2 minute read

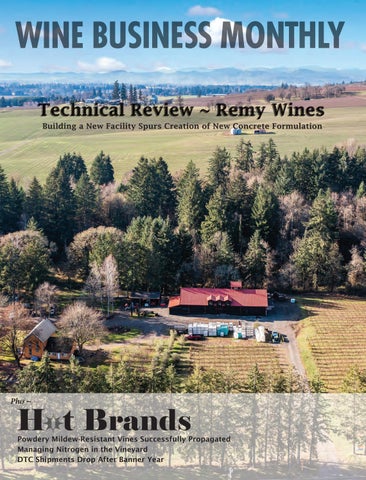

Technical Review ~ Remy Wines

pyrolyzation process again) and a solid but porous substance that looks a lot like charcoal.

To further sequester these sources of atmospheric carbon and other gases, the biochar needs to find an economically viable use. It has been used in agricultural applications for years because it can be buried in the ground, which removes it from the carbon cycle and also makes the soil better able to retain water and nutrients. Alternatively, “it turns out building with concrete is one of the things that’s happening on a big enough scale to make a difference for our atmosphere,” said Mead.

The challenge with developing a biochar-laced concrete for structural purposes was getting a building owner to accept the risk of using it. It’s difficult to be the first to try an experimental product—especially if that product is a foundational component of a very expensive construction project. But Drabkin signed on as a partner from the get-go, and Mead put the wheels in motion to develop what would become known as the Drabkin-Mead Formulation.

Mead knew that Bernert had been working on strategies to get the carbon footprint of concrete as low as possible. The two started comparing notes and came up with the technical pathway of using biochar in concrete. They reached out to other people, including experts at Holcim, Oregon State University and the Athena Sustainable Materials Institute, who offered advice, reviewed technical specifications and helped them refine their plans.

One of the people they contacted suggested using a specific type of biochar called Our Carbon in their formulation. While biochar can be made from many things, this one come from drying and pyrolyzing municipal waste, which includes both human and food waste, Drabkin said.

For her, using biogenic carbon would help with another problem beyond the need to shrink concrete’s carbon footprint. Due to her time in elected office, she was acutely aware of the cost for disposing of food and human waste. Her small town recently signed a seven-figure contract with a company that provides waste disposal services. If this waste could be transformed into a resource, it would save cities a tremendous amount of money. Those dollars could then be reinvested in the technology to dry and pyrolyze waste.

“My lens isn’t just wine,” said Drabkin. “I’m always thinking about how we fold things into larger system.” While it wouldn’t make sense for all cities to invest in the technology to create biogenic carbon, they could become part of cooperatives or regional partnerships that run the machinery and return the finished product to communities. With a ready source of biogenic carbon, cities could then rewrite their design standards to require carbon-fixing concrete in municipal projects—and provide the biogenic carbon and instructions for using it at little or no cost to contractors.

“It creates this closed loop where the city can say, ‘You have to use a carbon-neutral product, but we’re creating the source,’” she said. “You can put an RFP out to your normal suppliers, so you’re not cutting anyone out.”

Mead and Bernert sourced their biogenic carbon from the Bioforcetech Corporation in California. They were delighted to find that its addition improved the concrete’s performance as well. “When we started doing our tests, all of a sudden our concrete was setting faster and testing harder,” and performing on par with conventional products, said Drabkin. Those results remained consistent even as the concrete was exposed to a variety of stressors,