1 minute read

Technical Review ~ Remy Wines

CELEBRATING over 75 YEARS of COLLABORATION

with the best consulting winemakers in the world: Bordeaux, Rioja, Stellenbosch, Sonoma and Napa Valley.

including heat, cold, abrasion and submersion in wine and cleaning chemicals. (The biggest test that remains, Drabkin pointed out, is the test of time.)

The performance benefits of the Drabkin-Mead Formulations are in active research right now, Bernert said. “What we can definitively say is the biogenic carbon increases the durability of concrete because of a mechanism called internal curing. Cement needs water to be hydrated. Once you combine cement and rocks, you add water and that makes it stick together.” As the concrete sets, that water begins to evaporate, and it leaves the concrete at the top more quickly than it does in the middle. That causes faster shrinkage on the outside edges of the concrete than in the middle, which can weaken the finished structure.

“The beauty of using biochar in concrete is it absorbs massive amounts of the water,” said Bernert. “It’s two times greater than lightweight sands that are specifically added to concrete for their water absorption capacity. That water slowly leaves the biochar and hydrates those cement particles, so you get uniform hydration.”

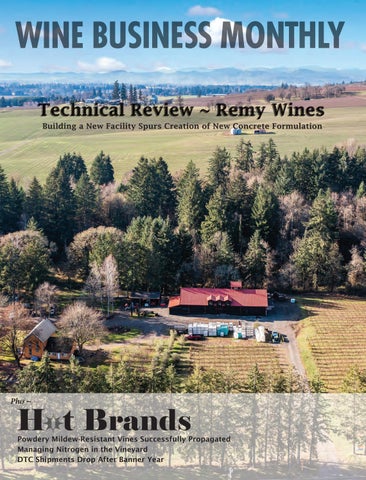

Mead said working with the concrete, which makes up the 5,000-squarefoot slab floor at Remy Wines, was easy. “The concrete went in like any other concrete. The fact that it was different was not obvious when you think about things like the workability, the transport and getting in through the concrete pumps. The Solid Carbon adds a little bit of pigmentation, but other than the color, it behaved like any other concrete.”

The biggest difference is its impact on the planet. “Remy’s slab sequesters over 10,000 pounds of carbon dioxide,” Mead said, and should do so permanently.

From the beginning, the team planned to make the Drabkin-Mead Formulation open source so others could copy it. “We weren’t looking for a product to keep close to our chest and capitalize on,” said Drabkin. “We were looking for a product that could make a real impact on the environment.” Anyone interested in learning about the formulation can get technical specifications on the website for Solid Carbon, a new joint venture by Mead, Bernert and others to create zero carbon concrete products in the built environment.

Bernert said he can’t stress enough how important her commitment was to making the project happen. “Her courage allowed us to demonstrate we can do this. That Remy was willing to take a risk means every project after this is easier.”

For her part, Drabkin said it felt like the right thing to do. “I believe that we really all can make a difference,” she said. “Sometimes you just have to do that. You have to show people it’s possible.” WBM