Q&A

Lt. Gen. Scott A. Spellmon

Commanding General and Chief of Engineers

By Christopher J. Augsburger

Providing Technical Expertise Around the Globe

By Craig Collins

Sponsored Advertising Content

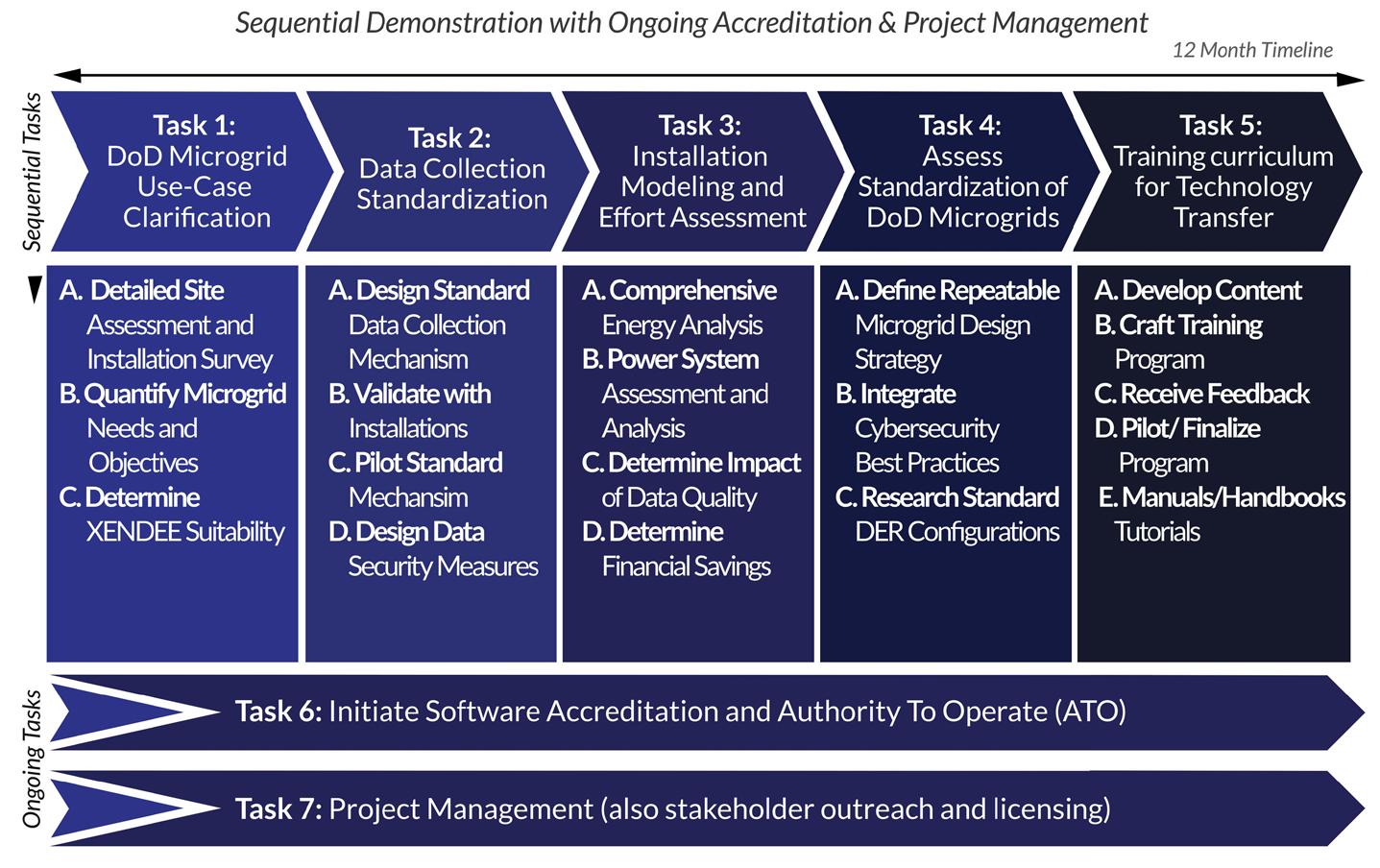

Xendee: How to Create a DOD-Certified Microgrid

NASTT: Trenchless Education and Training Help Mitigate Risks and Advance Technologies

Districts & Divisions

Middle East District

By Joe Macri Kansas City District

By Reagan Zimmerman Little Rock District

By Erin Jimenez

Europe District & DHA

By Europe District and the U.S. Defense Health Agency North Atlantic Division

By Joshua Voda

Europe District & ERDC

By Christopher Gardner Mobile District By Chuck Walker

Districts & Divisions

Sacramento District

By Jeremy Croft Southwestern Division

By Jeremy Croft

St. Paul District

By Patrick Moes

Institute for Water Resources

By Col. Joe Manous Jr., Ph.D., USA (Ret.), Paul Gagnon, Ph.D., and Michelle Hilleary, Ph.D. Detroit District

By Carrie Fox

Vicksburg District

By Sabrina Dalton

ERDC’s Martinez-Guerra Applies Military Installation Expertise to Jackson Water Crisis

By Holly Kuzmitski Portland District

By Christopher Gaylord

Ready and Responsive to the Needs of the Nation

By Craig Collins

Districts & Divisions

Baltimore District

By Eva Falls and Brittany Crissman North Atlantic Division

By JoAnne Castagna Louisville District

Shaping

a Sustainable Future By Craig Collins

Districts & Divisions

Charleston District

By Glenn Jeffries Alaska District

By Rachel Napolitan Tulsa District

By Tiffany Natividad San Francisco District

By Isabel Nieman Galveston District

By Melanie Ellis

By Craig Collins

By Katie Newton Pittsburg District

By Michel Sauret Mobile District

By Jeremy Murray

ERDC Uses Digital Twin Technology to Re-create Damaged Air Force Base

By Claiborne Cooksey

Seattle District

By Dallas Edwards Huntsville Center

By Kristen Bergeson

Modernizing

Water Infrastructure

the Nation’s

www.Americas-Engineers.com I 5

8 18 38 82 26 27 29 30 32 34 36 40 46 48 51 52 54 56 64 66 68 71 74 78 80 81 84 92 94 97 99 101 102 104 106

TABLE OF CONTENTS

by American Conference & Event Media, LLC. 2491 Nursery Road, Unit #53 Clearwater, Florida 33764 (727) 234-8760 www.americas-engineers.com www.acemllc.com

EDITORIAL

ADVERTISING

Chief Sales Officer

Beth Hamm +1 (727) 213-8844 beth.hamm@acemllc.com

EMEA Sales Director Andrew Moss +1 (727) 222-6953 andrew.moss@acemllc.com

AMERICAN CONFERENCE & EVENT MEDIA

Publisher Damion Harte +1 (727) 234-8760 damion.harte@acemllc.com

7

www.Americas-Engineers.com I

AND PRODUCTION

Editor in Chief Chuck Oldham Consulting Editor Karen Buehler Managing Editor Rhonda Carpenter rcarpenter@spaceandcomma.com Contributing Writer Craig Collins DESIGN

Art Director Robin McDowall www.mcdowalldesign.com

© American Conference & Event Media, LLC. 2022 All rights reserved. America’s Engineers: The People, Programs, and Projects of the U.S. Army Corps of Engineers is published by American Conference & Event Media, LLC., 2491 Nursery Road, Unit 53, Clearwater, Florida 33764. TEL (727) 234-8760. ADVERTISING SALES: Beth Hamm, TEL (727) 213-8844, beth.hamm@acemllc.com Reproduction in whole or part without written permission is prohibited. © American Conference & Event Media, LLC., and the U.S. Army Corps of Engineers (USACE) do not assume and hereby disclaim any liability to any person or company for any loss of damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and the opinions in the articles or advertisements are not to be taken as official expression of the publisher, staff, or writers, unless so stated. Neither the publisher nor USACE warrant, either expressly or by implication, the factual accuracy of the articles or advertisements herein, nor do they so warrant any view or opinions offered by the authors of said articles. Printed in the United States of America. Permission to use various images and text in this publication was obtained from USACE or U.S. Department of Defense (DOD) and its agencies, and in no way is used to imply an endorsement by USACE nor any DOD entity for any claims or representations therein. None of the advertising contained herein implies USACE or DOD endorsement of any private entity or enterprise. This is not a U.S. government publication. POSTMASTER: Send address changes to ACEM, 2491 Nursery Road, Suite 53, Clearwater, Florida 33764 Published

Cover: Mount Morris Dam and Letchworth State Park in New York the morning of Oct. 23, 2019. Fog rolls down the river and over the dam’s spillway as fall foliage fills the gorge.

Photo by Steve Winslow

Lt. Gen. Scott A. Spellmon

Commanding General and Chief of Engineers

Lt. Gen. Scott A. Spellmon assumed duties as the 55th chief of engineers and commanding general of the U.S. Army Corps of Engineers (USACE) on Sept. 10, 2020, after most recently serving as the USACE deputy commanding general for civil and emergency operations.

Spellmon, a native of Bloomingdale, New Jersey, is a 1986 graduate of the U.S. Military Academy at West Point, New York. He holds a Master of Science in civil engineering from the University of Illinois at Champaign/Urbana and a Master of Science in national security strategy from the U.S. Army War College.

Spellmon’s command assignments include commanding general of USACE’s Northwestern Division, where he oversaw an annual program of more than $3 billion in civil works, environmental restoration and military construction in 14 states, primarily within the Columbia and Missouri River basins; commanding general of the U.S. Army Operational Test Command, Fort Hood, Texas; commander, 1st Maneuver Enhancement Brigade, Fort Polk, Louisiana; commander, 317th Engineer Battalion and 3-3rd Brigade Special Troops Battalion, both as part of the 3rd Brigade Combat Team, 3rd Infantry Division at Fort Benning, Georgia.

