DIRECT MAIL STILL WORKS USE IT!

AVIATOR-TURNEDSHOP OWNER RAISES THE BAR

DIRECT MAIL STILL WORKS USE IT!

AVIATOR-TURNEDSHOP OWNER RAISES THE BAR

In this business, downtime isn’t an option. Nobody knows that better than NAPA. That’s why we’ve built America’s largest network of parts and care, here to give you the support you need to keep your business firing on all cylinders.

© 2022 National Automotive Parts Association LLC

EDITORIAL

CONTENT DIRECTOR

Matt Hudson

EDITOR

Chris Jones

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Joe Marconi, Aaron Stokes, Nolan O’Hara, Tess Collins, Kimanzi Consable, Noah Brown

EDITORIAL ADVISORY BOARD

John Miller, Fifth Gear Automotive; Doug Grills, AutoStream Car Care Center; Jimmy Alauria, 3A Automotive Service; Andrew Marcotte, American Pride Automotive; Bruce Howes, Atlantic Motorcar Center; Rob Choisser, Choisser Import Auto Services; Lucas Underwood, L&N Performance Auto Repair; Ryan Hillebrand, Urb’s Garage

SALES

ASSOCIATE PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Bob Marinez / rmarinez@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Michael Parra / mparra@endeavorb2b.com

Martha Severson / mseverson@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

Kenzie Verschoor / mverschoor@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO

Chris Ferrell

PRESIDENT

June Griffin

CFO

Mark Zadell

COO

Patrick Rains

CRO

Reggie Lawrence

CHIEF DIGITAL OFFICER

Jacquie Niemiec

CHIEF ADMINISTRATIVE AND LEGAL OFFICER

Tracy Kane

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

EVP TRANSPORTATION

Kylie Hirko

VICE PRESIDENT - VEHICLE REPAIR GROUP

Chris Messer

HOW TO REACH US

ENDEAVOR BUSINESS MEDIA

571 Snelling Avenue North, St. Paul, MN 55104

tel 651.224.6207 fax 651.224.6212 web endeavorbusinessmedia.com

LETTERS TO THE EDITOR editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

If you were to go into the front office of the NFL’s Pittsburg Steelers, you’d be confronted with a sign that says, “The Standard is the Standard.” It’s a phrase that, if you’ve seen a Mike Tomlin press conference, is reiterated time and again. It means that no matter what happens externally—calls don’t go the right way, players don’t make plays or injuries occur—there are no excuses. The baseline is you have a job to do, and you’re expected to perform it under any circumstances.

The shop owners in this month’s feature “Zero to $1 Million” (p. 26) are a reflection of Tomlin’s mantra. These stories are of people who opened shops under less than ideal circumstances and through determination, saw them through from zero to $1 million and beyond. When the going got tough, they took an any means necessary approach to solving their challenges to ensure success.

Travis Leavitt of Leavitt Automotive in North Logan, Utah, built his shop on grit and fortitude. After a sink-or-swim start, he struggled to learn the complexities of the business. He wisely hired a coach and built the systems necessary to get his shop to the seven-figure mark within five years.

For Judi Haglin, she and her husband, Dana, decided to go for it when Dana realized he needed to get something going to generate cash after college. He leaned into the mechanical repair skills he possessed and saw an opportunity. Judi, who was managing a Mcdonald’s, married her skills to his and a shop was born. They went on to build a shop with a sterling reputation across the industry.

High standards are the reason these shops are thriving today, but without good leadership and humility from the top, standards can be compromised or lost.

In his column this month, Joe Marconi discusses this need for humility from the top. In “When an Employee Brings You Bad News Say Thank You,” (p. 19) Marconi argues that shop owners should welcome all feedback from their team members, particularly if it’s not what they want to hear. He writes: “You need to do a little self-reflection to ensure that you are a leader that is approachable, and not on the defensive when an employee wants to sit down and discuss things.”

Whether you’re a Steelers fan or not—I am—it’s hard to refute the wisdom of a coach with the pedigree and accountability Tomlin brings. And who knows, perhaps the mantra of your shop belongs on a large wall for all to see that steels their commitment to the team every time they clock in.

The Standard is the Standard.

Maintaining the baseline when the going gets tough helps you to overcome the odds and realize your dream

