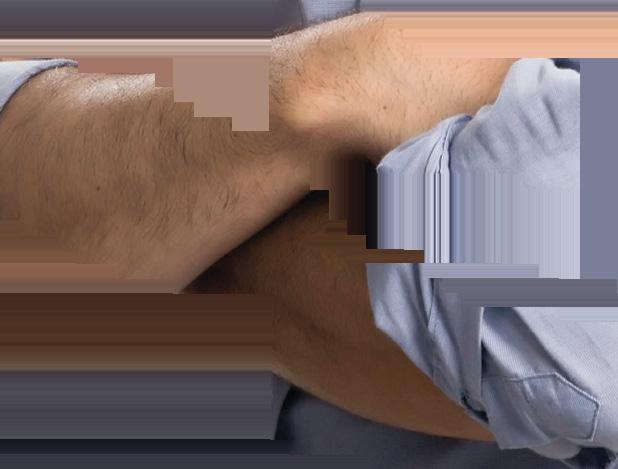

Chris Amato and Lisa Collins have set a vision for their suburban San Diego shop of quality repairs free of interference.

PAGE 38

PAGE 35

PAGE 42 FENDERBENDER.COM / JULY 2023 INDIE

one SoCal shop has seen success by staying independent PAGE 28

SPREADING YOUR GREEN MESSAGE

PREPPING TO WORK ON EVS

BOOKING IN BUSY TIMES

SPIRIT How

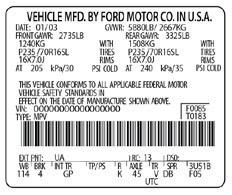

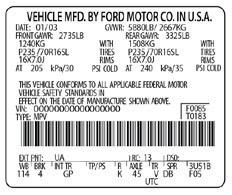

FRONTGAWR: 2735LB AT

REARGAWR: 3325LB 1508KG P235/70R16SL 16X7.0J

WITHTIRESRIMS

PSI

240 kPa/35 1240KG P235/70R16SL 16X7.0J

AT 205 kPa/30

01/03 00000000000000000

VEHICLESAFETY STANDARDSIN EFFECTON THEDATEOF MANUFACTURE SHOWNABOVE.

2 July 2023 fenderbender.com For additional information about Auto Data Labels visit our website at www.AutoDataLabels.com or call us at (631) 667-2382. NOTE: When ordering online or by email you will need to include a photo of the label you would like replaced. OUR LABELS WILL COMPLETE YOUR REPAIR! WITH AUTO DATA LABELS, YOU GET: EASY ORDERING ● FAST 1-3 DAY DELIVERY ● HIGH QUALITY MATERIALS RESTORES THE VEHICLE TO ITS ORIGINAL CONDITION VEHICLE EMISSION CONTROLINFORMATION Conforms to regulations: 2016 MY California:Not for sale in states with California emissions standards. TWC/HO2S/WR-HO2S/CAC/TC/DFI U.S. EPA:T2B4 LDV 2.3L-Group: GFMXV02.3VJW Evap: GFMXR0125NBV No adjustments needed. FED OBD II Fuel: Gasoline ABZ EMISSIONS ANTI-THEFT PAINT AND TRIM TIRE AND LOADING TIRE AND LOADING INFORMATION TIRE SIZE COLD TIRE PRESSURE 303kpa 44psi 303kpa 44psi 303kpa 44psi The combined weight of occupants and cargo should never exceed 505 Kg or 1114 Lbs. P265/70R17 P265/70R17 P265/70R17 FRONT REAR SPARE SEE OWNERS MANUAL FOR ADDITIONAL INFORMATION SEATING CAPACITY TOTAL 3FRONT 3REAR 0 VIN LABEL SERVICE PARTS 145 JTHCE96S870000000 145 JTHCE96S870000000 PQTP6P TG33405 BC/CC U 8624 93G 1GTZ7TBG6B1000000 135 0 C6 0 KC4 PDN US8 XHH ZX2 C6Y JL4 N33 USR WEN ZW9 93 B38 JH6 NU4 UJM V8D ZW3 93G BA3 G8 0 NE1 T74 V37 ZR7 7AL A31 GU6 NCF TGA V22 ZQ3 6AL A13 FHS MYD SLM V14 ZQ2 5 0U A12 E24 L96 R9N VT7 ZHH 1WT AXK EVA K68 R8A VR4 YHH 1SZ AU3 EF7 K34 R6C VK3 YD6 Z88 AS5 D31 KUP QB5 U73 YD5 Z82 AJ3 DE5 KD1 PPC UY7 YD3 ZY1 ©2020 LKQ Corporation. Visit us at Shop.LKQcorp.com and LKQcorp.com. | ADL-AUAOT0006-FLE Contact Us : Contact your LKQ/Keystone Local Sales Rep Upload your photos to the Website: www.AutoDataLabels.com Email your photos: Labels@AutoDataLabels.com Use the App: Download the ADL App And Upload your Photos VEHICLEMFD.BYFORDMOTORCO.INU.S.A. DATE: THISVEHICLECONFORMSTOALLAPPLICABLEFEDERALMOTOR

COLD F0085T0183 3 PP265/70R1P265/70R17 FRONT REAR SPARE 00000000 ⁄⁄H⁄⁄⁄⁄ ⁄F⁄ ⁄BY⁄ ⁄OYO⁄⁄ ⁄O⁄O⁄ ⁄⁄⁄⁄F⁄⁄⁄⁄⁄⁄⁄G , G⁄W⁄ ⁄⁄⁄⁄⁄B G⁄W⁄ F⁄ ⁄668⁄B ⁄⁄ ⁄668⁄B ⁄H⁄⁄ ⁄⁄H⁄⁄⁄⁄ ⁄O⁄FO⁄⁄⁄ ⁄O ⁄⁄⁄ ⁄PP⁄⁄⁄⁄B⁄⁄ F⁄⁄⁄⁄⁄⁄ ⁄O⁄O⁄ ⁄⁄H⁄⁄⁄⁄ ⁄⁄F⁄⁄Y , B⁄⁄P⁄⁄ , ⁄⁄⁄ ⁄H⁄F⁄ P⁄⁄⁄⁄⁄⁄⁄O⁄ ⁄⁄⁄⁄⁄⁄⁄⁄⁄ ⁄⁄ ⁄FF⁄⁄⁄ O⁄ ⁄H⁄ ⁄⁄⁄⁄ OF ⁄⁄⁄⁄F⁄⁄⁄⁄⁄⁄ ⁄HOW⁄ ⁄BO⁄⁄ ⁄ P⁄⁄⁄ ⁄ ⁄⁄⁄ ⁄ ⁄⁄ ⁄ ⁄⁄⁄ ⁄⁄ ⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄ --⁄⁄PGK⁄ ⁄⁄⁄ ⁄ ⁄⁄⁄⁄⁄ ⁄⁄⁄⁄ ⁄⁄ ⁄ ⁄⁄ ⁄⁄ ⁄ ⁄8⁄7⁄ ⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄ K⁄⁄⁄⁄⁄KY , ⁄⁄⁄ ⁄ ⁄⁄ ⁄ ⁄⁄ STK A AA5 --NH7 WE'VE GOT YOUR LABELS!

GVWR: 5880LB/2667KG WITHTIRESRIMS PSI COLD TO PLACE AN ORDER DELIVERY IN 1-3 DAYS! APPLE STORE GOOGLE PLAY

HOW

3 July 2023 fenderbender.com JULY CONTENTS 28 DOING IT THEIR WAY Chris Amato’s Body Werks is celebrating 10 years of independent vision BY TODD KORTEMEIER 22 MY BIGGEST DECISION Two perspectives on joining a national franchise network BY TODD KORTEMEIER FEATURE PROFILE 07.23 | VOLUME 26 | NUMBER 07 FenderBender (USPS Permit 25614), (ISSN 1937-7150 print) is published monthly by Endeavor Business Media, LLC. 1233 Janesville Ave., Fort Atkinson, WI 53538. Periodical postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($90 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at fenderbender@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2023 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

4 July 2023 fenderbender.com STARTER QUICK FIX 7 DRIVERS SEAT Planning your next step 9 PAST THE PAGE WIN hands out Cornerstone Awards 11 BREAKDOWN A partnership in education 15 NUMBERS DRP data 16 LIGHT HITS Mitchell/Caliber partnership, and much more 18 SNAP SHOP Doing things the right way 18 CONTENTS JULY 11

5 July 2023 fenderbender.com 32 THE SOP Keeping your brand unique 35 TECH+TOOLS Considerations for ADAS work 38 CASE STUDY Being a green shop 40 ADAPT Implications of autonomy 42 CUSTOMER SERVICE Managing expectations when busy 35 COLUMNS 21 SHOP PROFITS Effects of bonuses BY GREG LOBSIGER 45 COLLISION COURSE Reading the economic tea leaves BY TIFFANY MENEFEE 46 DUE PROCESS Makings of great leaders BY DREW BRYANT STRATEGY

EDITORIAL

Matt Hudson Content Director

Todd Kortemeier Editor

Hanna Bubser Associate Editor

Kacey Frederick Assistant Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Lindsey Gainer Contributing Writer

Emily Kline Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Universal Collision

