FAMILY MATTERS

RECOGNIZE AMAZING EMPLOYEES PAGE 40 REACH YOUR MARKET PAGE 46 BACK TO WEBSITE BASICS PAGE 38 How one owner has maintained and enhanced the reputation of his father’s business PAGE 32

FENDERBENDER.COM / APRIL 2023 Shawn Crozat took over five decades of history with G&C Auto Body and has grown the business while preserving its core community values.

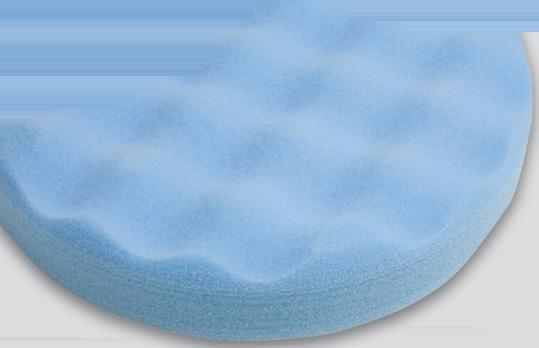

COMPOUNDING PADS

FINISHING PADS

Convoluted waffle foam construction designed to refine and eliminate swirl marks and imperfections.

ADV 1824 FIRSTCALLONLINE.COM Visit our website for a complete, internet-based catalog designed exclusively for the Professional. Let Us Be Your Parts & Equipment Supplier REFINISHING PRODUCTS FROM START TO FINISH PROFESSIONAL GRADE

LOCAL PAINT & BODY SUPPLIER FROM START TO FINISH

YOUR

MasterPro® compounding and buffing pads cut fast and last long, preparing the surface for fast, trouble-free finishing.

AVAILABLE EXCLUSIVELY AT MAKING IT FASTER AND EASIER THAN EVER TO ORDER PARTS Scan here with your phone’s camera to view catalog! WWW.FIRSTCALLONLINECATALOGS.COM

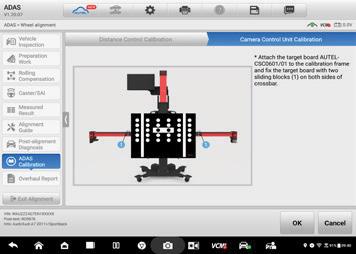

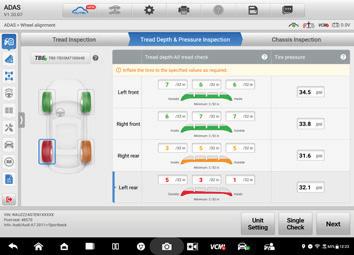

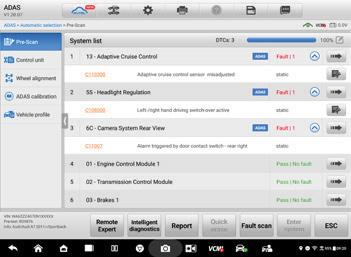

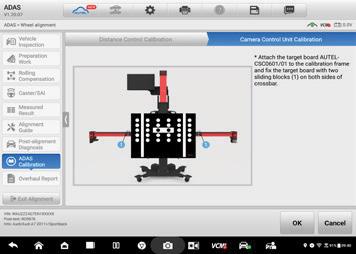

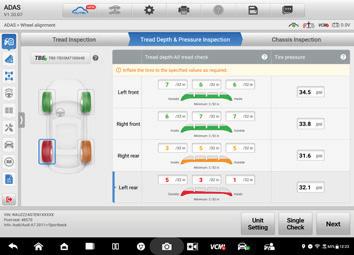

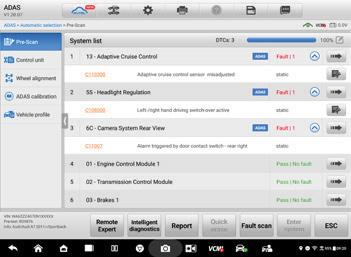

IA9OOWA SUBLET TO YOURSELF ALIGNMENT + DIAGNOSTICS + ADAS IN A SINGLE SYSTEM & WORKFLOW WEB: AUTEL.COM | SUPPORT: 1.855.288.3587 EMAIL: USSUPPORT@AUTEL.COM FOLLOW US @AUTELTOOLS DIAGNOSTICS 1 2 3 4 DIGITAL INSPECTIONALIGNMENT ADAS CALIBRATION Insurance Compliant Pre-SCAN and Post-SCAN Reporting. Text or Email All Customized Reports Instantly to Your Customer. 3D Wheel Alignment with Any Electronic Component Reset. Step-by-Step Illustrated Instructions with Automatic Vehicle Height Tracking. At the Cost of a Typical Alignment System MAXIMIZE PROFITABILITY & EFFICIENCY KEEP DIAGNOSTICS & ADAS IN-HOUSE CONTACT YOUR AUTHORIZED AUTEL DEALER TODAY FOR A PERSONALIZED QUOTE *Return on investment varies by service volume. CALCULATE YOUR REVENUE POTENTIAL RECOUP YOUR INVESTMENT IN AS LITTLE AS 30 DAYS

made easy. Cromax® EZ, an easy to mix, easy to match and easy to apply waterborne basecoat system that always delivers. See how easy waterborne can be. axalta.us/ez AXALTA COATING SYSTEMS Copyright © 2022 Axalta Coating Systems, LLC and all affiliates All rights reserved

Waterborne

5 April 2023 fenderbender.com APRIL CONTENTS 32 UPHOLDING A GENERATIONAL LEGACY Shawn Crozat has taken up his father’s reputation for quality and community BY TODD KORTEMEIER 28 BETTER KNOW A TECH Understanding a bit more about who technicians are and what they want in a career BY TODD KORTEMEIER FEATURE PROFILE 04.23 | VOLUME 25 | NUMBER 04 FenderBender (USPS Permit 25614), (ISSN 1937-7150 print) is published monthly by Endeavor Business Media, LLC. 1233 Janesville Ave., Fort Atkinson, WI 53538. Periodical postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($90 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at fenderbender@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2023 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

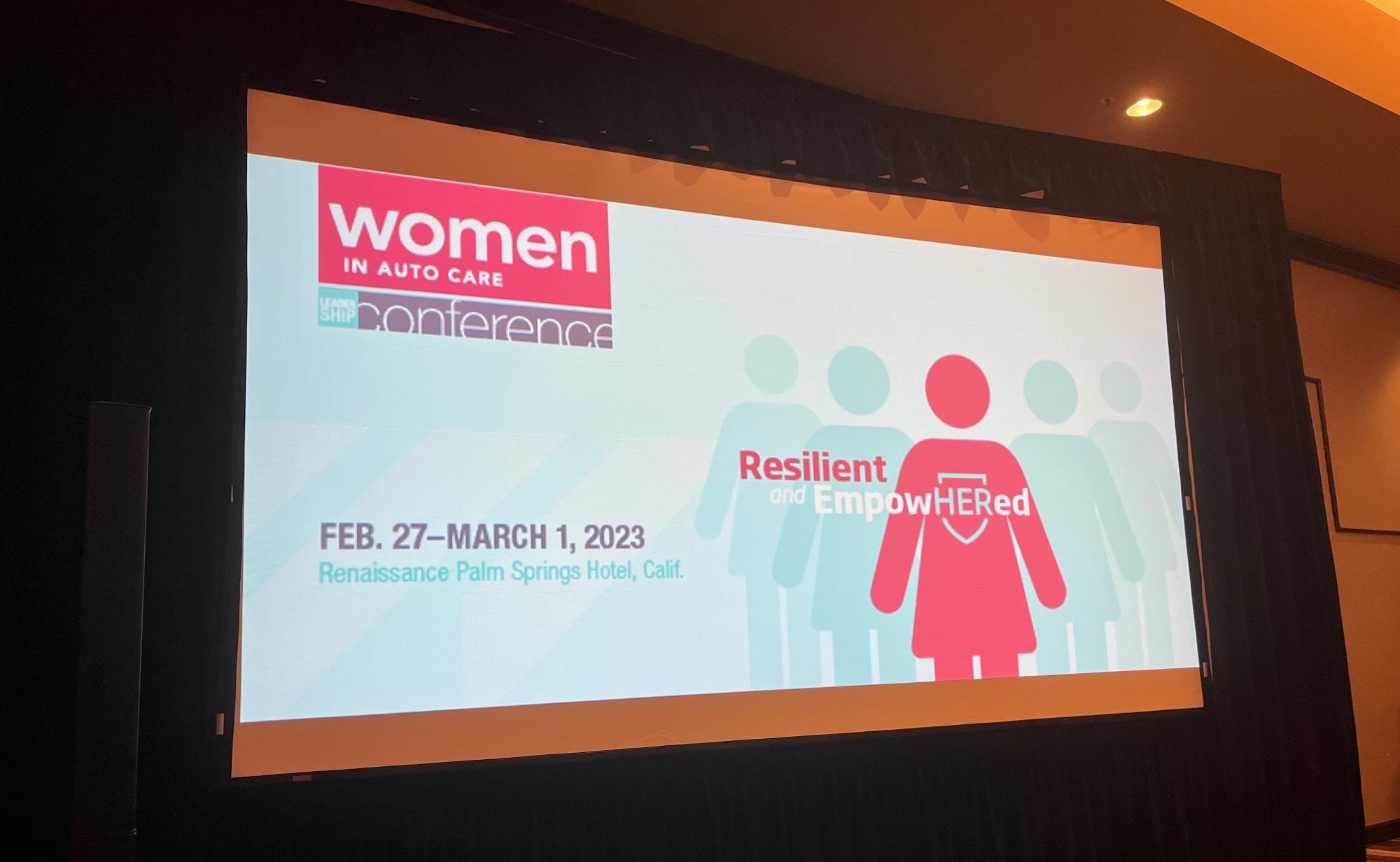

6 April 2023 fenderbender.com autojobcentral.com USE CODE: AJC123 TO TAKE $100 OFF YOUR FIRST LISTING! POST A JOB RECEIVE QUALIFIED APPLICANTS GROW YOUR TEAM 1 2 3 AS EASY AS... QUICK FIX 13 PAST THE PAGE LKQ acquires FinishMaster 11 DRIVERS SEAT A season for change? 15 BREAKDOWN Industry-leading women 19 NUMBERS The gender gap remains 21 LIGHT HITS Crash insurance report card, and much more 24 SNAP SHOP A ‘hidden gem’ in Florida 24 CONTENTS APRIL