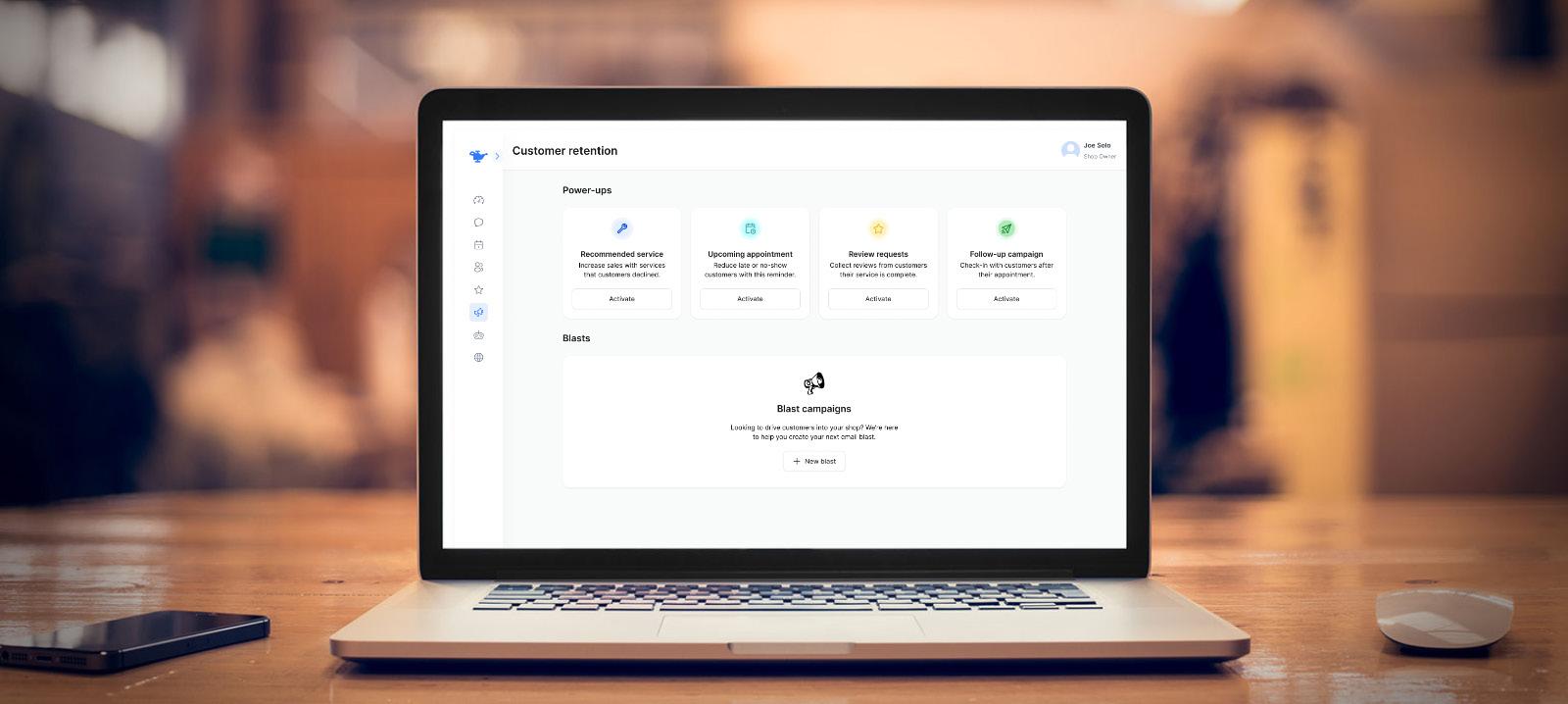

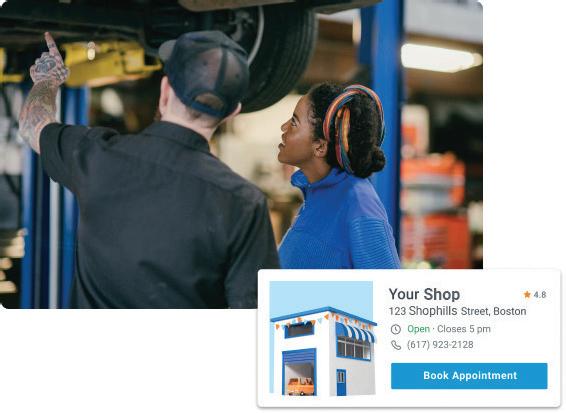

Shopgenie co-founder Kieran O’Brien believes his new CRM can drive more revenue by making it easier for online customers to choose your shop

BY CHRIS JONESTwenty-three-year-old Kieran O’Brien spent most of his life in and around auto repair shops. Embracing entrepreneurship early on, he sold his first tech company last year and began searching for what was next. Deciding to lean into the career capital he built in automotive, he started another tech company, this time to help auto repair shops solve a current problem they’re facing with today’s digital natives—frictionless online service.

O’Brien’s startup, Shopgenie, cofounded with partner Cayden Phipps, aims to better help independent auto repair shops with automated service reminders, texting, email marketing and online scheduling capabilities within one platform that integrates many popular shop-based CRMs.

“We do all of the things that get new customers to come into the shop … and then the most important thing, getting them to come back and become loyal customers,” O’Brien says.

Given that customer loyalty is the driving factor of a successful auto repair

shop, O’Brien polled 500 shops in the United States and Canada to find out how they were doing with prospective customer follow-up. The result became the proof of concept as fewer than 25% of auto repair shops reported responding to their online leads, and of those shops that did respond, the average customer wait time was five business days.

“That’s when we realized, ‘Oh, man, there’s a big problem here.’ And so if we think about what’s happening with this generational shift … you go to the dentist or any other type of small business (they) take appointments online. It’s this a very modern, forward-thinking customer experience. Unfortunately, the auto repair industry has lagged behind,” O’Brien says.

The data from his findings led O’Brien to develop the industry’s first real-time online scheduling tool that’s robust, customizable and doesn’t leave online leads waiting in a catch-all inbox. Shop owners have full control over Shopgenie’s customization tools to create automations

that qualify their ideal customer in order to save their service advisors time.

“You can customize your availability— cross-checking it with your management system—but we have everything down. Waiter and drop-off rules (for) setting the amount of waiters that you can take per day; limiting certain makes and models; limiting certain years, a lot of our shops only work on OBD-II cars, for example, so you can limit that,” O’Brien says.

Since the software integrates seamlessly into shop CRMs, there’s virtually no learning curve. O’Brien hopes auto repair shops will take advantage of Shopgenie to turn more leads into customers quicker, disqualify leads that don’t fit the shop, get customers scheduled for service online— that tool is free—and assist shops with automated service reminders to these same customers. O’Brien says it’s vital for shop owners to provide these frictionless digital interactions as more younger customers expect them and make purchasing decisions based on ease of interaction.

“Ultimately, if a Gen Z customer is deciding between Repair Shop A and Repair Shop B, and one of them has all of these things, and one of them doesn’t, it’s a pretty clear choice which shop that customer is going to pick,” O’Brien says. “And so we’re providing all of the tools that shop owners need to give those customer experiences to these younger customers, to essentially basically bring shop owners into the 21st century.”

Automotive Training Institute (ATI) has announced a new milestone of a $3 billion gross profit improvement “lift” for their members, according to a press release.

Less than three years prior, ATI accomplished its $2 billion milestone and recently achieved record-high attendance numbers at its annual SuperConference a few weeks ago.

ATI Chief Operating Officer Ron Greenman is confident about the trajectory of the program, with ATI members currently having an average weekly gross profit lift of $3,920 in repair and maintenance, and $6,079 per week in collision.

“This milestone is a testament to our shop owners–current and former,” Greenman stated. “They worked hard to make their shops stronger and more profitable. Seeing their cumulative

rewards and growth exceed $3 billion dollars makes ATI proud to be a part of it.”

The National Highway Traffic Safety Administration has instructed automakers to not comply with Massachusetts’ recently passed rightto-repair law, Yahoo News reports.

According to Vice, Assistant Chief Counsel at the NHTSA Kerry Kolodziej composed a letter to almost two dozen manufacturers–including BMW, Ferrari, Ford, and Hyundai–in which he argued that providing open access to a vehicle’s telematics poses a risk for hacking.

If open access to a manufacturer’s telematics is provided, Kolodziej writes that a “malicious actor here or abroad”

could have the ability to remotely send commands to a vehicle and interfere with vital safety functions, which include steering, acceleration, braking, air bags, and electronic stability control.

Kolodziej urged automakers to not comply with the law, suggesting that by doing so they would be jeopardizing the safety of drivers and thereby violating the National Highway Traffic Safety Act.

“Given the serious safety risks posed by the Data Access Law, taking action to open remote access to vehicles’ telematics units in accordance with that law, which requires communication pathways to vehicle control systems, would conflict with your obligations under the [National Highway Traffic] Safety Act,” Kolodziej’s letter read.

Texas Governor Greg Abbott has officially signed the elimination of annual vehicle safety inspections into law, Jalopnik reports.

The law was passed by the Texas state legislature a week prior to Abbott’s signature being penned on Tuesday, according to reporting from KXAN. There was a shadow of doubt thrown on whether Abbott would go through with the bill, with law enforcement officials such as Travis County Constable Stacy Suits urging him to veto it.

Supporters of the bill have argued it will save Texas residents time and money, but criticism cites that with the $7.50 fee for inspections being replaced with an “inspection program replacement fee” of the same price, people may only save money by putting off repairs for things that they otherwise would have been required to maintain.

Though the bill has been signed, it won’t be put into effect until 2025. Seventeen counties in the state will still require annual emissions inspections, which include Harris, Fort Bend, Brazoria, Montgomery, Galveston, Williamson, Travis, Dallas, Tarrant, Denton, Collin, Rockwall, Kaufman, Ellis, Johnson, Parker and El Paso.

The Alliance for Automotive Innovation has urged the Environmental Protection Agency to roll back the proposed emissions standards, Detroit News reports.

The organization’s CEO John Bozzella argued that the new rules would result in China taking over the auto industry in the U.S. due to them having greater access to the necessary

materials for EV batteries. Though much effort has been put into building mines and facilities to process and refine materials, it will take much time before it will be put into effect, Bozzella pointed out.

Bozzella claimed that the same will happen in the European Union, which has decided to ban the sale of gasoline vehicles starting in 2035.

