1 minute read

2.2 STRUCTURE DETAIL

by Alex Xie

The experiment uses the slime mold algorithm to form an adherent slime mold structure to form an optimized material saving and robust biomimetic structure.

This structure apply with carbon fiber reinforced polymer material with on site 3D printing set up, with reinforced rebar as secondary structure.

Advertisement

2.3 MATERIAL

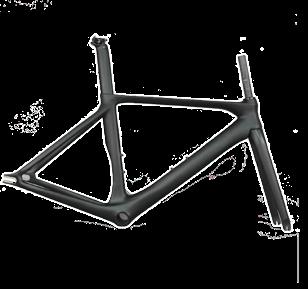

Carbon Fiber-Reinforced Polymer (CFRP)

CFRP is a new technology material with strength close to steel and weight similar to plastic. "Carbon fiber reinforced polymers have a specific strength that is almost 2.6 times greater than the strongest steel (maraging steel) and almost 3.6 times the specific strength of aluminum 7075-T6." CFRP has high fatigue strength per unit of weight, thus helping to improve safety, fuel economy, and durability. Emerging applications of CFRPs include medical devices, submarine and marine applications, offshore oil and gas pipelines, electric power transmission lines, the rail industry, and new bridge structures. CFRP would be a good choice for rainwater harvesting and flood buffer structures due to its high corrosion resistance.

Cfrp Recycle Process

PLASTIC WASTE RECYCLED PLASTIC

CARBON FIBER WASTE

CFRP 3D PRINT MATERIAL RECYCLED CARBON FIBER

CFRP is a new type of recyclable material that is expected to reach the same mature and fast recycle industry as steel and aluminum in the future. Although the cost is higher than metals per kg, but it has higher density and recent advances in composites are helping CFRP to be more competitive and cost effective. Due to it's durability, it provides a sizable cost benifit in operation and maintenance cost. With mature recycle process, large volume of production and advanced production technology and software, the industrial level carbon fiber raw materials available at $13.8/kg by 2017 with reducing 15%-30% by 2020 and going to get cheaper in the future.

While CFRP has extreme corrosion and fatigue resistance, carbon fiber can cause galvanic corrosion when attached to aluminum or mild steel rather than stainless steel or titanium. Adding a coating to the surface prevents this, making the material live longer. Oxidized coating technology is applied to the material surface to make the materials have better environmental adaptability.