7 April 2023 fenderbender.com CONNECT WITH FENDERBENDER FOR THE LATEST COLLISION REPAIR CONTENT FOLLOW WHAT THE LEADERS FOLLOW 38 THE SOP Optimizing your website 40 HUMAN RESOURCES Recognizing outstanding performance 42 CASE STUDY Utilizing remote diagnostics COLUMNS 27 SHOP PROFITS Managing cash flow BY GREG LOBSIGER 49 COLLISION COURSE Reconciling claims before supplements BY TIFFANY MENEFEE 50 DUE PROCESS Persistence through resistance BY DREW BRYANT STRATEGY 44 ADAPT An all-female industry panel 48 SALES+ MARKETING Identifying your market

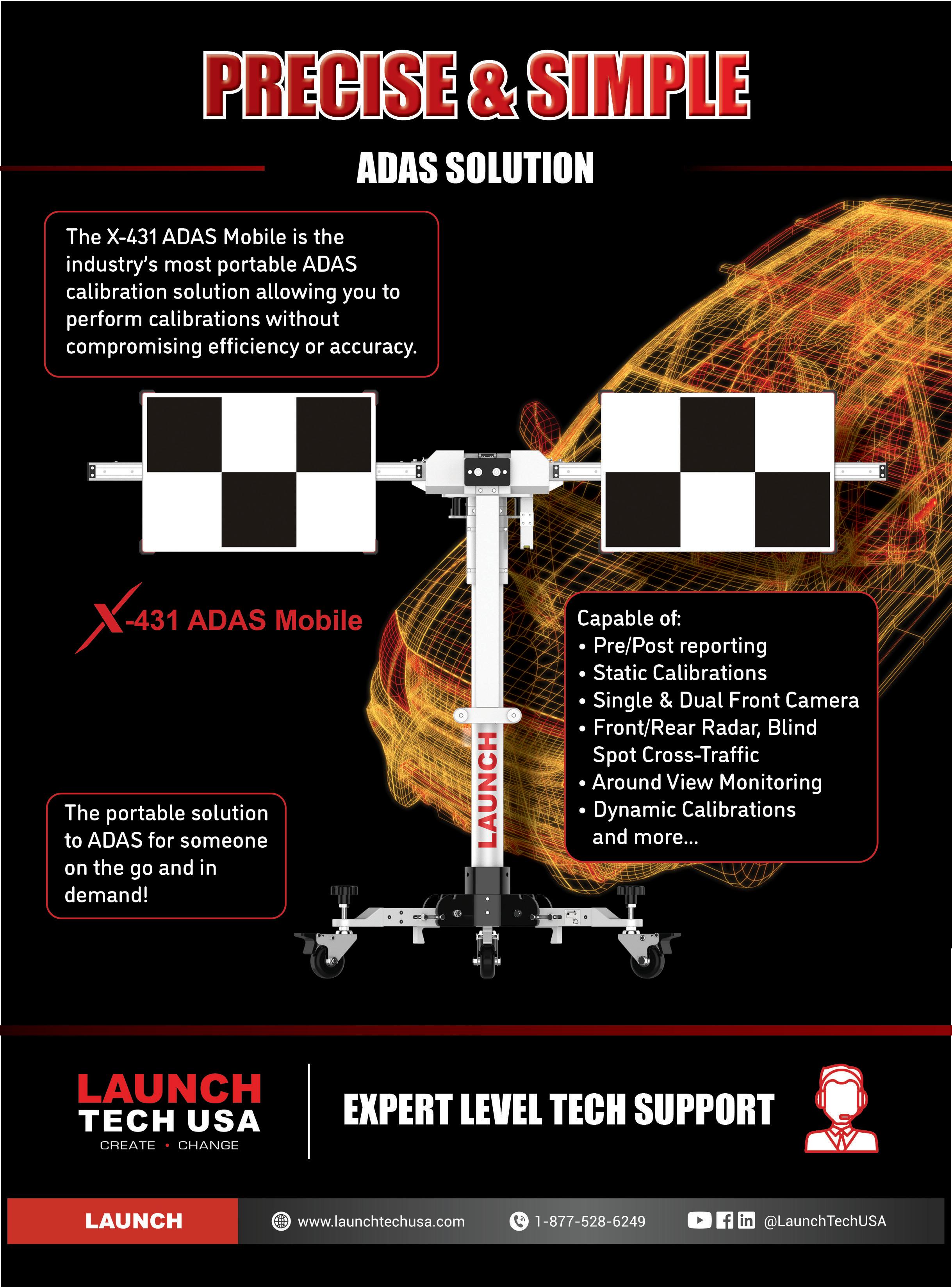

CLICK ON THE LOGO BELOW FOR PRODUCT INFORMATION

8 April 2023 fenderbender.com

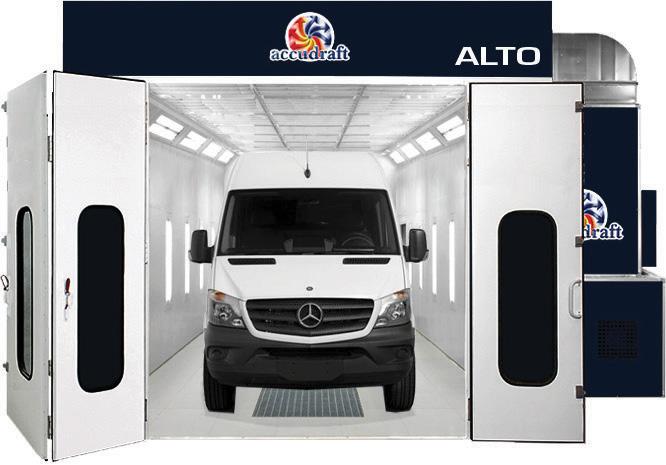

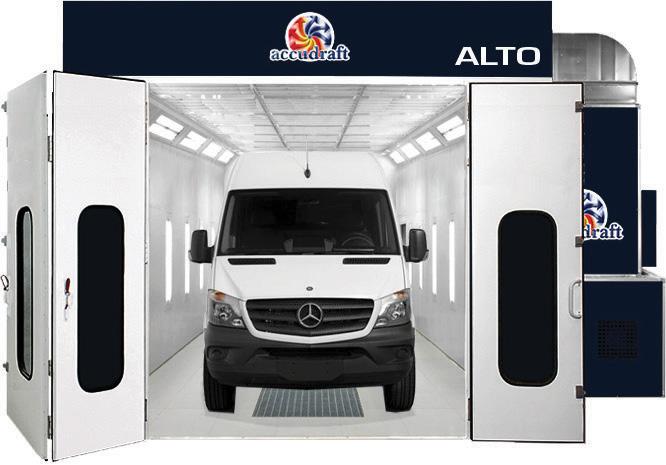

CONTENTS ONLINE EXTRAS SATA/Dan-Am Company Polyvance ProColor Collision AUTEL Car-O-Liner FBMC FinishMaster LKQ Corporation asTech PPG Industries I-CAR Auto Job Central Launch Tech USA Axalta Coating Systems Industrial Finishes O’Reilly Auto Parts Accudraft SEPTEMBER 24-26, 2023 • AURORA, CO HYATT REGENCY AURORA CONFERENCE CENTER FENDERBENDERCONFERENCE.COM EDUCATE & ELEVATE CONNECTING LEADERS IN COLLISION REPAIR OWNED& SPONSORED BY: 2303FB_House_FMBC.indd 2/2/23 11:30 AM

EDITORIAL

Matt Hudson Content Director

Todd Kortemeier Editor

Hanna Bubser Associate Editor

Kacey Frederick Associate Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Lindsey Gainer Contributing Writer

Emily Kline Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Universal Collision

Greg Lobsiger Loren’s Body Shop

John Magowan Ernie’s Auto Body

Stan Medina Certified Collision Works

ART AND PRODUCTION

Jonathan Ricketts Senior Art Director

Mariah Straub Production Manager

Mitch Bradford Art Director

Morgan Glisczinski Graphic Designer

Emme Osmonson Graphic Designer

Hana LeBrew Print Production Assistant

SALES

Chris Messer Vice President and Publisher

651.846.9462 / cmesser@endeavorb2b.com

Andrew Johnson Associate Publisher

651.846.9459 / ajohnson@endeavorb2b.com

Marianne Dyal Marketing Strategist (National Accounts)

706.344.1388 / mdyal@endeavorb2b.com

Chad Hjellming Marketing Strategist (National Accounts)

651.846.9463 / chjellming@endeavorb2b.com

Bob Marinez Marketing Strategist (National Accounts)

216.533.8747 / bmarinez@endeavorb2b.com

Martha Severson Marketing Strategist (National Accounts)

651.846.9452 / mseverson@endeavorb2b.com

Kyle Shaw Marketing Strategist (National Accounts)

651.846.8480 / kshaw@endeavorb2b.com

Dan Thornton Marketing Strategist (National Accounts)

734.676.9135 / dthornton@endeavorb2b.com

Sean Thornton Marketing Strategist (National Accounts)

269.449.0257 / sthornton@endeavorb2b.com

Kenzie Verschoor AssociateMarketingStrategist(NationalAccounts)

651.846.9472 / kverschoor@endeavorb2b.com

Matt Harper Regional Sales Manager

651.846.9551 / mharper@endeavorb2b.com

Melody Todd Senior Marketing Strategist (Regional Accounts)

651.846.9468 / mtodd@endeavorb2b.com

Tim Hill Marketing Strategist (Regional Accounts)

651.846.9454 / thill@endeavorb2b.com

Autumn Morey Customer Success Representative

651.846.9460 / amorey@endeavorb2b.com

Jen George Client Service Specialist

651.846.9465 / jgeorge@endeavorb2b.com

Ryan McCanna Administrative Assistant

HOW TO REACH US

571 Snelling Avenue North, St. Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

ARTICLE REPRINTS

For high-quality reprints or e-prints of articles in this issue call 651.846.9488 or email reprints@fenderbender.com.

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

READ WHAT THE PROS READ

9 April 2023 fenderbender.com

SUBSCRIBE OR RENEW AT FENDERBENDER.COM/SUBSCRIBE

TO

“The opportunity to read about ways to improve your business from credible owners and manufacturers is priceless.”

