years Codex and IDF have worked together. Just in the last 5 years IDF attended 55 Codex sessions with 141 delegates. IDF serves as an essential technical advisor to Codex on all issues related to milk and milk products and was thus given a special place in Codex procedures:

Dairy Times

Step 2 The Secretariat arranges for the preparation of a proposed draft standard….. In the cases of milk and milk products or individual standards for cheeses, the Secretariat distributes the recommendations of the International Dairy Federation (IDF). IDF/Codex Joint achievements encompass Codex Standards for Milk and Milk Products, Methods of analysis, Labeling, Hygiene and AMR. The following texts have been developed: Hygiene: Hygienic practice for milk and milk products, Preservation of Raw Milk by Use of the Lactoperoxidase System Contamination: Reduction of Aflatoxin B1 in Raw Materials and Supplemental Feeding stuffs for Milk-Producing Animals Terminology: Use of Dairy Terms Certification: Model Export Certificate for Milk and Milk Products Cheese: General standard for Cheese, Whey cheeses, Cheeses in brine, Cream cheeses, Unripened cheeses incl fresh cheese, Cottage cheese, Extra hard grating cheese, Brie, Camenbert, Cheddar, Coulommiers, Danbo, Edam, Gouda, Havarti, Mozzarella, Samsø, Emmental, Provolone, Tilsiter, Saint-Paulin Milks: Evaporated, Fermented, Sweetened condensed

35 Codex nutrition standards have also contributed to the implementation of the WHO Global Strategy on Diet, Physical Activity and Health. Finally, Codex and its partners have successfully advocated for creating a World food safety day (7 June each year) to have a constant reminder in the calendar that food safety is not a given but needs constant attention from all stakeholders. Powdered: Milk Powders and Cream Powder, Dairy Permeate Powders, Whey Powders Blends: Evaporated Skimmed Milk and Vegetable Fat, Skimmed Milk and Vegetable Fat in Powdered Form, Sweetened Condensed Skimmed Milk and Vegetable Fat Other: Butter, Dairy fat spreads, Milkfat products, Cream and prepared creams, Edible casein products 4. The future 4.1 Major Successes Codex has set the standards for all major issues in food trade and most legislations based on what Codex proposes. Major food safety texts are the General Principles of food hygiene (including the essential HACCP system) as well as the General standard for food additives and for contaminants as well as related codes to reduce contamination. The Codex Food labeling system offers all relevant guidance to countries to ensure that consumers receive all relevant information about products and are not misled. The Codex Risk analysis system both for application in Codex and direct application by government offers a comprehensive way for members to protect their population based on sound science. Major breakthrough texts are the risk analysis guidelines for GM goods and AMR.

Codex has been creating these networks since it was started, and its goal is to make food safety a topic known to consumers through activities celebrating the world food safety day. 4.2 Issues Codex is currently debating its next strategic plan (2020-2025). This is important to ensure that Codex is setting the right standards in the right way and make sure that the standards serve their purpose and are used by members.Speed of standard setting and efficient and effective participation of all members in the are still challenges as is the financing of the scientific advice underlying Codex. Codex has faced many challenges to standardization in the past, some of them were solved, others are still waiting for a solution in areas where consensus is difficult to achieve among members. Some examples are: Green oranges (solved by changing ripeness criteria from “orange” to sugar and juice content); Labeling of GM food (solved by concentrating on ge-

In the Nutrition and foods for special usesarea Codex has contributed to improve the situation for people intolerant to gluten as well as giving advice on infant and baby foods and on food supplementation.

Dairy Times

neric guidance and avoiding being overly prescriptive); Veterinary Drugs Residues for Growth promoters (RBST, Ractopamine, Zilpaterol – ongoing); Certain Food additives (differing opinions as to technological justifications e.g. coloring - ongoing); Use of the term “natural” in labeling (no consensus – work discontinued); follow-up formula (difficult discussions on avoiding misleading consumersongoing); Processed cheese (discontinued because the product is too diverse all over the world) and Makgeolli (should Codex set a standard for a product containing alcohol – ongoing). 4.3 Change is a thing we can count on The future will bring most certainly: More people, climate change, more countries trading, new products and production methods, changed consumer awareness/ demands, new sales channels–e-platforms, new diseases, food fraud, AMR and other unexpected challenges. 5. Conclusions There is a lot to do to achieve safe, tasty, nutritiousfood in every home all the time! Standards are a tool to avoid misleading consumers and ensure safety and fair practices in the food trade. Codex is an excellent international standard setting tool, but it can only be as good as the use members make of it and how good they are at finding consensus on critical issues and apply the standards in practice.