“With a 2035 ban on fossil fuel vehicles looming, Chinese manufacturers gained a foothold and entered the European market at a budget price point,” Bozzella stated. “They achieved a 5 percent share of Europe’s EV market in the first nine months of 2022 and are on a steady march to hit 20 percent by 2025.”

Though automakers themselves have been investing in the success of EVs, Bozzella said that the approach to the transition from internal combustion engines should be more “balanced.”

I’m replying right now to my 9 most recent reviews, and I’d say it’s excellent at personalizing each one without me having to agonize over it. Super cool!

w to m 9 most recent it’s e cellent at without me ha in to Super cool!

- Jennifer Ringham, Precision Imports (Milaca, MN)

We’ve trained and leveraged new AI tools to create a simple process for you to allow AI to respond to your business reviews for you.

It’s simple, straightforward, and puts you on a path to domination for your digital marketing.

rts (Milaca, MN)

Give your shop a true vision. Motorcraft® parts are premium replacement parts –designed, engineered and recommended for Ford and Lincoln vehicles. They’re tested to provide performance and long-life reliability. And they’re 20,000 active parts strong, with a deep inventory that includes wiper blades, fluids, brakes, batteries, spark plugs and much more. Clearly, a win for you and your customers. See your Ford Certified Parts Wholesale dealer for more details.

As new and more innovative technologies enter the automotive aftermarket, advanced driver assistance systems (ADAS) stand as the gateway technology most likely to usher shops into the electric future.

Silver Lake Tire and Auto Centers, with four auto repair shops in the Milwaukee, Wisconsin, suburbs has embraced ADAS and has effectively implemented the technology within its ADAS-specific location known as the Technology Center.

The Technology Center came as a result of the shop’s need to service ADAS vehicles and needing room to perform the repairs in a spacious environment since the targets needed specific distances for calibration. The center, 4,000 square feet (50 by 80 feet) runs as a standalone facility and is also used to advance other business relations, like with collision repair centers that don’t have the technology and need access.

General Manager Tyler Peartree and ADAS and Automotive Technology Specialist Jim Nawrocki have spearheaded the work at Silver Lake Tire and Auto’s Technology Center. While the shop’s first foray into ADAS was eight years ago, much of the work they do today is twofold—internal and external engagement.

“We started with a couple of things: 1) educating our own technicians that when you see (ADAS-related repairs), it has to be calibrated and showing them where to look inside service manuals to identify that … and then 2) educating our industry partners and our body shop repair facility relationships that we created on how they also need to be doing this stuff when they’re replacing bumpers, windshields, mirrors that have all these sensors and that we are capable of reprogramming that for them,” Peartree says.

For Silver Lake Tire and Auto, having ADAS capabilities as a service has added upwards of 10 cars per week, though Nawrocki says volume climbs in the winter.

“It has its peaks and valleys like any other repair,” Nawrocki says.

As more ADAS-enabled vehicles find their way into independent auto repair shops, one concern shop owners need to consider is the manufacturer’s safety protocol surrounding ADAS. In some cases, moving parts, like a bumper or a water pump to access other parts for repair jobs may seem routine, Nawrocki says manufacturer’s guidelines may put shops at risk when a car is no longer calibrated. It’s something he’s engraining into Silver Lake’s technicians.

“If you look at a lot of service information for Toyota, Honda, Audi, Volkswagen … they need to be calibrated after being touched, even if you put it back in the same spot,” Nawrocki says. “It can be as simple as you just bumping that sensor on that camera, and maybe it doesn’t go in the exact same place it was calibrated for.”

For Silver Lake Tire and Auto, having ADAS has made their shop a more valuable asset with external shops as well as for its new and existing customers. For auto repair shops looking to get started, the pair recommends shops create a minimum space of 1,500 square feet (30 by 50 feet) that’s clean, level, has consistent lighting and a strong internet connection for the scan tools. They also add shops should get comfortable with the financial investment—upwards of $35,000 to $40,000. They also recommend setting up your infrastructure for ADAS repair.

“Who’s going to be leading the charge on this? Who’s going to be your internal expert as far as finding your customers your equipment? The next step is your facility … and then finding your equipment and what ADAS system provider you’re going to go with. Who’s the manufacturer for the equipment that you’re going to purchase? And then of course, your customer base? Those are all things that you would have to consider before we make that jump into the ADAS world,” Peartree says.

As General Motors repositions itself as a software company that builds cars, Matt Carlson somewhat embodies that mantra. Carlson entered the auto repair industry after 15 years at Microsoft as a software developer.

A confessed car enthusiast, Carlson spent a lot of time wrenching on and restoring cars before trying his hand in the business, first starting a nonprofit auto repair shop.

“I spend a lot of time working on cars on the side—restoring cars, performance, stuff like that—as a hobbyist, (and) realized there’s a lot of need in the community for people who can’t afford car repairs,” Carlson says.

Today, the nonprofit still exists, still repairs cars, and still solves transportation scarcity problems for those in need, but Carlson has since added a pair of general auto repair shops into the fold that goes by the name Fix It Forward.

To Carlson, the crossed wrenches within the red shield aren’t just a statement of his faith, but a beacon to the community that they can put their trust in Fix It Forward to be a shop that cares about integrity, honesty and the customer. This also shows up in their mailers and commercials, all done in-house by a professional graphic designer on staff.

“We’re trying to invoke a place that people can trust. We are a faith-based organization. That’s where our nonprofit really lies. It’s the reason why we do everything,” Carlson says. “But we work with anybody, help anybody. We never ask anybody about their faith background. We don’t care; we’re helping anybody we can.”

Owners: Matt and Kristi Carlson

Location: Moorehead, Minnesota Staff Size: 9 Shop Size: 7,200 square feet

Number of Bays: 9

Average Monthly Car Count: 390

Annual Revenue: $2.3 million

Send a few photos and a brief description to submissions@ ratchetandwrench. com and we might feature it here.

At first glance, you might find it fitting that a shop that began as a nonprofit ministry would look like a church, or a Spanish mission (The Moorhead, Minnesota, location loosely resembles The Alamo). It’s not by design, though. It’s an immaculately kept shop that Carlson takes great pride in.

“We really focus on convenience and comfort for our customers. So, we’ve got a waiting room with some nice chairs and free snacks and coffee for the customer,” Carlson says. “We don’t encourage waiters; we have free loaner cars … and we do free Uber rides. So, if anybody wants a ride home, we will give it, but if they are going to stay, we want to make sure they’re comfortable.”

The repair shop—true to its corporate commitment to helping all—caters to vehicles of all sizes, both light and heavy-duty. In the front of the shop is the tire and lube area with four bays which is partitioned from the rest of the shop, which is comprised of a series of lifts in the back of the shop.

“We have a bunch of 10K two-post hoists. We like to have one 12K in each of our locations. If we have a one-ton truck, we can pick that up safely. We put an alignment rack in all of our locations,” Carlson says. “So all of our locations (have) 9, 10 or 11 lifts. They’re all roughly the same size.”

Steve Jobs may have been best known as the co-founder of Apple Computer and a great entrepreneur, but his style of leadership and management was highly controversial. Jobs would schedule meetings with his team, then randomly point to someone and ask, “Tell me what’s not working at this company?” After that person gave their opinion, he would then turn to the group and ask for everyone’s feedback. Then he would point to another person, and say, “Tell me what is working?” While his technique may appear divisive, Jobs placed a high value on getting valuable feedback. Which meant that he had to know the truth, no matter how ugly it might be.