—Stan Medina, Owner, Certified Collision Works, Corpus Christi, Texas

RIGOROUSLY TESTED PREMIUM QUALITY PRODUCTS ABRASIVES • ADHESIVES • BUFFING & DETAIL CLEARS & PRIMERS • MASKING SUPPLIES PAINT & BODY SHOP SUPPLIES • TOOLS & EQUIPMENT 866-711-5235 finishmaster.com/smart follow us @finishmasterinc TM of the refinishing process can be completed with professional grade products. 95% 95% to learn more $38800 exclusively from SMT 3300 CONTACT YOUR LOCAL REP OR CALL OUR TEAM OF EXPERTS TO LEARN MORE AND DEMO TODAY. LIMITED EDITION BY TM

THE SEASON OF CHANGES

Spring

IT IS NO WONDER THAT the coming of a new year became associated with making resolutions. The new year is a blank slate, it’s restarting the clock, it’s 365 new opportunities. For those wishing to make a change, it’s the perfect time.

But if I may make an argument for spring as the perfect time to make a change, the metaphors are pretty handy. It’s the rebirth of life after a long period of dormancy. It’s ever-lengthening days and the return to the outdoors. If you’re a baseball fan like myself, it means Opening Day and the boundless optimism of everyone being tied for first place.

Maybe this falls flat to those of you for whom the change of the seasons is less drastic. I’m a nearly life-long Midwesterner; I detest winter and don’t feel truly myself until it’s over. Spring is a time to be cherished—it means everything is getting better.

Whenever you choose, there’s never a bad time to make some improvements. Use whatever rationale you like. Maybe it’s something you’ll find in these pages.

This month, FenderBender brings you into the world of the technician for our main feature story (pg. 28). Shop owners know a skilled technician when they see one, but having skills is only half the battle. What are techs looking for in an employer? And what can you find in techs that are an indicator of success?

Elsewhere in FenderBender, you’ll read about G&C Auto Body owner Shawn Crozat (pg. 32). G&C is a family-owned business of more than five decades, and Shawn has helped it grow into one of the largest family-owned MSOs in the country. We think you’ll find his philosophies

and strategies enlightening.

You’ll also find a primer on working with a remote diagnostics provider (pg. 42). There are tips for how to reward your employees (pg. 40) and for reaching the customers you’re going after (p. 46). We hope you find it all useful for making your shop whatever you want it to be. Thank you for your continued support of FenderBender.

TODD KORTEMEIER EDITOR

11 April 2023 fenderbender.com DRIVER’S SEAT

is a time of rebirth, possibly for your business as well

tkortemeier@endeavorb2b.com 2303FB_Polyvance.indd 1 1/17/23 1:58 PM

SATA Spring Promotion

Beginning April 11th – while supplies last

SATAjet X 5500 + BBQ Kit: Awaken the Grill Master within!

Leap into spring with the SATA BBQ promotion and get yourself a stylish, strong and functional BBQ apron as well as solid, innovative and multifunctional BBQ tongs in stainless steel. Whether at the next family gathering or at the camp site - with the SATA BBQ Kit you are perfectly set.

Beginning April 11, 2023, all SATA customers will get the limited edition BBQ Kit along with the purchase of SATAjet X 5500 (all technologies and versions) as a gift. Available only from your local authorized participating SATA dealers – and only while supplies last.

INFO www.sata.com/bbq-set SATA, SATAjet and/or other SATA products referenced herein are either registered trademarks or trademarks of SATA GmbH & Co. KG in the U.S. and/or other countries. The exclusive independent distributor of SATA products in the US and Puerto Rico Phone: 800-533-8016 www.satausa.com E-mail: satajet@satausa.com

LKQ ACQUIRES FINISHMASTER IN DEAL FOR UNI-SELECT INC.

IN FEBRUARY, LKQ CORPORATION acquired refinishing and coatings distributor Uni-Select Inc. and its FinishMaster subsidiary in a transaction with a total enterprise value of $2.1 billion, the companies announced in a press release.

The deal brought together one of the aftermarket’s largest parts providers in LKQ and Uni-Select, which operates the FinishMaster brand across North America and is a parts distributor throughout its home base of Canada and in the United Kingdom. The company operates 145 FinishMaster brand stores in the U.S., serving 30,000 customers each year. LKQ anticipates advantages to tapping into FinishMaster’s existing network and expanding the company’s current offerings.

“This acquisition further enhances LKQ’s global automotive vehicle parts distribution business,” said Dominick Zarcone, president and CEO of LKQ, via the press release. “Uni-Select’s

North American automotive refinish paint and mechanical parts distribution operations complement LKQ’s existing footprint and will allow us to distribute a broader array of products to our customers.”

For Uni-Select, which employs 5,200 people across its markets, the deal is expected to add to its resources in what it is able to offer to customers.

“The transaction offers compelling value and liquidity to our shareholders and is the culmination of the efforts by our dedicated team to improve our operations and drive efficiencies with a focus on excellent customer service,” said Uni-Select Executive Chair and CEO Brian McManus. “We see great opportunities to benefit our customers, employees, suppliers and brands by combining our complementary strengths within the larger, multi-disciplinary and growing LKQ team.”

13 April 2023 fenderbender.com

GETTY

VIDEOS | PODCASTS | WEBINARS | NEWS PAST THE PAGE @fenderbendermag @fenderbendermag @fenderbendermag fenderbender.com/linkedin fenderbender.com

SEPTEMBER 24-26, 2023 • AURORA, CO HYATT REGENCY AURORA CONFERENCE CENTER FENDERBENDERCONFERENCE.COM EDUCATE & ELEVATE CONNECTING LEADERS IN COLLISION REPAIR OWNED & PRODUCED BY: SPONSORED BY:

ANALYSIS

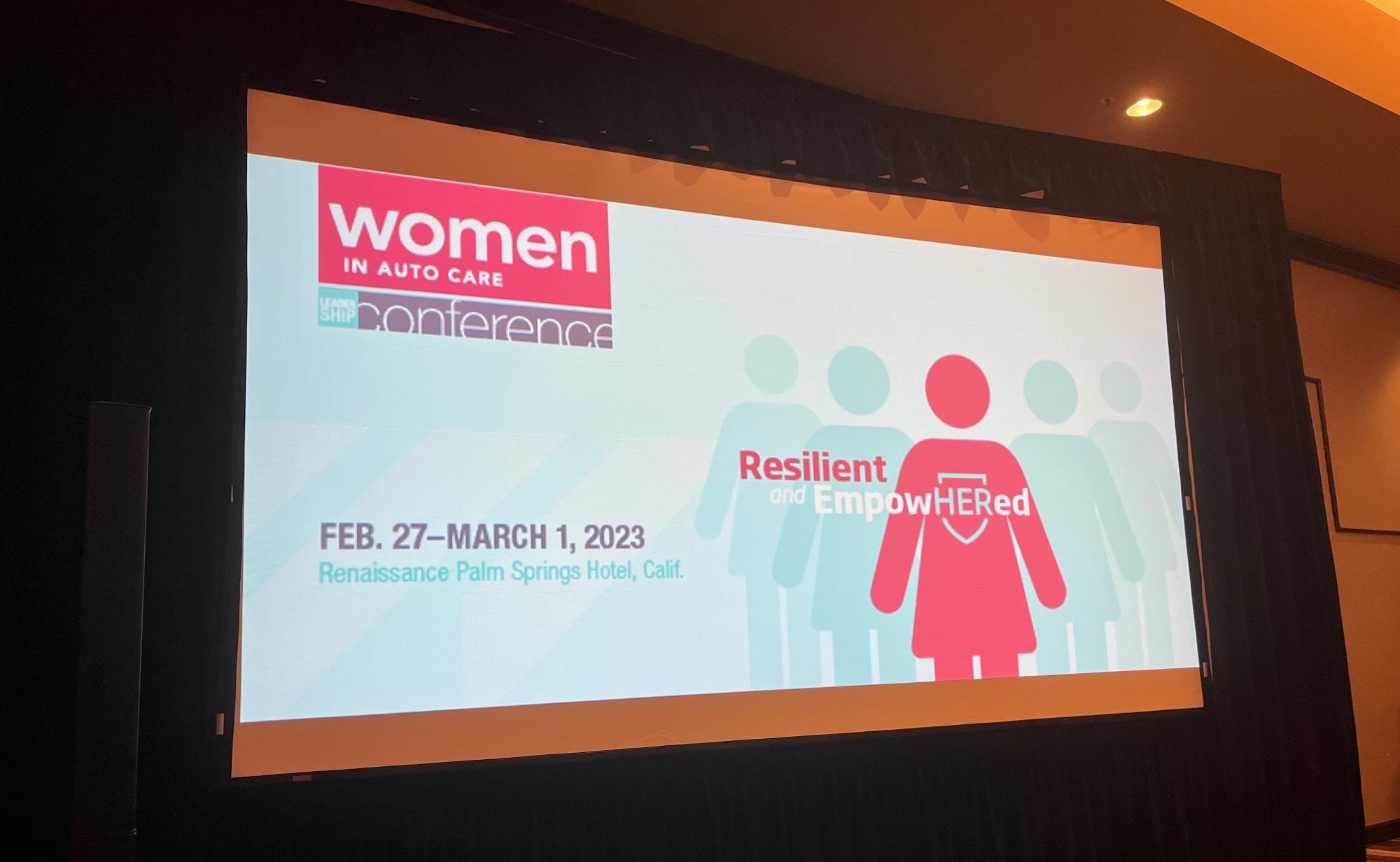

THE WOMEN OF CRASH CHAMPIONS

Four leaders at the company share their career stories

By KACEY FREDERICK

AUTOMOTIVE REPAIR HAS historically been a male-dominated field, but that’s been changing drastically over the past few decades. More women are making waves in collision repair, from the shop floor to the corporate office.

15 April 2023 fenderbender.com QUICK FIX GETTY NEWS | IDEAS | PEOPLE | TRENDS

Crash Champions has many women in leadership positions who have had to work especially hard to accomplish what they’ve done and get to where they are now. Check out the stories of four women who are shaping the future of this nationwide brand.

Striving to be the Best

Heidi Foster is the senior vice president of operations of the West at Crash Champions and has 20 years of experience in her industry—14 specifically working with body shops. Foster was previously a student athlete at Purdue University. When she graduated in 2003, she came home and did private lessons, held clinics and considered becoming a coach. Eventually, however, Foster’s mother

pushed her into getting a call center job at the insurance company she worked at when she was 22.