Spellmon’s key staff assignments include executive director, Office of the Chief of Engineers, Headquarters, Department of the Army; chief of staff, U.S. Army

BY CHRISTOPHER J. AUGSBURGER

8 I USACE AMERICA’S ENGINEERS

PHOTO BY CEPA

Q&A Lt. Gen. Scott A. Spellmon

Lt. Gen. Scott A. Spellmon, commanding general and chief of engineers.

PHOTO BY JAY WOODS, LITTLE ROCK DISTRICT PUBLIC AFFAIRS

“Let me give you an idea of what we’re facing. Between our normal civil works appropriations, emergency supplemental appropriations, the 2021 passing of the Bipartisan Infrastructure Law, and our normal yet massive military, interagency, and international efforts around the globe, our program responsibility has ballooned to more than $92 billion.”

Lt. Gen. Scott A. Spellmon

Maneuver Support Center of Excellence, Fort Leonard Wood, Missouri; engineer intelligence officer, Allied Command Europe Rapid Reaction Corps, Rheindahlen, Germany; and observer-controller, Combat Maneuver Training Center, Hohenfels, Germany.

Spellmon’s operational deployments include Operation Desert Shield/Desert Storm; Operation Iraqi Freedom; and Operation Enduring Freedom, Afghanistan. His military awards and decorations include the Distinguished Service Medal, Legion of Merit, two Bronze Stars, the Purple Heart, and the Combat Action Badge.

What is the greatest challenge you see facing the U.S. Army Corps of Engineers (USACE) during the next several years, given the recent increase in funding and authorizations?

Lt. Gen. Scott A. Spellmon: Workload –it’s our greatest challenge and our greatest opportunity.

We have embarked on one of the most historic – and perhaps important – missions in our 246-year history. As the United States faces economic and global security challenges at home and around the globe, along with the international instability we’ve witnessed recently, we are uniquely positioned to provide an array of solutions across the civil, military, and research and development fronts.

Let me give you an idea of what we’re facing. Between our normal civil works appropriations, emergency supplemental appropriations, the 2021 passing of the Bipartisan Infrastructure Law, and our normal yet massive military, interagency, and international efforts around the globe, our program responsibility has ballooned to more than $92 billion.

The challenge with that is we are structured, we are organized, and we are staffed, for what has historically been a $20 billion to $22 billion annual program.

This challenge also poses an opportunity, and we’re taking it. We are transforming

our organization and decision-making processes to safely deliver this historic program while finishing quality projects on time within budget and doing it safely.

To accomplish this, I have laid out four priorities: people, readiness, partnering, and innovation.

And it all starts with people. We have 38,000 professionals stationed in 39 different countries working on projects in 110 countries. The men and women of the Army Corps of Engineers and the Engineer Regiment have served our nation extremely well, and we owe them the best training, the best education, and the best technology so that they can stand up and deliver on their full potential.

I am committed to serving our workforce by providing them with the tools and products they need to succeed every day, and more importantly, to continue to shape a culture of flexibility.

When I speak at engagements, I highlight the USACE mission to deliver vital public and military engineering services, none of which would be possible without a world-class workforce. Without our people, nothing gets done.

Readiness is the second priority. The most important thing we can do for our Army and our nation’s readiness is to deliver on our engineering programs and projects. The facilities we build in support of DOD [the Department of

www.Americas-Engineers.com I 9

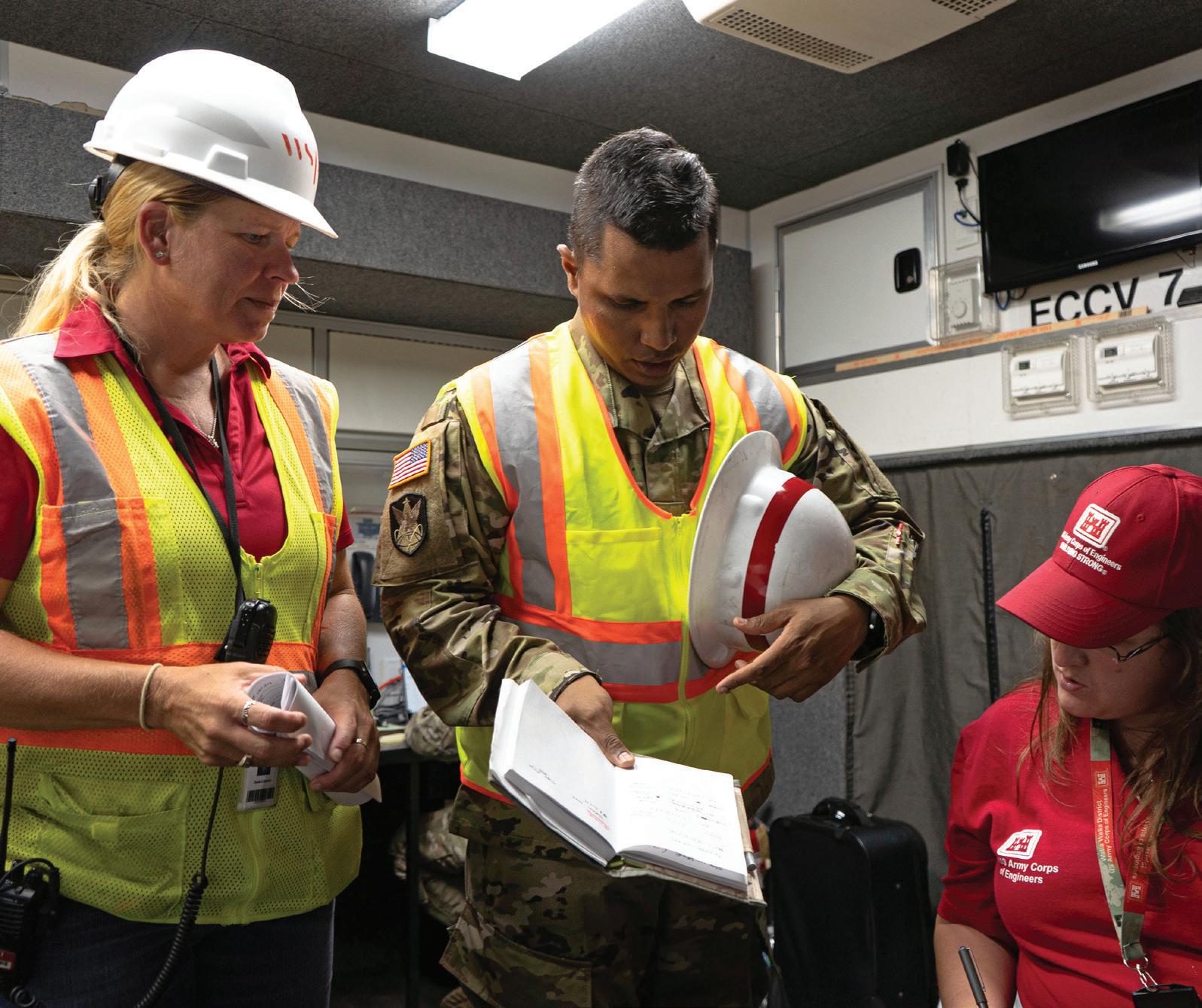

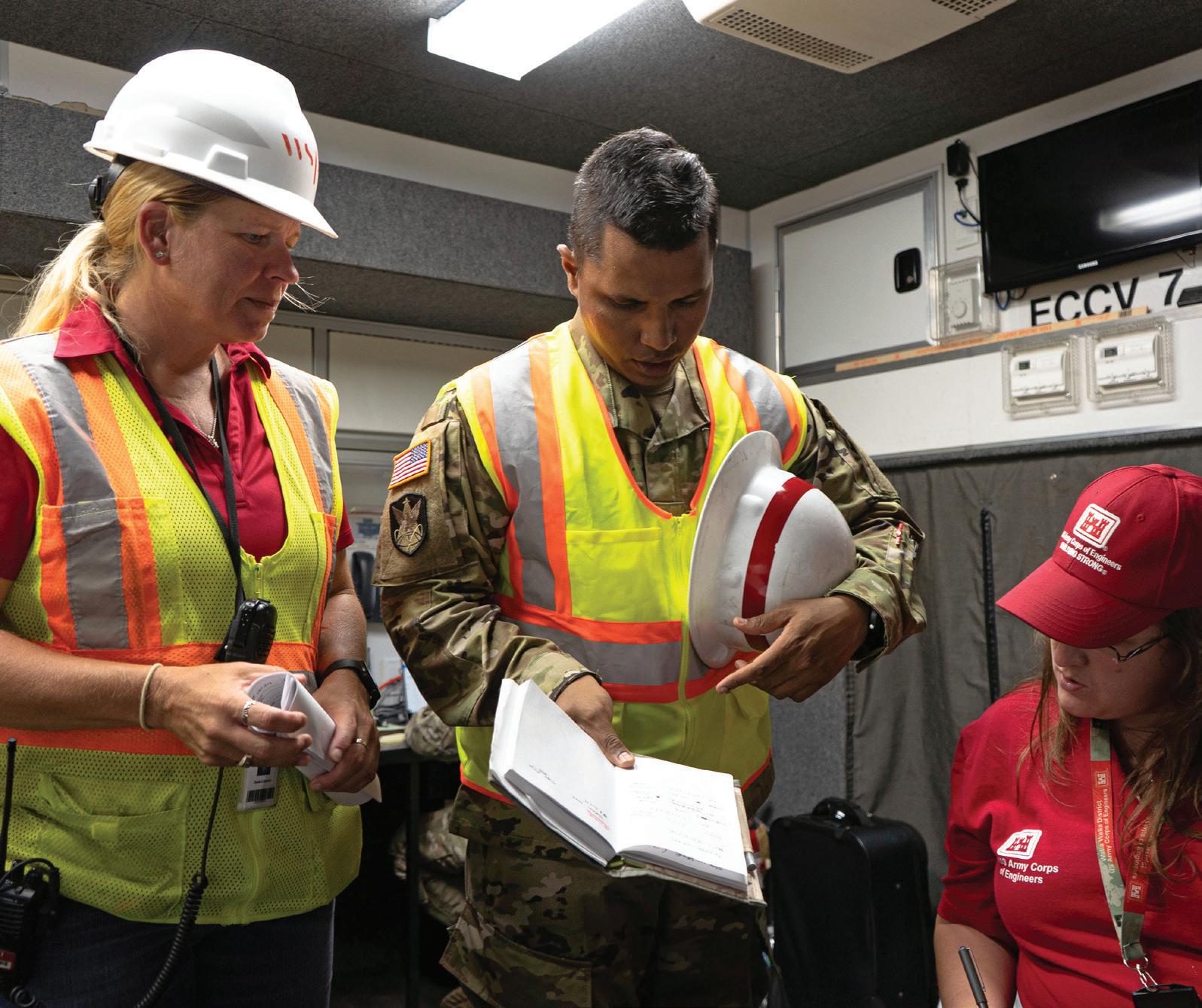

Staff Sgt. Patrick Duncan, assigned to Alpha Company, 249th Engineer Battalion, Prime Power, conducts a power assessment at a water lift station in Fort Myers, Florida. Without the assessment and possible generator install, water was not able to get to some residents of the community.

