14 minute read

YOU AIN’T SEEN NOTHING YET!

BY JIM BUSHA

RUNNIN’ DOWN A DREAM

JIM LYONS OF PUNTA GORDA, FLORIDA, has long been enamored with aviation oddities, especially the warbird and vintage types.

“I can’t remember a time when I wasn’t fascinated with airplanes,” Jim said. “My father was a Marine in World War II, and my interest in World War II history starts there. After the war, my dad became a flight instructor and was hired on with Capital Airlines. We lived close enough to the local airport that I could ride my bike there and watch planes. And that’s how my addiction started.”

While in high school in the late 1970s, Jim began his journey to the sky. He was the “old-fashioned student pilot” — when he was not in the air taking lessons, he was on the ground pumping gas and washing airplanes to earn enough to go back up. Jim zoomed through his certificates and ratings, including private, instrument, commercial, instructor, and airline transport pilot. After flying freight in Navajos and Aerostars, Jim began a career with a major airline in 1987 and is currently flying a Boeing 777.

“My interest in the old planes continued to grow,” Jim said. “Both my Stearmans were basket cases when I bought them. During the rebuild of my first one, I learned how to find parts and where to look for them. The parts search was very rewarding and addicting. I also began trading substandard parts for better parts. This included instruments, light panels, switches, sheet metal, fire extinguisher, and first aid kit, just to name a few. My goal with this project was to make it as original as possible.

“I love the history of these World War II airplanes,” he said. “Some of the veterans that have ridden in my blue and yellow Stearman smiled a lot and shed a few tears. For a moment, they were young again, until they looked into the hind-view mirror. I wanted to make sure history was preserved, so that’s when I turned to Rob ‘Waldo’ Lock, proprietor of Waldo Wright’s Flying Service at the Winter Haven airport, to make that dream come true.”

WALK, DON’T RUN

At 6 feet, 9 inches tall, Rob Lock, like the airplanes he restores, stands out in a crowd.

“I really started getting involved in restoring old airplanes through my father, Bob — learning how to work on wood, metal, fabric, and all other things that go on an airplane — in the late ’90s,” Rob said. “I bought a couple of Travel Airs, and my father would do work on them while I was playing basketball in Europe. When I would come home for three months in the summer, I would fly my Stearman during the day and do fabric work with my dad in the afternoon. He would teach me how to do things.”

Rob claimed that because of his size, the Stearman was a natural fit for him.

“I’m a big guy,” he said. “I don’t fit in a lot of airplanes, but I always fit in the Stearman. I grew up with one and flew them quite a bit. I have about 3,000 hours in the Stearman now, and I have learned how to work on them. More importantly, I have learned to appreciate how easy they are to work on. When I’m working on other types and other models, you really appreciate this Stearman.”

When Rob was approached by Jim Lyons to restore his Stearman back to factory-fresh condition, Rob took a tactical approach on how he would accomplish the restoration, since he was literally knee-deep in another restoration.

“About halfway through another customer’s project, I began receiving parts to Jim Lyons’ project,” Rob said. “Jim approached me years before and said, ‘I’m restoring the Stearman.’ Jim asked me, ‘Can I have you cover components to it?’ I said yeah. So the airplane would come to me in pieces. He brought me the horizontal stabilizer, so I would tear that apart and prime it and put it back together. And then I’d cover it. Then the elevators would come in, and I would do the same to that. He had somebody else cover the rudder and fin. But the big day came when the wings came in. They are incredibly labor intensive. It takes a lot of time, and a lot of money, and it’s really an important part of the process. To keep this project moving, I choose Dave Groh and his shop, Yesteryear Aviation in Mason, Michigan, to build all our wings. I think they’re the best in the business, personally. I’ve ordered three sets of wings from them over the years. They take about a year to build, so you have to be patient for them, but when you get them, they’re like furniture. I mean they’re gorgeous.”

Turn The Page

By the time Jim’s wings were done, Rob retrieved them to begin the covering process. Rob’s choice of covering material is Poly Fiber.

“It’s Chevy versus Ford stuff,” Rob said. “There’s many different options. Poly Fiber’s been around since the ’60s. It lasts for a long time. Some people complain about the smell of Poly Fiber. I like the smell. To me, it smells like it’s progress. There’s so much work that is involved in these covering processes; I don’t want to have to re-cover an airplane in 15 years. It’s 1,000 hours to do a Stearman. So I want to cover it one time, and then I don’t want it coming back into my shop ever again. So that’s why I choose Poly Fiber.”

While the wings were being covered, Jim’s fuselage was being worked on at Kenny and Danny Rutten’s shop in northern Florida.

“They had overhauled the frame and built it up, and it was a long ways along,” Rob said. “It was not done, however. Jim got to a certain point, and he had to make a decision, and it was his to make. Do you take the fragile stuff that I had in my shop, the wings that were already covered, and risk damaging them in transit? Or do you take the stuff that is not really going to get hurt — a frame, landing gear, all the metal parts — you put that in boxes, and do you bring that stuff to where the wings are?”

Jim ultimately chose the second option and delivered all the metal parts and frame to Rob.

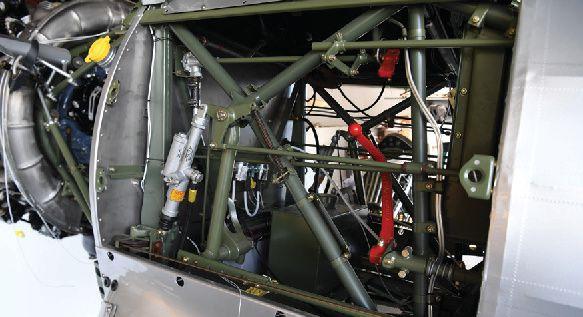

“I walked around his fuselage for seven or eight months,” Rob said. “I looked at it every single day, and I’m like, ‘Wow, this is going to be kind of challenging.’ Because Jim had many artifacts he wanted on that plane. I mean, we’re talking, if there was an option that Boeing offered, he wanted it in that plane.”