Foster remembered disliking the position initially, but she realized she enjoyed helping people.

“That’s ultimately how I fell into cars,” Foster says. “I love the people aspect of it, of just … being there for them during this time—times of crisis, in some cases.”

After going on to work at a body shop, becoming a national director of training at Service King, and then joining Crash, she feels she is setting an example for other women in the industry.

“That’s paving the way for a lot of women to not just think, ‘I’m just going to work the front, and answer the phones.’ You’re

not limited to that role anymore,” she says.

When she first entered the collision repair industry, she struggled to gain respect from those working around her. Foster remembers there being no women in the shop and the men showing no interest in working with her.

“They would make comments like, ‘You wear dresses to work. This is a body shop, you’re not supposed to wear dresses.’ But I’m dealing with customers—pretty highend customers, too—so although I’m going to get dirty in the back, I have to look good for my customers,” she recounts.

Foster took it upon herself to befriend one technician in the shop and worked with him to educate herself. She was able to write better sheets and proved herself, gradually gaining the respect that she deserved.

16 April 2023 fenderbender.com

QUICK FIX GETTY

“I equipped myself, I had to be better,” Foster says. “And I had to be better than the guys, not just be better at what I was doing currently. I had to be the best.”

A Desire to Help

Lisa Jarvis is Crash Champions’ director of operations for Montana. She has about 15 years of experience, and helps managers set goals, address issues and provides support for them.

The best part of her job is “getting to help the people” during a chaotic situation.

“This is one of the most stressful times they will have in their life,” she says. “You know, their mode of transportation is rendered unable to be used—and especially if you’re in Montana, we don’t really have

public transportation. You have to have your car.”

Jarvis had to work hard but had superiors who didn’t recognize that work. Eventually, she says she was “fortunate enough to have a couple bosses that were really great, too, with [saying] like, ‘You’re so good at your job, what else can you do?’”

Being able to show her kids that hard work pays off is what has driven her through her career. What keeps her going is feeling that she is helping customers and getting to work with and support talented team members.

“I mean, it feels good to help people, you know? And people like to be helped,” she says.

Taking a Chance

Natalie Zajc has worked in the collision repair industry for eight years and is currently Crash Champions’ vice president of business development. She works on a team that oversees all of Crash’s national carrier relationships and any incoming revenue sources for the company.

Prior to her current position, Zajc did business development for a medical company before taking some time off work when she had children. She then met Crash Champions CEO Matt Ebert in 2014 through a mutual friend. Ebert only had two locations and was eager to expand.

“He pretty much said, ‘I’ll take a chance on you; I don’t know if I can afford you, but if you pay for yourself, you can stick around.’ He gave me a box of business cards and sent me out to find work for him,” Zajc says about working with Ebert.

From there, Zajc moved up through the company, starting in outside sales and marketing, to director of business development, then recently being promoted to vice president of business development.

Zajc is part of the first generation of her family to attend college and was inspired by how her mother worked and always wanted better for her. She strives to do

the same now for her own children, and to mentor her two daughters “to be more than what I am.”

A Career of Learning

Mariah Sampson is Crash Champions’ brand manager and grew up around cars as the daughter of a body shop owner. When the company she worked for was sold to Crash about a year ago, she joined their team to do marketing.

Even though Samson grew up surrounded by discussions of car repair, upon entering the industry she quickly realized she still had much to learn.

She took it upon herself to attend classes held by the Montana Collision Repair Association and the Society of Collision Repair Specialists, which she says provided a great opportunity for her to learn. Those classes made a substantial difference in her industry trajectory.

What motivates Sampson is working with good teammates to help people that have been in accidents by “being able to turn a very tragic experience around for someone.”

“For a lot of people your vehicle is either your largest or second largest investment,” Sampson explains, “so they’re putting a lot of trust into us to make sure their vehicle is properly and safely repaired. They’re putting their families in those cars; they’re driving down the road every day to work.

The biggest advice given by the four women is to be ready to prove yourself, especially if you are another woman entering the industry, and to always be willing to learn from others.

Jarvis says that supervisors like Foster were key to spotting her potential and helping pave a path to greater roles.

Now she tries to instill that same attitude with those she supervises, by asking, “You want to be better, you want to do something great? Great, how are we going to make that happen?”

17 April 2023 fenderbender.com

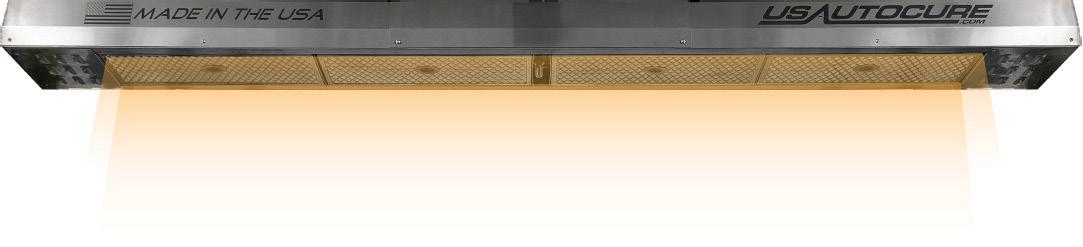

How Do We Get Started?

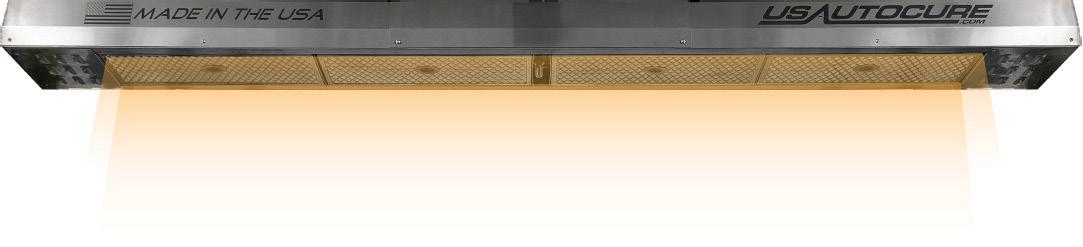

Gas-catalytic, medium-wave infrared curing is adaptable to a broad range of applications.

To determine how US Autocure systems can help you, we start with 3 simple steps: 3

1 PAINT: Our chemist will review a list of the coatings products and other technologies you use and their response to infrared curing.

2

PROFITABILITY: We’ll work with you to determine the areas of savings and gains that infrared curing can provide.

BOOTH: Some basic spray booth information is all that is needed to help us determine the best system for you.

There are no costs associated with these steps and we will not share this information with anyone but you. These activities can be completed quickly, but we won’t rush you.

We believe in our technology.

We want you to be comfortable that it’s right for you.

480.268.9703

USAutocure.com Get Started DISTRIBUTED EXCLUSIVELY BY

NUMBERS

WORKING TOWARD A BALANCE

IN THIS MONTH’S ISSUE, FenderBender is proud to feature numerous female voices, voices that all too often are absent from discourse in the collision repair industry. The numbers from the 2022 FenderBender Industry Survey bear that out, as the vast majority of shop leaders taking the survey were men, illustrative of the imbalance in the industry today.

PERCENTAGE OF RESPONDENTS TO 2022 FENDERBENDER INDUSTRY SURVEY

92% MALE

8% FEMALE

19 April 2023 fenderbender.com

QUICK FIX

CMI™300 PULSE

ADVANCED YET SIMPLE

LIGHT HITS

ABAT URGES LEGISLATORS TO SUPPORT SAFE VEHICLE REPAIRS

Professionals in the collision repair industry across the state of Texas came to the state capitol in Austin in February to advocate for two bills proposed by the Auto Body Association of Texas (ABAT), according to a press release.

ABAT Executive Director Jill Tuggle said that everyone split into 10 teams “to cover as much ground as possible.” They handed out flyers and pamphlets with “testimony from consumers who have been impacted by the appraisal process.”

The first of the two bills from ABAT, House Bill 1321, aims to “require proper repairs based on OEM-recommended processes” and address “the differences between original and aftermarket parts,” as well as getting rid of “‘gray’ areas” of what insurers define as a proper repair, and how insurance companies “indemnify policyholders.”

The second, House Bill 1437, seeks to mandate insurers to include a Right to Appraisal in all of their offered policies.

ABAT President Burl Richards said he and a group consisting of “Ware Wendell (Texas Watch), a couple board members and a technician from El Paso” found many legislators to speak with.

Richards believed that the legislators’ appreciated hearing the technician explain his inability to perform proper repairs when insurers won’t pay for them.

“It hurts the vehicle owner and creates the potential to hurt others on our roadways!” Richards added.

CRASH NETWORK RELEASES ‘23 INSURER REPORT CARD

CRASH Network released its 2023 Insurer Report Card in February as collision repairers rated more than 87 auto insurance companies on the quality of service provided to their clients, with 29 being placed on CRASH’s “Honor Roll,” according to a press release.

More than 1,000 body shops nationwide rated “as many as 30” insurance companies in their respective states on “how well each insurer’s ‘policies, attitude and payment practices ensure

quality repairs and customer service’” for their clients.

Four of the largest U.S. auto insurers were among ten companies that received a grade of “C-” or lower, and “none of the Top 10 largest, best-known auto insurers” were graded higher than “C+.”

Since 2020, the best grades have gone to “North Carolina Farm Bureau (‘A+’), Chubb (‘A-’) and Erie Insurance (‘A-’),” and this year was no exception.

Shops that assigned the grades stated that the best ones were given to companies that value customer safety, work efficiently with claims handling and have a team of people that seem to genuinely care. The lowest-graded ones received such scores due to disorganization, disregard for designated repair procedures and making it so that shops were “ordering parts all over the country just because of cost, even though they don’t arrive in a timely manner and are not quality parts.”

CCC: USE OF AI ASSISTANCE IN AUTO CLAIMS IS GROWING

CCC Intelligent Solutions Inc. issued a February update to its insurer AI adoption report, which found a growth in the use of AI in auto claims for the third row in a year.

According to a CCC press release, the use of “advanced computer vision AI” for processing claims saw a 60 percent increase “year-over-year.” CCC AI’s solutions were used to process more than “14 million unique claims.”

Additionally, the number of insurers using CCC’s “AI-powered touchless estimating solution” grew to 15, “representing 50% of U.S. auto claims volume.”

Besides insurers taking on the new technology, the increased use can also be credited to an increase in the use of digital photos to submit claims, accounting for “more than 27% of claims processed through CCC’s system” in 2022.