Q&A Lt. Gen. Scott A. Spellmon

Defense] and our allies have a deep and lasting impact on national defense, here and abroad. In order to meet that mission, leaders at all levels must be empowered to be open to new ideas and new methodologies, so that we can finish quality projects, on time, within budget, and do it safely.

USACE also has a huge emergency management mission and a foundational part of that is our Readiness Support Center in Mobile, Alabama. They have developed training programs to facilitate a knowledge-sharing culture within our emergency management community to increase both our preparedness for contingency response and our effectiveness in support of the nation.

We have several sets of authorities to respond to emergencies: Public Law 84-99,

Emergency Response to Natural Disasters, the Stafford Act that places us in support of the Federal Emergency Management Agency, and we also work as part of the DOD emergency response team in support to U.S. Northern Command.

Partnerships are my third priority. Engineers are always part of a larger team. Our role is indispensable, but so are the roles of our partners. Our relationships with industry, with academia and project sponsors are as important now as they’ve ever been, especially given the historic levels of investment our nation is making in our infrastructure.

Last year we published our Partnership Philosophy to guide our relationships across the enterprise and into the future.

But partnering is more than a series of discreet events that take place during

the construction phase of a project. It is a mindset which embodies a set of behaviors that shape how we interact with each other and our stakeholders. These behaviors are rooted in three interdependent and mutually supportive elements: Commitment, Communication, and Collaboration.

A key part of building relationships is listening. In the last year, we’ve hosted a number of important listening sessions with industry to help share new information on important laws, such as environmental justice, while also hearing from them on what key decisions we can make to help accelerate project delivery.

I want to highlight just a few of the outcomes.

In May, I signed a partnership charter with the Association of General Contractors of America to enable collaboration to overcome obstacles and increase innovation, resiliency, sustainability, agility, and efficiency.

In April, we published a “Construction Partnering Playbook,” developed in coordination with our industry partners and key practitioners in the field, that is filled with first-hand construction project partnering knowledge and experience. It provides guidance, best practices, and scalable tools and processes that should be used to implement partnering on all USACE construction projects throughout the delivery life cycle.

And we’re not done. We will focus our collective efforts towards further advancing our partnering practices and have awarded a contract to industry to assist in development of additional training and templates to support successful partnering on jobsites.

Finally, innovation is the fourth priority. During the past several years, we’ve fundamentally changed our project and program delivery methods so that we can continue to provide engineering solutions to our nation’s greatest challenges.

One of our initiatives is an alternative delivery program: the Public-Private Partnership [P3] that we can use for large infrastructure projects that are more

10 I USACE AMERICA’S ENGINEERS

U.S. ARMY PHOTO BY MAJ. GRACE GEIGER

p Lt. Gen. Scott Spellmon, 55th chief of engineers and USACE commanding general, and Col. Jamie Booth, Jacksonville District commander, assess the damage caused by Hurricane Ian in Fort Myers Beach, Florida, Oct. 3, 2022. Hundreds of USACE personnel were on the ground supporting emergency response operations such as temporary emergency power, infrastructure assessments, and Operation Blue Roof.

Q&A Lt. Gen. Scott A. Spellmon

Q&A Lt. Gen. Scott A. Spellmon

than $50 million. P3 is a program where a non-federal government partner takes on more responsibility that helps accelerate project completion while saving tax dollars.

Using this process, we partner with non-federal entities such as a city, state, or port authority who are willing to take on more responsibility in delivering the projects that benefit them. This partnering approach allows for the use of local contracting and financing that results in streamlined implementation of the project. In exchange for more responsibility, the non-federal entities take on more risk, which helps to reduce the risk to the federal government.

For example, the Fargo-Moorhead Flood Risk Management Project in North Dakota is a $2.8 billion effort, and our partnership has saved over $330 million in taxpayer dollars, and accelerated project completion by 10 years. The project will be complete in 2027.

Another example is the Los Angeles River Ecosystem Restoration Project, which includes water quality and recreation features, restoring 11 miles of the Los Angeles River while maintaining existing levels of flood risk management. It’s a $1.4 billion effort, and the city of Los Angeles is contributing about 33% of the cost, including land acquisition. The project should be complete in 2028.

Speeding up how USACE does business will save millions of dollars and complete projects sooner.

We’re not going to be able to engineer our way to success, and we can’t use the same processes we had 10 years ago. It’s surprising how quickly things speed up with delegation and transparency.

It was only a few years ago that companies like Uber and Lyft revolutionized the taxi industry. We don’t have to go stand on a street corner for long periods of time hoping an empty cab will happen to come by: now the taxis come to us. Pushing more information to the public web, for example, allows stakeholders to find career opportunities with us, apply to Operation Blue

Roof in the aftermath of a storm, or even to check on the status of a permit request.

People have a growing interest in the environment and the use of natural materials and nature-based processes in civil and military construction. How did this effort develop and how do you see it impacting future projects?

Nature-based solutions are particularly attractive because they are often less costly, self-maintaining, and offer a range of co-benefits associated with natural habitats, like habitat for threatened and endangered species and recreational opportunities.

In spite of the fact that natural materials and nature-based processes are great for the environment and have obvious benefits, they aren’t always the best solution for every project. Most of our successes are water management projects or projects adjacent to a body of water.

One of our early successes, for example, was Horseshoe Bend Island in Louisiana. The New Orleans District strategically placed dredged sediment in

the Atchafalaya River, above a persistent sandbar. They placed the sediment in such a way that it washed downstream and eventually built the sandbar into a 35-hectare island that became an avian habitat. An added benefit was that the island increased waterflow through the navigation channel, reducing shoaling, and maintenance dredging costs.

Of course, we didn’t do this alone. We worked with numerous partners, including the Port of Morgan City and the U.S. Fish and Wildlife Service. And this wasn’t done overnight. It took nearly 15 years for the island to form and the habitat to grow. Working with nature often requires more time than a normal civil works project, but the benefits are undeniable.

This project won several industry awards and was also certified in 2017 as a World Association for Waterborne Transport Infrastructure “Working with Nature” project.

Since then we’ve started numerous projects using natural and nature-based processes. One of the most notable is in support of Tyndall Air Force Base.

12 I USACE AMERICA’S ENGINEERS

U.S. ARMY PHOTO BY MAJ. GRACE GEIGER

p Lt. Gen. Scott Spellmon met with USACE’s temporary emergency power planning and response team deployed from the Tulsa District at the generator staging base Oct. 4, 2022, in Immokalee, Florida.

PHOTO BY RICHARD BUMGARDNER

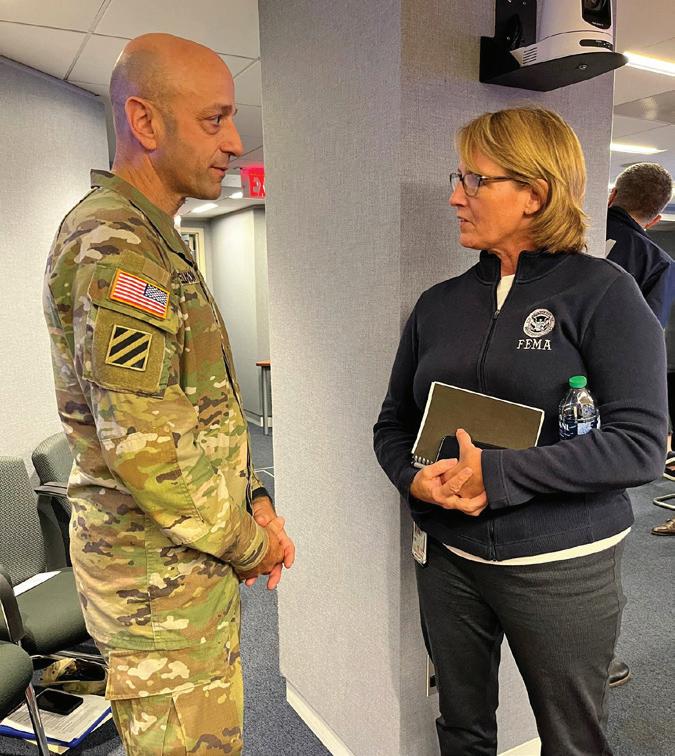

u Right: Lt. Gen. Scott Spellmon met with FEMA Administrator Deanne Criswell and administration leadership to discuss Hurricane Ian and to brief President Joe Biden on USACE activities, Sept. 30, 2022. q Below: Lt. Gen. Scott A. Spellmon met with Maj. Gen. Adel Al-Hafedh, the Kuwaiti Air Defense commander, and his staff, at a Kuwaiti base on Feb. 1, 2022. The air defense site is a Foreign Military Sales construction project, managed by the Middle East District. Spellmon was in Kuwait reviewing USACE projects and meeting with key leaders and stakeholders.

