5 minute read

PAN-DEMONIUM

Bonding patch panels without welding • Story and photography by Eric Geisert adhesives for massive bridge bearings, they also make some of the consumer-friendly adhesives you can readily purchase and use when repairing your old Volkswagen. The LORD website explains all of the types of adhesives they manufacture, and many have varied drying/work times, so you have to decide what’s best for you. But keep in mind: Nowadays these adhesives are so strong that you will end up tearing the metal around the joint before the sealed seam area will fail.

There are a few things in life that will always be true: The sun will come up in the east, Karmann Ghias will always have at least one nose dent, and if you want to do some rust repair on your pan, you’ve got to know how to weld.

Advertisement

VW Trends can’t help you with the perpetual sunrise or the eventuality of Ghia nose damage but, as it turns out, you DON’T actually need to know how to weld in order to repair rusted-out battery pans or some of the Swiss cheese that vintage VW floorpans seem to acquire over time.

That’s because over the past few decades there have been some enormous gains made in adhesives for the automotive aftermarket. If you’ve ever seen the goop between the inside of your new-car trunk lid and some internal bracing, that’s the stuff. Carmakers around the world have embraced its use for years and now you can, too.

GET THE STUFF: Parker LORD lord.com/fusor

The more you look into the science behind the goo, the more you realize what a vast application these products have. One U.S.-based global company, Parker LORD, has been at it for 90 years and, besides making aerospace and defense flight-control systems as well as rubber-to-substrate

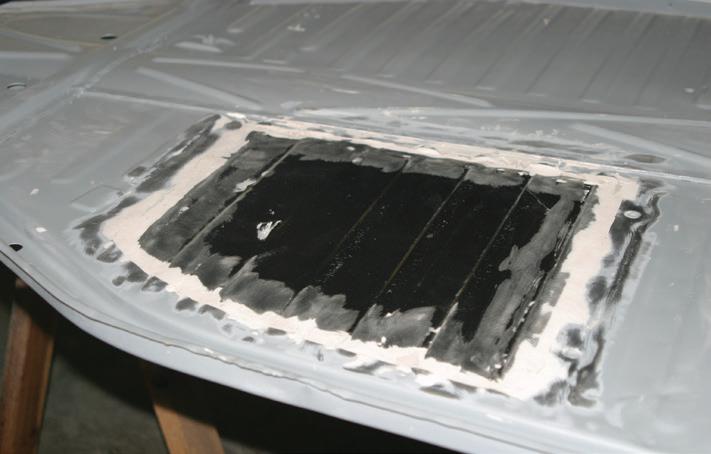

We used LORD’s Fusor line of epoxy adhesive (and their specialized tools to apply it) for a simple pan repair project with a chopped-down dune buggy pan, then covered it with a 3M-based rubberized undercoating (which doubles as sound deadener). It was just a one-day job, but using the product made us think: What else could be made if we bonded fabricated body panel sections together rather than welding or riveting them? Could we actually build an entire fabricated one-off aluminum body by gluing it together, like a giant Revell model? While we sit down to ponder that wild concept, check out how we did a quick pan repair with absolutely no welding.

15. With the replacement piece set in place, we added some weight to make sure the lip didn’t lift while the epoxy cured.

16. To blend the edges, we used some body filler. This is only cosmetic; the adhesive did the bonding.

By

In 1984, a mere 20 years after this 1964 11-window Type II rolled off the assembly line, Billy Ocean released his hit single “Caribbean Queen.” Daniel “Dan-O” Olortegui was just 18 when that song came out, but the impact must have lasted a lifetime. Dan-O’s got VWs in his blood: He grew up with them in his house. His dad owned ’69 and ’71 Squarebacks, while his mom got the honor of rolling a ’78 Landmark (a limited-edition late-Bay conversion. It’s estimated that fewer than a dozen are still around.) Dan-O’s dad taught him how to wrench on his VWs, and by age 13, Dan-O was changing oil and gapping spark plugs. But enough about the past, let’s check out Dan-O’s awesome ’64 Kombi!