Greg Lobsiger Loren’s Body Shop

John Magowan Ernie’s Auto Body

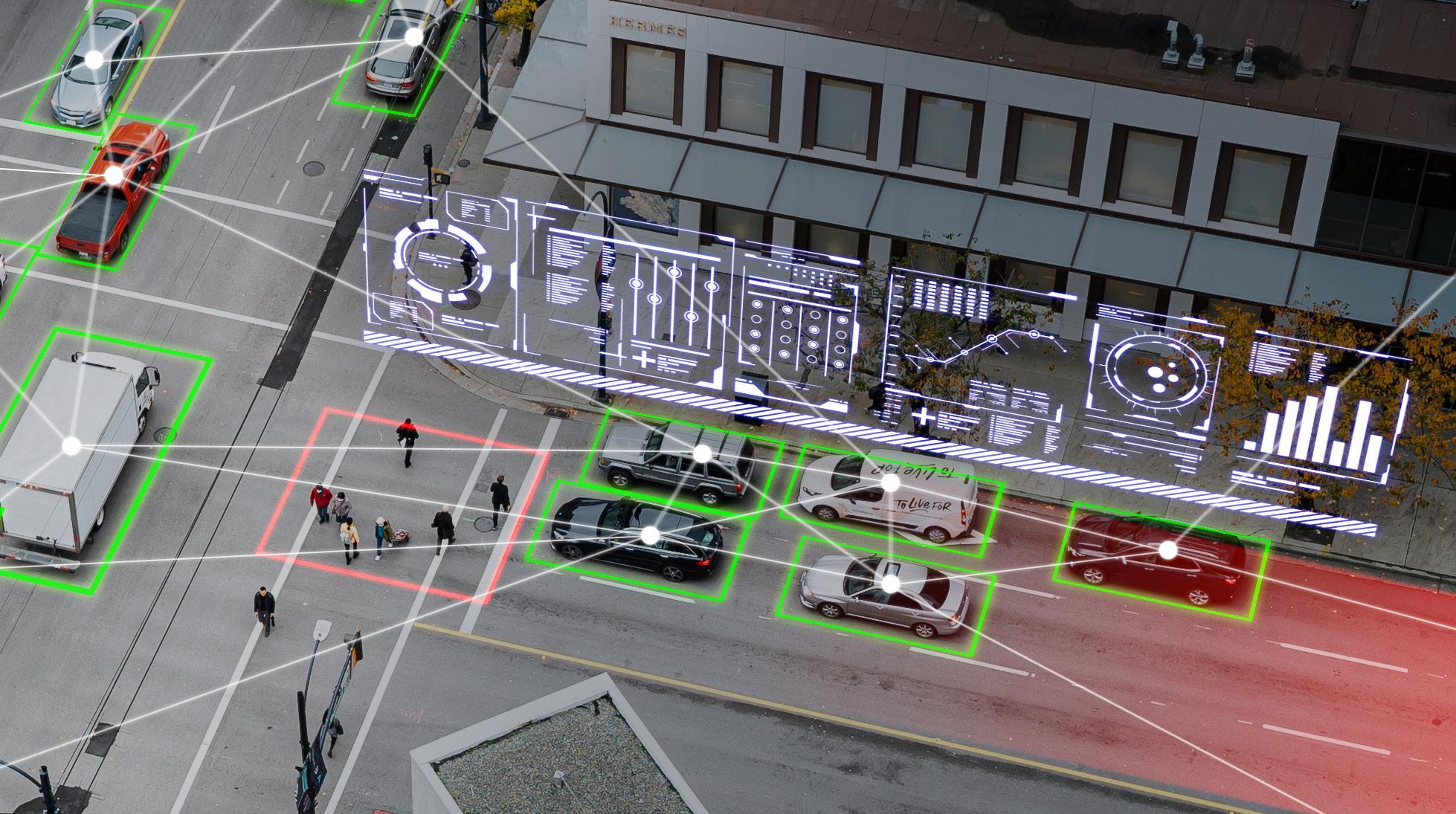

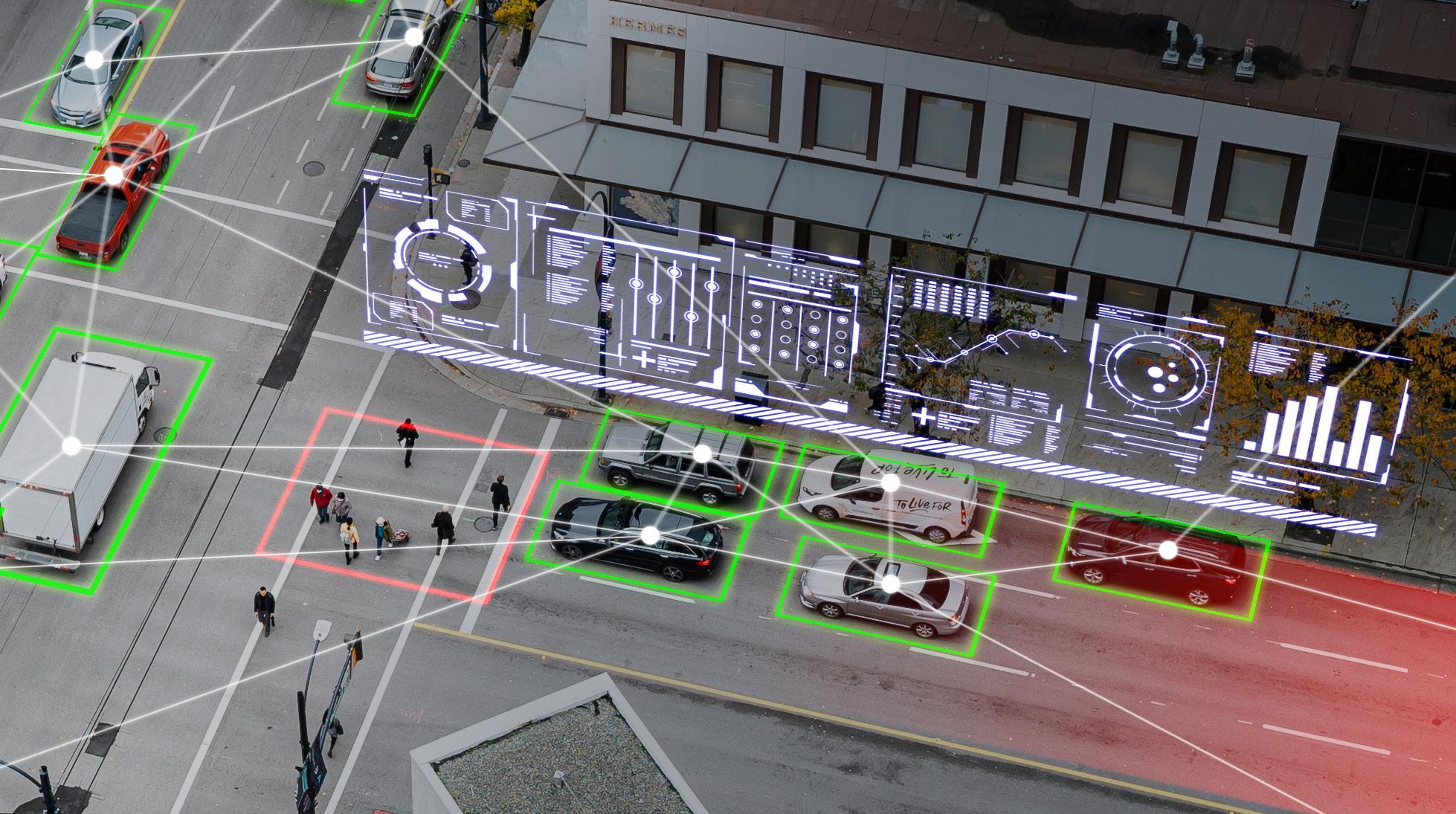

Stan Medina Certified Collision Works

SALES

Andrew Johnson Associate Publisher ajohnson@endeavorb2b.com

Mattie Gorman Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Bob Marinez Account Executive (National Accounts) rmarinez@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Michael Parra Account Executive (National Accounts) mparra@endeavorb2b.com

Martha Severson Account Executive (National Accounts) mseverson@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Kenzie Verschoor Account Executive (National Accounts) mverschoor@endeavorb2b.com

Ryan McCanna Administrative Assistant

ART AND PRODUCTION

Mariah Straub Production Manager Jen George Ad Services Manager Mitch Bradford Art Director

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

President June Griffin

CFO Mark Zadell

COO Patrick Rains

CRO Reggie Lawrence

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli Kylie Hirko EVP Transportation Chris Messer VP and Group Publisher

HOW TO REACH US

Endeavor Business Media, LLC

571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

6 July 2023 fenderbender.com

CLICK ON THE LOGO BELOW FOR PRODUCT INFORMATION CONTENTS ONLINE EXTRAS Polyvance ProColor Collision AUTEL Axalta Coating Systems LKQ Corporation FBMC 2 0 2 3 Auto Data Labels Bosch Launch Tech USA PPG Industries

EVERYTHING ENDS

On the ends of eras and what they mean

I WANT TO TALK ABOUT “SUCCESSION.”

Note the quotation marks—we’re not talking about planning for retirement. I’m talking about the acclaimed HBO series that concluded its award-winning run several weeks ago. Whether you’re like me and consider it one of the greatest works of television of all time or you’ve never heard of the show, I think we can take some lessons away from thinking about how things end.

For the uninitiated, the premise of “Succession” is right there in the title. It is the story of a family-owned media empire and its aging, acerbic patriarch. Who will take over is the running plot line of the series, whether it be one of the sibling heirs to the throne or somebody else. It’s not a spoiler to state the obvious, that there can only be one successor and many people end up upset that it isn’t them. For some of them, they wind up right back in the same place when the series began, rich, but without power nor direction.

To paraphrase an old saying which I cannot confidently state the origin of, the way it begins is the way it ends. If something begins positively, it will end positively—and vice versa. You get what you give. You don’t get to control the way or the manner in which something ends, change is the only thing that doesn’t change.

Life and business are full of endings both expected and unexpected. You know a relationship with a customer is temporary, but who can predict if that relationship will end positively or negatively? Building leases expire, equipment breaks down, valued employees leave. Nothing is permanent; expect change.

All an ending is is change, and change can be difficult. But to toss another saying at you, you don’t lose, you learn. Even if your ending had a negative outcome, certainly there is something you learned from it that can be a positive going forward. Bidding goodbye to a favorite show isn’t the same as bidding goodbye to a valued employee, but

in both cases, it was the experience you had that matters most.

There is no end in sight for FenderBender as we bring you another month’s edition. We enjoyed bringing you the story of Chris Amato’s Body Werks (p. 48) and how they’ve managed to stay independent and do things their way as they celebrate 10 years in business we think you’ll enjoy reading about them. We also think you’ll enjoy this month’s strategy stories as we offer information on how to bring green practices into your shop (p. 65) and what to consider as you start to work on more electric vehicles (p. 59). Thank you for continuing to support FenderBender.

TODD KORTEMEIER EDITOR

7 July 2023 fenderbender.com 2303FB_Polyvance.indd 1 1/17/23 1:58 PM

DRIVER’S SEAT

tkortemeier@endeavorb2b.com

fenderbender.com A proven business model for 20 years, ProColor Collision is growing! Independent body shop owners driving their business forward are choosing ProColor. Standardized operations, management tools and consolidated technology solutions improve performance. The ProColor team of industry professionals are dedicated to performance excellence offering the sales, operational and marketing support needed to take business to the next level. ProColor Collision is committed to helping shop owners grow their business locally while leveraging established relationships with global insurers, suppliers, and fleet companies. The ProColor PROcess is a winning formula. Find out more at procolor.com ProColor Collision USA LLC, 650 Pelham Blvd, Suite 100, St. Paul, MN 55114 ® Registered Trademark of MONDOFIX INC. JOIN THE NETWORK

WIN ANNOUNCES CORNERSTONE AWARD RECIPIENTS

THE WOMEN’S INDUSTRY NETWORK (WIN) CORNERSTONE AWARD was presented at the 2023 WIN Educational Conference to Laura Kottschade and Jeanne Esquivel, according to a press release.

The conference took place in San Antonio, Texas, May 1-3. The award was presented by WIN Chair Tanya Sweetland to Kottschade, the operations manager of Jerry's ABRA Auto Body & Glass in Mankato, Minnesota, and Esquivel, the business development manager of Enterprise Holdings.

With the Cornerstone award intended for individuals who have provided “high impact actions,” “unique contributions,” and a positive example for others, Sweetland credited the two with “completely overhauling” WIN’s scholarship program and showing dedication through personally donating shop tools to scholarship recipients.

The 2023 WIN scholarship program was expanded this year to reach a record number of 20 WIN scholarships being awarded. Kottschade said their goal is to double the number of scholarships in 2024.