For most people, it’s difficult to receive critical feedback. No one enjoys learning that we dropped the ball, or that something isn’t going right. And how often does an employee walk up to you, and pull you aside to inform you of bad news? Not very often, right? While receiving praise and recognition does motivate us, growth opportunities also exist when things go wrong. How we deal with adversity and bounce back from failure tells us a lot about our mental toughness. Great success is never dependent on everything going right all the time. That’s not reality.

Look at it this way: getting only good news all the time is mostly useless. On the contrary, bad news can be good news. And we should accept and welcome it. If employees are reluctant to bring you bad news, it’s an indication that they may fear confronting you. As the shop owner, you need to do a little self-reflection to ensure

that you are a leader that is approachable, and not on the defensive when an employee wants to sit down and discuss things. Be mindful of how you interact with others too. Your body language and the tone of your voice will either draw people to you or push them away.

If you truly want to grow as a business owner and as a leader, you need to allow others to voice their opinions and let you know that your company, at times, may not be the paradise you believe it is. The question is how do you create an environment that gives people the confidence and willingness to confront you with critical issues?

Make it known that you want to create a work environment where feedback, especially when things go wrong, is accepted and welcomed. Remember, if people fear bringing you bad news or only tell you the good things, you may not have an open environment where people feel they can discuss all issues, good and bad. It’s also important to realize that to give critical feedback to others, you must be open and willing to receive critical feedback.

At the start of any team meeting, let your employees know that you will be asking for everyone’s opinions on ways to improve. Emphasize that you want to hear not only what’s going right, but also where the company is failing. People’s opinions may not be shared by everyone, but one’s perspective is their reality. We need to listen to all voices. Be transparent and let everyone know that you will listen to everyone and do your best to act on everyone’s feedback.

Another thing to be aware of; don’t allow an atmosphere that encourages gossip or venting. This will promote negativity and bring down morale. You need honest, healthy feedback that everyone can accept and learn from.

The bottom line? The next time someone brings you bad news, look them straight in the eye, smile, and say, “Thank you!”

BY CHRIS JONES | PHOTOS BY HANNAH ISRAELSEN

BY CHRIS JONES | PHOTOS BY HANNAH ISRAELSEN

Travis Leavitt’s boss met him in the shop’s parking lot before his shift started with a message: leave.

He was told no one wanted to work with him anymore, and that he had created a hostile working environment. None of which Leavitt says were true. Handing Leavitt a box with all his personal effects, his boss told him he was in for a rude awakening as a shop owner—and then he bid Leavitt an unpleasant farewell.

“When I talked to him (about resigning), he actually took it very well,” recalls Leavitt, admitting his astonishment at the change of attitude.

Before his unceremonious firing, Leavitt was in line to be his boss’s successor. However, once he learned his boss’s retirement plan would take seven

more years, Leavitt made the difficult decision to hand in his notice to pursue his own dream. According to Levitt, he thought he was on good terms with his boss. The exchange was pleasant after the pair met, and Leavitt felt good about it.

“I even offered to stay on for three weeks to help them; maybe try to find somebody and train or whatever. I felt pretty good about it,” says Leavitt.

He set out on his own and opened his shop in 2017, hiring a technician he once worked with at Firestone. Though he knew the roles within the business and how they worked—technician, service advisor and shop manager—ownership was a different animal. Leavitt had come faceto-face with a complete lack of knowledge about business operations, finances and

leadership. That’s when the words of his former boss became prophetic.

You’re in for a rude awakening

“I didn’t know when I made payroll, I had to pay payroll taxes,” says Leavitt. “It was all a completely new learning curve.”

He says he governed his shop not by KPI, but by his checking account.

“I didn’t (know) what effective labor rate was, or ARO or GP per hour. I was basically going off at total sales and running my business based on what was in my checking account, which wasn’t very much. You think you have it figured out, and I did to some degree, but there’s just so much more,” Leavitt says.

Despite having only one other employee, he struggled with being the front man and his pockets were feeling it.

Leavitt’s guaranteed income was replaced by start-up uncertainty. He struggled to pay the bills, to pay the rent and to make payroll to cut checks for his lone employee. He lived off credit cards for the first two years and borrowed against his 401(k). He hadn’t counted the cost that operational expenses would take from his business such as payroll and other taxes and software subscriptions. At home, he had a supportive wife and three children to provide for, which created a daunting amount of pressure for the fledgling shop owner.

“For the first couple of months, I remember talking to my older brother at night, just basically in tears. I didn’t know how I was going to do it. I was motivated and driven. I didn’t have a choice but to make it work. I was all in,” Leavitt says.

To make matters more difficult, the shop was only producing $7,000 to $8,000 per month.

“There (was) just no money,” Leavitt says. “And I mean, you get in that situation where you don’t have money to pay this bill and pay that bill, it starts to take a toll on you and you freak out. I didn’t know how to pay for everything.”

The darkest days for Leavitt had him nearly $100,000 in debt between his personal and business lives. Still gritty to his core, he tightened his bootstraps and shifted his focus on getting the necessary education he needed to win.

He joined Facebook groups where he learned from other shop owners, listened to podcasts, read books and went to major training events.

“I realized the importance of training and learning. We don’t know what we don’t know. If we can hopefully

better ourselves and learn more (we can) do better work and provide a better experience for the customers,” says Leavitt.

He invested in self-paced learning videos through ShopFix Academy before settling on working with the company after pulling Aaron Stokes aside at a VISION conference. Leavitt admits he didn’t know how he would pay for the coaching, but knew he needed the help and would come up with investment money one way or another.

“I figured I’d always get to where I wanted to get eventually but I wanted to get there now. And so, I felt like a coach would be the way to do that. I looked at a couple of different coaching companies, (but) there’s just something about Aaron; when he talks, you know, he just resonates with you,” Leavitt says.

Through coaching, Leavitt was pushed out of the aerie like a young eagle. He was challenged to hire more employees, get his shop’s workload to capacity and do more advertising. Within six months, his car count tripled. In his third year of business, he was able to wipe out his six-figure debt and in year four become profitable.

“I want to be held accountable. I feel like that’s going to make me a better person, better leader and everything else. Not only did it help me learn things, but they gave me confidence and they basically confirmed what I was doing and that I was doing it correct,” Leavitt says.

Leavitt hit $1 million in Q3 of 2022. This year, he’s projecting $2.5 million and $3.6 million in 2024. For a guy thrown out to the wolves, he now leads the pack.

“I was all sorts of excited, and I felt accomplished. We made it, but at the same time, I wanted to do a lot more,”

Leavitt says, adding that he still reflects on everything it took to get there. I feel proud of how far we’ve come.”

When you think of a shop owner, Leavitt has the standard industry pedigree. He was an industry veteran, had become a successful service advisor and had his eye on shop ownership.

Dana and Judi Haglin were industry outsiders when they founded Haglin Automotive. For Dana, it doesn’t go much further from auto mechanics than his undergraduate degree from Colorado in saxophone performance. As for Judi, the CU elementary education graduate spent three years managing a McDonald’s

after college. Today, Haglin Automotive, which sold to the SimplyTRUE Auto Group on March 1, is a $2.4 million shop.

Ask Judi and she’ll tell you that Dana is a maverick.

“My husband, Dana, has never worked for anyone,” she says. “He would work on cars with his dad and his brother to make extra money. They’d fix cars and sell cars. That’s how they made extra cash money.”