Autohaus Autobody in Costa Mesa, California brought the exterior sheet metal back to showroom-perfect condition before laying down numerous coats of Caribbean Blue and white paint. Painting a vintage 11-window Type II is no small task, and you can only imagine the hours of prep work and color sanding it took to make the colors pop. Speaking of popping, all the pop-out windows, including the split windshield, are in perfect working order.

Inside, the aqua and white color scheme matches the exterior to perfection. Dan-O designed and installed the L-shaped seating, complete with matching seat belts for all passengers (safety first, people). He also did all the panels, front and rear, and finished everything off with a simple yet striking white shag carpet. Instead of a traditional headliner, Dan-O went with an authentic sarape blanket as a tribute to the previous owner’s daughter. Up front, standard gray charcoal carpeting covers the floorboards.

Nope, this conversation pit-style seating was not a factory option back in 1964. Dan-O designed and installed this unique seating configuration.

The two-tone lowback front seats with stitched-in VW logos look sharp, while a custom upholstered center console holds a nice cool beverage. The parcel shelf houses a cluster of gauges in a custom chrome diamond-plate. Oil pressure, oil temperature, and voltmeter keep Dan-O informed of the engine’s vitals, while a T-handle shifter makes gear selection a breeze. Opening the rear hatch of the Kombi reveals more aqua and white upholstery, this time accented with a custom Volkswagen license plate and another stitched VW emblem.

This 1964 Type II is as clean as they come! Everything flows together. From the safari split windshield to the quad-tip exhaust, Dan-O really nailed the look he was going for!

