3 minute read

New security gate system from UKSSH

from AccessPoint Issue 10

by AccessPoint

UK System Scaffold Hire has introduced a new security gate system designed to control access to all types of HAKI Stair Towers and Public Access Staircases.

The security gate system is quick to install on HAKI Stair Towers, whether they have staggered or in-line standards or are Mk2 stairs.

Robust and providing a totally enclosed security system, the gate is lockable from both sides and features cladding panels which can accommodate signage and advertising.

The UK System Scaffold Hire gate system provides a good security solution for when site staircases are accessed from pavements or for other areas used by the public. In addition, the solution provides a cost-effective way for event organisers to ensure that Public Access Staircases and Bridges can only be used by visitors during public opening times.

www.ukssh.co.uk

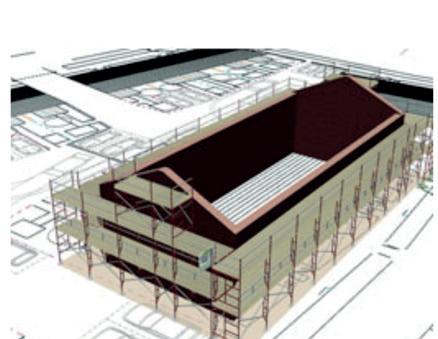

ITP supports Dublin restoration work

Scaffolding sheeting from Industrial Textiles & Plastics (ITP) has been used to wrap historic Leinster House in Dublin – the Georgian building that is home to the Houses of the Oireachtas – during a major programme of restoration while government business continued as usual.

For temporary containment and weather protection during the project, the client wanted a full PVC building wrap, digitally printed with an image of Leinster House’s facade. The material had to be flame retardant and certified to the highest standards, but they discovered that the cost would be very expensive and the installation would require specialist contractors.

Scaffolding contractors McCrory Access Solutions approached ITP, manufacturers of Powerclad FR Scaffold Sheeting that is certified for both plain and printed sheeting.

ITP’s in-house design and print department took up the challenge of recreating the facade image on 2m-wide scaffold sheeting and then enhanced, tiled and layered the image for digital printing on custom 52m length sheeting to accommodate the building’s full 50m width.

McCrory Access Solutions meticulously installed the precisely aligned and printed sheeting, enabling restoration work to progress safely behind a full-size, flame retardant reproduction of the building’s elegant facade. www.itpltd.com

SMART Scaffolder launches new scaffold design software

New SMART Scaffold Designer is a desktop software package that allows for the rapid calculation of leg loads, tie duty and bridge beam checks for tube and fitting independent scaffolding as well as the TG20:13 wind factor for sites in the UK and Ireland.

SMART Scaffold Designer, which can be used by any competent person with an understanding of TG20:13, is for use either on its own or with SMART Estimator Check IT TG20:13 or the NASC TG20:13 eGuide when a client needs calculations or drawings. The software checks scaffold bridges of up to 20m span, including moment and shear capacity, deflection, coupler slip and standard capacity, with an option to double the standards.

Leg loads are calculated precisely, allow for the number of boarded lifts and can be supplied to the client to check the foundations. The tie duties are also calculated exactly and the reduced loads can allow the user to use fewer ties where permitted by TG20. www.smartscaffolder.com

Safe working at height with MACDECK

MACDECK Safety Decking from Teesside-based J.Mac Safety Systems is improving contractor safety and productivity on-site for housebuilders including Persimmon, David Wilson Homes and Story Homes.

The MACDECK internal fall protection system is available to buy or hire and has been tested to support J.Mac’s statement that it is the strongest injection moulded system on the market. J.Mac manufactures all of its products in the UK.

In addition to providing a safe working platform on-site, the decking can be manufactured with a client’s branding, making the system unique to that specific client and adding security as a theft deterrent.

New products to promote safety on construction sites include an Extendable Leg, Brickguard, MACHATCH and MACLADDERSAFE.

www.jmacsafetysystems.co.uk

SCP Forgeco celebrates one million tube welds

SCP Forgeco is celebrating its one millionth tube weld nine years after introducing a scaffolding tube welding service.

As part of its multi-million-pound move to new premises in 2010, SCP Forgeco installed an automated Fusion Tube Welder commissioned specifically for the welding of recycled scaffolding tube. Initially in partnership with Lyndon SGB, the project was envisaged to re-life their underutilised short tubes by converting them to higher-demand 16ft and 21ft lengths. Traditionally these short lengths would have been ‘scrapped’ and new tubes purchased – welding them offered an environmentally conscious and financially beneficial option.

The same high-quality processes and testing procedures initially introduced are still followed today with full in-house production records and third-party batch testing.

Nine years on and with dozens of customers regularly taking advantage of the process, SCP Forgeco has completed its one millionth weld.

Managing director R Dale commented: “This is another milestone in SCP Forgeco’s history. We were proud to be chosen to partner with Lyndon SGB and it’s great to see where that original idea has led.

“The welding plant has generated and maintained many local jobs. Additionally, re-lifing has recycled more than 18 million feet of scaffold tube, giving a carbon saving of over 55,000 tonnes.” www.scpgroup.co.uk