After graduating college in May 1981, the pair married the following month, and it was time to find work. Dana, who has mechanical skills, applied to work at a service station.

“We didn’t have jobs and he went and

applied for a gas station attendant-type person. Fifty people applied to be the person that pumps gas. He came back and he goes, ‘Well, OK. That’s not going to work. What do I do?’” says Judi.

Dana’s older brother, a machinist who rebuilt engines, worked next to a vacant unit that Dana would claim and begin taking on the engine work.

Judi jumped headlong into leadership at McDonald’s, gaining valuable knowledge through the corporation’s Hamburger University before coming to work with Dana after three years.

“The stress got me, so I quit and came to work for Dana and said, ‘Babe, it’s you and me.’ And then we’ve never looked back,” says Judi.

For the Haglins, reaching escape velocity wasn’t as monumental a task as it was for Leavitt. When the two of them were working, running the shop was easy. They knew who was responsible for what and when something went undone or an error was made, they knew who was responsible. As they added employees, that ability to get to the root of issues evaporated and they had to learn how to communicate with and adjust to other people and their work ethic.

“When you have more people, and you have those responsibilities—Is it my job? Is it yours? Well, he was supposed to do it—it’s those kinds of communications and (learning about) holding people accountable,” Judi says.

‘Zero to the Mil’

Judi and Dana lived the shop life. Dana was a one-man band removing engines, answering phones and servicing customers. As they moved into more general repair, they shop went from Haglin’s Garage to Haglin Automotive.

The couple invested in management success training, where they learned to understand and manage their numbers.

“That doubled our business,” says Judi of management training, which took her shop from $250,000 annually to $500,000. “I learned marketing, (how to) to keep an eye on our numbers and watch the trends. We did that for a couple of years.”

She credits ATI for getting her shop over the million-dollar mark. There, the Haglins were taught which KPIs to pay attention to and participated in weekly phone calls. They also made significant personnel upgrades allowing them to back out of the day-to-day operations.

“I think going from one technician, my husband, and him fixing cars and writing service, all on his own to having a second guy, like a helper technician coming in, and somebody answering the phones. To do both, is very difficult,” Judi says. “So that’s the first big step. And then the next big step, I think, is getting you out of those major roles. You can be the second backup person but have a dedicated service writer and dedicated technicians.”

Up to the point of sale, Haglin Automotive was a $2.4 million shop. It’s gone from a single-bay, owner-run shop in 1981 to 12 bays, five technicians, two service writers, one service manager and a CSR. And as Judi sunsets from the auto repair business, she’s leaving her options open for the future.

“I love facilitating 20 groups. So that’s something I might do with ATI. Those are my two (favorites): teaching and running 20 groups. (That’s) what I might be leaning towards,” Judi says.

Pilot-turned-shop owner Dutch Silverstein runs his business with the meticulous touch he learned at the airlines

BY ALISON JOHNSON PHOTOS BY DEANNA DURAIt’s safe to say the backup plan has turned out pretty well for R. ‘Dutch’ Silverstein.

Silverstein is a former airline pilot who’s carried some of the lessons he learned in that field over to his current role as president of A&M Auto Service in Pineville, North Carolina.

He’s built the business on safety, accountability and attention to detail after learning at an early age he liked ‘to fix stuff’, beginning with repairs on bicycles and lawnmowers before becoming a small engine mechanic with Sears.

After becoming a pilot, Silverstein says things weren’t always so smooth.

“In aviation, you always had to have a backup because aviation is incredibly cyclical,” Silverstein says.

The worlds collided when he went to buy a lawnmower while in full uniform after coming off a trip and began talking with a salesman, whom he learned was a former captain with Eastern Airlines.

“When Eastern Airlines went out of business, he was left with nothing, so at that point, I became consumed with my backup plan,” Silverstein says.

He says he started by dabbling in auto repair in 1996 before putting more effort into it in 1998.

“I worked seven days a week for nine years without taking a day off,” Silverstein says. “If I was sick, obviously, I was sick and couldn’t work, but I knew that with layoffs and furloughs and the economy, that having a family, I didn’t have the luxury of not being able to provide. Accordingly, I started repairing cars out of my house, and then from there, rented a space from a friend of mine who had a shop and just kept on working.

“I’d fly for 19 to 21 days a month and then come back during the first couple of years and occasionally sleep in my car to take care of the customers that would wait for me because there was no pressure,” Silverstein continues.

Silverstein says the airline he worked for declared bankruptcy twice, and in 2004, he learned he had a medical condition that disqualified him from flying.

“I still had a family to provide for, so I just continued to do what I was doing, just did it on a larger scale–went from one bay to two, two bays to seven,” he says. “Now we’ve got eight lifts, seven bays.”

Moving into auto repair full-time also brought some challenges for Silverstein.

“Although I graduated college with a business degree, I didn’t have realworld business experience, and what I did was I made a lot of mistakes,” he says with a laugh. “I was good as a diagnostician. I could do the work. That

wasn’t the problem, but in so far as actually running the business and knowing what to charge, how to charge, how to deal with customers successfully, how to present information so that they could understand better.”

Silverstein says he used his experience as a flight instructor to help with that part of the job, but he says he was discouraged by ‘the lack of professionalism and standardization in the automotive world’ with the exception of franchise shops.

“At the airline, when I was in the left seat as captain, I was responsible for everything–I mean everything,” he says. “We used to have a saying which was that you could delegate all the authority in the world to somebody else, but none of the responsibility.’ In this profession … that lack of accountability still exists. Now it’s slowly changing, but people don’t want to be held accountable, and it goes from line techs

to management to suppliers, vendors.”

He says there’s also a major difference between the airline and auto repair industries.

“There was constant testing to determine that you were and could do what you said you could do (with the airlines),” he says. “There’s none of that in automobile repair. There isn’t. You want to call yourself a mechanic, it’s not a problem. You just go out, tell people you’re a mechanic and start working on stuff. You could never do that (in the airlines).”

But being a pilot helped Silverstein establish some cornerstones to his business–safety and accountability.

“It doesn’t matter to me if it’s going to be a single person who’s going to be driving their Honda Accord or it’s going to be a 767 with 210 passengers,” he says. “It doesn’t matter to me. The responsibility for safety is the same.

“My first consideration is safety above and beyond anything else,” he

continues. “The second is accountability with regard to being accountable as a shop owner for the actions that happen in the shop. It’s my business, and I hope to have imparted some of that accountability and sense of obligation to my staff. But can I guarantee it? No. I just try to set a good example with it.”

Silverstein says another reason for his businesses’ success comes from ‘no pressure sales.’

“I don’t employ salesmen,” he says. “I’m not a salesman. I’m an advocate. The people that I employ are advocates. We put people first, and then the money follows. We don’t put money first.

“If there’s something that we see during a comprehensive 30-point courtesy inspection that requires service or retention, we simply bring it to the attention of the owner and let them make a pressure-free decision about their property, and once you start doing that, it’s amazing the amount of people (who) hear about it.”

TM

Dorman OE FIX TM parts are designed to improve reliability or simplify service.

AutoZone and Dorman puts repair professionals and vehicle owners first. Whenever an OEM doesn’t offer the service solution you deserve, Dorman develops a better solution—an OE FIX™ solution.

