TECHNICAL PAPERS

Considerations for Kitchen Exhaust Design and Specification in Hospital Environments JONATHAN BUNGE (M.ENG CHEMICAL), SHANNON ROGER (B.ED) AND DR ALLAN HECKENBERG (PHD) I AIREPURE AUSTRALIA 2016

Considering the vast number of hospital and commercial kitchens in Australia, one would expect that exhaust treatment solutions for these applications would be routine. However, whilst the aims of good kitchen design and the effective treatment and exhaust of cooking fumes, are easy to express – the diverse range of sites and environments, create a remarkably complex situation.

D

ifferent cuisine types produce varying amounts of moisture, grease, smoke and odour and the resulting cooking fumes comprise a combination of solid particles, liquid droplets and vapour/gaseous phase contaminants. Various kitchen exhaust treatment technologies are available to choose from – each with pros and cons affecting the cost versus performance scale. This article seeks to set out the broad aims and parameters of commercial kitchen exhaust design within hospital environments to ensure exhausted cooking fume matter complies with relevant standards to reduce fire risk and will appease sensitive receptors to the exhaust odours.

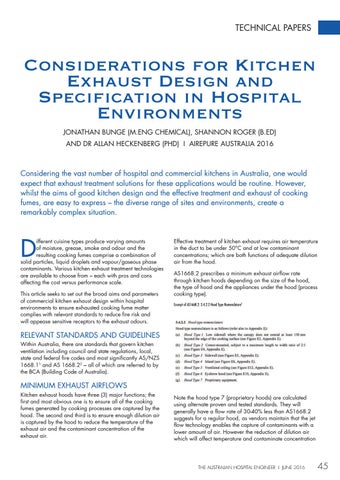

Effective treatment of kitchen exhaust requires air temperature in the duct to be under 50°C and at low contaminant concentrations; which are both functions of adequate dilution air from the hood. AS1668.2 prescribes a minimum exhaust airflow rate through kitchen hoods depending on the size of the hood, the type of hood and the appliances under the hood (process cooking type). Excerpt of AS1668.2: 3.4.2.2 Hood Type Nomenclature2

RELEVANT STANDARDS AND GUIDELINES Within Australia, there are standards that govern kitchen ventilation including council and state regulations, local, state and federal fire codes and most significantly AS/NZS 1668.11 and AS 1668.22 – all of which are referred to by the BCA (Building Code of Australia).

MINIMUM EXHAUST AIRFLOWS Kitchen exhaust hoods have three (3) major functions; the first and most obvious one is to ensure all of the cooking fumes generated by cooking processes are captured by the hood. The second and third is to ensure enough dilution air is captured by the hood to reduce the temperature of the exhaust air and the contaminant concentration of the exhaust air.

Note the hood type 7 (proprietary hoods) are calculated using alternate proven and tested standards. They will generally have a flow rate of 30-40% less than AS1668.2 suggests for a regular hood, as vendors maintain that the jet flow technology enables the capture of contaminants with a lower amount of air. However the reduction of dilution air which will affect temperature and contaminate concentration

THE AUSTRALIAN HOSPITAL ENGINEER I JUNE 2016

45