22 minute read

Best practice: Digitising the SVS

by medianet

Hans Aubauer, Director General of the Social Health Insurance for the Self-Employed (SVS) on the necessary transformation from a paper plane to a digital high flyer.

The Social Health Insurance for the Self-Employed (SVS) is the representative of the insurance sector and public services, and is like so many others right in the middle of the digital transformation. Consolidating existing systems, a fortunately growing number of clients and the creation of digital channels for customer services are some of the challenges that the SVS has to tackle. The SVS considers digitisation a holistic project as it wants to continuously reach out to customers with preventive measures and medical services in a digital way. Implementing this service channel for social security sounds trivial but is anything but easy in an industry that does not always have regular contact to its target group.

Advertisement

Digitisation is not purely an IT issue to the SVS. Efficiency also matters, of course, but the aim is always to free up more staff for customer consultation. Director General Hans Aubauer offers more insights.

When did the SVS start its digitisation process? The kick-off was in 2015. Since then, we are pursuing a consistent digitisation strategy within the SVS. The predecessors SVA and SVB were strong, long-standing social health insurance carriers. At that point it was necessary to set a new course to seize the chances and opportunities of digitisation in order to facilitate direct communication with our insured. We wanted to turn our administrators into customer consultants.

The new technologies give us a new scope. We have the opportunity to reach a whole new service and communication level which has not been possible so far. We have always looked at digitisation in a holistic way. On the one hand, we have updated internal processes, organisation and internal IT systems, and on the other hand, we took the contact to our customers to a new level. We have launched a website that increased the usability of our services dramatically and we created incentives to establish it as our primary communication channel. An app, a chatbot and other features followed. Our internal motto was: No more paper. That means: digitise files, update the core system.

The Covid pandemic proved our efforts right. It was an unplanned litmus test that we passed with flying colours. We guaranteed the social security of 1.2 million Austrians. Despite the increased demand, we were always available to our customers. Communication moved from direct, personal communication on location to digital channels. We had the infrastructure already available.

What does this infrastructure encompass? Users only see the app on their phone or the chatbot “Fritz” on the website. There surely is more? You need an integrated channel concept. All elements need to interact perfectly. The three elements digital, telephony and

© SVS © xxxxxxxxxxxx

Hans Aubauer, Director General of the Social Health Insurance for the Self-Employed: “Our internal motto was: No more paper. That means: digitise files, update the core system.”

personal contact are all interconnected. Routine questions can be answered anytime from anywhere digitally. If a more intensive, individual contact is needed, the first step is via telephone and then with personal consultation and advice. Everything goes hand in hand. Our customers are taken care of completely.

The second dimension is the one that our customers don’t see. Internally we call it “production”. It is the basis for services and takes care of our internal processes. We use artificial intelligence to recognise, to evaluate, to extract and to collate. We increase the automation of standardised processes and rely on the interplay of humans and machines. Thanks to the automation of routine tasks, our experts have more time for personal consultations.

What triggered this development? Did you simply want to keep up with the times or did you really run into the danger of going under with too much paperwork? We had a mountain of files – 21 kilometres long, which would get you from Vienna’s city centre to the airport. So, yes, mountains of paper were one reason. But we also needed technological updates and saw the incredible potentials that the digital transformation and the use of new technologies offered.

The SVS has the same DNA as self-employed entrepreneurs: We want to constantly develop ourselves further, we want to be better and adapt to new situations. We see ourselves as a modern service provider. Our 1.2 million customers demand this as they face competition out there every day and act accordingly.

It is a mixture of the pressure to be innovative as well as the will and the delight in change and modernisation.

Were you able to do this all on your own or did you have external help? If so, in what way? Yes and no. The defined goal, the strategic direction and the guidance comes from the SVS in the first step. When it came to

development and implementation, we also used external capacities. There are different models and concepts for cooperation: From classic service agreements to PPP models.