I think we’re going to see increasing use of natural and nature-based solutions as people become increasingly aware of climate change. We’re also going to see an increase in designing multiple benefits into projects.

It wasn’t that long ago that most civil works projects had a single task: for example, dams stop water, levees channel water away. Now we’re analyzing the possibility of additional functions to our infrastructure. Can we build hydropower capability into that dam? Can we build habitat along that levee? Is there another organization we can partner with to help resource the additional expense of adding more benefits to that project?

I believe the future of construction will be more partner-oriented. Not just for USACE, but communities across America as they upgrade their infrastructure.

As we build the Army of 2030, how do you see the Engineer Regiment fitting into Multi-domain Operations (MDO), and how will emerging doctrine affect combat, general, and geospatial engineering missions?

Army doctrine is shifting to Large Scale Combat Operations across a five-domain model: air, land, sea, space, and cyber. We will field divisions as the “Unit of Action” capable of engaging in Multi-Domain Operations. The Engineer Regiment is designing a force structure that will be flexible enough for division commanders to weight the main effort and apply capabilities to

support combat priorities, in addition to close support for brigade combat teams [BCTs]. The types and number of units assigned to armored 2030 and joint forcible entry divisions, along with standard heavy and light divisions, will be optimized to each formation, but will include combat, construction, bridging, and geospatial engineering capabilities.

For several years, Army senior leaders have endorsed enhancements to the Army’s capability to cross wet gaps [river crossings] by creating additional active-duty multi-role bridge companies, along with appropriate engineer command and control headquarters to execute this complex mission set. While we have a solution for that critical need, there are also capability gaps in terrain shaping, breaching, and other areas. As Secretary

[of the Army Christine E.] Wormuth mentioned at the recent Maneuver Warfighter Conference, engineers must be capable of rapidly advancing with and enabling other close combat forces to maneuver, cross gaps, and execute combined arms breaching. She also called out the importance of modernization and engineer unit redesign to the Army of 2030.

The Army continues to field the Joint Assault Bridge and Assault Breacher Vehicle. However, many engineer units are still equipped with M113 Armored Personnel Carriers, M60-based Armored Vehicle Launched Bridges, and other obsolete systems. These units must be fielded with modern M1 Abrams and M2 Bradley-type vehicles to keep pace, communicate, and fight with the units they support. While we are making progress in developing the next generation explosive breacher and terrain-shaping capabilities, we must sustain current equipment sets to bridge the gap until full modernization occurs. Engineer units should be modernized at a pace and level matching the BCTs and divisions they support.

Echelon above brigade engineer units will continue conversion to more capable and flexible combat engineer companies optimized to support armored and infantry units [CEC-As and CEC-Is]. For instance, CEC-Is will add a third “Sapper” platoon and rapidly emplaced bridging capabilities. Clearance companies will combine route and area clearance capabilities and streamline equipment assets for a more capable and efficient company.

Engineer MDO doctrine will evolve to align with the new FM 3-0 as well as adapt to optimized unit designs, modernized equipment, and emerging capabilities. It will align with the “2022 National Defense Strategy,” the secretary of the Army’s six objectives, the “Army Campaign Plan 202330,” and the Army’s foundational priorities of People, Modernization, and Readiness. It will be shaped by the Army’s Arctic and Climate strategies, as well as emphasis on a data-centric Army that leverages analytical tools to optimize Mission Command.

www.Americas-Engineers.com I 13

U.S.

USACE PHOTO

ARMY

“I think we’re going to see increasing use of natural and nature-based solutions as people become increasingly aware of climate change. We’re also going to see an increase in designing multiple benefits into projects.” Lt. Gen. Scott A. Spellmon

Q&A Lt. Gen. Scott A. Spellmon

Commanders will need and expect our engineers to provide advanced geospatial products and services across all security domains and mission command systems, from strategic base to the frontline troops, while operating in disconnected, intermittent, low-bandwidth environments to ensure decision advantage. In the future, engineers will leverage robotics, artificial intelligence, tele-operation, virtual/augmented reality, directed energy, alternative power, and other cutting-edge technologies to maximize efficiency and effectiveness while reducing risk to exposed personnel. Engineer units will continue to provide exceptional combat, general, and geospatial engineering capabilities that impact all six warfighting functions and enable commanders to fight and win across every domain in 2030 and beyond.

During the last several years, we’ve seen devastating natural events around the world, from tragic flooding in Pakistan, to wildfires out West, and the recent destruction by massive hurricanes like Fiona and Ian in Puerto Rico and Florida.

What is USACE doing to address these types of events?

Obviously, climate change and resulting severe weather events have had a tremendous impact on communities across our nation. I believe that we are unique in how the technologies, innovations, engineering, and science within the U.S. Army Corps of Engineers – as well as our diverse, talented and geographically dispersed workforce – is prepared to support communities both on and off post, at home, and abroad.

I like to call it a “Whole of USACE” approach to fighting climate change.

First off, hurricanes, floods, droughts, wildfires, or any other extreme weather events don’t care if they impact the neighborhood community, a city, or Fort Bragg, North Carolina.

So, we view climate change as a threat to both our Civil Works infrastructure –think dams, levees, waterways – around the country and our Army’s camps, posts, and stations – CONUS and OCONUS – from which we mobilize and deploy our forces.

We are addressing climate change with two complementary efforts: first through

adaptation, meaning how we plan for future climate change impacts to projects we design and build, to ensure they are ready for future conditions.

The second is through mitigation. These are the behaviors and actions we can take today on our own USACE-managed lands and facilities, in support at our Army’s posts, camps and stations, and through project planning and design with our stakeholders to reduce the emission of greenhouse gases.

And to better enable resiliency, adaptation, and mitigation, our Engineering Research and Development Laboratories are hard at work helping us understand how climate change may impact our projects and our communities, and we are working with our partners to share expertise and apply lessons learned so we can be ready and, if impacted, bounce back quickly.

In USACE, we have five actions that drive our ongoing efforts to adapt and mitigate for climate change:

Our first action is to modernize USACE programs and policies to support climate-resilient investments. For us, that means updating our practices to leverage new knowledge and new technologies as we design for the environment of tomorrow.

Our second action is managing USACE lands and waters for climate preparedness and resilience.

The Corps of Engineers owns and operates more than 700 dams across our nation and territories. When we talk about how extreme water events impact communities, it’s imperative that we use the latest actionable climate science and engineering practices to ensure we operate our dams in the most effective way possible, so we have capacity available to prepare for a flood, and we can hold as much water as possible during times of drought.

Our third action is really all about sharing information with state, local, and tribal government partners to improve preparedness.

We have several key programs that allow engineers and community planning

14 I USACE AMERICA’S ENGINEERS U.S. ARMY CORPS OF ENGINEERS

PHOTO BY JUSTIN GRAFF

p USACE’s Albuquerque District conducts post-wildfire debris removal in Rociada, New Mexico, Aug. 15, 2022. USACE began removing debris in the city of Rociada on Aug. 15, after receiving a mission assignment from FEMA to provide private-property debris removal in San Miguel and Mora counties.

Q&A

Lt. Gen. Scott

A. Spellmon

experts to engage in key dialogue with us and our partners as well workshops to engage with the public.

Our fourth action is all about the tools and technology on the projects we build for civil works and military communities.

We use and make freely available information on historical and current conditions and projected future climate changes. This is critical data that policymakers can use to counter climate threats to projects, and mission areas.

As a service provider to the Army, Air Force, and other agencies, we are providing sustainable solutions to our partners and our stakeholders across the entire spectrum of our capabilities, from engineering, design, construction, and environmental services.

Finally, our fifth action directs our agency to plan for climate change-related risks to missions and operations, so that when climate and weather events strike, we are ready to absorb that impact and continue to deliver the mission.

This includes actions like continuity of operations plans, cross-training, and data backup so we can keep delivering even when one of our offices is affected by disaster.

What didn’t I ask about that you’d like to share while you have the forum? Any other challenges, opportunities and/or Corps achievements we should discuss?

We’re hiring! We are always looking for strong talent, especially in Science, Technology, Engineering and Math [STEM] disciplines. Being able to complete our projects on time, within budget, safely means that we must attract and retain top notch talent.

How do we do that? First, we make sure USACE is a great place to work so we can attract talented people. We’re in the top 100 best places to work in the federal government, and our leaders are actively engaged in moving us up that ladder of great places to work.

We turn vacancies into developmental opportunities within our workforce to

diversify skills and provide a challenging workspace that is inclusive, diverse and team oriented. Black Engineer of the Year Awards named us the No. 3 top recruiter at Historically Black Colleges and Universities.

We have some of the fastest onboarding times in the federal government. Most of our new hires begin in less than 90 days and we’re working to reduce that even more.

Onboarding time remains one of our greatest challenges. Industry can bring new hires onboard in a few days. We, as part of the federal government, have extra checks and balances like security clearances to work through. Most of the time, talented young people won’t wait for us.

Finally, while we focus on the mission today, we also have to proceed with an eye to the future. To that end, USACE is also making a significant push to add more teammates to better accommodate this growing mission, and in particular, in STEM disciplines.

We believe that there will be about 3.5 million STEM jobs in America that need to be filled by 2025. So, we owe it to ourselves and to our nation to do everything we can to expand and diversify our current and future pool of talent.

In November, I was proud to join Sarah EchoHawk, American Indian Science and Engineering Society president, in signing a partnership agreement that provides Native American students with formal access to Army STEM job and educational opportunities.

By signing this Memorandum of Understanding, we are literally opening the doors to the Corps by providing opportunities to better engaging with Native Americans through job fairs, career days, engagement with the USACE workforce, and access to projects, labs and research.

It also provides employment opportunities for indigenous peoples to contribute their passion, talents and ingenuity towards enhancing the USACE workforce. AE

16 I USACE AMERICA’S ENGINEERS COURTESY PHOTO

p USACE Commanding General Lt. Gen. Scott Spellmon visited the Flood Risk Management Rio de la Plata project in Dorado, Puerto Rico, Oct. 11, 2022. During his visit, Spellmon was briefed by Wimel Varela, resident engineer, North Resident Office, USACE Antilles Office, on current status and performance of the project after the landfall of Hurricane Fiona.