Jason Verlen, vice president of product marketing at CCC, said that the AI programs are “capable of auto-generating a complete repair estimate with line level detail in seconds without human intervention,” but that the technology still had a long way to

go due to factors such as “labor shortages and increasing vehicle complexity.”

NEW CRASH CHAMPIONS LOCATION OPENS IN CAROL STREAM, ILLINOIS

Crash Champions has announced the opening of a new location in Carol Stream, Illinois, according to a recent press release.

The new collision repair facility opened at 125 Stark Drive on Feb. 6 and is the latest of over 600 locations within the company’s network across 36 states. Four hundred of those locations have been acquired in the last year.

The Carol Stream location is close to Crash Champions’ home base of Chicago, where the company was founded in 1999 and where 55 locations operate today across the greater Chicago region. Crash Champions founder and CEO Matt Ebert said that the company is “proud of our roots.”

“Chicagoland is our home, and it’s always special when we can grow the team right here in the Windy City,” Ebert said.

CLASSIC COLLISION ACQUIRES MINNESOTA BODY SHOP

Gale’s Auto Body, a shop in Blaine, Minnesota, has been acquired by Classic Collision, according to a press release.

Gale’s Auto Body is the latest addition to the multi-site collision repair operator’s 213 facilities in the country, and was first opened 25 years ago and was owned by Troy Westerlund.

“We have taken pride in ourselves on delivering top-notch customer service for several years in the community and believe that Classic Collision will continue that service and commitment,” Westerlund said.

CEO of Classic Collision Toan Nguyen said the company needed more locations in Minnesota and that they “look forward to this market’s continued growth.”

GERBER COLLISION FIRE IN TEXAS STOPPED BY EMPLOYEES

A Gerber Collision and Glass location in Texas caught fire and was extinguished with the help of employees on-site, according to a report from the Daily Trib.

21 April 2023 fenderbender.com

QUICK FIX

A small fire sparked at the shop located in Marble Falls, Texas, the morning of Feb. 16. According to Marble Falls Fire Marshal Thomas Crane, the fire was most likely started by “discarded smoking materials” lighting cardboard on fire.

When employees at Gerber first saw the fire at around 9:30 a.m., they immediately took action: they found fire extinguishers and a hose and attacked the flames.

Firefighters appeared minutes later, dealing “the final blow to the blaze.” Fire Marshal Crane told reporters that there was “minimal damage to the exterior of the building” and that no injuries or fatalities occurred as a result. The fire was extinguished before it could spread to any nearby structures.

Amanda French is the office manager of Gerber Collision and Glass in Marble Falls and helped to put out the fire that morning. She said she and her team “reacted pretty quickly to save all the vehicles inside the shop.”

Crane “commended Gerber employees for getting the fire under control so quickly on their own.” French expected her and her team to return to work “within the day.”

CALIBER CEO MARK SANDERS RETIRES, TODD DILLENDER PROMOTED TO COO

President and CEO of Caliber Mark Sanders announced his retirement after a 36-year career in the industry, according to a press release.

Sanders worked with the company for 26 years, and upon retiring, will serve in a “special advisory role for the next 18 months” which began March 6, 2023.

Sanders worked with his father in the collision industry and joined Caliber when their two collision repair shops were acquired by the company in 1997. Sanders eventually went on to become chief operating officer before becoming president and CEO.

Steve Grimshaw, chairman of the board at Caliber, said that Sanders “led Caliber back from the global pandemic and successfully responded to multiple industry challenges.”

David Simmons will take Sanders’ role as president and CEO, with Sanders’ support. Simmons has a background in the pharmaceutical industry, previously serving as CEO of PPD and president of emerging markets at Pfizer.

Simmons is “honored to continue Caliber’s legacy” and promises to ensure they are “the most trusted automotive service provider” at all their locations.

Earlier in the month, Caliber announced the promotion of Todd Dillender, executive vice president, operations, to chief operating officer, according to a press release.

Dillender has more than 30 years of experience in the industry and has worked in nearly every center-level position since 1997. He started out as “a shop helper, then a detailer, a body tech helper, painter,” and “service advisor,” before going on to leadership positions such as general manager and regional manager.

Dillender moved from California to Texas to take on additional leadership responsibilities such as senior vice president. In 2019 he was then promoted to executive vice president, operations, and oversaw Caliber Collision’s west region, consisting of 11 states.

Since then, the company credits Dillender with being instrumental in projects such as their Technician Apprentice Program and an EV training program.

Dillender said in a statement that he has seen “first-hand” the company grow from six locations to more than 1,600.

“These milestones were possible because of the collaboration and shared purpose with my fellow teammates, specifically operations leaders Mitch McMaster and Paul Krauss,” Dillender said. McMaster and Krauss will be starting new leadership roles soon as well, according to Caliber. Dillender’s new role was effective immediately.

ABRA EXECUTIVE MARK WAHLIN RETIRES

ABRA Vice President of Franchise Services and Operations Mark Wahlin announced his retirement, according to a press release.

Wahlin became the first ABRA franchisee in December 1987. After growing his business to three locations, he sold them to ABRA corporate in October 1998. He was then offered a position with ABRA’s corporate team and has served as VP of franchise services and operations since then.

Wahlin takes with him over 50 years of experience in the collision repair

industry. ABRA said that Wahlin improved operational processes within their network and built “amazing” relationships with owners.

Wahlin was succeeded by VP of eastern operations at CARSTAR, Wayne Kelly, who started his career in the industry as a technician at one of Wahlin’s ABRA locations.

“I’m thrilled to pass the torch on to Wayne and watch as he continues to shine and support this family of owners,” Wahlin said.

CUSTOMERS’ VEHICLES TOWED FROM SHOP WITH NO NOTICE

Nearly a dozen car owners found their vehicles impounded in February after being towed from a body shop after the owner stopped paying rent and responding to customers, Fox 19 reports.

Bennetts Body Shop in Middletown, Ohio, had more than ten vehicles being worked on, but owner Tom Bennett had failed to pay his rent for “two to three months.”

The shop was operated out of a building owned by Tom Young, who said he had made numerous attempts to work with Bennett. He “didn’t want to ask Bennett to leave,” but eventually, Bennett told Young he would be out by Feb. 6, which was false.

“I took him at his word, but the building was full of cars, and there were five cars outside,” Young recounted.

When he attempted to obtain vehicle owners’ information from Bennett so they could retrieve their vehicles, “he just wouldn’t respond,” Young said.

Owners eventually were able to locate their vehicles at Steve’s Towing, where owner Steve Gebhardt waived some of the affected drivers’ towing fees; the rest paid a discounted price.

Regardless, many are still left with a huge net loss. Julie Holmes had her car at Bennett’s for “a little over a year,” for repairs she was told would take four months.

According to Holmes, Bennett was “initially polite,” but became unresponsive. She only found out what happened to her car through a Facebook post her stepson saw.

After retrieving the vehicle, paying the impound fees, and towing it back home, the family was out $3,000, and their vehicle is still in disrepair.

23 April 2023 fenderbender.com

QUICK FIX

JACK’S COLLISION CENTER

B y TODD KORTEMEIER

Photos by DARREN MILES PHOTOGRAPHY

LOCATION: BONITA SPRINGS, FL

OWNER: KEVIN LIPSCOMB

SIZE: 7,500 SQUARE FEET

STAFF: 9

AVERAGE MONTHLY CAR COUNT: 80

AVERAGE REPAIR ORDER: $ 2,500

ANNUAL REVENUE: $ 2.4 MILLION

1. WHAT’S IN A NAME

When Kevin Lipscomb and his father Jack were trying to decide on a name for their business in 1990, they for a time settled on “Jack & Son.” But they later decided that “Jack’s” simply sounded better, and the rest is history. Kevin bought out his father several years back, but Jack’s legacy remains in big, red letters.

“We stuck with [the name],” says Lipscomb. “I’m glad that we did. Because it seems like it’s been a really, really good name for us.”

King, leaving the current location in Bonita Springs under the Jack’s name that opened in 2008. The building was already a body shop and Lipscomb felt it was a “hidden gem” with little competition in that part of Florida.

“There’s only three body shops within probably a 15-20 mile radius,” says Lipscomb. “So it was a great opportunity for us in ’08 to go ahead and actually acquire the shop.”

2. POLISHING THE GEM

Submit Your Shop

Proud of your shop and want to show it off to your peers? Tell us about it at SUBMISSIONS@10MISSIONS.COM

That name has endured through 32 years of history, including selling the original Fort Myers location to Service

After taking over the shop, Lipscomb spent about $100,000 on improvements. That included aesthetic upgrades such

24 April 2023 fenderbender.com

SHOP QUICK FIX 1

SNAP

as new paint and pavement. And it also included upgrading the paint booth and other mechanical improvements.

“And they just put everything brand new in the system, brand new frame machine, brand new measuring system, I wanted to make sure that we had the best of everything,” says Lipscomb.

Lipscomb is also proud of the human resources his shop has deployed. Among his nine employees, seven have been with the shop for more than 10 years. One painter has been there 23 years.

“Longevity, it’s about taking care of your customers, taking care of your employees,” Lipscomb says. “And then in fact, they turn around and take care of my customers, because good help is hard to find. And I’m so blessed that I have such a great crew.”

3. FINDING A NICHE

In their area of Florida, Lipscomb says the shop gets to work on a lot of high line vehicles—think Bentleys and Ferraris. But a bulk of the shop’s work is relatively quick fender and bumper repairs, and they don’t cater to any particular car or customer.

“We’ll have a Ford Escort to a Hyundai Genesis to a Bentley to a Mercedes and then to a Dodge Ram truck, it doesn’t matter,” says Lipscomb.

That’s a niche that has served the shop well and will continue to do so. The area has seen an influx of new residents since the pandemic, and Hurricane Irma in 2022 has also brought an influx of work. So Lipscomb is planning a small expansion to handle more cars. Other than that, it’s all about maintaining the team he’s built and preparing for any future challenges.

“I’m just very fortunate that I’ve got a great, great staff,” says Lipscomb.”… I’m always basically trying to see who I can draft and prospect and make sure that I’ve got a full all-star team here.”