Which are the technological highlights of the new digital SVS? What are they for? We are particularly proud to have reached a new level of availability and service. We increased the transparency and consider our insured our customers. “SVS-Go” is a kind of state-of-the-art digital banking for social health insurance. Submitting the bills of your Wahlarzt [N.B. a non SHI-accredited doctor of your choice, whose bill gets fully or in part paid by your health insurance in Austria] is done as quickly and easily as transferring money online. Then the digital processes in the background come into play. It only takes a few days until your money is in your account. We were able to prove our digital agility during the Covid pandemic when processing the bridge financing for artists for the federal government. The subsidies were usually in people’s accounts after four days. We completed this task quickly, efficiently and with the nous of a service provider.

Internally, we upgraded our mailroom with artificial intelligence. It automatically assigns tags with a high recognition rate and the corresponding allocation. The AI also identifies callers and provides our call centre agents with information on the customer.

Data is often considered a company’s crown jewels and the SVS has a lot of it. Do you plan on doing something with it one way or another? Using data in the health system would be unethical. Data and the corresponding data usage serve individuals and society. This goes for our medical services but also for customer communication servicing. Customers benefit when their telephone number is recognised and our agent immediately knows who he is talking to while having access to all relevant information. Out health centre offers patients with high blood pressure an app for constant surveillance and analysis. We use his blood pressure data to provide the best individual health service. Our pacemaker programme reads a pacemaker’s data out once a day and transmits it. It discovers atrial fibrillation instantly and prevents a possible stroke.

We have a lot of new programmes in the concept or pilot phase such a sick day consultation and an evaluation of risk data in security consultation.

When it comes to our data strategy, we are at the same point as we were in 2015 with the digital transformation – we are starting into a new future. It goes without saying that the data of our customers has to be secure. Health and pension data is sensible data – like bank data. Therefore, we are treating it the same way. Data protection and data security have the utmost priority.

And how have you secured this data? Thinking of cyberattacks… Our datacentre is a specialist service company. We use a stateof-the-art approach with regular checks and tests such as intruder attacks.

How is artificial intelligence used in social health insurance exactly? How and where is it used? Admittedly, when most people think of artificial intelligence, they have science fiction films in their mind and might imagine several robots in the mailroom who have been hacked by the baddies to create chaos… But on a

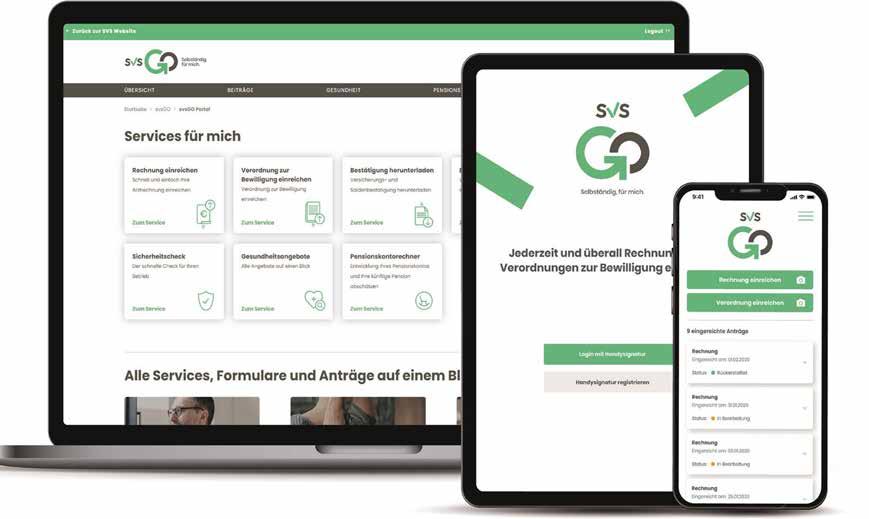

The SVS’s online presence: Clear and easy to use. Often complex background processes ensure a smooth operation.

more serious note, how long do you have to test an AI before you can release it on staff and customers? There are many myths surrounding artificial intelligence. In reality, an AI simply helps to relieve staff from routine tasks. We do use AI, for example, in our mailroom. Artificial intelligence supports staff in granting medicinal products, for example. However, this is always done under strict quality assurance by our staff.