AutoZone® carries thousands of Dorman OE FIX™ parts that come in countless varieties, featuring:

Upgraded materials to increase reliability

Time-saving designs, such as multi-piece and flexible features, separately serviceable components, etc.

Smarter electronics, featuring plug-and-play modules, included programmer tools, faster processors, etc

Serviceable components to simplify future maintenance

Scan to learn more or visit DormanProducts.com/AZ

Oil filter adapters for Pentastar engines that feature upgraded metal designs to eliminate leaking common in plastic original units

Expanded Availability, Delivered Fast

When the Magnuson-Moss Warranty Act was passed in 1975, the automotive industry saw a huge win for customers. The act, which required any consumer good with a warranty to follow its rules and regulations, helped provide peace of mind for customers by creating a standard application process for all warranties.

Because of that, whenever warranty disputes between an OEM and a customer arise, there is a fairly standard order by which those cases play out.

“The law is fairly robust,” says Allison Harrison, owner of ALH Law Group in Columbus, Ohio. “From a litigation defense, we see (Magnuson-

Moss) brought up a lot, and it coincides with a lot of consumer protection laws. Often, you’ll see something be a violation of a state’s consumer law and then a federal Magnuson-Moss issue.”

As technology becomes increasingly more complex and cars require more sophisticated repairs, customers may have less of an understanding of what is actually covered by the warranties on their vehicles. Harrison says shops can play a critical part in helping customers know what their warranties cover and, maybe more importantly, what they don’t cover.

Harrison says warranty disputes are quite common between customers and whoever holds the warranty for their vehicle, adding that customers can bring up disputes on a wide range of alleged issues with their vehicles.

“It’s all over the board,” she says. “It can be anything from smaller parts of a vehicle to a specialty engine that costs $15,000.”

In most cases, if a customer brings a warranty issue to court, they try to recover the cost of the part and attorney’s fees. In some cases, they might be eligible to receive other statutory damages.

However, in her experience, Harrison says it’s best to avoid taking an issue to court if at all possible; very rarely will that work out for either party involved.

“I don’t think anyone wins. If you’ve gotten to the part where you’re bringing a lawsuit, the consumer has to pay the attorney and the repair shop has to pay an attorney,” she says. “The only people who really win are the attorneys.”

That’s where independent shops can come in and help play a key role in educating and helping customers. A common misconception that consumers have is that allowing an independent shop to work on their vehicle will invalidate its warranty. The Magnuson-Moss Warranty Act has a provision that prohibits “tying arrangements,”

which require a customer to use parts or services from specific brands or companies. It’s illegal for an OEM or dealership to void a warranty simply because a customer took the vehicle to an independent shop.

Regardless of who provides the warranty for a vehicle, whether its an OEM or a third party, Harrison says warranties are required to outline what they cover and what they don’t very explicitly. If a customer has a question or a concern about their warranty, the best place to tell them to start is the warranty packet that comes with their vehicle.

“It comes down to, frankly, reading it. That’s something that often gets overlooked,” Harrison says. “(Customers need) to really look at it to see what it covers. That’s the biggest miscommunication that we see.”

If the language in a warranty is unclear, calling the warranty holder can often provide answers, too. Most

warranties are held by an OEM or a third party instead of a specific dealership, so hesitant customers can avoid causing an issue with a specific dealer.

In addition to seeing customer/dealership warranty disputes, customers can also bring complaints against an independent shop if they believe their car was repaired improperly.

If your shop is going to work on a vehicle that is still under any kind of warranty, Harrison says familiarizing yourself with the terms and conditions should be one of the first things you do before opening the hood.

“There’s so much information,” Harrison says. “Those warranty booklets are getting bigger and bigger as cars get more complicated, but if you make sure that you double-check that, you should be just fine.”

In the event that a customer does raise a warranty dispute with your shop,

there are a couple of key things Harrison says can help resolve the situation.

It can be really easy to get defensive when a customer raises a dispute, especially if the claim is baseless–it can feel like an attack on your shop’s work ethic. Harrison says taking a step back and recognizing the customer isn’t trying to maliciously attack you or your shop. Instead, they probably don’t have a good understanding of the situation.

“It’s never good if you’re upset to have that conversation. Take a step back and breathe,” Harrison says. “A lot of times, if the parties talk it out with level heads, everyone is going to feel better about it.”

In the event that a customer is trying to question your work, Harrison says you can protect yourself by documenting what you do to the vehicle. If you don’t have a way to reproduce and validate your work, that can create a “we said-they said” argument. If you

document it, you can show the customer and the warranty holder. Taking notes on what you fixed and how you fixed it, shooting a quick video on a phone to show the quality and extent of a repair and being transparent in how you talk to a customer can all help.

“Cars are really complex. Taking time to explain to your customers how the mechanics work, how parts are physically located on the car and if they’re connected goes a long way,” Harrison says. “(A lack of clarity) is usually where we see these issues come from.”

Though warranty law can seem overwhelming, there are several ways you can help protect yourself and your customers.

Quite simply, Harrison says in many cases, the solution comes down to one key thing.

“Read. Read, read, read,” she says. “It sounds so silly, but that’s how we usually resolve it.”

It’s not out of the question for the detailer at Kubly’s Automotive in Brodhead, Wisconsin, to spend eight or nine hours on a single vehicle. At Kubly’s, they pride themselves on providing exceptional customer service and will take the time necessary to make sure that the detailing work is memorable. In fact, Roxy Kubly, who owns the business with her husband, Dusty, says many customers have made the comment that their vehicles look even nicer than when they first purchased them.

Kubly’s is the place to go for almost all of your vehicle needs. They offer auto repair, pre-owned vehicle sales, accessories and detailing. Kubly explains that offering the detailing service isn’t necessarily a huge profit center and that’s OK. For the Kublys, it’s not about the money, but rather a way to set their shop apart and offer something to their customers that will keep them coming back.

Backstory:

Dusty Kubly has been in the auto repair business since 1994 and added auto sales to the shop in 2015. In 2016, the business added a detailer to get the used vehicle lot ready.

Problem:

Being a small, independent auto sales location with a limited inventory, there wasn’t always enough work for the auto detailer with just auto sales

alone, Kubly explains. In order to keep the detailer busy with full-time work, they decided to expand their shop’s offering.

Solution:

On top of wanting to keep their auto detailer busy, auto repair customers were asking about the detailing service, so the Kublys saw an opportunity to attract new customers to the business by offering detailing services to auto repair customers.

This isn’t your typical detailing that’s all about quantity over quality. Kubly explains that they are meticulous about their work and offer the highest quality job that they can. Has it added a huge profit? No, but it’s added a huge draw to the shop and helps set Kubly’s apart from the competition.

“We make a little profit, and it keeps us busy,” Kubly says.

Aftermath:

Kubly says a lot of their repair and auto sales customers come back for detailing services.

“Adding that additional service helps the overall customer portfolio,” Kubly says. “They come for more than just one service.”

Kubly says she believes offering detailing services is becoming more popular and that it’s a good way to fill a void if there’s space available— especially for those that are getting into used car sales.

Takeaway:

Wondering whether detailing is right for your shop? First and foremost, Kubly says you have to make sure you have the space and resources to accommodate this added service. Once you’ve determined that, Kubly suggests surveying your customer base before making the leap to see if it’s a service they actually want. If you have both the space and the want for it, get the right type of training, products, equipment and tools to do an outstanding job. Kubly says a lot of companies offer free training.