U.S. ARMY CORPS OF ENGINEERS Providing Technical Expertise

U.S. ARMY CORPS OF ENGINEERS Providing Technical Expertise

Providing Technical Expertise Around the Globe

It happened in Honduras: The BuckEye sensor system, combining a digital camera and light detection and ranging (LiDAR), was flown aboard a Super King Air turboprop aircraft over some of the Central American nation’s most floodprone areas. The resulting geophysical data was used to create two- and three-dimensional colored maps, down to a resolution of 6 inches, over more than 5,400 square kilometers – elevation models that will allow engineers to assess and build infrastructure, reduce flood risk, and plan for humanitarian assistance and disaster relief. The collection flights were completed in February 2022.

BY CRAIG COLLINS

BY CRAIG COLLINS

A Beechcraft Super King Air conducts a calibration flight for the Joint Airborne Lidar Bathymetry Technical Center of Expertise (JALBTCX) at Stennis International Airport, Mississippi, on April 18, 2022. JALBTCX surveys the sandy shoreline of the U.S. on a reoccurring basis. The high-resolution, three-dimensional data collected aboard the aircraft, by a system originally developed to support warfighters, has been used to great beneficial effect at home and abroad.

BuckEye was developed in 2004 by the U.S. Army Engineer Research and Development Center (ERDC) to support warfighters with geophysical maps and urban terrain data that could be used in conducting tactical surveillance, intelligence, and reconnaissance in Iraq and Afghanistan. In the years since, the experts who developed this technology, along with U.S. Army Corps of Engineers (USACE) customers and partners around the world, have capitalized on

the many potential uses for the unclassified color imagery and LiDAR elevation data collected by the system. In 2012, BuckEye was deployed in support of operations by U.S. Africa Command (AFRICOM). In recent years, BuckEye’s high-resolution three-dimensional (HR3D) imagery and data have been used to support a series of engineering initiatives in Florida’s Okeechobee watershed, and to create “digital twins” of sections of the U.S. border wall, which can be

18 I USACE AMERICA’S ENGINEERS USACE

WALKER

PHOTO BY CHUCK

PHOTO BY STAFF SGT. JOSHUA HAMMOCK

u U.S. Army Capt. William Megon, Mosul Dam Task Force logistics officer, explains the use of a grout reel in Mosul, Iraq, May 12, 2019. The grout reel is used in the emergency drilling and grouting operations within the grouting gallery.

used to support construction, maintenance, and repair.

According to David Hibner, who directs the Army Geospatial Center, the data and intelligence generated by the center’s experts serve several USACE missions: For example, to update and manage the inland electronic navigation charts that enable travel on 7,000 miles of intracoastal waterways, and provide the geospatial information that enables the modernization and maintenance of the nation’s 91,468 dams. “In terms of our international partnerships,” Hibner said, “the most obvious example is our BuckEye program. We do a lot of things with partner nations, with interagency partners – and, of course, we do a lot to support our Army and our combatant commands.”

Aircraft-mounted sensors collecting data for making HR3D watershed maps in Honduras, was not something Col. Richard Gridley imagined when he was appointed the U.S. Army’s first chief engineer in June 1775 – he was busy trying to win the Revolutionary War, recruiting the sappers, miners, and engineers who would design and build batteries and fortifications for the Continental Army. But neither did Gridley, nor his immediate successors, likely foresee the events that would, over the next two-and-a-half centuries, compel the United States to assign the Army’s engineers authority and responsibility to address some of the nation’s most crucial issues: overseas contingency operations, inland navigation, flood protection, water resources development, environmental restoration, emergency response, and more.

Today’s Corps of Engineers is noteworthy not only for this diverse mission set, but also for the global demand for its expertise and services:

• In South Korea, biologists with USACE’s Far East District work with partners

in the South Korean government and environmental community to prevent or minimize the impact of U.S. military facilities on natural resources and species. In the country’s most populous province, containing the capital of Seoul and its surrounding communities, 13 protected species have been identified, and the Integrated Natural Resources Management Plan, the joint effort to protect these species at the facilities of U.S. Forces-Korea, has produced a set of recommendations, in alignment with South Korean law and environmental policy, for personnel at these installations to manage surrounding natural resources.

• From its home in USACE’s Middle East District, the Technical Center of Expertise (TCX) for Aircraft Hangar Fire Protection shares its knowledge around the globe, designing, constructing, inspecting, and maintaining systems designed to protect assets often valued in the billions of dollars. USACE fire protection engineers have recently provided services in Honduras, India, Korea, Germany, Norway, and the Bahamas.

• In Mosul, Iraq, the Mosul Dam Task Force, a group consisting of 50 to 70 Soldiers, USACE civilian engineers, Iraqi engineers, and employees of private construction firms, worked to prevent the catastrophic collapse of Iraq’s largest dam – considered by many experts to be the world’s most dangerous dam. While USACE’s engineering experts helped to stabilize the dam with the largest drilling and grouting project ever undertaken, USACE project managers helped integrate the team of engineers and technical specialists – from the United States, Iraq, and other partner nations – who would train and build a capable, resilient Iraqi Ministry of Water Resources, a team equipped and capable of maintaining Mosul Dam into the future. With this mission accomplished, the task force left Iraq in the summer of 2019.

• In the West Africa republic of Benin, engineers from USACE’s Europe District implemented and managed the construction of two medical facilities in the remote villages of Money and Godjekoara, both of which lie near a volatile border area under constant threat from

www.Americas-Engineers.com I 19 U.S. ARMY RESERVE

“In terms of our international partnerships, the most obvious example is our BuckEye program. We do a lot of things with partner nations, with interagency partners – and, of course, we do a lot to support our Army and our combatant commands.” David Hibner, Director of the Army Geospatial Center

U.S. ARMY CORPS OF ENGINEERS Providing Technical Expertise

violent extremist groups and transnational crime. The facilities, completed in spring 2021, were funded by AFRICOM and coordinated with the U.S. State Department. The clinics offer an alternative to villagers who had been compelled to cross the border and seek care in either Niger or Burkina Faso; they give rural citizens secure places to seek health care and document the birth of new Beninese citizens – who, in the border region, have been at risk of human trafficking. The work of USACE in completing these and other humanitarian assistance projects in Africa – including the construction of several schools in Benin – is critical to meeting the missions and priorities of both AFRICOM and the State Department.

Today’s Corps of Engineers

The U.S. Army Corps of Engineers employs more than 36,000 civilians and 800

p A recently completed health clinic, with a water well hand pump on a concrete pad and a solar-powered light pole in the foreground, is seen here in the remote village of Money in Benin in Africa.

active-duty service members, who provide a suite of services to customers in more than 130 countries worldwide. It is an agency in the midst of a historic transformation: Typically authorized to execute an annual program of around $20 billion to $22 billion, USACE, at the outset of the 2023 fiscal year, was charged with performing between $90 billion and $95 billion in annual work – an increase largely due to projects authorized through the Infrastructure Investment and Jobs Act (also known as the Bipartisan Infrastructure Law) of 2021.

It’s important, when looking at these numbers, to remember that they represent the value of the projects USACE works on, not its budgetary appropriation. Most of the projects in the USACE portfolio are funded

in whole or in part by customers who solicit the expertise of the Corps of Engineers. “We are a project-funded organization,” said USACE’s Director of Military Programs Christine Altendorf. “Our people work on projects in their various stages – planning, construction, operations, and maintenance – and we bill for those services. But we work for the federal government, and we don’t do anything that isn’t authorized.”

This workload is shared between two core mission areas:

MILITARY PROGRAMS. At its inception, USACE’s mission was to serve the warfighters of the Continental Army; one of its first tasks was to build fortifications at Bunker Hill, near Boston. Today’s Corps of Engineers supports the Army’s Engineer Regiment, headquartered at Fort Leonard Wood, Missouri. The Army engineers in this regiment compose units that perform combat

20 I USACE AMERICA’S ENGINEERS

PHOTO COURTESY OF COSME QUENUM

U.S. ARMY CORPS OF ENGINEERS Providing Technical Expertise

engineering, rescue, construction, and other specialties, and all fall under the command of the Army Chief of Staff. The only uniformed unit that falls directly under the command of USACE is the 249th Engineer Battalion (Prime Power), which provides commercial-level power to military units and federal relief organizations in time of need.

USACE carries out a program of military construction (MILCON) and installation readiness – designing, building, or upgrading facilities or infrastructure for:

• the Department of the Army ($4.9 billion at 287 installations throughout the United States).

• Air Force, Navy, the Defense Health Agency; and the Defense Logistics agency ($10.7 billion) installations and infrastructure; and

• the Missile Defense Agency ($875 million to five critical projects in Romania, Poland, and Alaska).

For the Army, said Altendorf, USACE doesn’t just build real estate – it buys, sells, and manages it. “We’re responsible for about 25 million acres of land,” she said, “and our real estate people do about 46,000 real estate transactions a year.”

USACE offers additional engineering support to the Department of Defense (DOD) and the other service branches – for example, $5 billion in support to the activities of the 11 combatant commands (COCOMs), such as SOUTHCOM, AFRICOM, etc.

Every year, USACE performs about $2 billion in environmental remediation work, providing technical expertise in cleanup and environmental restoration. This work is often done in collaboration with the other service branches, through programs such as Formerly Used Defense Sites (FUDS); with the Department of Energy, to clean up sites used by the U.S. Atomic Energy Commission; and with the Environmental Protection Agency (EPA), which executes the Brownfields and Superfund programs.