“They really pushed the scholarship program to another level this year through their efforts of getting packages and applications together,” Sweetland said. “They helped build a different level of camaraderie within the Scholarship Committee and were willing to seek out additional resources to help better support keeping women in the collision industry.”

9 July 2023 fenderbender.com VIDEOS | PODCASTS | WEBINARS | NEWS Visit FenderBender.com/news for daily updates from around the collision repair industry. PAST THE PAGE @fenderbendermag @fenderbendermag @fenderbendermag fenderbender.com/linkedin fenderbender.com

TODD KORTEMEIER

Week of Honors The WIN Cornerstone Award was presented alongside honoring WIN’s Most Influential Women.

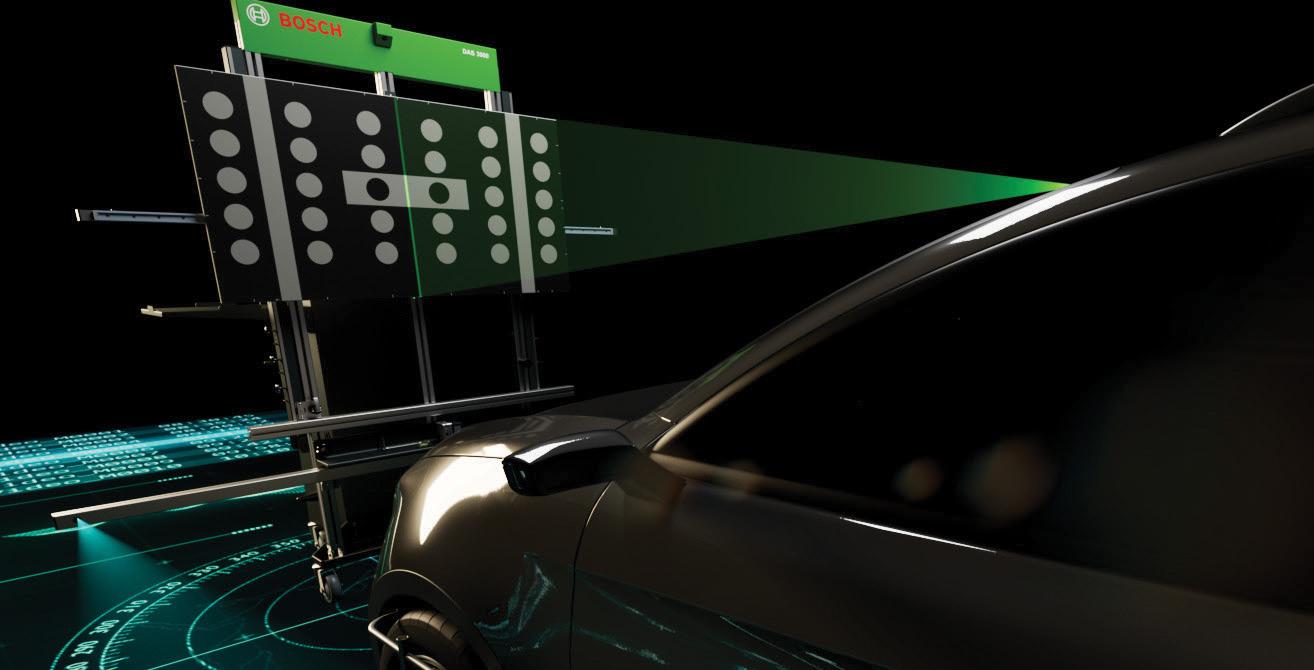

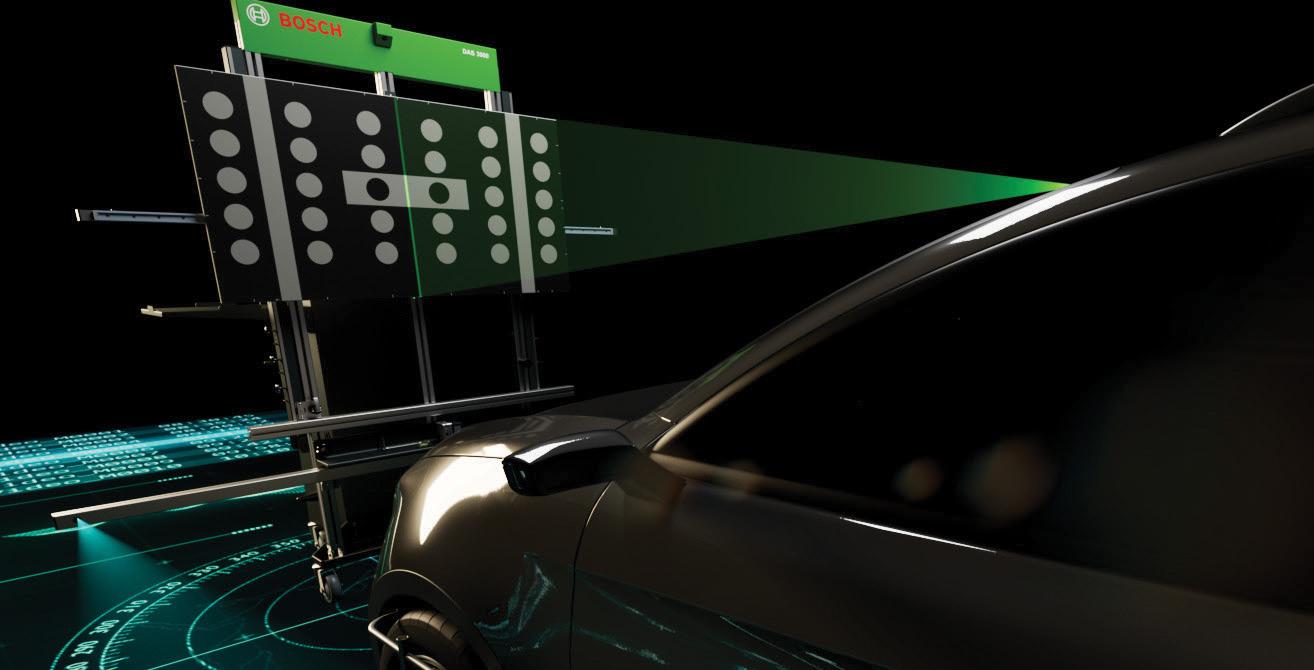

Future-proof your investment with the confidence that your calibrations are completed to the tightest tolerances and the the first time.

A commonized set-up approach based on OEM specifications provides an easy to follow setup without sacrificing accuracy and precision

Guided interactive workflow. Step-by-step instructions and consistent user interface across all makes and models.

Fast and efficient placement using digital vision positioning which automatically measures vehicle distances and angles to ensure precise calibration

Bosch DAS 3000

The calibration solution for fast, reliable and precise calibrations on a wide range of advanced driver assistance systems.

Modular and future-proof: Designed to work with new targets and the next generation of ADAS technologies

Integrated storage and maneuverability keep your equipment clean and serviceable and ready to use at a moment’s notice

Get more information about the DAS 3000

We develop ADAS vehicle technologies for OEMs. Trust us to recalibrate them.

Solutions for every job. boschdiagnostics.com/adas

DAS 3000

ANALYSIS

JUMPSTARTING CAREERS

How shops are helping launch a high school automotive program in North Carolina

By KACEY FREDERICK

IT’S NO SECRET that in recent years shops have had to grapple with struggling to find talent for their businesses. As the need for emerging technicians grows, automotive school programs have become more common nationwide to prepare and encourage those entering the

11 July 2023 fenderbender.com QUICK FIX NUTHAWUT SOMSUK / ISTOCK / GETTY IMAGES PLUS

workforce to pursue a career in fields such as collision repair.

One of the most recent of these programs is in Huntsville, North Carolina, at Aspire Trade High School. The school offers training for high school students in different trades, such as carpentry and HVAC, and is now opening a collision ed-

ucation center with the help of Absolute Collision Center and IDS Automotive.

Absolute Collision owner Thomas Goforth sat down with FenderBender to talk about the program his company is helping start and what it means for shops.

Aspire Trade High School and Absolute Collision decided to work together

to create the program after contacting a member of the school’s board of directors, Jennifer Nichols. Absolute Collision’s corporate office is in Cornelius, North Carolina, about 10 minutes from the school’s campus.

With the program slated to begin in the fall semester later this year, a

12 July 2023 fenderbender.com

UNIQUEPIXEL / ISTOCK / GETTY IMAGES PLUS

QUICK FIX

curriculum and the process of selecting an instructor were still in development at the time of this reporting. A body shop for students to perform hands-on work was also being planned. It’s estimated to be around 1,400 to 1,600 square feet in size when it’s completed.

When students first enter the program, the first semester will focus on giving them a foundational understanding of the automotive field, touching on topics including estimatics, ordering parts, body paint, mechanical work and ADAS. From there, as students progress through the program, they can understand what they would like to pursue as a specialization.

“Whatever they gravitate towards in that freshman year, they’re going to kind of go from the sophomore to senior year more in-depth–whether it be estimating and parts, whether it’s paint and body, whether it’s mechanical and ADAS,” Goforth says.

The shop provided for students will allow them to perform a variety of work throughout the process of car restoration. It will come equipped with a paint booth, a frame machine for calibration and computers for ordering parts and creating estimates.

“The students [that are] interested in the parts, in estimating handle that, then it goes into paint and body, then it goes into the mechanical and the ADAS, and they actually see a working car getting repaired through the model,” Goforth explains.

As the students reach their junior and senior years in the program, they can do summer internships. Students that complete the program can earn different ICAR and ASE certifications, depending on their focus.

The goal of the program is for students to be able to come out of high school already equipped with valuable skills that they’re ready to use. Absolute Collision is committed to bringing on as many graduates onto its team as possible and will help any that they cannot hire to connect with dealerships, independent shops, and regional MSOs needing help.

Aspire’s new program already has a waitlist for the coming semester, and as more programs such as these crop up around the country, the earlier shops make themselves known to students in the community, the better chance they have of attracting them after they graduate.

“Actually getting in front of these schools and guidance counselors and

principals, and, you know, let them know it exists before their 12th-grade year when ... they’re out of time and have to make a decision starting early, I think is the biggest thing,” Goforth says.

Shops can do this by becoming involved with the community and showing support to trade and charter schools, such as Absolute Collision inviting 8thgrade students to tour its shop. While good for brand promotion, it also keeps that business at the forefront of students’ minds as they grow and consider career options.

A shortage of available help has been a problem in nearly every trade, but Goforth believes that Absolute Collision and Aspire are helping to show students that they can have a fulfilling career that provides for them through the automotive industry.

“Our reasoning behind this is to, you know–and I’ve always said it and the team believes it–to leave the industry better than we found it,” Goforth remarks. “So, you know, I think this is going to be something that’s been much needed in the industry. That’s today’s technologies, today’s trends, and the soft skills and the hard skills that are needed in today’s workforce.”

13 July 2023 fenderbender.com

“OUR REASONING BEHIND THIS IS ... TO LEAVE THE INDUSTRY BETTER THAN WE FOUND IT.”