Roxy Kubly readily admits that it’s hard to find a good detailer as it’s not always a high-paying job and at certain places. It’s looked at as the “low man on the totem pole” position. That said, it’s not impossible to find someone if you know what you’re looking for. The most obvious choice would be to hire someone with previous detailing experience, possibly from a dealership. This is one way to do it, but Kubly never does. Why? She says that, in her experience, they often think they know what they’re doing but often rush through jobs and don’t do quality work as that’s what’s been expected of them in the past.

Here are Kubly’s tricks for finding the right candidate:

• Be open to unlikely candidates. Kubly says high-school students, recent tech grads and people without automotive experience are all welcome to apply for a detailing

position at Kubly’s Automotive. “It could really be anyone,” Kubly says of a good detailer.

• Make sure they have this one trait. The one quality your detailer needs to have is attention to detail. She’s open to speaking to many people about the position, but she makes it clear in her help wanted ad and at at the interview that attention to detail and a passion for keeping things looking nice is non-negotiable. She adds that in her experience, females often make the best detailers.

• Test them out before hiring. Kubly never hires before doing a working interview. It helps both her and the candidate determine if it’s the right fit. Detailing is hard work, she explains, and it’s definitely not for everyone. She often puts her candidates through a two to three-day process of actual on-the-job experience before determining whether or not to offer the position.

In an ever-connected world, shop owners should market to the mailbox for customer attention

BY KIMANZI CONSTABLE

BY KIMANZI CONSTABLE

The world has turned digital. And while digital marketing gets all the attention, there is money to be made using tried and true marketing techniques, namely direct mail. According to Statista, in 2021, direct mail advertising revenue in the United States amounted to $14.47 billion dollars.

“Direct mail has helped our shop a tremendous amount. I was doing direct mail back in 2019 without knowing the return it would give us,” says John Rauscher, owner of Thunderbird Automotive Specialists.

“Once I dove in and saw our customers coming back more often, or even customers saying, ‘I never knew you guys were here until after getting your mailer; I wanted to try you guys out!’, I was convinced of the effectiveness of direct mail.”

One of the most important parts of effective marketing is understanding and

using the right customer targeting. You can spend thousands of dollars and still not acquire clients if you’re not marketing to your ideal target customer.

In direct marketing, sending flyers and adverts to targeted zip codes is the most effective marketing approach. Spending some time doing customer research is essential.

“Your best results will come from people within easy driving distance of your shop. In urban and suburban neighborhoods, focus on customers who are geographically closer to your shop,” says Joe Flammer, business development manager at Turnkey Marketing.

“In rural settings, people are used to driving longer distances. Because of that, you can target homes farther away from your shop, and many people will still be willing to drive to get to you. Be cognizant of geographical boundaries that may make it unlikely for potential customers to come to you—like rivers or highways,” says Flammer.

Start with the zip codes closest to your shop where customers can benefit from your services. You can buy lists of zip codes that include the demographic of the residents in those zip codes. Then, expand to areas drivable to your shop.

“We’ve been using direct mail for years and can’t do without it. Direct mail reaches people we wouldn’t have otherwise and can get us in front of the right customers,” says Steve Killian, owner of TK.

“We can offer deals through direct mail, and new customers come because we’re close to where they live. Google ads and direct mail complement each other and have been great for our shop. My advice is to pick your mail routes carefully; pick the right zip codes for those who can afford your services,” says Killian.

People are visual by nature—they need to see things for them to click in their

brains. Visuals are a vital marketing and branding strategy that shops can use to convert potential customers into regular customers.

Spending a few extra dollars to make your direct mail flyers and adverts more appealing results in more attention and more business.

You can use online creative workfor-hire platforms to get your direct mail designed in a visually appealing way or work with a marketing coach, consultant or agency to create the best copy for your direct mail advertising.

“I used to think direct mail was a scam because I would think of the ValPak envelopes that would come and everyone just throws those away. On the other hand, working with Upswell and Turnkey, we mail individual address cards to our current and potential customers. We have customers bringing them in all the time or saying, ‘Oh, I got your mailer,’ and having our picture (myself, my manager and sometimes, my mother) on them

shows them that this is a shop to try,” says Rauscher.

One way to leverage direct mail is by offering deals in your flyers and adverts. You can offer buy one, get one offers, as well as giving a percentage off for first-time or repeat customers or variations of sales offers.

To increase success with direct mailers, Flammer says you must include an irresistible offer, something that gets your potential customer’s attention, solves their problems and motivates them to pick up the phone and call you. That starts by knowing how many people will value the service you’re planning to offer.

“Make sure you are marketing something that many people need; otherwise, your pool of prospects is small. Is it something that makes people think, ‘Wow, I need to take advantage of that now!’ or is it easy to shrug off and throw out?” says Flammer.

“If you’re spending money on postcards and marketing, you will get the

best return on investment (ROI) from following the basic marketing principles—sending the right thing, with the right offer, to the right people, at the right times. Do that and you will reap lots of success.”

For marketing to be effective, it has to be consistent. Shops tend to feel as if they’re marketing too much, whereas the reality is that they need to be marketing more.

“You rarely see great results if you send out mail one or two times and then stop. Mailing to the same customers once a month for four to six months is when results start to become apparent,” says Flammer.

People need to see direct mail numerous times consistently with deals and offers. Rauscher says in a threeyear window since using direct mail, his shop grew from four to 11 employees— a 54% increase—to accommodate the growing car count his mailers pushed through the door.

“We are on a very busy corner in North Phoenix, so it was crazy to think customers still drove by and didn’t notice us. We as a shop have been able to grow year after year, and in 2022, I knew it was time to expand and gain as much customer market share as possible using direct mail consistently,” says Rauscher.

“From 2018 through 2022, we have effectively doubled our car count, and our No. 1 attribution to this was due to the direct marketing plan we created (with Turnkey and myself) with the primary money spent on direct mail,” says Rauscher.

Direct marketing is an effective way to reach a customer base you would have been unable to through other means. Some of your customers don’t use the Internet or aren’t as tech-savvy—direct mail is the answer.

“Direct mail helps you get new customers, be consistently more relative to your current customers, and effectively build your brand so your company is visible and well known in your area. If you are not doing direct mail, you should!” says Rauscher.

Carquest Premium fuel pumps are now built by Carter Fuel Systems and Agility Auto Parts, industry leaders in high-quality replacement fuel system components. Carquest Premium fuel pump modules and assemblies are manufactured to meet or exceed Original Equipment (OE) specifications for fit, form and function. We have invested in industry-leading quality improvements like upgraded turbine impellers and 100% carbon commutators to deliver greater reliability. Carquest Premium fuel pump modules are engineered with superior quality components to provide the longest life and reliable performance.

Application Specific Formulations, Expanded Late-Model Coverage, OE Performance or Better… Guaranteed.

Duralast Brakes offers the most OE-equivalent program in the industry, from OEM-matched formulations to innovative designs, delivering OE or better performance, for any braking need. Duralast Brakes are reverse-engineered from application-specific OE sources to meet or exceed the original fitment, feel, and quiet stopping. Third-party, life cycle testing ensures these high standards of quality are met, that’s why they are all proudly backed by a 100% Noise-Free Guarantee*. Whether you’re looking to restore original braking or something better than the OEM, Duralast has the pad for you:

Duralast - The dealer service design, meets or exceeds OES fit, form, and function. Semi-Metallic or Ceramic formulations available, with OES-matched slots, chamfers, 2-layer shim, and a powdercoated backing plate for noise and vibration control. Available with Hardware, where required by OE.