Another USACE military mission is known broadly as Interagency and International Support (IIS), through which the

Corps of Engineers provides $4 billion in technical assistance annually to about 70 non-DOD federal agencies, state and local governments, tribal nations, foreign governments, NGOs, and private U.S. companies. This includes USACE competencies in disaster response and humanitarian assistance – expenditures that vary from year to year, depending on need. USACE also provides design, construction, engineering, and training to these non-DOD customers, including the design and construction of 22 projects for the Department of Veterans Affairs worth $8.7 billion, and $3.7 billion worth of Foreign Military Sales projects in 35 other countries. Other federal customers for whom USACE has recently designed, built, or renovated facilities include the U.S. Department of Agriculture, the State Department, and the Bureau of Engraving and Printing.

CIVIL WORKS. Now the largest USACE work portfolio in terms of personnel and other resources, the Civil Works mission grew naturally out of the nation’s demand for engineering expertise: In 1824, when Congress needed to survey road and canal routes for a nation that was rapidly expanding westward, it authorized the use of Army engineers for the task. In the same year, it assigned the Corps of Engineers responsibility for improving the safety and navigability of the Ohio and Mississippi rivers by removing sand bars, snags, and other hazards. In 1850, USACE built the nation’s first water supply project, the Washington Aqueduct; in the 1920s, it began building hydroelectric power plants.

As the nation suffered devastating floods in the late 1920s, Congress assigned USACE work on projects in the Mississippi River and Sacramento River watersheds – and, in 1936, assigned the agency the mission to provide flood protection, which USACE and its other partners now more precisely refer to as “flood risk management.” In response to the devastating floods that compelled this legislation, USACE also expanded its role in responding to natural disasters.

USACE expertise became increasingly important in environmental preservation and restoration in the late 20th century, and, in recent decades, USACE helped lead some of the most ambitious environmental restoration efforts in history, including the Comprehensive Everglades Restoration Plan (CERP) – the largest environmental restoration project ever undertaken. The Clean Water Act and its amendments authorize USACE to issue or deny permits for the deposit of dredge and fill materials into the waters of the United States and their adjacent wetlands – an activity often linked to agriculture or land development.

It’s difficult to capture the scope of everything USACE does today in its Civil Works mission area, but a few numbers offer a glimpse:

• USACE maintains or operates about 740 dams, and performs safety inspections of more than 2,000 federal and non-federal levees. Through its Dam and Levee Safety programs, it ensures that these sites meet criteria for safety and function. In collaboration with FEMA, it maintains the National Inventory of Dams, documenting data for all known dams in the United States and its territories;

• USACE now maintains an inland navigation system consisting of 25,000 miles of navigable channels and 196 commercial lock and dam sites;

• About 100 billion kilowatt-hours – onefourth of the nation’s annual hydropower supply and 3% of its total electrical capacity – is produced by 75 USACE-operated hydroelectric power plants on the nation’s river systems. The Corps of Engineers is the nation’s largest hydropower provider, and one of the largest in the world;

• USACE is one of the nation’s largest water-supply agencies, with 9.8 million acre-feet of water storage space available for municipal and industrial use; and

• USACE maintains more than 4,400 recreation sites – including 100,000 campsites and 3,800 boat ramps – on 12 million acres of land at more than 400 lakes

22 I USACE AMERICA’S ENGINEERS

Expertise

nationwide. USACE lakes receive about 370 million visits annually, and more than a third of all the freshwater lake fishing that takes place in the United States happens on reservoirs maintained by the Corps of Engineers.

In the 2023 fiscal year, USACE’s Civil Works mission area is its fastest-growing. Already busy with $8.34 billion worth of projects, numbering more than 1,000 across the country, the agency is working with partners to implement more than $25 billion in disaster relief and emergency assistance in response to wildfires, hurricanes, earthquakes, and other natural disasters. The Infrastructure Investment and Jobs Act added more than $17 billion in additional work to the USACE civil works portfolio.

In support of its military and civil works missions, USACE conducts a varied and vigorous research and development program, valued at more than $1.3 billion annually, on more than 2,000 projects aimed at solving problems for the Army, DOD, and IIS customers. From its roots as the first

federal civil engineering laboratory – the Waterways Experiment Station in Vicksburg, Mississippi, established in 1928 – the multi-facility research enterprise collectively known as ERDC provides science, technology, and expertise through its seven component laboratories:

• Geospatial Research Laboratory (GRL), Alexandria, Virginia;

• Coastal and Hydraulics Laboratory (CHL), Vicksburg, Mississippi;

• Cold Regions Research and Engineering Laboratory (CRREL), Hanover, New Hampshire;

• Construction Engineering Research Laboratory (CERL), Champaign, Illinois;

• Environmental Laboratory, Vicksburg, Mississippi;

• Geotechnical and Structures Laboratory (GSL), Vicksburg, Mississippi; and

• Information Technology Laboratory (ITL), Vicksburg, Mississippi.

ERDC’s wealth of expertise – among its 2,100 employees, about half are engineers and scientists with Ph.D. or M.S. degrees –has made it a frequent winner of the Army

Research Laboratory of the Year Award. Its work, conducted on all seven continents and in the Arctic, is diverse, investigating not only solutions for American warfighters, but also improvements to the lives and lifestyles of people almost everywhere in the world.

Combining a Wealth of Talent ... Literally, almost everywhere in the world. USACE’s technical experts design packed-ice cargo-plane runways for Antarctica’s McMurdo Station; study water security in Botswana’s Okavango Delta; collaborate with their counterparts in Indonesia on structural awareness for urban search and rescue; work with Brazil’s National Water Agency on flood risk management planning and training; design and build Coastal Crisis Management Centers in Bangladesh; collaborate with professionals in the Netherlands to design coastal protection technologies; build schools and clinics in Vietnam; and much more.

Technical expertise is what USACE is famous for, but engineering is far from the only vocation necessary to achieve this rich and varied mission set: Nearly all the Corps of Engineers’ reservoirs are served by USACE park rangers who help ensure fun, safe recreation while also working

24 I USACE AMERICA’S ENGINEERS USACE PHOTO

p A small portion of the flooded Okavango Delta is shown where the water is clear for about a foot or more. Locals claim this water is so clean that a person can drink directly from it. USACE personnel traveled to Botswana to assess opportunities to support water management and water security in the country’s Okavango Delta region.

U.S. ARMY CORPS OF ENGINEERS Providing Technical

on other missions, such as the control of invasive species with USACE ecologists and fish and wildlife biologists, or the preservation and protection of cultural resources with USACE archaeologists. Designing, building, and purchasing real estate require the expertise of architects, contracting and realty specialists; legal counsel, and – like every part of the USACE enterprise – increasingly skilled and knowledgeable information technology specialists and managers. Maintaining safety and navigability on 25,000 miles of channels demands a fleet of survey vessels, each of which must be crewed by capable operators.

To leverage this vast collection of wisdom and expertise in pursuit of efficient problem-solving and best practices, without the stove-piping and red tape that often hinder big bureaucracies, USACE has established nearly 50 Communities of Practice (COPs): groups, independent of formal organizational structures, who regularly interact to collectively learn, solve problems, build skills and competencies, and develop best practices around a shared concern, goal, mission, set of problems, or work practice. COPs are as varied as USACE vocations, and include emergency management; library; inland navigation design; radio and satellite communications; hydrology and hydraulics; internal review; collaboration and public participation – and dozens more.

USACE never works alone. Its partnerships are often local collaborations with stakeholders and officials to make decisions at specific sites, or on specific projects. Some of its regional collaborations have been historic, such as the Interagency Performance Evaluation Taskforce (IPET), a joint effort among more than 150 government, academic, and industry partners that convened to study and report on the performance of the hurricane protection system in New Orleans and southeast Louisiana during Hurricane Katrina in 2005. The USACE Institute for Water Resources (IWR) is among the USACE institutions that work on a variety

of academic, domestic government, federal, and international partnerships –including, for example, USACE’s collaboration with the United Nations Educational, Scientific and Cultural Organization (UNESCO) to promote safe, efficient, and environmentally sound water management systems.

In September 2022, when Altendorf and a team of USACE disaster support experts visited the nation of Azerbaijan to practice earthquake preparedness and response, it was a reminder, she said, that – at least for the professionals in the Corps of Engineers – there is no meaningful distinction between “military” and “civil works” activities: “A lot of the people who are working right now on responses to hurricanes in the Atlantic, when they’re not working at home, will be on these small teams that go to countries all across the world.”

In Azerbaijan, the team worked with the Ministry of Emergency Situations, the Ministry of Defense, and other officials and stakeholders, to lead a natural disaster workshop and a tabletop exercise in response to a simulated earthquake – and shared the U.S. model for disaster relief, in which the mili-

tary works in support of a civilian effort led by FEMA. Altendorf – who, several years ago, oversaw the USACE environmental mission – watched as her Azerbaijani counterparts grappled with the same issues our own nation debated as its emergency response and homeland security capabilities evolved: “A lot of different agencies know different things,” she said. “Nobody is able to pull it all together and see the whole elephant. Everybody has their part.” Azerbaijani officials began to see opportunities for drawing on the resources of other agencies – its State Border Service, for example, or its neighboring countries –to execute a more thorough and effective disaster response.

It’s a perfect example of how completely the collaborative mindset, which has brought USACE expertise to every corner of the globe, has infused the organization: Its experts are collaborating with partners to learn how to collaborate better. The technical prowess, agility, and varied skill set the U.S. Army Corps of Engineers – an agency with stakeholders in every conceivable community, working and living in every type of environment

– are unmatched.

collaboration is the key to

success.

www.Americas-Engineers.com I 25 USACE PHOTO

imaginable

But

its

AE

p U.S. and Azerbaijani military and civilian officials participate in a disaster response tabletop exercise Sept. 20-22 in Baku, Azerbaijan. The exercise was sponsored by the Civil Military Emergency Preparedness (CMEP) program and included the participation of first responders from Azerbaijan and the United States. CMEP program events facilitate inter-ministerial and civil-military cooperation, enhance armed forces capabilities to provide defense support to civil authority, and foster regional/multilateral cooperation to support response to disasters.