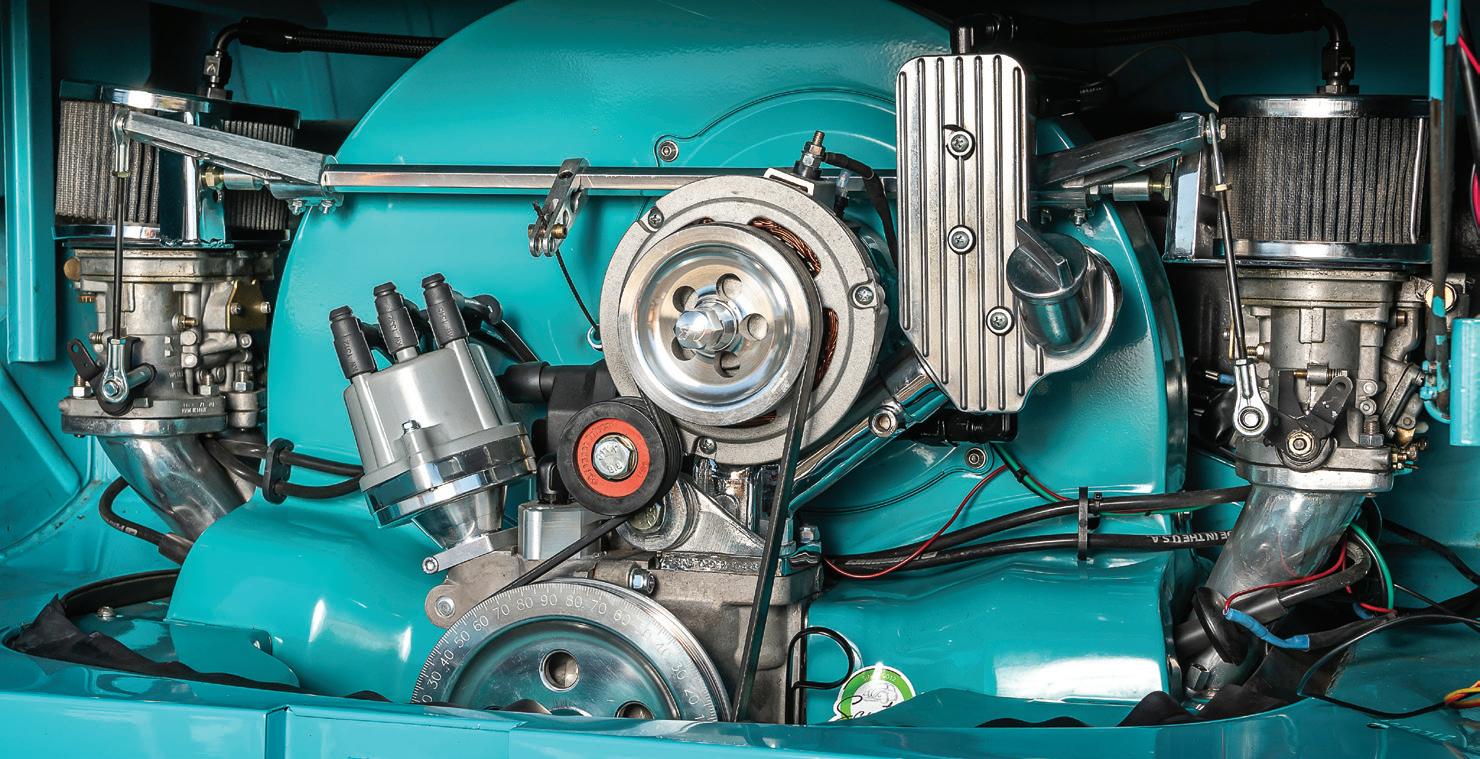

A little further down from the rear hatch beats the true heart of this Queen: a 2110cc Scat Volksracer powerhouse built by Josh Fullenwider of Sawtooth Aircooled in Jerome, Idaho. This fire-breathing flat four has all the right components for a super-street daily driver: 82mm Scat Chevy journal crank, 5.500 H-Beam rods, 90.5 AA Performance forged pistons and cylinders, Scat Super D swirl-polished heads with 42x37.5 valves, and tons of CB Performance components. Estimated horsepower is 150 — not too shabby for a daily driver.

The stance of Dan-O’s dream Queen is dropped via a Wide Five 4" adjustable front beam. A Wagenswest 5-lug disc brake conversion with a dual master cylinder helps this ultra-fast Bus come to a halt. Not content with stock wheels, Dan-O added a set of 15" Flat Four BRM replicas with 195/65/15 tires in the back

the build sPECS

EXTERIOR: Bodywork and paint (in Caribbean Blue and white) by Autohaus Autobody in Costa Mesa, CA. 7" halo headlights with amber turn-signal rings.

CHASSIS: 4" adjustable front end by Wide Five. Flat Four 15" BRM replica wheels. Tires: 165/45/15 front, 195/65/15 rear. Wilwood disc brake conversion by Wagenswest. Dual master cylinder.

ENGINE: VW magnesium case, 2110cc built by Josh Fullenwider of Sawtooth Aircooled. Scat 82mm crankshaft with Chevy journals. AA Performance 90.5mm forged pistons. Scat C35 camshaft. Scat Super D swirl-polished heads with 42x37.5 valves. Dual Weber 44 IDF carbs with Bugpack linkage. 8.5:1 compression ratio. CB Performance Magnaspark ignition. 4-tip high-flow exhaust. CB Performance stock-weight flywheel.

TRANSAXLE: 1968 VW Type 1 case.

INTERIOR: Aqua and white industrial vinyl. Upholstery work by George and Dan-O. Stock lowback seats. Custom door panels. GlowShift oil temp, oil pressure, and voltmeter gauges. Custombuilt L-shape “conversation pit” seating, interior mood and limo lighting, custom gauge cluster, Scat T-handle Bus shifter, surfer foot accelerator pedal, dice knobs.

and 165/45/15s in the front. Notice the rake this Bus has… looks like it’s going 120 standing still!

Dan-O Olortegui spent a year (plus a pile of cash and more man-hours than he can count) turning this Bus into the killer queen Kombi. No wonder he’s smiling now.

A lot of blood, sweat, and tears — not to mention a pile of cash — went into making Dan-O’s Caribbean Queen a showstopper. This badass Bus has won Best in Show twice and nabbed the coveted People’s Choice trophy three times. That’s a royalty trifecta that’s going to be hard to beat!