—Thomas Goforth, owner, Absolute Collision

Get access to the industry’s first 3D rendering technology using color and help your body shop find the best matches and variants. Explore the PPG LINQ™ Digital Ecosystem. Visit PPGLINQ.com The PPG Logo is a registered trademark and PPG LINQ and VisualizID are trademarks of PPG Industries Ohio, Inc. ©2023 PPG Industries, Inc. All rights reserved. Save materials PPG VisualizID™ Exceptional color visualization technology Best match every time Improve efficiencies Increase profits

NUMBERS

DWINDLING DRPS?

IN THIS MONTH’S PROFILE you’ll ready about Chris Amato’s Body Werks, which celebrates its 10th anniversary this year and has had success operating as a non-DRP shop from the very beginning. In the latest FenderBender industry survey, an all-time high of 44% of shops reported seeing no revenue from DRPs. While a majority of shops still report having at least one DRP, the trend shows more shops moving away from these partnerships.

How many DRPs is your business on?

7-9 4.55%

4-6 12.99%

10+ 2.60%

0 46.10% 1-3 34.77%

percentage of 306 survey respondents

15 July 2023 fenderbender.com QUICK FIX

LIGHT HITS MITCHELL AND CALIBER PARTNER ON LICENSING AGREEMENT

Mitchell and Caliber Collision have announced a multi-year, enterprise licensing agreement that will allow Caliber to utilize Mitchell’s software at its locations, according to a press release.

The agreement will provide all Caliber locations with access to Mitchell Cloud Estimating, Integrated Repair Procedures, a Paintless Dent Repair (PDR) Calculator, and miScore, as well as enhanced software solutions and data analytics to better serve Caliber’s needs.

The Cloud Estimating will allow damage appraisals to be written from any Internetenabled smartphone, tablet, or laptop computer. Integrated Repair Procedures will provide over 30 years of vehicle data and OEM information as appraisals are written to decrease research time and increase accuracy.

The PDR Calculator will help shops estimate prices for minor dents, dings, and body creases, and to easily add them to a bill. The miScore feature will be used by Caliber’s corporate support center as a way to track key performance indicators.

Remote training sessions for the programs were held for over 200 Caliber centers and more than 1,000 Caliber employees, with the remaining locations to be added throughout the rest of the year.

CRASH CHAMPIONS OPENS FLORIDA LOCATION

Crash Champions has announced the opening of a new location in Lutz, Florida, according to a press release.

The new store is located at 26430 Pine Creek Drive. It joins the 50 Crash Champions locations within the state of Florida, and over 600 locations throughout 36 states.

Crash Champions founder and CEO Matt Ebert said the new store will help the company further expand its footprint in the regional market.

“The opening of a new high-quality repair center in the Tampa market is another proud step forward for our team,” Ebert stated. “This is a strategic market

in our overall growth plan, and we look forward to serving local customers and business partners with the reliable and high-quality collision repair service they expect from Crash Champions.”

CLASSIC COLLISION ACQUIRES TEXAS AND NORTH CAROLINA LOCATIONS

Classic Collision has announced the acquisition of four different collision repair shops–one in Texas and three in North Carolina, according to a press release.

David Collision Repair, Inc., in Georgetown, Texas, was part of the acquisitions and has been in business since 1978.

Larry David, the former owner of David Collision Repair, said that he and his team “have been passionate about our work and always go the extra mile to ensure your complete satisfaction and believe that Classic Collision will continue this approach with customers.”

The North Carolina acquisitions consisted of three CARSTAR Jerry Rhynes Collision locations: in Albemarle, Charlotte and Pineville.

“We believe in thoroughness, and we take a comprehensive path to repairing the customer’s vehicle and know that Classic Collision operates under the same high standards,” said former owner Jerry Rhynes.

Classic Collision CEO Toan Nguyen stated that the company is “pleased to welcome” all four acquisitions as it expands its footprint in the Texas and North Carolina markets.

KIA AND HYUNDAI THEFTS PLAGUE NORTH CAROLINA SHOPS

A dramatic increase in Kia and Hyundai vehicles being stolen in North Carolina as a result of a viral video online has caused a backlog of parts, Spectrum News 1 reports.

The Charlotte-Mecklenburg police have reported thefts doubling in Charlotte during the first part of 2023, with thefts in Raleigh increasing by 54% from five years ago, according to the state’s attorney general’s office.

Most vehicles being stolen are Kias and Hyundais as a result of a video showing how to break into those two makes going viral online. Many vehicles are being found within days, but typically with damage such as smashed windows and broken ignitions.

The phenomenon has resulted in Kia and Hyundai replacement parts being put on backlog. According to a Kia spokesperson, many of the vehicles being damaged have been out of production for years and need parts that “had very little demand” prior to the increase in thefts.

Kia Head of Corporate Communications James Bell said the company has taken measures to increase safety in response to the thefts, such as making victims of thefts top priority in part distribution and working directly with suppliers to “facilitate the necessary flow of parts most-needed.”

AUTO SHOP PLANS BUILDING DEDICATED TO COLLISION REPAIR

An automotive shop in Jacksonville, Illinois, is adding another building to its operation to accommodate the number of collision repairs it does, My Journal Courier reports.

Tom Finch Automotive will be constructing a 6,240-square-foot building dedicated to collision repair to assist with their West Walnut Street location. Operations Manager Tim Hughes said that when this location first opened, around 75% of the work being done was mechanical. But over the past ten years, collision repair has increased and now takes up half of their work.

“Since we moved to this location 14 years ago, our business has grown, and we have needed more room,” Hughes stated. “About six years ago we added to the existing building with three wash bays, a restroom and break room for employees. Even that isn’t enough room now.”

After years of consideration, the shop decided to expand this past September. After gaining approval from the Plan Commission and the Jacksonville City Council for the building, it’s expected to be up and

16 July 2023 fenderbender.com

QUICK FIX

running by September 2023. The expansion will clear up more space in the shop’s main building for mechanical repairs.

CONNECTICUT CARSTAR LOCATION HOSTS COMMUNITY DAY

Ray’s CARSTAR in Bristol, Connecticut, recently held a community day for local residents, according to a press release.

The CARSTAR location at 137 Terryville Road held the event on May 13, where 2023 University of Connecticut men’s basketball team member Donovan Clingan was present to sign autographs and meet with fans after winning the national championship this season.

The event featured a vintage car show with vehicles loaned by the community. Each attendee was given a complimentary raffle ticket to win either a University of Connecticut gift basket or a jersey autographed by Clingan.

“We would like to extend a heartfelt thank you to everyone involved in this special community day event,” said Steve Merchant, co-owner of Ray’s CARSTAR, via the press release. “From the Bristol residents who attended, the CARSTAR team that helped us get to this point, and of course, Donovan Clingan, I couldn’t be prouder.”

AASP OF NEW JERSEY TO HOLD 16TH ANNUAL GOLF OUTING

The Alliance of Automotive Service Providers of New Jersey (AASP/NJ) has announced plans for the 16th annual Lou Scoras Memorial Golf Outing to be held again this September, according to a press release.

The event will take place on September 19 at Knob Hill Country Club in Manalapan, New Jersey. It is held in memory of Lou Scoras of Holmdel Auto Body, who served as both a shop owner and association leader.

The day will begin with registration and lunch followed by a shotgun start that afternoon to kick off the golfing. That evening a cash bar, dinner and prizes will then be offered to attendees.

“The event not only pays tribute to a former influential member, Lou Scoras, but it also raises funds for a scholarship in his name that can only help to engage and inspire the next generation of technicians,” said AASP/NJ Executive Director Charles Bryant. “Attracting new blood to our industry is crucial in this day and age.”

NABC OPENS NOMINATIONS FOR AWARDS

The National Auto Body Council has opened nominations for its Changing and Saving Lives Award and the President’s Award, according to a press release.

The President’s Award will be given to an NABC member company that has devoted time and resources to support “the vision of the National Auto Body Council.”

Members of any level are eligible, and nominees will be elected by the NABC Board of Directors. The winner will be announced later this year and recognized on the lifetime traveling trophy. A donation to a philanthropic charity of the company’s choice will be made in its name by the NABC.

The Changing and Saving Lives Award will recognize an individual that has gone to great lengths to support their community or has provided help through a time of crisis.

Nominees will be elected by the NABC Board of Directors or by the public, with a winner being announced this fall. An engraved trophy will be presented to the winner as well. A donation to a charity of the recipient’s choice will be made in their name by the NABC.

Nominations are open now and will conclude on August 1. Those who have been previously nominated may be nominated again.

BODYSHOPJOBS.COM SHOWCASES SERVICES AT TRADE SHOW

BodyShopJobs.com, a service connecting auto body professionals with employers, recently showcased its offerings at the 17th Annual Tom Ferguson Crawdad Boil and Trade Show, according to a press release.

The event from Tasco Auto Color

took place on May 11 at the Ford Arena in Beaumont, Texas, and provides opportunities to network and advertise products and services. This year there were more than 1,500 attendees, 600+ shops and over 60 vendors.

BodyShopJobs.com showcased a user-friendly interface and its job search capabilities to those at the event. Team members were able to discuss the company’s services with both employers and job seekers at the trade show.

“We are thrilled to have participated in the TASCO’s Crawdad Boil and Trade Show and had the opportunity to connect with influential figures in the collision industry,” stated BodyShopJobs.com President Diane Benting. “Our presence at the event allowed us to demonstrate the value we bring to employers and job seekers, and solidify our position as the go-to platform for collision career opportunities.”

SAFELITE GROUP ACQUIRES NEW ANGLE GLASS

Safelite Group has announced an acquisition of auto glass assets from New Angle Glass, according to a press release.

New Angle Glass operates in the Boston metro area. Following the finalization of the deal on May 19, the companies aim to provide those in Massachusetts with vehicle glass repair, replacement and recalibration services.

Safelite has said the acquisition will strengthen its operational systems, advanced safety system recalibration resources, distribution network, global purchasing ability and relationships with insurance and commercial partners.

Safelite Group President and CEO Renee Cacchillo said that the partnership has expanded the company’s influence.

“As we continue to grow and reach even more customers, we’re proud to provide the quality services they expect from Safelite,” Cacchillo stated, via the press release. “Our New Angle Glass team members will contribute to our future success, and we’re glad they are joining us.”

17 July 2023 fenderbender.com

ORLANDO AUTO BODY

LOCATION: ORLANDO, FL

OWNER: BRAD CHESNEY

SIZE: 10,000 SQUARE FEET

B y TODD KORTEMEIER Photos by JESSICA FRIEND Submit Your

1. FOUNDED WITH A PURPOSE

To paraphrase an old ad campaign, Brad Chesney isn’t just the owner of a body shop, he was originally a customer. Before starting his business in 2011, Chesney was working at a law firm when he was in a car accident. He took the car to a shop he knew, where a friend worked, but he was surprised when the work was done that the fit of everything just didn’t look right. Chesney’s friend explained that it was because Chesney’s insurance policy called for only aftermarket parts. Chesney was shocked, but also inspired to start a shop that did things, in his view, the right way. A short time later he did so, with that same friend as the body man, at first renting a single stall in a mechanical repair shop where they now run the entire building.