“A lot of the people who are working right now on responses to hurricanes in the Atlantic, when they’re not working at home, will be on these small teams that go to countries all across the world.” Christine Altendorf, USACE’s Director of Military Programs

t The Kuwait Ministry of Defense (KMOD) and Middle East District teams in Old Town Winchester during the KMOD’s recent Program Management Review in Winchester, Virginia, at the U.S. Army Corps of Engineers Headquarters there.

Middle East District Hosts Kuwaiti Mission Partners

The small town of Winchester, Virginia, located about 90 minutes from Washington, D.C., would not be the first place that comes to mind as an international business hub. But with an active construction program worth almost $4 billion, executed across multiple countries, and another $2.7 billion in future potential work, the U.S. Army Corps of Engineers (USACE) Transatlantic Middle East District (TAM) has been quietly making it just that for almost 50 years.

The district provides construction and related support services for U.S. military and allied nation partners throughout the Middle East, and although it has offices in eight countries in the region, the bulk of its program is managed from its headquarters in Winchester.

In most cases, TAM project managers and engineers meet with their mission partners in the countries where their projects are located, but on occasion, partners are hosted in Winchester and a bit of local hospitality is showcased along with project overviews.

That hospitality was on display recently during an Engineer Program Management Review (PMR) in Winchester with the Kuwait Ministry of Defense (KMOD) when the district decided to try something other than business as usual with the Kuwaiti engineers by opening each day with a diwaniya.

BY JOE MACRI

PROVIDING TECHNICAL EXPERTISE Middle East District 26 I USACE AMERICA’S ENGINEERS

COURTESY

PHOTO

Diwaniyas are formal meetings, often business related, but also have a social facet that’s equally important. A special area is typically set aside, and they are considered a place to hold frank discussions on a variety of topics as well as get to know each other.

“Diwaniya plays an important role in the Kuwaiti society in the strengthening of social relations among Kuwaitis,” said Hamed Issa, TAM’s senior program manager in Kuwait. “They can be business related, but the social aspect is very important. They are also a place to discuss general issues with friends and relatives and circulate news and information.”

Issa added that it also provides a good opportunity to strengthen the bonds between partners.

“We often get stuck in a loop of briefings and project update visits, so we see our

mission partners frequently but don’t really get to know them. Breaking that paradigm allows us to actually get to know each other. It’s much easier to do business with those you know and trust.”

Joseph Zaraszczak, a program manager and the chief of the TAM branch responsible for Kuwait programs, said although the district has always had a strong relationship with its Kuwaiti partners, he appreciated their desire to come to Winchester and see the district’s capabilities in their entirety.

“Although we’re constantly engaging with our mission partners, they are often working directly with our program and project managers on specific projects. Bringing them to Winchester allows them to see the full scope of assets the U.S. Army Corps of Engineers can bring to the table. The value engineering, the scheduling tools, the

ability to reach out to other districts with specific expertise, are things that might not be front and center to our mission partners but are a key reason they choose to work with USACE,” said Zaraszczak.

After the visit, the Kuwaitis indicated they’d like to make the Engineer PMR and the included diwaniya with the district a more official annual occurrence.

“During the visit, I was getting daily feedback from the Kuwaitis, Col. Osama [director, FMS Directorate, Foreign Procurement Sector, KMOD], and the Office of Military Cooperation-Kuwait [OMC-K],” said Issa. “They indicated they saw a lot of value in this and possibly conducting one every year. It was reverberated by OMC-K staff to other USACE management that the ´PMR went great’ and ‘the USACE team did outstanding!’” AE

PROVIDING TECHNICAL EXPERTISE Kansas City District

From Florida to Puerto Rico to Kansas: 249th Engineer Battalion Practices Industry Skills

Soldiers from the 249th Engineer Battalion, Prime Power, put their lineman skills to the test when they competed in the 38th International Lineman’s Rodeo at the National Agricultural Center and Hall of Fame in Bonner Springs, Kansas, on Oct. 15, 2022.

Teams and apprentices from four of the five companies within the battalion competed: three active companies, Alpha Company, Charlie Company, and Headquarters and Headquarters Company, as well as the battalion’s reservists, Delta Company.

BY REAGAN ZIMMERMAN

Competitors participated as journeyman teams, which consist of two journeyman climbers and one journeyman groundman, who specialize in building and maintaining electrical power systems, and as individual apprentices, who were there to practice their skills in hopes of becoming a journeyman.

Teams and apprentices competed in four events, two known events and two that were

a mystery until the day before the event. Each event tested a different set of skills and gave Prime Power Soldiers the chance to practice those skills.

“We are here for justification of our skills … It is to prove ourselves in the industry –that we are an asset and that our knowledge justifies us being in this industry,” said Sgt. 1st Class Virgil Jordan of Charlie Company out of Fort Belvoir, Virginia. “[The competitors] do this on a daily basis [and we don’t], so to be here and be alongside of them … we know our training is paying off.”

As Prime Power Soldiers, working on power lines is not their “everyday” job. The Soldiers competing in the rodeo hold the 12P Military Occupation Specialty

www.Americas-Engineers.com I 27

PROVIDING TECHNICAL EXPERTISE Kansas City District

(MOS), but also took on a U4 identifier, Power Line Distribution Specialist, under their MOS. The identifier gives them the additional responsibility of working on power lines when that skill is needed on missions.

The “normal” 12P jobs include three different missions: National Response Framework missions, or NRF, where they deploy to support disaster relief efforts across the country; Task Force Power or Safe missions, where they travel to bases and conduct safety checks on electrical systems; and Prepare to Deploy missions (PTDL), where they set up new base camps overseas.

“We are the force that brings sustainability to the battle front,” Jordan said. “We build, sustain, and support.”

Many Prime Power Soldiers, even some that attended the rodeo, are either actively supporting or just finished supporting NRF missions in Florida in the wake of Hurricane Ian, and in Puerto Rico, in the wake of Hurricane Fiona.

“I went from Florida directly to [Kansas] after being in Florida for about two weeks,” said Staff Sgt. Rafiqy Tucker of Alpha Company out of Schofield Barracks, Hawaii.

His team, and many others across Florida and Puerto Rico, traveled to locations prior to the hurricanes to pre-stage a response effort, and activated after the hurricane to provide temporary emergency power. The U.S. Army Corps of Engineers (USACE) is helping to coordinate, run, and facilitate the temporary emergency power missions in both Florida and Puerto Rico.

“[Our mission is] to kick out generators and restore temporary emergency power to facilities that are deemed by FEMA as mission critical. Typically [the mission critical] facilities are hospitals, prisons, nursing homes, and water distribution plants,” Capt. Adam Hamilton, USACE Kansas City District project engineer, said.

Hamilton is part of USACE Northwestern Division’s Power Planning and Response Team and is currently serving as a power mission commander on a temporary emergency power mission in Puerto Rico.

Hamilton works with Prime Power Soldiers every day in the field.

“[Prime Power’s] most important thing is assessments. When someone requests a generator, we send them out immediately to go recon a site. They will deem whether that site needs a generator. If it [needs one], then they need to figure out what generator would be suitable for that site … They use their technical expertise to determine if and at what level the site is powered,” Hamilton said.

Though they are not restoring powerlines like they are at the Lineman’s Rodeo, these Soldiers’ industry skills still transfer into these emergency situations.

“[Understanding] the lineman facet is very beneficial because if I need to figure out the power coming into a building for a generator, I can go and look at their overhead lines and say, ‘They have this many insulators, this

many lines coming off of the transformer and this is the way this system is set up, so it is most likely this voltage or power coming into this building and can then pick a generator,’” Tucker said. “I don’t get to do the job of climbing up the pole all the time but having that skill set definitely is beneficial because it allows me greater insight into how utilities systems are set up.”

Events like the Lineman’s Rodeo help Prime Power Soldiers train for all types of situations, so that when they are called to fulfill a mission, they will exceed the expectations.

“The outstanding non-commissioned officers that have remained flexible and able to execute beyond expectation repeatedly are just awesome. I’ve been able to work with Prime Power two times now and they continue to impress me every time,” Hamilton said. AE

Journeyman Results Top 30%: 64. 249th Engineer Battalion Charlie Company (Prime Power) – Jason Wilson, William Coleman, Steven Fargo.

Apprentice Results Top 30%: 33. 249th Engineer Battalion Headquarters and Headquarters Company (Prime Power) – Luis Davila. Full results can be found here: https://www.linemansrodeokc.com/results-final/.

PHOTO BY REAGAN ZIMMERMAN

PHOTO BY REAGAN ZIMMERMAN

28 I USACE AMERICA’S ENGINEERS

p Sgt. Gabriel Mata, assigned to the 249th Engineer Battalion (Prime Power) Delta Company, competes in one of the apprentice mystery events during the 38th International Lineman’s Rodeo at the National Agricultural Center and Hall of Fame in Bonner Springs, Kansas, on Oct. 15, 2022.

USACE Archaeological Program

When you think “archaeology,” do you think U.S. Army Corps of Engineers (USACE)?

Probably not. Archaeology brings up images of Indiana Jones, dusty tombs, and getting chased out of caverns by giant rolling boulders. Yet, despite this, USACE curates the second-largest collection of cultural resources in the United States, second only to the Smithsonian Institution.

We even own a full Tyrannosaurus Rex skeleton.

Sure – we’ve loaned it out to the Smithsonian Institution’s Museum of Natural History for half a century, but facts are facts: That big mean fossil is ours.

So how did USACE become this powerhouse of archaeology and natural history? According to Little Rock District archaeologist Allen Wilson it didn’t start in a tomb, or being chased by boulders while dodging arrow traps.

“Although archaeology is an exciting field, it’s not like what you see in the movies. In fact, Indiana Jones is a terrible archaeologist,” said Wilson.

In truth, USACE’s relationship with cultural artifacts and archaeology stem from the work they do in support of Section 106 of the National Historic Preservation Act. Section 106 states that the federal government must consider historic properties during any undertaking that takes place on federal lands, uses federal funds, or requires federal permissions.