Is your digital transformation finished now? Or is it a case of the journey being the destination? What’s next? We have already reached a very high level of digitisation with our systematic digitisation strategy. But that is no reason to stop and rest on our laurels. It is our mission to continue. This transformation will probably never end as technologies advance and with it the opportunities that arise.

We will continue to develop our automation and we want to develop customised solutions and individual offers through CRM (Customer Relationship Management). There are also tremendous potentials in medicine. Digitisation and data usage help in switching from curative to preventive medicine.

Imagine, the digitisation fairy is stopping by, Mr Aubauer. What do you wish for? I would wish for an innovation-friendly environment in Austria that always asks first about advantages and benefits of solutions. Public service can, should and needs to be a driver of innovation and as well as being a trailblazer.

And how do you see yourself or the SVS, respectively, in that context? At the SVS we are pursuing the fast follower strategy and see ourselves in a European and global context. In certain areas we aspire to be an innovation leader. That makes us a hidden champion of digitisation in the public sector. And we are very proud of this. ◆

We export safety

With intelligent, sustainable solutions, new ideas and innovative concepts, TÜV AUSTRIA makes the economy and society safe.

Digitisation is pervading business and society fast. Existing business models are changing forever and completely new ones are springing up. But both only have a future if they are safe and secure. And TÜV AUSTRIA is making sure they are. What’s more, the company pro-actively and creatively supports customers in leveraging growth potential and thus makes an important contribution to ensuring that digital business models are not only secure, but also successful. Why is TÜV AUSTRIA able to do this? Quite simply because TÜV AUSTRIA has always been much more than a testing, inspection and certification company.

Thanks to its comprehensive understanding of the tasks and challenges customers face in an increasingly networked working world, TÜV AUSTRIA is in a position to develop appropriate solution packages that go far beyond individual tests. In addition, the internationally active group of companies has positioned itself in the best possible way in times of digital transformation, is constantly expanding its own technological position and is continuously optimising digital solutions, for example with test apps, artificial intelligence for modern test procedures, test solutions, inspection logs, the online assistant tami, and OT and IoT security for networked industrial plants. TÜV AUSTRIA’s own systems house SPP complements the portfolio with individual software solutions in the field of e-commerce.

Facts & Figures TÜV AUSTRIA GROUP

The solutions offered by the independent TÜV AUSTRIA Group range from cyber security, IoT, robotics, OT security and artificial intelligence to lift technology, pressure equipment, plant safety, materials testing, education and training, medical and electrical engineering, environmental protection, Industry 4.0, Production 4.0, carbon footprint evaluations, staff, system and product certification. With locations in 27 countries, the leading Austrian testing, inspection and certification company also provides solutions such as e-mobility, loss adjusting, real estate management, calibrations, product testing, technical due diligence and legal compliance checks, testing of photovoltaic and wind power plants, hygiene (water, soil, space, air) and COVID-19 prevention.

tuvaustria.com

Labs for cybersecurity and functional safety

TÜV AUSTRIA established its own Safe-Secure System Lab in Vienna for testing cyber-physical systems with regard to functional and IT security. The interdisciplinary TÜV AUSTRIA #SafeSecLab, a major cooperation with the Vienna University of Technology, makes a significant contribution to increased integrative safety. In Cologne, TÜV AUSTRIA maintains a lab for security analyses of software and hardware architectures of IoT devices and, in cooperation with the consulting firm DHGP IT-Services, a Certified Security Operations Center (CSOC), which is tailored to the individual needs and requirements of medium-sized companies. With the integration of CIPHRON, a specialist IT service provider from Hanover, TÜV AUSTRIA is strengthening its comprehensive services for IT security in companies and public authorities. In Malaysia, the company operates the TÜV AUSTRIA Cybersecurity Lab with LGMS, one of the world’s leading providers of IT security services, for testing and certification in the Asia-Pacific region. TÜV AUSTRIA is also the first company worldwide to certify AI applications – a result of several years of cooperation with the Johannes Kepler University in Linz.