“That’s one of our, call it a claim to fame is,” says Chesney, owner of Orlando Auto Body in Orlando, Florida. “We started this in May 2011 and we’ve never

18 July 2023 fenderbender.com

STAFF: 11 AVERAGE MONTHLY CAR COUNT: 60 AVERAGE REPAIR ORDER: 4,200 ANNUAL REVENUE: $3 MILLION

Shop

SNAP SHOP QUICK FIX

Proud of your shop and want to show it off to your peers? Tell us about it at SUBMISSIONS@10MISSIONS.COM

1 2

had an aftermarket part be installed on a customer’s car for an insurance repair. It has been all OEM parts, 100% of the time has the car left with an OEM part on it.”

The shop started out with just Chesney, the body guy, and a painter— who is still with the shop today. Gradually as they took on more jobs they took over more of the facility as other tenants moved out. After a couple years, the owner sold the entire building to Chesney. With no desire to own more than the single location, it’s safe to say the shop has its permanent home.

“We’re always going to be, you know, you hate to say always, but we will always be a single location shop,” Chesney says.

2. FOR THE CUSTOMER

Orlando Auto Body does not advertise. Its website features just the basic info. The shop doesn’t even have a Facebook page. But Chesney says it all goes back to standing on the shop’s reputation as doing repairs with the best possible quality—that is what gets the name out there.

The shop strives to go the extra mile for the customer. In its early days doing a relatively low volume of repairs, cars even received a full detailing and a tank of gas. Today, Chesney has instituted a $100 policy for each car stating that if there is something extra the shop can offer that’s less than $100, employees are empowered to do that without approval.

“Our goal is to give that car back to them not just as nice as it was before the accident, we want to give that car back to them nicer than they’ve ever seen that car,” says Chesney.

3. KNOWING THEIR ROLE

Orlando Auto Body doesn’t perform in-house calibrations or work on electric vehicles. While Chesney acknowledges that “may be the death of us at some point,” he’s not willing to compromise the things his shop does well on. It’s related to his philosophy on staff and why the shop has had a loyal set of long-tenured employees—it’s allowing people to do what they do best with minimal interference. The shop knows what it does well and focuses on that.

“My thought now is it’s like, you know what, we got a good gig right now. And if it’s not broke, don’t fix it,” says Chesney.

19 July 2023 fenderbender.com

3

SEPTEMBER 24-26, 2023 • AURORA, CO HYATT REGENCY AURORA CONFERENCE CENTER FENDERBENDERCONFERENCE.COM EDUCATE & ELEVATE CONNECTING LEADERS IN COLLISION REPAIR OWNED & PRODUCED BY: SPONSORED BY:

Are Bonus Systems Important?

Small compensation for better-rounded employees

Why do our employees, on average, get up five days a week, get dressed in work clothes, leave their families and drive to work to spend roughly 40 hours of their lives in our businesses? These employees use, for the most part, the best hours of their week working. In the 1940s, the American psychologist Abraham Maslow advanced the idea that human motivation is broken down into a fivelevel pyramid he called the "Hierarchy of Needs." Starting at the bottom, Level 1 is physiological needs: food, water, warmth and rest. Level 2 is safety and security needs. Level 3 is belongingness and love needs: intimate relationships and friendships. Level 4 is esteem needs: prestige and the feeling of accomplishment. At the top is Level 5, self-actualization: achieving one’s full potential, including creative activities.

Most anyone reading this column has heard, “there is more to work than just money.” Unfortunately, here is the reality. Statistics show that 60% of Americans live paycheck to paycheck and the average family has less than $5,000 in savings. So, even though there are five levels to Maslow’s pyramid, the bottom two (physiological needs and safety needs) are still a very big deal to our employees’ motivation to return to work every day.

When I first purchased my shop back in 2000 from my uncles, we had three employees including myself. We ran with just a straight clock hour plus overtime pay system. With some coaching after a few years, we started to grow and add employees. We then went to a flat rate pay system for the technicians. Even though the business grew along with profits, I grew to hate the flat-rate system. This was due to the stress that came with figuring out who would get what hours.

In 2013, I received some in depth Lean training and we kicked out flat rate to focus on quality in everything we did. We resorted back to the clock hour pay system with daily targets we needed to meet. In a flat-rate world, it is hard to have in-depth discussions on ways to improve, while technicians are so distracted about how they are going to make their weekly/bi-weekly paycheck.

In September of 2018, I was looking at our numbers and we were at a plateau in sales and profit. In prior years, I had always given out a very nice Christmas bonus. After doing some math, I sat all

the employees down and laid out the monthly/daily goals we would need to reach as a team by Dec. 15 for all to receive the bonus. So, Oct. 1 we started the plan. Through some blood, sweat and triumphs, we made an amazing goal by Dec. 15.

Up until this point, I had never seen the synergy in my team that I saw in the fall of 2018. Now my wheels were spinning over the holidays that year. I ran through every number imaginable with cars per day, hours per day, refinish hours per RO, etc. I was trying to figure out the best bonus system for the entire team in the soon coming new year and I knew we needed to start Jan. 1, 2019. Without diving deep into the math, we just used the backwards flat rate compensation for the additional hours necessary to give every employee a $10,000 bonus per year or $833.33 per month per employee front to back. We started the program in the beginning of 2019, and it was like wildfire. Through continuous improvement of processes from engagement of all employees the last four plus years, we have made strides I never imagined. For the core group that was here when we started the bonus system, if we can hit the 2023 goals, each will make $40,000 more than they did Dec. 31, 2018.

At the end of the day, whether we run a clock hour or flat rate compensation plan, either can be successful. The key is, we must have a bonus system that promotes teamwork. I have seen shops that have all these complicated compensation and bonus plans for each department. This even includes bookkeeping for, say, AR or estimators for gross sales and gross profit, then each technician for what they each produce. When I see these pay plans, it makes me want to go just lay in the middle of the road! These types of pay plans really promote silos or individuals to just look out for what is best for themselves. If independent shops want to be like MSOs, just pay like MSOs and you will get your wish.

Back to Maslow’s Hierarchy of Needs: When a shop implements a global bonus program, this enables each employee (no matter the level) to get the same dollar amount each month. Every level of Maslow’s pyramid is covered. On top of that, business profitability skyrockets due to surpassing their breakeven even farther than before. Reach out to me if you need more clarity.

GREG LOBSIGER Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

21 July 2023 fenderbender.com JOSIE SMITH PHOTOGRAPHY

COLUMNS SHOP PROFITS

Two shop owners look back on their choices to join national networks

By TODD KORTEMEIER

TOPICAL

starts out with a vision. Where that vision comes from varies. It could be following in the example of a mentor, or it could even be the opposite. Perhaps a cautionary tale from early in an owner’s collision repair career demonstrated the wrong way to run a business. Often, it’s a combination of experiences.

For Tyler Griffiths, as soon as he began his journey to ownership as a general manager in 2017, he knew what name he wanted hanging on the building.

“I joined CARSTAR in Yelm [Washington] in 2017, I ran that store until 2021 when I bought my store in April, and my goal was to become a CARSTAR,” says Griffiths, owner of CARSTAR Hub City Collision in Centralia, Washington. “That was my goal when I jumped off from that, I said I’m going to become a CARSTAR. How long is it going to take me? I don’t know.”

Whether it is a goal from the very beginning or a product of changing circumstances, the decision to partner with a national franchise is a big one. These partnerships take many different forms, but essentially offer the same benefits: Greater access to resources and relationships that can potentially take a business to the next level.

Elsewhere in the state of Washington but on the other end of the spectrum in years in business compared to Griffiths, Kevin House joined up with 1Collision’s network of locations roughly 18 months ago. House opened Center Collision in Tacoma, Washington, in 1995, and had been a part of repair networks before. Like CARSTAR, 1Collision offers the benefits of working under a corporate umbrella while

24 July 2023 fenderbender.com

MY BIGGEST DECISION

retaining independent ownership. For House, it was an opportunity to enhance a business he’d already built into a success over more than 25 years.

“I believe everybody needs to have—it’s like any football player that really thrives, they have to have a coach,” says House. “So many guys get into this industry and think, ‘OK, I’ve gotten as far as I can on my own.’ … I think everybody needs some help and guidance and some different perspectives on things.”

FenderBender explored the perspectives of these owners and why they made the decision to partner with their respective networks, how it’s been and how they’re looking toward the future.

CARSTAR ROCK STAR

An accumulation of experience was very much a part of the journey to ownership for Griffiths, who grew up building motors with his grandfather before deciding he didn’t want to be a mechanic. He served nearly a decade in the military, doing everything from sweeping for bombs to working as a water treatment specialist, but nothing mechanical. After leaving the service he went back to school for collision repair, gradually working his way into a GM position. It was in that role in a CARSTAR shop he saw the benefits that would one day affect him as an owner.

“I went to some of the business meetings, and just seeing how much support you have behind you was huge,” recalls Griffiths. “It was like night and day of, why would I even want to be a ma and pa when you have so [many] connections and so much support behind you that they’re willing to help you and engage you to be successful.”

Griffiths found what he thought would be the perfect spot for his new business, a former laundromat in Centralia that he purchased in April of 2021. The building dated back to the 1920s and maintenance had not been kept up to par, Griffiths says. He gutted the building, put up new walls to reorient the space and put a coat of paint on the outside. But when CARSTAR showed up to take a look, Griffiths found he still had a way to go.

“They’re like, ‘Yeah, this ain’t going to happen. We’re not going to put CARSTAR on the front of this,’” says Griffiths. “And I’m like, well, what is it going to take? What do I have to do to become a CARSTAR? And

they’re like, ‘Well, you need to do this, this and this.’ OK, I said, give me three months.”

After the building was squared away, and his financials were examined and fees were sorted, Hub City officially became a CARSTAR shop in November 2021. Griffiths says that while CARSTAR was always his goal, he did his research on all the other large networks to see what they offered and what they required. He favored CARSTAR’s “family-friendly” approach and the support the network offered for his growing business.

“If you have questions, you can make a phone call,” says Griffiths.

While making sure he was up to the franchise standard, Griffiths appreciated the tools and resources he had access to as a part of the network. There was also a lot of guidance in the transition process, with a dedicated integration manager. One thing Griffiths would caution new owners about is the transition time, three months is the standard but Griffiths recommends five months.

“Why is because there’s so much information,” says Griffiths. “And so much you have to learn, to understand, to make yourself successful. Why I was able to do it so quick in three months is I came from a CARSTAR. So I knew a lot of the reportings, I knew all the ins and outs of the backside of it. But if you don’t know, you’re going to be kind of lost after they kind of let you go on your own.”