Duralast Gold - Factory-matched, OEM design, fitment, and performance. Offers, application-specific, semi-met and ceramic formulations, and hardware. OEM-matched slots, chamfers, and

3-layer shims to neutralize vibrations and eliminate noise. The powder-coated backing plate provides superior rust prevention and delivers OEM fit.

Duralast Elite - Designed to outperform the OEM, with the next-generation ceramic, and delivers ultra-quiet, low-dust, premium braking performance. Engineered with an application-specific advanced hexagonal coating that provides an additional transfer layer, enhancing both the rotor and pad performance, vs competitors abrasive painted metal or strips. Uses Copper-Free material to meet new industry requirements for maximum noise control and stopping power. Duralast also offers specialty performance pads and rotors. Learn more or see the full selection at DuralastParts.com/brakes

*Noise free guarantee requires the purchase of any set of Duralast, Duralast Gold, Duralast Elite pads, 2 Duralast or Duralast Gold rotors and hardware (when available) on the same invoice. Guarantee covers parts and labor for 90 days.

The all-new TruSensor from Ranger is the premier diagnostic and programming tool that works on all import and domestic vehicles using wireless or OBD connectivity. With this tool in hand, technicians will be able to see all critical information at a glance, information like Sensor Battery Life, Tire Pressure, Broadcast Frequency, Sensor ID, and more. The TS58R package kit combines the TS58R diagnostic and programming tool with eight TruSensors for total TPMS service repair. TruSensor interchangeable valve stems are available in either silver aluminum, or black snap-in rubber. All Ranger TruSensor valves are tested to meet or exceed SAE industry standard J1205 / J1206 ratings.

The TS58R has four modes for programming new sensors –Copy by Activation, Manual Input, Auto-Create ID (up to 5 sensors at a time) and Copy by OBD. You’ll also be able to enjoy other essential TPMS service capabilities including Manual Input ID, Duplicate ID, Automatic Create ID, Sensor Position Change, and Modify ID Functions. Three relearn functions include OBD Relearn, Auto Relearn, and Stationary Relearn, providing a variety of solutions for quick and efficient TPMS service. Featuring a universal design that works on both 315 MHz and 433 MHz frequencies, TruSensor replaces hundreds of OE sensors including snap-in, clamp-in and banded types.

KUKUI's KPI Snapshot Report and Customer Map help shops visualize their success.

KUKUI's KPI Snapshot Report provides an easy to understand assessment of the shop's main metrics and measures of success. The report highlights crucial pieces of information such as revenue, car count, average repair order, customer conversion rate, customer satisfaction ratings, and other important key performance indicators. This allows you to rapidly evaluate the overall state of your business and spot areas that require attention or improvement.

The KPI snapshot report visually presents your shop’s data through graphs, charts, and tables, making it easy to comprehend and review in no time. It allows you to keep an eye on your progress, compare the current performance to previous intervals, and create benchmarks for upcoming goals.

Add in KUKUI's Customer Map and you will have the ability to see your customers on a map highlighting any related marketing sources and even dollars spent in the shop. The insights provided by the Customer Map will help you tailor your services and offers to different groups of your customer base and maximize your shop’s potential.

KUKUI's KPI snapshot report and Customer Map give automotive repair shop owners like you, the tools needed to carefully

With TruSensor, parts stores and service facilities can dramatically reduce the number of sensor SKUs required to provide full TPMS coverage. Program updates are available through a USB-equipped PC with internet access or by micro-SD card option.

With Ranger’s TruSensor TS58R TPMS diagnostic and programming tool you’ll be able to quickly find faulty TPMS sensors, turn off annoying TPMS lights, reprogram sensor ID’s, and retrieve and clear TPMS diagnostic trouble codes. Shop now at:

www.bendpak.com/trusensor

monitor your business performance, make decisions based on data, and take proactive steps to enhance your marketing and operations. This report and map are an invaluable resource for tracking progress, recognizing trends, and achieving continuous improvement in the automotive repair industry.

METRIX®️ climate control and engine cooling products are made to do the job right the first time. With a complete line for automotive and light truck applications, METRIX provides OEM fit and quality to maintain the integrity of the vehicle and restore optimal performance.

METRIX climate control products are engineered to deliver superior performance, extended reliability and reduced noise. METRIX provides complete climate control solutions, including compressors, receiver driers, expansion valves, heater cores and blower motor assemblies.

Engineered for today's higher performance cooling systems, METRIX engine cooling products are manufactured to do the job right the first time. METRIX radiators and water pumps are tested to ensure quality and performance. All METRIX products fit the same as the OE parts with no need to move fittings, drill added holes, or stretch hoses.

METRIX products are distributed exclusively by Autopart International and Worldpac.

February was a surprise for a lot of us. While high-performing shops showed a slight decrease in volume, a lot of shops that weren’t really backed up saw a massive decline.

Owners and advisors have gotten used to work being served on a silver platter. Since March 2020, we haven’t had to work the last couple of Februarys like we did in the past. Suddenly, we get to 2023 and started to see a “normal” slowdown unlike what we’ve seen in the last couple of years. For the last three years, we’ve been extremely busy, and we haven’t had to put in the same effort to get the same number of sales. We aren’t having callbacks like normal. We’re not having to advertise like normal. We’re not having to negotiate prices like normal. And now, we’re starting to see things shift back to “normal.” We should have seen this coming. We should have been more ready for it. By the time we get to 2024, it’s going to be normal to have slow Februarys, Septembers and Novembers. We’re also going to have crazy busy Januarys, Junes, Julys and Augusts. Our shops will be back into the original groove in which they’ve always operated.

Right now, there are going to be a lot of owners who have advisors they think are pretty good. They’re about to find out that they’re not. And we’ve got many advisors who thought their owners were good at marketing and they’re about to find out that wasn’t the case. This is a chance for all of us to step up our game.

We need advisors to make sure that they’re doing whatever they can to generate gross sales. We need to make sure advisors are focused on curb selling. We need advisors focused on the customer’s needs who understand financing options if a customer needs them. We need them to offer different timelines to get repairs done if customers can’t do all of it right now. And honestly, an empathetic heart. We also need to make sure that owners are getting advisors the necessary training to succeed as customers start to tighten up their belts.

Today’s advisors are in an amazing position to show their worth by putting in the work and studying to become great at their craft. But if an advisor does not have a supportive owner who is going to provide a way for them to get that training, then that advisor is going to slowly become discontented and start looking elsewhere. We need those advisors to want to stay with us, especially the ones that have talent and ability. We want to be the best opportunity for them. We want to have the best support system in the office. We want to have the best technicians in the shop, and we want to have the best customers out there on the street. If an owner is not going to provide those, that advisor will ultimately leave.

As owners, you need to understand that you may have that amazing advisor on staff who needs a little more training and for you to back off and give them room to succeed or fail. There’s a healthy balance

between owner and advisor, as the owner continues to provide opportunity, and the advisor continues to push themselves to become better, they can have an amazing marriage in business. But it’s going to take teamwork. It starts with admitting that things aren’t where they should be right now, and that it’s time to step up and go to the next level. That means training. That means teamwork. That means

As volume levels decline for some shops, owners and advisors should work hard to stay on the same page

AARON STOKES