Austria’s most modern testing and research centre

For TÜV AUSTRIA, modern testing and inspection services are always the result of its own research activities. The company has therefore been investing for years in the expansion of corresponding infrastructure, additional qualifications for employees, new hires and collaborations. It started with the construction of a new office building in Vienna-Inzersdorf and the creation of a state-of-the-art working environment for employees, training guests and customers. The EMC Hall, the hall for product safety testing and the Safe-Secure-System-Lab with special services for IT and data security were a first strong signal for the new research and innovation location of TÜV AUSTRIA in Vienna. With the expansion of the Technology & Innovation Center in Vienna, another important development step is now being taken, which will put TÜV AUSTRIA in an optimal position for the challenges of the future. State-of-the-art test halls and laboratories are currently being built for the areas of automotive and e-mobility, materials technology, environmental technology and digital testing services.

TÜV AUSTRIA is thus guaranteed to have the right solution for all the safety technology requirements of its customers - but also for partners from research and development collaborations.

Sustainability and clean technologies

Environmental protection has long been part of every company’s daily routine. This is a factor that often has a significant impact on costs. At the same time, competitiveness must not be lost. The challenge is therefore to combine effective management with the conservation of resources and the environment. Key words here are “sustainability” and “clean technology”. With its integrated solutions, various authorisations and accreditations, experience and, last but not least, the expertise of its employees, TÜV AUSTRIA is able to provide its customers with tailor-made support in the implementation of these measures. TÜV AUSTRIA itself attaches great importance to environmental protection and resource conservation. With sustainable buildings, green electricity from Austria, heat from woodchip plants, modern climate control, LED lighting, PV systems, waste avoidance, the promotion of electric mobility and business trips by train, the company makes its contribution to carbon reduction.

Expand market positions, open up new markets

TÜV AUSTRIA’s acquisitions and participations in companies are not only a perfect match for the Group’s diversity, but above all for its solid growth strategy. The aim is always to find solutions for local challenges and to develop existing customer relationships horizontally. At the same time, TÜV AUSTRIA is increasingly integrating its solutions vertically – a great advantage for companies with globally distributed production and development sites, which TÜV AUSTRIA supports with safety technology throughout the entire project life cycle, regardless of loca-

© TÜV AUSTRIA, Osmond

Fong Choong-Fook, LGMS Group; Detlev Henze, TÜV TRUST IT; Michael Post, Austrian Ambassador to Malaysia and Brunei with Stefan Haas, CEO TÜV AUSTRIA Group (from left) at the opening of the TÜV AUSTRIA Cybersecurity Lab.

tion. More than 50 companies in 27 countries in Europe, Asia and the Middle East now belong to the TÜV AUSTRIA Group – with a comprehensive range of services in the areas of safety, technology, environment and sustainability, quality management, as well as training and further education. After growing against the industry trend in the crisis year 2020 to 230 million euros, TÜV AUSTRIA Group is aiming for a turnover of around 250 million euros for the business year 2021.

With the strong TÜV AUSTRIA brand, a unique networked range of services, local presence, competence, reliability, team spirit and innovation, the TÜV AUSTRIA Group creates decisive added value for customers and partners. It exports safety. From Austria to the whole world. For 150 years.

© TÜV AUSTRIA, Andreas Amsüss © Georg Trummer / Andreas Amsüss, TÜV AUSTRIA

Austria’s 6G research is state-of-the-art in every way

6G for signal processing in high frequency systems, machine learning and unlimited data transfer.

Whenever a new technology is introduced, somebody is already working on making it obsolete again. Silicon Austria Labs (SAL), Austria’s top research centre for electronic based systems, is working in Linz, one of its three locations, together with the Johannes Kepler University (JKU) on key technologies for the wirelessly networked factory of the future. Reliable wireless networking of the production systems is intended to enable highly efficient control of production using digital twins. “Linz should become a centre for 6G in Europe for industrial applications. This collaboration between the JKU, SAL and subsequently with industrial partners also strengthens Upper Austria as a production location,” emphasises Markus Achleitner, Regional Councillor for Economic Affairs and Research.

