2 minute read

Coverall selection — handling harmful substances

COVERALL SELECTION

HANDLING HARMFUL SUBSTANCES

Drew Dauncey, Technical Safety Specialist, Blackwoods

Chemicals do not differentiate. From the tops of our heads to the soles of our feet, every single millimetre of us can be damaged beyond repair if we are not properly protected against harmful chemicals and substances. It can be diffi cult to determine which chemical coveralls are right for your workplace, that’s why protective standards are in place.

In the past few years, there have been several high-profi le accidents across Australia that have drawn attention to the issue of protection against harmful chemicals and substances. People have been seriously injured, and there have been fatalities. Tragically, as some accidents have shown, workers have been injured because they didn’t have access to suitable personal protective equipment (PPE), and/or weren’t properly guided on correct procedures concerning the handling of harmful substances, including during spills and in clean-up operations.

Protection from harmful chemicals and substances requires a complete head-to-toe solution. This includes the use of PPE that meets relative standards, is appropriate for all individual hazards in the workplace and fi ts correctly. PPE includes face masks, eyewear, footwear and coveralls. There are many different types of coveralls, and it can be diffi cult to determine which type is right for the type of work and workplace. However, there are protective standards in place.

There are various types of coveralls to protect workers from a broad range of chemicals. Most workers will never need to look further than a type 5/6 coverall, to protect them from dry chemical powder and liquid droplets. The best way to ensure the correct coverall is selected is to compare the chemicals being used against a coverall permeation guide. No two workplaces are the same, so it’s best to engage with a technical safety specialist to ensure that the appropriate protective coverall is identifi ed. A specialist can do the analysis of the chemicals being used with the coverall permeation data to select the correct coverall.

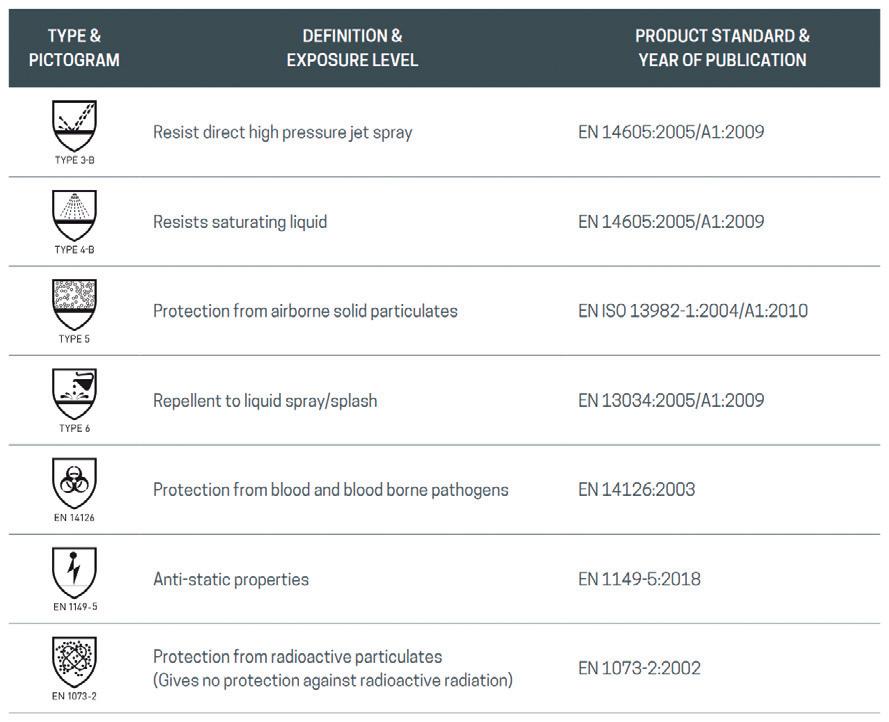

Protective coveralls undergo rigorous testing to ensure that they provide the correct level of protection. Different chemicals will ‘break through’ the coverall at different times, so it’s important to understand the permeation data and how they interact with specifi c environmental conditions. It’s the very reason why many overalls are disposable and should be replenished frequently. While there’s a lot of permeation data available, at the base level employers should familiarise themselves with the EN standards and types for guidance.

When selecting chemical coveralls for your workplace, ensure they have the EN standards marked on the garment. For example, a type 5/6 should display the pictograms for particles and liquid droplets along with EN 13034 and EN 13982. Some, but not all coveralls, will have antistatic properties, so it’s imperative that you check for the ‘lightning bolt’ pictogram, if you work in a hazardous electrical environment. By identifying these key features, you will ensure that workers and workplaces are kept safe from injury and even death.