Griffiths’ goal is to build a long-lasting shop that his children can inherit one day. That means becoming a pillar of the community, and establishing an identity. While CARSTAR has its brand standards, it was important to Griffiths to be able to communicate his business’ own identity as well.

“I wanted the ‘veteran owned’ sign in my CARSTAR sign,” Griffith says. “So we were able to work something out with the colors and I was able to beside my CARSTAR sign put ‘veteran’ down. As long as you have the communication and keep it open with CARSTAR, there’s no ifs, ands or buts about it, they’ll help you along.”

BLUEPRINT TO SUCCESS

Working with outside consultants is what helped Kevin House transform his business from zero employees to 13, from $300,000 a year to north of $3 million. A 12-year partnership with DRIVE is what he credits in taking Center Collision to the next level and

25 July 2023 fenderbender.com

OLEG LYFAR / ISTOCK / GETTY IMAGES PLUS

two locations across Tacoma. But at a certain point, he felt he had learned all he could, and a friend suggested while at the FenderBender Management Conference that House meet 1Collision Director of New Location Development John Hollingsworth.

The terms sounded good, but House was hesitant to lock into any kind of long-term commitment with something new. Hollingsworth reassured him that after an initial three-month commitment, the partnership would be month to month.

“I’m a guy that will really advocate your product if I like it,” says House. “But if I don’t like it, if it’s not doing me good, I don’t want to be paying for something like that.”

Soon after coming on board, House was impressed with the amount of in-house training available to shops. House had sent employees out to training before, and though he had no regrets, it was at a significant expense. Having a professional trainer come out to the shop meant no employees had to miss time and it was just a better learning environment to stay hands-on in their own shop.

“Sending somebody out to our shop and spending time in our shop and getting to know our operation—and they weren’t necessarily trying to change things, they’re just trying to understand it, and made sure that we had good workflow, and that, if we had questions, they would have some options,” says House.

One particularly helpful area of training for the shop was in blueprinting. What once seemed like a difficult process to implement was made simpler while employees also learned the importance of it. That’s left a lasting impact that the shop has seen pay dividends long after the trainer left.

“He spent time with each of our employees that were involved in the blueprinting process and just made sure that they understood the importance of it,” House says. “Slow down enough to do a good thorough job, rather than, let’s just rush through this so we can get to the repair, because you always end up circling back and like, shoot, should have caught that in the blueprinting process, now we’ve got to wait two weeks to order this specific part. So that was just a big thing for us.”

House credits the improvement in their blueprinting as a key factor in the shop expanding to a second building. The reasoning was the new process greatly increased their efficiency and production.

“With the help of 1Collision we were able to overcome the blueprinting thing and give us a point where we were being more productive and able to have a little bit of a brighter future,” says House. “Like, OK, well, yeah, this being the case, now that we know we can do this and that, we can clearly see that we’re going to just keep growing.”

Both shop owners stressed the importance of having access to information as a key in their decisions to join their respective networks. Whether it was a quick phone call for advice or a having a trainer in the shop to work hand in hand with employees, both Griffiths and House feel that their decision has elevated their business growth. Neither one is looking back.

“You could do it the hard way or the easy way,” says House. “Why would you choose the hard way?”

MY BIGGEST DECISION Copyright © 2023 Axalta Coating Systems, LLC and all affiliates. All rights reserved. AN AXALTA COATING SYSTEMS BRAND Get more from your finish. Nason ®XL is an affordable, easy to use refinish system available in thousands of collision-quality colors. Deliver a long-lasting finish with Nason ®XL. VALUE THAT LASTS nasonxl.us

INFORMATION AT YOUR FINGERTIPS UP-TO-DATE INDUSTRY NEWS AND EVENTS, NEW PRODUCT LAUNCHES AND MORE! https://www.fenderbender.com/subscribe Scan to sign up for FenderBender Enewsletters Scan for a FREE subscription to FenderBender Magazine

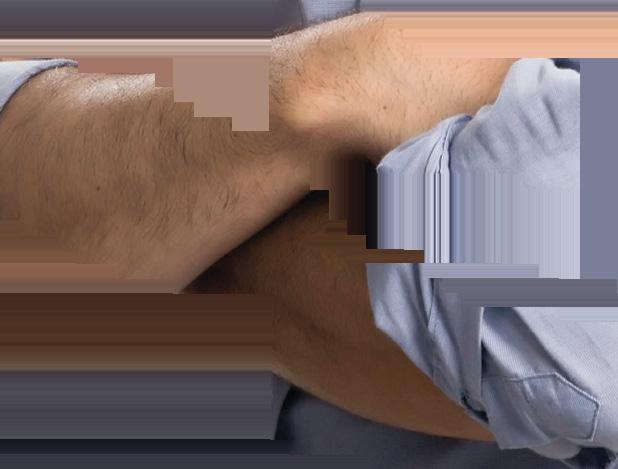

A DECADE OF DOING IT THEIR WAY

Chris Amato and Lisa Collins have never strayed far from their vision

By TODD KORTEMEIER

JULIET PEEL PHOTOGRAPHY

By TODD KORTEMEIER

JULIET PEEL PHOTOGRAPHY

PROFILE

you surf on over to the website for Chris Amato’s Body Werks, you’ll find the word “luxury” scattered about. You could also easily infer that from the badges scrolling past, representing the OEM certifications the shop holds— Porsche, Lucid, BMW and more. But lest you think this is a shop born with a silver spoon in its mouth, think again. It wasn’t always that way. And it makes the shop’s 10-year anniversary this year all that more special to its owners.

“When we took the shop over in 2013, it had minimal equipment, it was only 10,000 square feet. We were painting coolers,” says Lisa Collins, Amato’s partner in life as well as in their Oceanside, California, shop.

Those early challenges were the expected growing pains of any new business, certainly nothing to do with a lack of experience or knowledge. Amato is the product of many fine influences in collision repair, starting with his father, who began his career as a body man in a Cadillac dealership in the 1950s. That example instilled a love of cars in his four sons, with Amato’s oldest brother Paul eventually starting his own shop.

“I was brought up in the industry, working on cars as a kid, officially started working on cars when I was 16,” Amato says. “When I was in high school, instead of playing sports, I took a job experience deal through the high school where you could get out of school early. So I used to get out of school about 1:30 and then I would run to my brother’s shop and work with him.”

Chris worked as a body technician at Amato’s Auto Body for 25 years, during which time he was exposed to many of the high-end OEM certifications his own shop holds today. He then decided to strike out on his own in 2013. That meant carving out some territory of San Diego County for himself, leaving the south for Amato’s shop in Sorrento Valley and setting up for himself straight up Interstate 5 in the North County beach community of Oceanside.

“I tried to get as kind of far away from him as possible just so that we could separate a little bit,” says Chris.

From Box Trucks to Benzes

Watching his brother’s flourishing shop was

fenderbender.com

certainly a great example for when Amato started his own shop, and he certainly had all the knowledge necessary from a quartercentury spent in collision repair. But starting any new business is never easy, and Amato and Collins--who was new to the industry-had their share of growing pains early on. They took over an existing shop, which had some built-in advantages but was not optimized for the high-volume, high-end business Amato wanted to build.

“There were only four technicians here and no office staff at all, and $50,000 was considered a good month,” recalls Collins. “So, it was scary.”

There were few high-end vehicles back then, Amato recalls. The shop would work on anything that came through the door. One boost that came built in was the relationship the previous shop had with the United States Marine Corps and its Camp Pendleton base located in northern Oceanside. The Marine Corps brought in an influx of box trucks, trailers, heavy equipment, cars from its fleet of vehicles and more. The shop did every bit of work it could get its hands on from the Marine Corps, Amato said.

That business provided a steady stream of work for the first three or four years of the shop’s operation. But still those early years were difficult as the shop found its footing. Amato had the collision shop expertise and Collins had a business background but there were aspects of this new venture that were new to each of them, and both felt the weight of the risk personally and professionally.

“It was scary for probably about a year and a half, really scary,” says Amato. “Where we were, you know, I came from a shop that was super high [volume]. And so when I opened this, I had to basically reinvent myself, because any work that we took in was good work, where before it was we’d walk outside to write an estimate and the customer’s basically sold before they pulled in the parking lot. We had to scratch and claw to keep the business going and the doors open and pay everybody salaries.”

The couple also had their personal relationship to consider.

“And since we put all our eggs in one basket,” added Collins, “since we’re together and working together, it was scary.”

While volume was an important metric

as the shop was beginning to grow, it wasn’t the ultimate business model Amato had in mind. He wanted the top priority to be on quality repairs, and to do that he felt it was important to do two things: Pursue OEM certifications and not operate on DRPs.

A DRP model could have been a natural way for a young shop to pipe in a steady stream of cars through the doors. But it wasn’t for Amato, nor was it for his brother, who never operated on a DRP. Amato followed that same model in his own shop, believing it to be essential to prioritizing quality.

“Just produce the quality work and hopefully the name would get out there and we would get the referrals and producing the best repairs that we possibly could,” Amato says of his approach to business.

When it came to getting started on certifications, some pre-existing relationships helped. Amato had some relationships with Tesla and also some dealerships in

need

succeed.

30 July 2023 fenderbender.com

PROFILE

Power of Team Employees at Amato's receive the benefits they

to

nearby Carlsbad. Exploring these relationships helped get the shop started on its certification journey.

“We slowly started to gain traction where [the dealerships] were starting to send us, and we were producing, high quality repairs, which I was accustomed to, and slowly started getting certifications and worked our business from there,” says Amato.

By Amato’s recollection, Tesla was the first certification for the shop, which opened the door to more high-end certifications like Jaguar Land Rover and Mercedes. All the equipment necessary for the Tesla certification helped down the road with others, as well. This approach has had a downstream effect of continued business for the shop.

“We try to do really, really good quality and work with some of the dealerships that are near us,” says Amato. “So, all of our work is word of mouth, and dealer direct referrals. We do a lot of manufacturer repairs for Tesla, so we do a lot of warranty repairs.”

Maintaining a High-End Reputation

Obviously, there is no shop that sets out to not do quality repairs. But the product is often self-evident whether a shop is truly making quality a priority or not. Striving for quality first, Amato believed, would be the best way to not only compete but stand out.

“After a lot of marketing, hiring great staff and chasing certifications, we’ve been very blessed,” says Collins. “It’s been really, really lucrative for us. And one of the things that we really focus on is quality of staff.”

While Amato is no longer in the back working on cars, he does lend his expertise to the team from a training perspective. Employees also receive extensive training through the shop’s myriad of OEM certifications. The shop also provides a host of attractive benefits to recruit and retrain the most skilled team members, such as unlimited PTO, full medical and dental coverage and a retirement plan. Technicians are also salaried instead of paid on commission, which Amato reports is a rarity in his area, if not across California.

“My belief for the years is that commission—and I was a body man—commission tends to sacrifice quality,” Amato says. “So, if you have a body man that you put on a car, and the faster he is, the more money he

makes, I tend to believe that creates an issue where you skip steps. … Obviously we need technicians to produce, but I don’t want cars produced over quality. If it costs us as a business a little bit more to repair the cars properly and make it undetectable that the car was ever in an accident, that would be my ultimate goal.”