25 April 2023 fenderbender.com

3 2

The Cashflow Fix

Examining the relationship between profit and cash flow

Decades back, I had put most everything my wife and I had to purchase our family’s shop from my uncles. After the purchase, a smart businessman I knew named Chuck asked me a question, “How is your new business going?” Because of pride, I told him things were going OK, even though I was working myself to death, etc. I also told him I would fortunately have something to sell for retirement down the road. Chuck stopped me in my tracks and gave some, unbeknownst to me at the time, words of wisdom. He said, “Greg, when you look at retirement, you need to look at it as though your business will be worth nothing!” After just investing our life savings a year prior, I was a little ticked off with Chuck’s statement!

Fast forward several years later. After swallowing my pride and investing in consulting/ coaching, my business had grown several times over, profits were much higher, we had a great staff and even built a new facility. I was at the point that I was debt free and then able to build up a nice reserves account. Then I started pulling out cash for investments. Ironically, when good things come, they always bring new challenges. It seemed like every time I pulled money out of my business—bam, I would get a surprise bill, whether a piece of equipment needed to be replaced or an estimated tax bill was just around the corner, or even some large jobs were piling up in A.R., etc. All at once, I was now stressed with cashflow issues. Then I would end up dipping into reserves and move cash around to weather the storm. After the storm had passed, cash would build back up and I would then pay back the reserves account. Then maybe a month or two later, pull more cash out for investments, then—bam, another surprise followed by cashflow issues. It was just a vicious cycle.

Overall things were good, but I thought there just must be a better way! So, I did what most anyone else would do and Googled it! I searched for books on profitability. I was trying to figure out a way to pull profits out like clockwork and not have cashflow issues. Well, I ran across a book that probably 25% of those reading this column have already read. The book is called “Profit First” by Michael Michalowicz.

Yep, that’s right, the book is about taking your profit first and then paying your bills. Many of you are thinking, good luck with that!

Here is the deal, for my business I have nine actual bank accounts: Income, parts paint sublet, sales tax, owner’s compensation, profit, personal (estimated) tax, operational expense (OPEX), equipment and reserves. All incoming dollars, whether that be checks, cash, EFTs or credit card payments go directly into the income account. Then every week or bi-weekly (pending your payroll frequency), all funds in the income account are allocated to the other eight accounts. The income account becomes a giant serving tray. The other eight plates are the dinner plates. There are CAPs (Current Allocation Percentages) and TAPs (Target Allocations Percentages). Through an assessment process, you can determine your CAPS and then strive to reach your TAPs by cutting out waste, increasing sales & innovation, etc. There is lots more to this, but hopefully you get the idea. Disclaimer: I had an advisor help set mine up, as my time is too valuable to dilly dally. One of the coolest parts is, every month the money is there for sales tax, for parts paint & sublet, for my quarterly estimated tax, for payroll, for new equipment, for my paycheck and, most importantly my profit (it’s all mine!).

Some will say, I know how to read my P&L, have a good net profit, and don’t need anything like this. Here is my challenge to this thinking, can you take out a desired amount of money like clockwork and not affect your cash flow? The P&L is great way to manage our business, of course. Here is the catch, our P&L may say we made, for example, $40,000 last month in net profit, but where is that cash in our bank accounts?

In summary: If you read the book, but then put it back on the shelf, I encourage you to re-read it and then act. “Profit First” works in a $500,000 or a $500,000,000 per year business and I will NEVER run my business without this system. As far as Chuck’s statement to me decades back, I now fully understand that the sale of our business should not be our retirement fund. Rather it should be funding our retirement now. Fortunately, I was able to thank him recently. And he is also, by the way, a decamillionaire.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

27 April 2023 fenderbender.com

JOSIE SMITH PHOTOGRAPHY

COLUMNS SHOP PROFITS

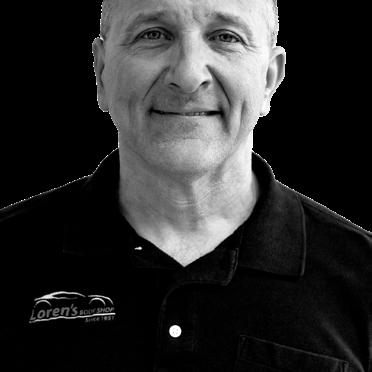

GREG LOBSIGER Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

By Todd Kortemeier

28 April 2023 fenderbender.com

Some kids just get lucky. Some people are still searching for their career path in high school, in college, or just after college—some of us are still looking. But for some kids, their destiny is pre-ordained if they want it.

That was the case for Samantha Welch. Long before her current role as an estimator at Key Collision in Rochester, New Hampshire, her grandfather inspired a career in automotive repair by putting a wrench in her hand at a young age. From there, the decision was easy.

“As I grew up I realized, you know, the more I look at cars, the more I wanted to get into it, and I finally just decided to go for it,” says Welch. “And it was one of the best options in my life to do.”

But of course, not every tech comes to collision repair like Welch. Some prospective employees have no experience with collision repair or even cars before starting their careers. That is, in essence, a good thing. The industry needs so many techs that no background can be overlooked.

But a background is more than just some words on a resume. Who are these technicians, and what do hiring managers need to know to attract them and retain them? To begin to answer these questions, FenderBender spoke to one of them, as well as some people who have seen enough of them to offer some insight.

Loving the Challenge

Even for someone like Welch, who had been interested in automotive repair nearly all her life, she still faced obstacles when it came time to choose a career. While her family was completely supportive, she says, friends were more skeptical.

“Some of them told me I’d never make it,” she recalls, “It’s a man’s field. I should do something more girly. But my family backed me 100% of the way and definitely helped push me through it.”

Welch was indeed undeterred, attending a technical high school near Corning, New York, where she was a standout student. She was a member of the National Technical Honor Society and was a finalist for the TechForce Foundation’s 2020 FutureTechs Rock Award in the collision repair segment. She won a SkillsUSA regional competition and placed fifth in the national event.

While in high school Welch started work as a detailer, which wasn’t really her strong

suit, she says. But she decided to go on to college and earned an associate’s degree in applied science. While she says all of it was “awesome,” estimating is what really stuck out to her and at the time of this reporting had been an estimator at Key Collision for four months.

“[In estimating] just like, everything changes, and you're constantly changing, and you're constantly trying to challenge yourself, it's a puzzle to get it all together,” Welch says “It's a puzzle to find every little piece you need, and help out the techs as much as you can.”

For Welch, the challenge is part of the attraction. But for others, they may not see the level of work that is involved to having success in collision repair. Identifying employees that want to take on that challenge to get better every day is a key part of recruitment, Welch believes.

“You never really know what you're getting into with each car,” Welch says. “It's always going to be different. And I've seen a couple of people come in, be really confident about it, and then they mess up one thing and now they're all down on themselves. And you can't get down on yourself, you have to keep pushing and keep pushing. You can't stop.”

Welch believes it’s important that prospective techs get exposed to what it’s like to work in a real shop early in the process, in high school. The opportunity to pursue an internship in a working body shop exposes that student to find out if this is really something for them or not. And if so, the shop then has an employee already in the building, ready to learn.

For that tech to want to stay there for the long haul, the culture also has to be right.

“There's been quite a few places I've worked that it's all work and strictly no fun,” says Welch. “And it gets kind of aggravating because you can walk in having a bad day or you can walk in having a good day, and just the mood of that shop, you know, kind of takes it down. But the place I work, that's nowhere near anything like that, like, we have fun, but we have fun while we're working. We lighten the mood. We laugh, but we also make sure we're getting our work done on time.”

29 April 2023 fenderbender.com

“Look for the ‘Give a Sh*t’”

Jaime Angell and Karin Ruser describe themselves as “work besties” with Caliber

Collision even though they come from very different backgrounds. Angell, regional vice president for Colorado, was like Welch, she grew up in collision repair as her parents owned a body shop. Such was the influence of cars in her family’s household that she had to rebuild a total loss in order to get her first car at the age of 16.

“The funny part is that made me say, I will never ever, ever work for a body shop, and I will never get in this business,” Angell says now. “And then I took a job while I was going to college at the University of Denver, at an independent multi shop here in Colorado, to work at part time that was working with my college schedule, and paying well, and I loved it, I ended up just falling in love.”

Ruser, operations specialist for the Colorado and Wyoming market, was from a completely different background. Her parents both worked white collar jobs and Ruser expected to go to a standard fouryear college and enter the corporate world. But college didn’t turn out to be what she thought it was, and she ended up taking a year off to figure out what she really wanted. It was during that time she got a job answering phones at a body shop. She gradually learned her way into other aspects of the business and developed a passion for it.

“Just kind of grew from answering phones, teaching myself how to write estimates, running the shop, upper management,” Ruser says. “And now I'm to the point where I want to give back. So, training and development and making sure that we bring our next generation out of body technicians and estimators.”

Though both women are now well established in their careers, the disparate backgrounds they came from are still common paths for technicians getting into the business today. Some have extensive experience and some have none. The challenge shop owners face today is how to identify talent in people with limited experience. Ruser has a simple formula.

“So, the first thing that comes to mind is I always say, you probably can't put this in print, but you always look for the, ‘give a s--,” she says. “You can teach the skill, but they need to have to give a s---. So, when we typically hire newer, not even necessarily younger, but newer people into the industry, because sometimes there is a second career in their development, they have to have that drive of, ‘I really want to be here, I want to learn, I'm

going to put my phone away for eight hours and just focus. So that's kind of what I look for when I'm looking for somebody to train.”

Though perhaps phrased more colorfully, it’s the same sentiment Welch shared about her experience coming up with other students. Those who are most excited about the work are the ones who are going to push through challenges and work to get better. And that starts with capturing their interest in the first place.

Angell gives an example of her father, who went to school to be a body tech, and that was what he did for 20 years. She contrasts that with techs coming up today who may want to move into another area eventually. So it isn’t enough to get them interested in one path, shops need to offer more to present a full career option.

“There's so many different options, there's so many different opportunities, that even if, let's say they struggle with doing mud work, but they've got a mechanical aptitude, we have a huge need for collision mechanics as well within the shops,” Angell says. “And so trying to kind of stay with them to develop them so that we capture their interest, because

a lot of the people coming into the business, it's more of a, once you get them there and they're captivated for a year, they can become lifers, but it takes a little bit longer to create that relationship and create that interest.”

Ruser cites an example of how no matter how much you try and recruit new techs, sometimes you find them in totally unexpected ways. She has had parents who come in as customers and end up asking for information they could pass along to their sons and daughters about how to get started in collision repair.

Angell cites an other example: She had a customer who herself saw the help wanted signs and decided collision repair might just be for her. It all comes back to capturing attention and being on the lookout for the right talent, in whatever form it takes.