“The innovation location Upper Austria wants to shape the digital transformation – a central field of action of our Upper Austrian business and research strategy #upperVISION2030 – and be at the forefront. By using the latest technologies such as 5G and 6G in production, our flagship companies can continue to produce competitively and sustainably in Upper Austria in the future. This keeps the added value in the country and secures highly qualified jobs”, says Achleitner.

Focused cooperation

The idea behind the “University SAL Labs” is the focused cooperation with universities on key topics for electronic based systems. Researchers from the University and SAL conduct basic-oriented research in the lab, which can later be implemented in collaborations with industry. “Silicon Austria Labs was founded to conduct international cutting-edge research and to strengthen the Austrian electronics industry and the entire EBS eco-system. The cooperation with first-class researchers from JKU in the field of radio frequency technologies and artificial intelligence is a central part of our strategy,” says Gerald Murauer, Executive Director of SAL.

In addition to JKU Linz, SAL is also working with TU Graz and the University of Klagenfurt in such joint research labs. Several JKU institutes participate in the research labs. “Only those who think one step ahead can shape the future. This cooperation is supposed to do just that: 5G is here now – so we want to think about 6G today, conduct our research and thus shape not only the technology of tomorrow, but also its effects. It is a holistic

© JKU

Although 5G is just now reaching market maturity, research on 6G is already underway.

approach that goes beyond the technological implementation. This is what JKU and the LIT, the Linz Institute of Technology, stand for with their interdisciplinary approach and proven technical know-how,” says Meinhard Lukas.

High-frequency technology meets AI

Radio frequency systems provide the physical connection for wireless communication systems. This enables mobile broadband connection of mobile devices, wireless “machine-to-machine” communication and increasingly wireless sensor networks in industrial applications. “Radio frequency technology is the technological backbone, especially for digital applications in the areas of 5G/6G, autonomous driving, medical technology or material testing. While 5G is only just getting market-ready, we are already researching the next generation, 6G,” explains Thomas Lüftner, CTO and Head of Research Divisons RF Systems and Embedded Systems at SAL. “New with 6G is the targeted use of embedded machine learning, i.e. artificial intelligence, for signal processing in radio frequency systems. With our joint labs with JKU, we are now at the forefront of international research in this area,” explains Lüftner. The focus on radio frequency technology in combination with artificial intelligence is well located in Linz, as Upper Austria has been operating very successfully in these areas for years.

The labs involved

Researchers at the mmW Lab will work together to drive research on millimeter-wave technologies, meaning in the frequency range of 100 to 300 GHz, both of which are used at high data rates in short-range radar and wireless communications. The mmW Lab is managed by Gernot Hueber (SAL), Andreas Stelzer (Institute of Communications Engineering and RF Systems, JKU), and Harald Pretl (Institute of Integrated Circuits, JKU). The interdisciplinary Lab team works primarily on the 6G objectives that include converging communications, radar and high-frequency sensor technology, meaning semiconductor chips containing integrated high-frequency circuits and the correlating system solutions.

The eSPML Lab will focus on new approaches to combine signal processing and machine learning with integrated circuit design to boost performance, be more cost-efficient and reach new levels of performance and capability in the area of embedded solutions. The Lab is managed by Mario Huemer (Institute of Signal Processing, JKU), Thomas Pleschke (SAL) and, lately, also by Pedro Julian (SAL). SAL was able to win the internationally renowned Argentine professor, Pedro Julián, as head of the research unit “Embedded Artificial Intelligence”.

Internationally renowned top researcher

Prof. Pedro Julián, an internationally recognised researcher, has recently joined as the head of the research unit “Embedded Artificial Intelligence” at Silicon Austria Labs (SAL) in Linz. Julián has been working on the implementation of neural networks in digital hardware (“Neuromorphic Computing”) for 20 years and has also worked at the University of California Berkeley and Johns Hopkins University in the US state of Maryland, where he still holds a position as visiting professor. Before joining SAL, the native Argentine was a professor at National Del Sur University in his home country.

At SAL, he and his international team are now dedicated to the research topic “embedded artificial intelligence”, a new and highly innovative research field with high growth potential for domestic industry – and an essential part of 6G research, which has been carried out at SAL in Linz for almost two years. The targeted use of artificial intelligence for signal processing in high-frequency systems is new at 6G. This is intended to reduce complexity, costs, and energy consumption of today’s electronic-based systems.