36 From 1998-2005 he was Secretary of the UNECE Working Party on Agricultural Quality Standards. In 2005, he joined the Codex Secretariat in Rome as Senior Officer responsible for communication. In October 2014, the Directors General of FAO and WHO appointed him to the position of Secretary of the Codex Alimentarius Commission. Codex Alimentarius Commission The Codex Alimentarius Commission is the worlds’ food standards body established by FAO and WHO in 1963 with the main objectives of protecting the health of consumers and ensuring fair trade practices in the food trade. A longer term strategic outlook on the future of food and food standards will be needed in addition to the medium term strategic plan in order for Codex to remain relevant. Partnerships with other organizations need to be strengthened as food safety and quality are a shared responsibility of all actors in the international supply chains. Tom Heilandt – tom.heilandt@fao.org

Tom Heilandt, born 30/12/1961 is a German citizen with degrees in Mathematics and Computer Science. From 1990-1992 he worked at Bayer in operations research and expert systems then joined AION International as systems engineer. From 1994-1998 he worked in the Secretariat of the United Nations Economic Commission for Europe (UNECE) in Geneva on the international regulations for the transport of dangerous goods.

The Commission develops harmonised international food standards, guidelines and codes of practice and promotes coordination of all food standards work undertaken by international governmental and non-governmental organizations. Codex contributes to the safety, quality and fairness of international food trade. Consumers can trust the safety and quality of the food products they buy and importers can trust that the food they ordered will be in accordance with their specifications.

C

Enterprises

CoolBiz Enterprises

CoolBiz Enterprises is a leading trading company fully focused on food processing & Ice cream industry and have solu�ons for all industry needs. Our product range consist of Homogenizer, Ice cream filling machine, con�nuous freezers and deep freezers, upright freezer, chest freezer, milk coolers, display freezers, blast chillers, visi coolers and electronic fly Catcher, of popular brands. We offer custom made FOW and carts on wheels as per specifica�on of the clients.

C

Enterprises

CoolBiz�Enterprises

B-407 Om Narmada CHS, Station Road, Near Nupur Palace, Mira Road (E), Thane- 401107, Mumbai Mob: +91-8779231570/9769278424 Email: salse@coolbizent.com Website: www.coolbizent.com

Dairy Times

37

38

FSSAI pushes dairy firms to start voluntary milk fortification

U

informed elements are creating confusion around the issue. We need to ensure it does not get derailed due to misinformation or lack of awareness,” he said.

“A large majority of stakeholders are in favour of food fortification but a few mis-

Last month, FSSAI notified standards for fortifying staples such as edible oil, milk, atta, maida and salt. The food safety authority has been urging industry to undertake voluntary fortification of their products especially edible oil and milk, before

rging private and public dairy companies to begin voluntary milk fortification, the Food Safety and Standards Authority of India CEO Pawan Agarwal said food fortification is the most cost-effective and globally-recognised strategy to address micro-nutrient deficiencies.

it is made mandatory. “Several ministries and government bodies have written to FSSAI to make fortification mandatory. However, we want to first assess whether the industry is ready. Fortification needs to be scaled up step-by-step before being made mandatory,” Agarwal said while speaking at the National Consultation of Milk Fortification recentlly .

ITC to Take on Amul, Coke with Milk-based Drinks

I

TC, plans to launch ready-to-drink, milk-based beverages that will compete with the likes of Coca-Cola, Amul and Britannia next month. The new product range — Sunfeast Wonderz — will be launched first in the southern states of Tamil Nadu, Karnataka, Telangana and Andhra Pradesh before being rolled out nationally. Unlike existing products made with artificial flavours, ITC will use real fruit pulp for the milkshakes, the company said. “This innovative range of milk-based beverages will be powered by the company’s institutional capabilities including agri-sourcing, distribution, infrastructure, among others,” said Hemant Malik, divisional chief executive – Foods, at ITC. “The ready to drink milk beverages market has seen high growth in the recent past with a paradigm shift to healthier

beverages and we believe innovative offerings in this segment could have great potential for the future.” The range will be manufactured in ITC’s new facility in Kapurthala, Punjab, where the company has invested in an aseptic pet facility. Globally, shifting consumer tastes are prompting beverages giants, including Coca-Cola and PepsiCo, to diversify away from traditional soda and high-calorie juices. Growth has consistently slowed down in the Rs. 22,000-crore carbonated soft drinks Co will use real fruit pulp for beverages market as consumers increasingly switch to healthier beverages such as juices, energy drinks, flavoured tea, fortified water and dairybased beverages. Several companies are

experimenting and bringing in flavour innovation; products including oats a n d fruits are combined with drinking milk products to cater to the needs of healthconscious consumers. A research from global market intelligence agency Mintel said flavo- ured milk products accounted for 39% of dairy drink introductions in India in the first half of 2017, up from just 20% in 2012. Over one in four (28%) consumers of pre-packaged, ready-to-drink dairy drinks consume it for breakfast, said the researcher.

Patanjali enters cow milk business; eyes Rs. 1,000 cr sales next fiscal

B

aba Ramdev’s Patanjali Ayurved announced its foray into the dairy segment by launching milk and milk-based products, including curd and cheese, targeting sales worth Rs. 1,000 crore from the segment. Besides, Patanjali had also ventured into frozen vegetable segment and has introduced products such as sweet corn, pea and potato fingers. “We are aiming to have a business of Rs. 1,000 crore next fiscal. This fiscal, we would have a business of Rs. 500 crore,” said Baba Ramdev while