“She said, ‘You know what, I want to get my hands dirty. I want to do this. It sounds super fun,’” Angell says. “And she was a customer at one of our locations a month ago. And she starts now and two weeks from today, in our technician apprenticeship program. So we'll get them from anywhere if they're the right person.”

30 April 2023 fenderbender.com

The View from Management Karin Ruser (left) and Jaime Angell (right) of Caliber Collision.

YOUR COMPLETE REPAIR SOLUTION

asTech®, Driven by Repairify™, simplifies your repair workflow by providing access to OEM and OEM-compatible diagnostic tools, ADAS insights and calibrations, and programming capabilities all from a single device.

REDUCE CYCLE TIME AND KEEP MORE SERVICES IN-HOUSE WITH ASTECH

From blueprint to post-repair scan, asTech is your partner. We provide the tools, diagnostic data, expertise, and insights required for a quality, fast, and safe repair.

DIAGNOSTICS

INDEMNIFICATION

CALIBRATIONS

INTEGRATION

The most accurate and cost-effective scan for every vehicle

Verified scans backed by warranty for liability protection

Tools and guidance to perform dynamic and static ADAS Calibrations

Seamless estimating platform integration and reporting

www.asTech.com or 1-888-486-1166 CONTACT US AT

UPHOLDING A GENERATIONAL

LEGACY

SHAWN CROZAT HAS HAD A WEIGHTY RESPONSIBILITY MAINTAINING & GROWING HIS FAMILY’S BUSINESS

By TODD KORTEMEIER / Photos By MARK SERR PHOTOGRAPHY

PROFILE

In the Family

All three Crozat sons hold leadership roles today at G&C Auto Body, with Shawn (center) serving as CEO.

In the Family

All three Crozat sons hold leadership roles today at G&C Auto Body, with Shawn (center) serving as CEO.

ike many shop owners, Shawn Crozat came to collision repair by growing up in the business. He didn’t enjoy school that much, he says. So, at 18 he decided college wasn’t for him and took a seat at the reception desk at G&C Auto Body, the business his father Gene started in 1972.

But Shawn didn’t get to enjoy a slow, methodical introduction to the world of collision repair. He got thrown into the fire right away when one of the shop’s estimators was injured in a car accident. That meant all hands on deck and an earnest beginning to what’s been a lifelong career.

“They threw me a clipboard and a Mitchell book, that’s how long ago it was, and said, ‘Well you’re an estimator now, dude,’” Crozat recalls.

Crozat’s role in the family business only accelerated from there. He opened his own shop at the age of 20, the second location for G&C Auto Body. Crozat had no experience remodeling a business, no experience managing a business, but his dad told him to go out and learn.

“It was just the school of hard knocks,” Crozat says. “I’ve made a lot of mistakes, I probably cried at my desk more than I would like. But, you know, learned from there.”

It’s fitting Crozat was involved in what was the company’s first expansion. His success in leading that second shop begat a third shop, and that was where the company stayed for a long time. Again came more learning, working through challenges, overcoming bad processes, growing in spurts to 11 locations by 2016.

That was the year Crozat’s father died, leaving big shoes to fill in both the business and their Northern California community. Gene Crozat was an icon in and around the North Bay region of the San Francisco Bay

Area, known for his radio commercials, charity work, and, of course, quality repairs. Guiding quotes from the family patriarch still dot the G&C website.

“When people ask me how long I’ve been in the auto body business,” one reads, “I tell them I’m in the people pleasing business.”

Taking over from a legend wasn’t easy, but the knowledge gained from both successes and mistakes helped Shawn expand the business to 15 locations by the time of the COVID-19 pandemic. Instead of retreat, Crozat took the time to re-examine the company’s processes and refine its leadership

team. Since September of 2020, the business nearly doubled in size with 14 more locations. Crozat says G&C is now the largest family-owned body shop business in the United States, and he knows exactly how they’ve done it.

“I think it really comes down to your people and culture,” Crozat says. “And I think that, I honestly know, we have the strongest leadership team and we have a great ability to build our own bench, and we’re very good at that, building our own leaders, our technicians, our own writers and we also have an incredibly good culture.”

34 April 2023 fenderbender.com

PROFILE

MAINTAINING CULTURE

The efficacy of that culture is right there when looking at the G&C team. Crozat says the business experiences very low turnover, and that’s not easy to do when talking about nearly 30 locations. Crozat credits the leadership team for maintaining company standards, which can get forgotten during times of growth.

Crozat reports the business is roughly 3% down in cycle time from pre-pandemic levels—”which isn’t good enough,” he says. For years G&C has hung its hat on the reputation of repairing cars faster than its competitors. But there are signs that is on its way back up,

as Crozat is able to quickly call up the numbers from the fourth quarter of 2022, showing they repaired cars 32% faster in December than they did in August. CSI scores are also back to pre-COVID levels or above.

“We just had to change our focus, had to figure out hey, look, we’ve gotten sick of the excuses,” Crozat says, “It’s really benefited us.”

That “no excuses” approach encapsulates Crozat’s business philosophy. There is no magic bullet process to fix any scenario if you don’t have the right people in place. The right people, culture and leadership will result in the right process.

G&C does what it can to routinely monitor its culture even with hundreds of employees across dozens of locations. Every six months the company sends out surveys to its employees to track not only that employee’s self-evaluation but their evaluation of the company as a whole. Crozat says the most recent survey, compiled just before Christmas, gave the company its highest scores yet.

“And I read every single one of [the surveys] twice,” Crozat says, “to look for every opportunity, how we can be a better employer but also learn from our people because they are the ones doing the work. And a lot of our best ideas come from our people, not our leadership, because they’re the ones down there.”

The extra appreciation for employees maybe stems in part from G&C being founded and still operated as a family business. Crozat says his mom, his two brothers, sister, cousin, two sisters in law and a second cousin all presently work in the business—“I think I got everybody,” he says with a laugh. The business has helped keep the family together.

35 April 2023 fenderbender.com

IT WAS JUST THE SCHOOL OF HARD KNOCKS, I'VE MADE A LOT OF MISTAKES, I PROBABLY CRIED AT MY DESK MORE THAN I WOULD LIKE. BUT, YOU KNOW, LEARNED FROM THERE.”

Golden Years

G&C Auto Body celebrated its 50th anniversary in 2022— Crozat family patriarch Gene founded the business in 1972.

—Shawn Crozat, owner, G&C Auto Body

Crozat offers the example of his cousin that he grew up with, who formerly lived in Sacramento, a two-hour drive or more away. He came to work for G&C more than 20 years ago and was able to move his family closer. G&C’s home base is like the center of the family universe.

“A benefit that I think about often is that so many people, you get a job and you got to go where that job is and it splits up families,” Crozat says. “You got to take the job, you got to move to this state or that state or this town or that town. So it’s cool to run this business. It’s kept us close.”

COMMUNITY RESPONSIBILITY

Crozat and his family also enjoy a close relationship with the North Bay communities they serve, in continuation of the legacy started by Crozat’s father years ago. That assistance has taken many forms over the 50-plus years G&C has been in business, but for approximately the last 10 years, a focus of charity outreach has been the Crozat Family Foundation. On the foundation website another quote from Gene is displayed:

“It is our responsibility to help our fellow men.”

The foundation does that through the gift of reliable transportation. G&C operates locations mostly in rural areas, where access to a car is a necessity as public

transportation can be scant. There is an application process to nominate a person going through hardship and the foundation gives away 24 cars per year. These are either donated through insurance partners or the company buys them, then performs the repair work to make safe, reliable vehicles.

The foundation is so much of a focus at G&C that there is a full-time employee that oversees it. Crozat says recipients are often people who have been the victims of domestic violence and are starting over with little. In addition to the car, recipients receive six months of gas and insurance, among other benefits.

Giving back to the communities the business serves in this way is something Crozat is proud of and something he hopes his dad would be proud of. He recalls learning at a 2021 National Auto Body Council meeting that G&C had donated the thirdmost cars in the country that year, behind much larger brands Caliber and CARSTAR in first and second, respectively. He still has a photo saved to his phone to prove it.

“We ranked third in the whole nation,” Crozat says proudly. “… So, it was kind of exciting for us to, you know, we’re very small compared to all these companies and I think giving back to our community is pretty damn important to us.”

36 April 2023 fenderbender.com

PROFILE

A Name that Stands for Something G&C Auto Body is well known throughout the communities it serves and strives to be a good citizen.

THE BASICS OF WEBSITE BUILDING

Your shop’s website should be clear, with all relevant info

By LEAH MARXHAUSEN

YOUR WEBSITE IS OFTEN the first line of communication between you and a potential customer. Making sure your website is effective and easy to navigate can determine whether a customer chooses you over a competitor.

38 April 2023 fenderbender.com

STRATEGY LEARN | GROW | WORK SMARTER THE SOP

GETTY

FenderBender spoke with marketing professional Danielle Wallace from Danielle Branding LLC to find out what unique elements you should include to ensure your collision repair website is effective and how to avoid a cluttered mess.

When designing your website, there are two things that every page should have. The first is an up-to-date list of your hours. The next is a clear link to schedule an appointment. Without these elements, your website is practically useless.

“In reality, [your website] only needs to provide a place for people to learn about your shop and schedule an appointment,” says Wallace.

While these basic features may be most important, adding in additional information can help show how your shop is unique.

Build Trust

Taking the time to include photos of your business can help increase the legitimacy of your business. Getting an inside look at the shop they have chosen can help reassure customers and remove any concern they may have on their way to the shop.

Photos of employees can help begin to build trust and put a face to a name should they have to contact the shop for any issues. This gives you the opportunity to present your shop and staff in the best light and establish trust before the customer even steps in the front door.

Another trust-building element is your shop’s rating on Google. Wallace surveyed her staff and they agreed that having positive

Google reviews heavily impacts where they decide to service their vehicles.

“Testimonials provide social proof that real people had a good experience at this shop,” says Wallace. “People like these people can relate with that.”

Listing awards or special certifications can also help your shop stand out from competitors and reassure potential customers that you provide service they can trust.

Prepare Your Customers

Taking the time to let your customer know what to expect before they arrive can help ease nerves that may come with visiting a shop for the first time.

“A lot of people are afraid to look stupid when they take their vehicle in for service because it’s unfamiliar territory,” says Wallace. Help make your shop feel accessible by providing detailed instructions for how and where they should drop off their vehicle. Another source of uncertainty comes with repair cost.