Additionally, being a land management agency, USACE is subject to environmental laws such as the National Environment Policy Act and the National Historic Preservation Act. Upon full implementation of these laws in the early 1970s, USACE had to employ its own environmental staff, including archaeologists, to keep up with the infrastructure needs of the nation. Passage of the Clean Water Act in 1972 expanded the scope of USACE’s duties and

BY ERIN JIMENEZ

authorities under Section 106 of the National Historic Preservation Act.

If a site is located and determined to be eligible, and if that site cannot be avoided by the proposed undertaking, USACE must then enter into an agreement with the state and any cultural or tribal organizations with an interest in the area. The intent is to mitigate any damage to the site while learning as much as possible.

Yet project sites aren’t the only place you’ll find archaeologists like Wilson working.

One of the most common places you’ll find them are at USACE project offices, working alongside rangers and natural resource specialists to preserve artifacts found by campers, hikers, and hunters.

“USACE parks and lakes draw a lot of people, including amateur archaeologists and treasure hunters,” Wilson said. “Yet taking artifacts or starting your own excavation on federal land is very illegal and comes with severe penalties.”

According to Wilson, the Archaeological Resources Protection Act enacted in 1979 protects artifacts found on federal property and can levy heavy fines or even jail time for those that disturb or remove artifacts.

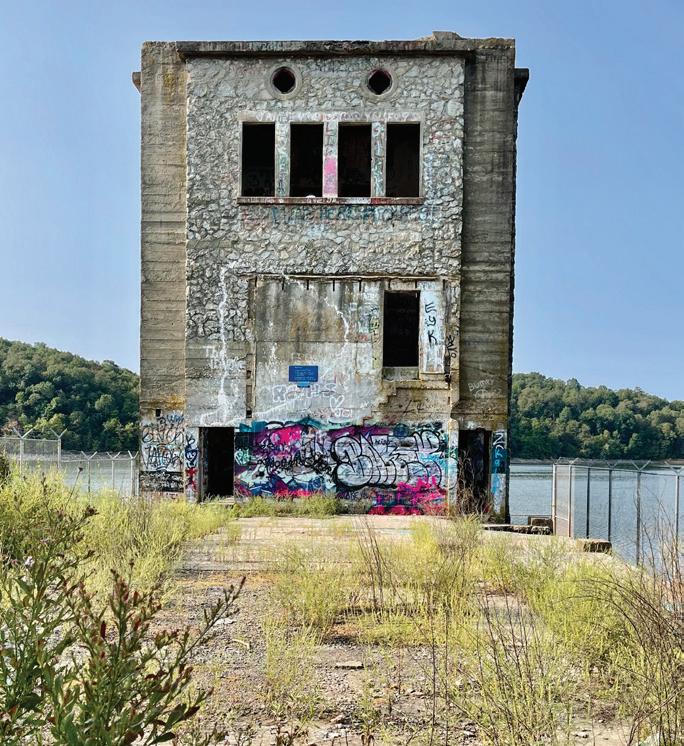

Currently, there are numerous ongoing archaeological sites in the Little Rock District. One that is listed on the National Register of Historic Places is the resort town of Monte Ne located in Rogers, Arkansas. Monte Ne was founded in 1900 and had the world’s largest log hotels, attracting visitors from across the country for more than two decades.

The property became USACE’s after the White River was dammed to create Beaver Lake in the mid-1960s, leaving much of the resort and original town of Monte Ne under water.

It is important that historical sites are preserved, because there are very few

protections afforded to these resources outside of those located on federal lands.

USACE balances the needs of our continually growing nation by preserving an area, if possible, and documenting it and studying it extensively – if only to ensure the historical legacy of those who came before us is not lost. AE

www.Americas-Engineers.com I 29 PROVIDING TECHNICAL EXPERTISE Little

Rock District

COURTESY IMAGE

p Top: The Oklahoma Row Site at the former Monte Ne Resort, a three-story concrete tower, is listed on the National Register of Historic Places. Above: Little Rock District archaeologist Allen Wilson digs holes in a grid pattern during a Phase 1 Survey.

PHOTO BY JAY TOWNSEND

Contract Awarded for Largest Overseas U.S. Military Hospital

The contract to build the largest U.S. hospital outside the United States was signed in February 2022, marking a significant step forward in progressing the Rhine Ordnance Barracks Medical Center Replacement (ROBMCR) project.

The German Construction Administration, in partnership with the U.S. Army Corps of Engineers (USACE) Europe District and the U.S. Defense Health Agency

(DHA), awarded a €859 million (approximately $969 million) contract to Züblin and Gilbane Joint Venture to construct a new hospital at Rhine Ordnance Barracks, Germany.

BY EUROPE DISTRICT AND THE U.S. DEFENSE HEALTH AGENCY

p Rendering of the Rhine Ordnance Barracks Medical Center Replacement (ROBMCR) project. The contract to build the largest U.S. hospital outside the United States was signed in February 2022, marking a significant step forward in progressing the ROBMCR project. The German Construction Administration, in partnership with USACE’s Europe District and the U.S. Defense Health Agency, awarded a €859 million (approximately $969 million) contract to Züblin and Gilbane Joint Venture to construct a new hospital at Rhine Ordnance Barracks, Germany.

The contract includes construction of a modern 985,000-square-foot hospital that features nine operating rooms, 120 exam rooms, and 68 beds, with a surge capacity of 25 additional beds. Construction is expected to be completed in late 2027.

“We are incredibly proud of our team’s contribution to achieve this critical milestone that will enable us to provide our service members and their families with the best facility modern medicine has to offer,” said USACE Europe District Commander Col. Patrick Dagon.

30 I USACE AMERICA’S ENGINEERS U.S. ARMY CORPS OF ENGINEERS, EUROPE DISTRICT, IMAGE PROVIDING TECHNICAL EXPERTISE Europe District & DHA

The German Construction Administration is executing this large-scale project through a partnering process, which involved construc tion industry expertise during the design phase. The award to Züblin and Gilbane Joint Venture, a strong partnership of leading con struction firms, brings both German and U.S. perspective to the project quality, schedule, and cost requirements.

When this new medical campus opens, it will replace and co-locate the Landstuhl Regional Medical Center, constructed in 1953, and the 86th Medical Group Clinic to become the largest U.S. medical center on foreign soil, providing primary care, spe cialized consultative care, hospitalization, and treatment for more than 200,000 U.S. military personnel, Defense Department, and interagency civilians and dependents in Europe.

The strategically located medical center will serve as the only forward-stationed evacu ation and treatment center for injured U.S.

service members, civilians, and contractors serving in Central and Southwest Asia, Eu rope, and Africa, and provide critical medical support to seven combatant commands. When completed, the new hospital will employ approximately 2,500 people.

“The Defense Health Agency looks for ward to the completion of the new medical center at Rhine Ordnance Barracks in 2027, which will continue to provide primary and specialty care for our beneficiaries around the world,” said Capt. Mark Lieb, DHA division chief for Facilities Enterprise. “This project is truly a large-scale collaboration between the Defense Health Agency, the U.S. Army Corps of Engineers, and the German government.”

This contract represents the next – and most significant – phase of the campus con struction that already includes almost $200 million of recently completed hospital infra structure work, such as a new access control point, bridge, utilities, and roadways.

The German government is contributing more than €151 million (approximately $180 million) for design and construction man agement. The new hospital is part of the U.S. forces’ substantial investment in Germany.

“The U.S. invested approximately $350 million annually in construction projects in the past few years, which are executed by the Federal Construction Administration. This demonstrates the excellent reputation the Ger man Construction Administration enjoys with our international partners,” said Sören Bartol, Parliamentary State Secretary, Federal Minis try of Housing, Urban Development and Con struction. “Furthermore, these investments boost Germany’s economy and preserve jobs in economically distressed regions.”

“The German Construction Authority is proud to be responsible for the design and implementation of this unique project for the U.S. forces,” said Bettina Bachem, the LBB Weilerbach director. “It is truly a once-in-a-life time project.” AE

USACE Real Estate: The Foundation of Military Recruiting

Local armed forces recruiting offices are often the first place a prospective service member interacts with the military. It’s here where America’s sons and daughters make the decision to serve their country, and as a gateway to service, it’s important these spaces honorably reflect the branches that will welcome Americans to the profession of military service.

What may not be known about the military recruitment effort, however, is these offices are all

BY JOSHUA VODA

facilitated by the U.S. Army Corps of Engineers (USACE). It is through USACE’s Real Estate function that military recruitment offices for all branches are procured and maintained.

As a former regional program manager for the Armed Forces Joint Recruiting Facilities Program, Janice Williams worked for USACE for 32 years, before recently retiring with more than 40 years of federal service. In that time, she oversaw many recruitment projects across 22 states.

“What I always tried to instill in my realty specialists was people no longer join the military by way of a draft. It’s an all-volunteer armed force. When someone visits a recruiting office, it’s important that we make sure it represents our nation. We don’t want a parent to feel uncomfortable leaving their child in a setting that, from the start, doesn’t feel safe. Realty specialists should take great pride in every recruiting office we build and ensure each is top quality. This is the first impression they are going to get of the military, and we don’t want to do anything that would make them second-guess their decision,” she said.

Real Estate doesn’t simply oversee the lease acquisition of properties, however. It’s

32 I USACE AMERICA’S ENGINEERS PROVIDING TECHNICAL EXPERTISE North Atlantic Division

COURTESY OF JANICE WILLIAMS

p Renovation work at the Times Square military recruitment booth in 2017 included enhancements to the now-iconic U.S. flags illuminated along the booth’s sides.

PHOTO BY BRAD TERRILL

an all-encompassing effort. Once a property is leased and build-out is complete, realty specialists are responsible for all necessary contracting, such as janitorial, utilities, parking, security, facilities maintenance, seasonal upkeep, and more.