Amato and Collins, who both serve on the board of the San Diego chapter of the California Autobody Association, are proud of the standard of quality they’ve been able to maintain and also that they’ve managed to remain one of “very few” independent, nonDRP shops in their part of San Diego. The shop has nearly doubled in size as the team celebrates its 10th anniversary this year, still in the same building but having acquired two additional buildings on the property. Collins says any further expansion would be at a different facility as there isn’t much more to add to the current location. Having carved out a niche where it is with a singular focus from the beginning, there is no reason to change things up now.

“I’m surrounded by body shops down here,” says Amato. “So we just don’t really worry about what the other guys are doing. We just try to focus on fixing cars, right? And making the customer happy.”

31 July 2023 fenderbender.com

A Great Match Chris Amato and Lisa Collins are partners in life as well as in business.

Maxed Out Chris Amato's Body Werks has grown to take over two extra buildings on the property in 10 years.

STANDING OUT IN THE FRANCHISE SYSTEM

Staying on brand, even as part of a network

FOR PHIL RICE, general manager of Huber Collision Center in Fredericksburg, Virginia, being a part of 1Collision’s franchise network is like being a member of a big, supportive family. Much like a family unit, he says, the company’s focus is on helping each of its shops succeed without trying to change what makes each one unique.

“Our identity has always been Huber Collision and we are proud of that,” says Rice. “Our desire was not to change our identity, it was to increase the quality of resources available through the partnership of a franchise operator.”

And 1Collision was fully supportive of that.

“I worked with 1Collision for roughly nine months before coming on board,” he says. “Never once was branding a topic of conversation. Our talks revolved around processes, culture, education and business.”

1Collision made it clear from the start that Huber’s brand was Huber’s to keep— and that was a major selling point when identifying the right franchise partner. Here, Rice explains why.

As told to LINDSEY GAINER

Finding the Right Franchise Network

My father used to tell me a man is the average of the five people he hangs out with the most—and you are either pulling the average up or pulling it down. I knew I needed to surround myself with industry veterans that understand what today’s collision centers are doing, what our battles are, what our struggles are. And more importantly, how we need to evolve as a team.

I don’t think I am capable as an individual to guide this team or this business where it needs to go. No one person is. If I want to surround myself with like-minded people, the only way to do that without being an acquisition to an MSO is to join a top-quality network that has MSO-like resources, but encourages independence.

That’s what I was looking for in a franchise partner and, as it turns out, that’s 1Collision in a nutshell—they encourage a strong, independent culture while providing their shops with MSO-level resources. The tools available to a network shop are truly only limited by the individual’s willingness to grow and learn. Just knowing that if I’m having a problem, I am a phone call away from getting help from someone—or multiple people—and they will assist me in

resolving my issue in a way that’s best for our team … that’s invaluable.

And it’s not only about guiding me, it’s about guiding my team, too. What happens if I’m in a car accident tomorrow and I can’t come to work for a while? My team still has the depth and knowledge of 1Collision right there, ready to help.

Building A Brand Around Integrity

When we joined 1Collision in February of this year, we already had over 20 years of busi-

32 July 2023 fenderbender.com

STRATEGY THE SOP

OATAWA / ISTOCK / GETTY IMAGES PLUS

ness under our belt and were a well-known shop in the community … so it was incredibly important that our brand remain intact.

Our parent company is Huber Motor Cars, the local Mercedes-Benz and Volvo dealership … so when clients purchase a vehicle from Huber Motor Cars, they come to understand as part of the sales process that we have a collision center, too. Customers are familiar with the Huber name in our community. Because of that, having the ability to maintain our name and logo was an important part of

finding the right franchise partner. We didn’t want to lose brand recognition.

Our brand is much more than just our name and logo, though. It’s the integrity behind the work we do, and it’s important that my team and I protect that integrity each and every day. We’ve worked extremely hard to build trust with our customer base by giving our best to every job, and owning and fixing mistakes when they happen. Honesty and excellence are synonymous with the Huber Collision Center name … and we’re continually strengthening

the brand with every customer interaction. Our customer’s experience has and will continue to remain the same moving forward.

The Final Word

If you’re looking to franchise your business, do your homework. Talk to your peers and get recommendations. Then vet those recommendations thoroughly, and don’t settle until you find the right fit for your business needs. It’s an incredibly important decision, and one that can’t be made lightly.

33 July 2023 fenderbender.com LEARN | GROW | WORK SMARTER

www.passthease.com #1 TRUSTED SOURCE FOR ASE TEST PREP YOU PASS OR YOU DON’T PAY!

TECH+TOOLS

EXTRA CONSIDERATIONS FOR EV REPAIR

Making sure your shop and your techs are prepared for EVs and hybrids

By NOAH BROWN

By NOAH BROWN

WHEN HONDA BEGAN producing the Insight in the U.S. in 1999, the first commercially available vehicle in the country to offer a hybrid powertrain, it was easy to view the compact two-door car as little more than a fad.

35 July 2023 fenderbender.com

STRATEGY

CHOOCHART CHOOCHAIKUPT / ISTOCK / GETTY IMAGES PLUS

Honda’s Integrated Motor Assist system was the first of its kind to supplement engine power with electric motor assistance, but the unconventional-looking hybrid ultimately never developed a loyal following.

Despite the initial lackluster performance of its first hybrid, though, Honda proved to be ahead of its time when it came to electric drivetrains.

Nearly a quarter-century after the Insight made its U.S. debut, hybrids and electric vehicles have finally caught on in the mainstream automotive landscape. Data from Statista shows that the number of EVs and PHEVs in the U.S. has steadily increased since 2015, with both accounting for a combined 1.32 million new vehicle sales in 2021.

Electric drivetrains are quickly saturating the industry, and Barry Dorn, owner of Dorn’s Body and Paint in Mechanicsville, Virginia, says it’s becoming increasingly pertinent to learn more about these vehicles and begin working on them safely and effectively.

“The design and architecture [of EVs and hybrids] are completely different,” Dorn says. “You have to have a completely different mindset when working on them. It’s not the same at all.”

The Wild, Wild West

Though EVs and hybrids are increasingly common, Craig Van Batenburg of the Automotive Career Development Center says rules around who can work on EVs and how to work them are still very far behind.

“It’s the Wild West, the sheriff is drunk, cowboys are in town and nobody cares,” Van Batenburg says. “That’s pretty much how this is regulated.”

Because of that, there aren’t set standards for repair procedures on EVs or hybrids, making automakers the de facto standard bearers for their own vehicles. Many OEMs will require body shops earn a certification before allowing those shops to work on their vehicles. Dorn says this is the first thing shops need to keep in mind before jumping into an EV or hybrid repair.

“They should not be doing a thing to the vehicle until they know if they can work on it. Even the smallest of accidents could com-

promise an area of the high voltage system,” Dorn says. “There is a lot to consider when you’re working on these vehicles.”

In addition to making sure your shop is capable of working on a vehicle, making sure that it makes sense for your shop is equally important.

“The main thing you’ve got to keep in mind is cost. It’s not just the cost of the tooling, the training and the total amount of equipment,” Dorn says. “Can you take the best group of techs in your shop and be without them for three to six weeks? When they’re gone and in training for weeks at a time, not only are you losing them and paying them and their expenses, you’re also missing their productivity.”

Training is necessary to work on EVs, but it isn’t always the smartest decision for a shop to make if they don’t have the volume to support it. If your shop isn’t equipped, either with the proper tools or the proper training, Dorn says it is significantly easier and safer in the long run to pass on the vehicle.

“We get cars in where someone has started a repair before realizing they couldn’t do it, and that makes it a lot harder on us to start the process and figure out what the scope of repair is,” he says.

Extra Considerations

If your shop decides to take on EV and hybrid repairs, Van Batenburg says there are extra steps that need to be taken.

As most shops know, disabling the high voltage system is required before starting any work on a vehicle. Van Batenburg says that almost all EVs and hybrids have failsafes that automatically shut down a vehicle’s high voltage system if an airbag is deployed in an accident. The only exception, he says, are model year 2005-2012 Ford Escape hybrids, which feature an inertia switch that shuts off the system in the case of a collision. There are ways that modders and aftermarket techs can disable those systems, but Van Batenburg says that is incredibly difficult to do. Still, it’s best practice to perform a system down procedure with proper personal protective equipment to make sure a vehicle’s system is offline before starting repairs.

Dorn’s shop takes an extra step and

scans vehicles with a thermal gun to make sure there are no unusual temperature readings or heat sources coming from a vehicle before beginning work on it.

If there is damage to a lithium-ion battery pack, the vehicle needs to be stored outside 30 feet away from anything. If there isn’t room, call your local fire department—Van Batenburg says they are the goto resource to figuring out where to store hazardous materials.

In addition to making sure the system is offline, having a plan in place for the worstcase scenario–the battery igniting–is critical to ensuring your team stays safe.

Vehicle fires are rare, and despite public perception, EVs have actually been statistically less likely to catch fire than internal combustion engines–data reported by Auto Insurance EZ shows there were only around 25 fires for every 100,000 EVs sold last year, compared to nearly 1,530 in ICEs for every 100,000. Still, fires can happen, and making sure your team is able to evacuate that vehicle safely and remove it from your shop is critical.

“You need to have an evacuation plan for that car. You’re really at the mercy of that battery,” Dorn says. “Once a fire starts, then it’s virtually impossible to stop it. You need to make sure your staff knows what to do in that situation.”

Even after a vehicle is repaired, there are still extra considerations that have to be taken into account. Van Batenburg says most auto paint manufacturers specify their paint to bake for an hour at 160 degrees Fahrenheit. Nickel batteries cannot be exposed to more than 150 degrees, and lithium shouldn’t be exposed to higher than 140.

Each manufacturer is going to have significantly different standards and systems that it uses for its EVs and hybrid vehicles. Understanding that and how different it is to work on those vehicles, Dorn says, is the single most important thing a shop should do before taking on electric drivetrain work.

“OEMs take working on a battery electric vehicle very seriously because they’re worried about something happening to the high voltage system,” Dorn says. “The big issue that repairers face is not only can they work on a vehicle, but also if they should.”