Adding a feature for customers to send in images of their vehicle or describe what repair is needed and receive a generic estimate lets them know what cost to expect and gives them the ability to price shop to find the best shop for their budget.

Keep it Clean

Adding detailed information can help legitimize your shop and build customer trust, but it’s important to know how much is too much. Checking in throughout the year to

make sure your information is concise and up-to-date helps prevent information overload and highlight what’s most important.

“What’s most important is that the website should be very clean and clear language and very easy to navigate,” says Wallace. “I think a big thing is if the website is not clean, if there’s too much information, people don’t know what the directive is or where they’re supposed to go.”

Organizing your information helps clean up your homepage and direct customers to your appointment scheduler, getting more customers in your shop.

“Take a look at all the information that you want to include and create a hierarchy for that information of what’s the most important,” says Wallace. “Not everything is going to make it to the homepage. Have your call to action front and center. Those two things are really important.”

Final Takeaway

Whether you are redesigning an old website or starting one for the first time, having it be well-organized is crucial. Update your website frequently to make sure you are providing accurate information to your customers. Listing any promotions you may be running and making sure you have up-to-date hours and photos helps present your shop in the best way possible. Your website is your virtual storefront, so make sure it’s something you can be proud of. You could be one click away from finding your next customer.

39 April 2023 fenderbender.com

FINANCE+OPERATIONS RECOGNIZING OUTSTANDING PERFORMANCE

Being genuine with employee recognition in the shop

By EMILY KLINE

HIGH TURNOVER IS very prevalent in the job market. As minimum wage increases and expectations of employee treatment in the workplace change, many people aren’t willing to stay at a job that underpays or underappreciates them. In the automotive industry the turnover is even more prevalent.

A major reason for high turnover in the automotive industry is the high levels of stress shop owners face daily while trying to meet quotas, as well as the frustrations that come with owning a shop.

40 April 2023 fenderbender.com

STRATEGY

GETTY

“Shop owners just don’t know a better way [to run their shop],” says Jill Meeuwsen, CEO of Synergy Peak Performance Thru People, a staff consulting firm. “They feel like they need to make a bottom line. And they’re frustrated with what they’ve been doing. So, they start being difficult and creating rough cultures.”

Therefore, the rough culture created in shops leads to a negative chain reaction.

“If you’ve got a poor culture, not only do you have turnover, but you’ve got poor efficiency, poor productivity, poor quality, all those costs are part of a poor business culture,” Meeuwsen says.

Employee recognition programs are one tool that can help change a negative culture. Instituting recognition programs is an easy way to motivate employees and to help them feel recognized when they work harder.

The rewards don’t have to be grand gestures; both Meeuwsen and DeWayne White, shop manager at Tom Bush Collision Center in Jacksonville, Florida, provided some examples of programs they’ve seen or implemented that help employees feel rewarded for a job well done.

Special Award Program

White recognizes his employees by implementing a special recognition award program.

“We have an Employee of the Year award, and we have an Employee of the Month award,” he explains. “But the thing that seems to stand out a lot is the Special Award. Somebody [in the shop] notices that [a co-worker] is going above and beyond their normal scope of duties. We then get everybody together and recognize him. It’s nothing big but it’s a group recognition. It’s in front of the whole shop and then there’s a little $25 gift card that goes along with it.”

White has noticed that his Special Award program has been the most effective employee recognition program for his shop.

“Since instituted, the majority of the shop seems to want to earn one,” White says. “When everyone is trying harder everyone wins, especially our clients.”

A Simple Thank You

Meeuwsen believes that sometimes just a simple thank you goes a long way.

“Some of my clients recognize great performance among employees by just putting a thank you note and maybe a Starbucks gift card or something in with their paycheck,” Meeuwsen says.

Bonuses

Meeuwsen also suggests bonuses for employees.

“My clients and I also talk about bonuses. Because it seems to be a very popular one. A bonus for a great performance or something like that,” Meeuwsen says.

Although bonuses are a great way to recognize an employee, it’s not always the best way. Meeuwsen talks about her own experience receiving bonuses.

“I’ll tell you in my entire career, within auto body, which spans about 30 years, I’ve gotten a lot of big bonus checks, great big ones. I don’t remember the bonuses,” Meeuwsen says. “You know if somebody gave me a trophy, I still got it sitting in my office, I’m looking at the trophies, right now. That for some reason I remember.”

Sincerity

When instituting employee recognition programs, it is important for employers to remember that sometimes genuine sincerity is more important than a prize. Sometimes an employer’s sincerity is more memorable than a stack of cash.

“It isn’t always about money. It isn’t always about public accolades. It’s really about appreciation. And sincere appreciation,” Meeuwsen says.

If an employer doesn’t know their employees, and just applies an employee recognition program because it’s another part of their job, the program won’t work.

“Recognition programs start to really impact when employees trust and believe what their managers or leaders are saying,” Meeuwsen says. “If they just think that somebody’s doing it because they must and it’s the deal of the day, it feels insincere. That hurts more than it helps.”

Get to Know Employees

It is important to know your employees. There is no ‘one-size fits all’ formula.

“Some people love to be publicly acknowledged,” Meeuwsen says. “Some introverted people cringe at that, so you can’t just call everybody out. [Don’t] think that every piece of fruit out there is an apple because we’re all different and what motivates us as people is different. [Therefore,] as leaders, you’ve got to be able to know your employees: What motivates them, what they like, what they don’t like. Because if you call someone out on something publicly, and it makes them cringe, have you gotten where you want to go? No.”

Be Purposeful in Conversations

A great way to get to know your employees is to be purposeful in your conversations with them.

“One of the things I have personally done is I try to start my day walking around the shop and talking with each individual about something other than work,” says White. “It starts out by saying, ‘Good morning, how are you doing?’ But then it gets into deeper conversations; you find out one of their kids may be sick or their mom’s visiting from out of town, it allows open conversation and that’s how I like to start the day.”

By talking to your employees and having conversations, you are validating them and showing them that you see them as more than just an employee.

“We have to remember everybody is somebody, right? They’re not just a body technician. They’re not just a painter. They’re not just a mechanic or a detailer,” says White. “Everybody’s got a life and you never know what’s going on in it, good or bad. So, it is important to find that out. It’s always important to make sure everybody’s getting recognition.”

Invest in Leadership

Recognition programs are a great way to improve culture within your shop. But it is important to remember that they are only successful if those in a place of leadership are sincere with their recognition. If an owner or manager does not know their employees and institutes a program that does not effectively work for the different personalities in their shop, then it is not effective.

“Invest in your middle and higher-level leaders in your organization, invest in their development. That’s the smartest money ever spent,” says Meeuwsen. “Because if those people that touch those other employees in your organization, if those people are doing it in ways like we’ve been talking about, your culture is going to be great. Your profitability is going to be five times what it would be if you didn’t do it that way. You’re going to be a destination employer.”

If employers are taught to ask the right questions, to be sincere, and to care, then everything else will follow. Employee recognition programs are important for the culture of the shop, but sometimes a simple conversation, a simple thank you from an employer can go further than a trophy or an extra couple hundred.

41 April 2023 fenderbender.com

CASE STUDY

TAKING YOUR SHOP TO THE NEXT LEVEL WITH REMOTE DIAGNOSTICS

Working with a remote provider means everyone can play to their strengths

By LINDSEY GAINER

THE BACKSTORY

Modern technology has changed the way cars operate in almost every way possible, ways auto experts even 30 years ago could never have imagined. And while these modern engineering feats provide us with capabilities beyond our wildest dreams, breakdowns in the technology systems of today’s cars mean a lot of work—and a lot of expertise—is needed to diagnose and fix them. That’s where remote diagnostics comes into play.

The Problem

Modern vehicles present unique challenges to a collision shop that their predecessors never did, mostly due to their ADAS and electronic components. Manufacturers now install upwards of 150 million lines of code in a car’s software—and that code requires high-level scanning equipment and expert diagnosticians to troubleshoot.

“Historically when a car’s been in an accident and is brought to the collision shop, you could see what’s broken, see what’s damaged,” says Chuck Olsen, senior VP of automotive technology solutions for AirPro Diagnostics in Jacksonville, Florida. “You see it and you fix it. But now, with electronics, there could be so many things wrong with the vehicle that you can’t necessarily see without a diagnostics scan.”

42 April 2023 fenderbender.com

STRATEGY GETTY

The tools needed to perform such a scan—and then reprogram and calibrate the car—are incredibly expensive, however, and many shops don’t have the bandwidth or expertise to carry them out in-house. It’s not lack of skill, Olsen points out, but rather the specialized nature of technical repair that makes it impossible for any one employee to master the full spectrum of diagnostic assessments. With over 60 automotive brands and countless models on the road today, it’s no longer practical to apply a “one size fits all” approach to diagnostics.

“If you don’t specialize in just one or two car brands, the problem multiplies from there,” he says.

And, for many shops, employing a diagnostic technician full-time just isn’t feasible in the first place.

“Depending on the size of the shop, you may not have enough work to gainfully employ a high-level diagnostic technician for a full 40 hours a week … you may only need that person 15 hours a week, for example,” he adds. “And, normally, technicians in that category, you’re not going to find them in a paint booth or fixing body issues, because that’s just not their skill set.”

That’s where remote diagnostics comes in, Olsen says. Rather than having an employee distracted by doing something outside their normal duties, utilizing remote technicians allows everyone to do what they do best.

“Collision repair, getting a vehicle straight, painting … that’s an art in and of itself,” Olsen says. “Being an electronics guy, a diagnostics guy, I would never, ever attempt to do that side of the repair. I would make a mess. Those guys are true artists in their own right, so there are different skill sets that need to be there, and you need both equally these days.”

The Solution

When shops partner with a remote diagnostics company, they benefit from access to the collective diagnostic power of a team of specialized experts.

“We don’t expect our technicians to be able to run diagnostics on every make and model of vehicle,” says Olsen. “That’s unrealistic. Instead, they’re specialized by brand or manufacturer with maybe one, two, or three skill sets.

“Our process is very straightforward; however, each step is not always easily achieved. Damaged vehicles can induce faults in areas not normally encountered by routine maintenance or component failures. This means the technician’s thorough understanding of what was damaged and repaired from a collision is critical in diagnosing and repairing faults. Access to high-level vehicle scan tools and service information is a must too to look in the right areas.”