“With Pedro Julián we were able to find a renowned professor

mmW Lab

A world-class millimeter wave RF laboratory and test facility paving the way for the RF PHY technology convergence for next generation of sensing and communications up to the high GHz frequency range (30 GHz to 300 GHz) by combining research forces, know-how, infrastructure, and expertise in a joint lab growing PhDs, tenure tracks, and scientific progress of the stateof-the-art jointly done by JKU and Silicon Austria Labs.

We are working on advanced signal processing and integrated circuit design concepts targeting competence to realize class leading integrated circuits on component and SoC level and provide corresponding advanced signal processing methods and algorithms. By making use of circuits and signal processing methods for wireless communication (e.g. 5G and mmWave RFID) and radar systems shall be targeted. System integration aspects in RF and mmWave frontends must be considered and will be correspondingly handled. For wireline systems, again energy efficiency, interconnect density, and multi-Gb/s data transmitters are current research topics.

Lab Management:

c Gernot Hueber (SAL) c Andreas Stelzer (Institute for Communications Engineering and RF-Systems, JKU) c Harald Pretl (Institute for Integrated Circuits, JKU)

In close cooperation with: c Institute for Communications Engineering and RF-Systems,

JKU Linz c Institute for Integrated Circuits, JKU Linz

© SAL

The mmW Lab team: Gernot Hueber, SAL (centre) with JKU Linz members Harald Pretl, Simon Heining, Georg Zachl and Andreas Stelzer

The eSPML Lab team: Sepp Hochreiter (JKU Linz), Robert Wille (JKU Linz), Markus Hofmarcher (JKU Linz), Venkata Pathuri-Bhuvana (SAL), Simon Schmid (JKU Linz), Lothar Ratschbacher (SAL), Christian Huber (SAL), Gorgoe Bognar (JKU Linz), Andreas Springer (JKU Linz), Thomas Pleschke (SAL) and Mario Huemer (JKU Linz).

for our future-oriented research topics,” says Thomas Lüftner, CTO and head of research divisions RF Systems and Embedded Systems at SAL, on the new addition to his team. “I am convinced that Professor Julián and his extraordinarily diverse team of researchers from four different continents and different disciplines will take our 6G research to the next level. Our partners from the industrial sector, with whom we work on various projects, benefit from this in particular.”

Pan-European cooperation

But not only SAL and the JKU are busy working on 6G: A European consortium has joined forces with regards to future mobile communication standards and develops the next generation of antennas for wireless networks. NXP, Technikon and the Graz University of Technology are major contributors.

In Europe, all eyes are currently on the 5G roll-out – yet a European consortium consisting of leading companies and re-

eSPML Lab

The embedded Signal Processing and Machine Learning (eSPML) Lab is chartered to research with two main focuses: 1. data-driven machine learning algorithms to complement and/ or replace model-based advanced signal processing algorithms and 2. related novel embedded implementations through applying digital, mixed signal and/or analog integrated circuit design in new ways.

Machine Learning, Neural Networks and Deep Learning approaches are meanwhile becoming increasingly prominent in various computer science and circuits and systems societies, where system identification and dimensionality reduction are the challenge. The underlying idea of this lab is to bring diverse, yet complementary skillsets in these fields together to jointly achieve solution inspiring research results. The vision of eSPML Lab is to research and develop a new basis for paradigm shifting signal processing solutions changing the industry. The Lab combines machine learning and signal processing with novel integrated circuit design approaches to make leaps forward – in terms of power as well as cost efficiency and to reach yet unachieved performance and capabilities of embedded solutions.

Lab Management:

c Pedro Julián (SAL) c Mario Huemer (Institute for Signal Processing, JKU)

In close cooperation with (all institutes JKU Linz):

c Institute for Signal Processing c Institute for Machine Learning c Institute for Communications Engineering and RF-Systems, c Institute for Integrated Circuits https://research-network.silicon-austria.com/espml-lab/