36 July 2023 fenderbender.com

STRATEGY

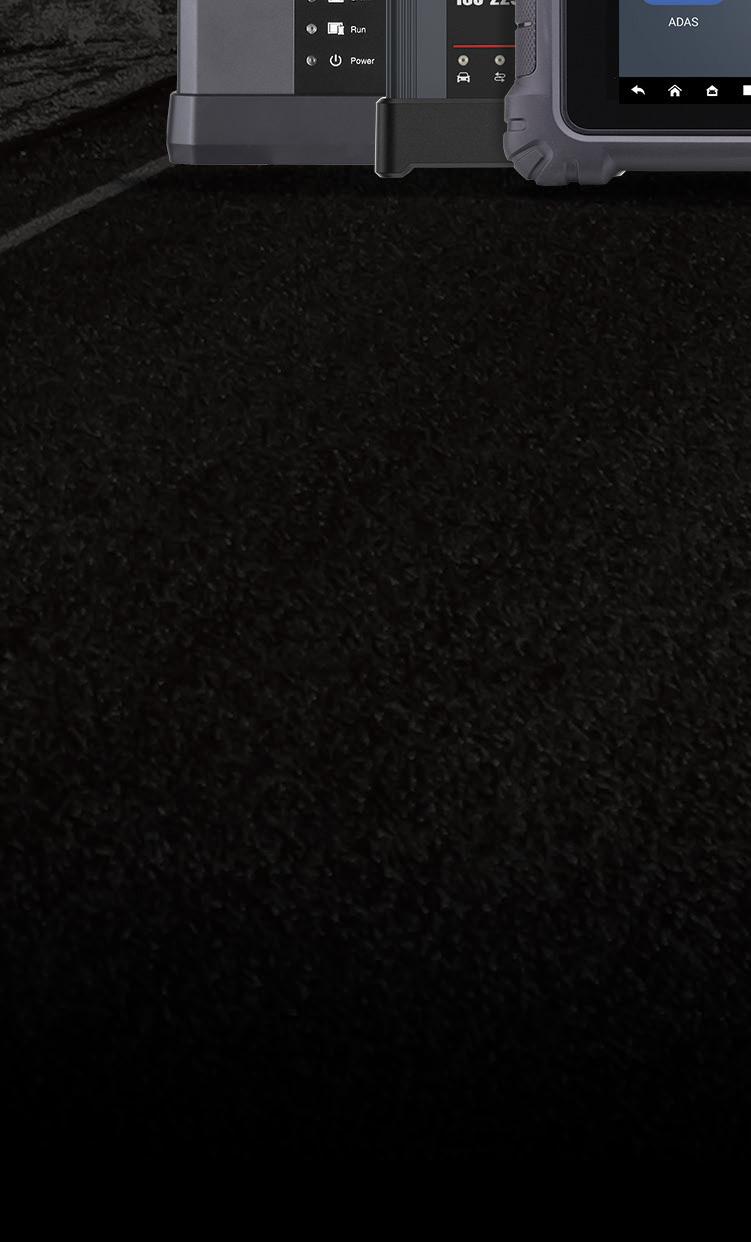

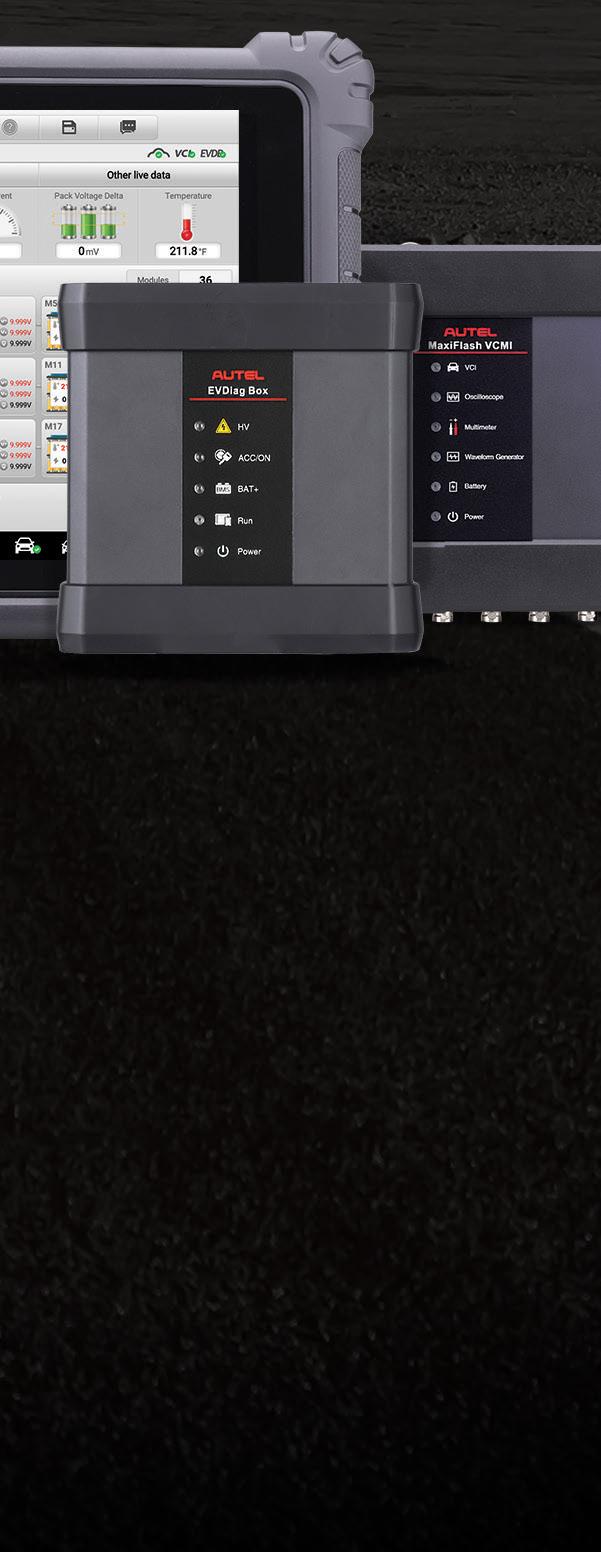

EV DIAGNOSTICS

DIAG

GAS|DIESEL + HYBRID|EV

MAXISYS MS909EV

EVDIAG BOX + VCI INCLUDES ALL FEATURES OF THE MS909

MAXISYS ULTRA EV

EVDIAG BOX + 5-IN-1 VCMI INCLUDES ALL FEATURES OF THE ULTRA

• DETAILED BATTERY PACK DIAGNOSTICS

• STATE OF CHARGE & STATE OF HEALTH ANALYSIS

• SPECIALIZED BATTERY ANALYSIS VIA BMS

• DETAILED CABLE CONNECTION DIAGRAMS

UPGRADE YOUR MS909, MS919, MSULTRA

KIT INCLUDES EVDiag Box & Adapters for Specific Electric Vehicles to Perform Battery Pack Analysis. (Connects to MaxiFlash VCI or VCMI)

37 July 2023 fenderbender.com

EV

WEB: AUTEL.COM |SUPPORT: 1.855.288.3587 EMAIL: USSUPPORT@AUTEL.COM FOLLOW US @AUTELTOOLS AUTEL COM | SUPPORT: 1 855 288 3587 EVDIAGKIT

CASE STUDY RUNNING A GREEN SHOP

How to be environmentally friendly with intention

By LINDSEY GAINER

SUSTAINABILITY HAS BECOME somewhat of a buzzword these days, with plenty of businesses using green practices as a marketing tactic to drum up business.

38 July 2023 fenderbender.com STRATEGY

CAGKANSAYIN / ISTOCK

GETTY IMAGES PLUS

/

But for John Carmack, owner of John’s Paint and Body in Lexington, Illinois, running a “green” shop is anything but an advertising ploy. It’s the way he’s operated his business from Day 1.

“When I purchased the shop 20 years ago, we started with the cleanest refinish process right out of the gate—from a multi-filter system for the paint to protect the surrounding environment all the way down to putting all waste through a recycler at the end of the paint cycle,” he recalls. “I’ve just always felt that it’s my responsibility to do what’s right … and focusing on the long-term health of the planet is definitely the right thing to do.”

Carmack believes that environmentally friendly practices should be the standard for every business, in fact, regardless of the industry they serve.

“Outside of the website, we don’t market our green practices,” he adds. “I feel that being ‘green’ should be more of a priority for businesses and less of an advertising gimmick. Being environmentally friendly should be a bare bones standard, not a plus for consumers to look at.”

The Problem

The nature of body shop work necessitates the use of paint and other materials that are damaging to the environment if not disposed of properly.

Focusing on those areas first is where shops can make the biggest impact, in Carmack’s opinion.

“We have a paint recycler, of course, but it goes beyond that,” he says. “The biggest asset to a shop when it comes to improving its carbon footprint is the team you surround yourself with. You can put as many of these ‘practices’ into place as you want, but it only matters if the people around you share a similar worldview and follow the practices because they truly want to help. Without a solid foundation, the whole journey forward will crumble.”

He’s quick to add that simply ignoring environmental responsibility isn’t an option, either. That only leads to a faster deterioration of the planet.

“If we want to leave any kind of healthy environment behind for future generations to enjoy, it’s up to individuals and corporations alike to push for sustainability.”

The Solution

When it comes to implementing the kind of green practices Carmack advocates for, alliances with other companies who share a similar mindset is key.

“As I mentioned before, I believe the biggest areas of pollution in a collision shop traditionally revolve around paint and materials. So, you can make a change today by simply evaluating your partners in business … by partnering with likeminded companies, you can start changing how things are done today.”

Carmack and his team have relied on partnerships with multiple vendors like 3M, NCS, Axalta and New Pig to help them achieve the high environmental standards in place at John’s Paint and Body.

“If you’re serious about improving your carbon footprint, start with partners,” he recommends.

With the help of his partners, Carmack has gone beyond improving his carbon footprint to eliminating it all together, in fact. His website says it best: “With no waste stream and by recycling 100% of parts and liquids used, the EPA classifies John’s Paint and Body as leaving no carbon footprint. Every piece of sheet metal or damaged fender goes through a recycling process. Potentially hazardous chemicals are turned into thinner that will be reused. While other shops take waste off-site to dump, we recycle and reuse leftover chemicals and parts at our location.”

According to Carmack, achieving a zero-carbon footprint isn’t difficult when it’s a top tier priority in your business model. A small change in mindset will change your way of thinking and the rest will follow. Think of it as prioritizing the future rather than focusing solely on profits, he advises.

“It might sound silly, but it even comes down to something as miniscule as recy-

cling paper for reprint and reuse at my facility, something I’m a real stickler for. You will find yourself actively seeking out ways to get better with sustainability the more you make it a priority. Not to mention, outside of a mindset change and a small initial investment, there’s no downside!”

The Aftermath

“At John’s, our team shares a similar view when it comes to pollution, so any practices implemented are almost customary at our facility,” says Carmack. “Not having to use oil dry due to our relationship with New Pig, keeping everything well filtered, things remain a lot cleaner around the shop. Everyone loves a clean workspace.”

Carmack is also a proponent for electric vehicles, and feels strongly that body shops should fully embrace and support the EV market.

“Don’t be afraid to jump in feet first for EV certifications,” he encourages. “It can seem scary at first, but that’s the future of sustainability and we can help usher that along.”

John’s Paint and Body has started working closely with a local EV manufacturer, and Carmack says he’s been nothing but impressed with their worldview and the technological advances they’re bringing to market.

“They’re leading the charge into an adventurous future,” he says, and it’s a future John’s has every intention of being a part of.

The Takeaway

The ability to implement successful “green” practices into any shop really comes down to two things, in Carmack’s opinion: The right mindset and the right partners.