Some of these examples include a signal light on the turtledeck. There’s a small box that goes in the rear cockpit, and you can use that signal light for Morse code, a very rare item. Another item is the oil dilution system, which Jim found parts for. Mainly used in cold-weather flying, once the cadets were done flying the Stearman for the day and ready to shut it down, you flip the switch, and it puts fuel from the fuel system into the oil system. The book called for running it for 30 seconds, and it dilutes the oil that’s gone into the engine. When the next cadet started it the next morning, the oil’s thin and your oil pressure won’t be 120 psi when you start.

“And that’s what these things had, that was an option,” Rob said. “No one is flying their Stearman when it’s below 30 degrees, or whatever, 40 degrees. This one can be flown. You can do anything you want with it.

“I had to figure out how it worked and wire it all in,” he said. “It is operational on that plane. Jim wanted a smoke system in, so that was installed, along with a Garmin avionics package. He decided against the strobe lights. But he wanted the airplane to be able to be flown in today’s airspace, so it’s got ADS-B In and Out. The list goes on and on of all the things that were installed in the Stearman.”

Handle With Care

Restoring a Stearman, according to Rob, can be like the movie Ground Hog Day, where every day is the same and you do not feel like you took a step forward.

“Every morning, when I’m lying in bed, I’m like, ‘Okay, what’s my game plan for today?’” Rob said. “I kind of come up with a mental note — ‘I’m going to work on this airplane, and we’re going to get A, B, C, and D done today.’ And it’s kind of been working for me. So when I go to work, I have a plan of attack. Unfortunately, many of the times you have to put stuff on the airplane and make sure it fits, and then you have to take it off; then you have to prime it, paint it, and you have to put it back on. When we started covering Jim’s fuselage and the wiring was done, and you start looking at it and you are like, ‘Wow, this is a nice plane.’”

From the time Jim started the restoration on his Stearman until the time the airplane flew again, 16 years had passed. In that time, Jim had accumulated all sorts of what he calls “oddball parts.”

“Jim is very knowledgeable about the Stearman,” Rob said. “So he would buy these parts, and he’d just store them, and then he would bring them to me.”

These include a very low-time McCauley prop he bought 20 years ago and put underneath his bed. Besides radio and navigation equipment, Jim did not want modern stuff in the airplane, because he wanted originality, to a certain extent.

“There’s no Airwolf oil filter in it,” Rob said. “It has the screen, as it was original. There is no bracket air filter. It has the original air filter in it. The whole front of the airplane is as original as we can make it. I mean, you go back behind the firewall wall — he wanted a smoke system in it. We put in an original E-80 electric starter. And it does have a Jasco alternator system in it as well.

BOEING-STEARMAN PT-17/N2S

NUMBER OF ENGINES: 1

ENGINE MAKE: CONTINENTAL

ENGINE MODEL: W670

ENGINE POWER: 220 HP

RECORDED TBO: 1,500 HOURS

STANDARD FUEL: 46 GALLONS

MAX FUEL: 46 GALLONS

75 PERCENT CRUISE: 124 MPH/107 KNOTS

STALL: 52 MPH/45 KNOTS

RANGE: 505 MILES/438 NM

SERVICE CEILING: 11,200 FEET

RATE OF CLIMB: 840 FPM

WINGSPAN: 32.33 FEET

LENGTH: 24.6 FEET

HEIGHT: 8.85 FEET

EMPTY WEIGHT: 1,936 POUNDS

GROSS WEIGHT: 2,717 POUNDS

“To the point where the brakes, most people say, ‘Got to put those Red Line brakes on it. Got to put disc brakes on it,’ he said. “And I have Red Lines on my Stearman, and they are really good brakes. But the original Hayes brakes are really good brakes as well. And the only problem with the original brakes wasn’t the brakes; it was the master cylinders. So he got modified original master cylinders. They’re called Gid Townsend master cylinders. The originals were cantankerous; they would lock up and weren’t very good, and they’d fail. So Gid modified them and bored out the reservoir and he sleeved them, and it’s all STC’d. So it’s got the original master cylinders.”

Jim found two original map cases, one in the rear seat and one in the baggage compartment. Jim’s Stearman has the enlarged baggage compartment, along with the heavy-duty Dusters & Sprayers tail wheel.

“After 16 years, he didn’t skimp on anything; he wanted the best one that he could have restored,” Rob said. “This airplane came to me with all the instruments done. But to the point where, originally, there’s different panels for the Stearman. There’s PT-13 panels. There’s PT-17 panels. There’s N2S-3 panels. There’s N2S-4 panels. There’s all different types of panels. I think there were seven different panel layouts. And each model had a specific panel layout. And so some instruments have a little cutout in the dials; some don’t.

“So when you get these panels, there’s these holes, and the one might have a little dog up on the top or a little cutout on the bottom. And then let’s just say you’re putting an instrument in that hole that doesn’t have that, so you have these holes that stand out like a sore thumb. He had new panels made, and the holes were cut to fit his instruments. So all the instruments match in color; they’re all overhauled by Keystone. All the panels were made for the instruments. And so there’s no holes that are in the panel that shouldn’t be there. New windscreens, everything on the airplane was new. I give Jim credit, because he was involved in the project.”

Looks That Kill

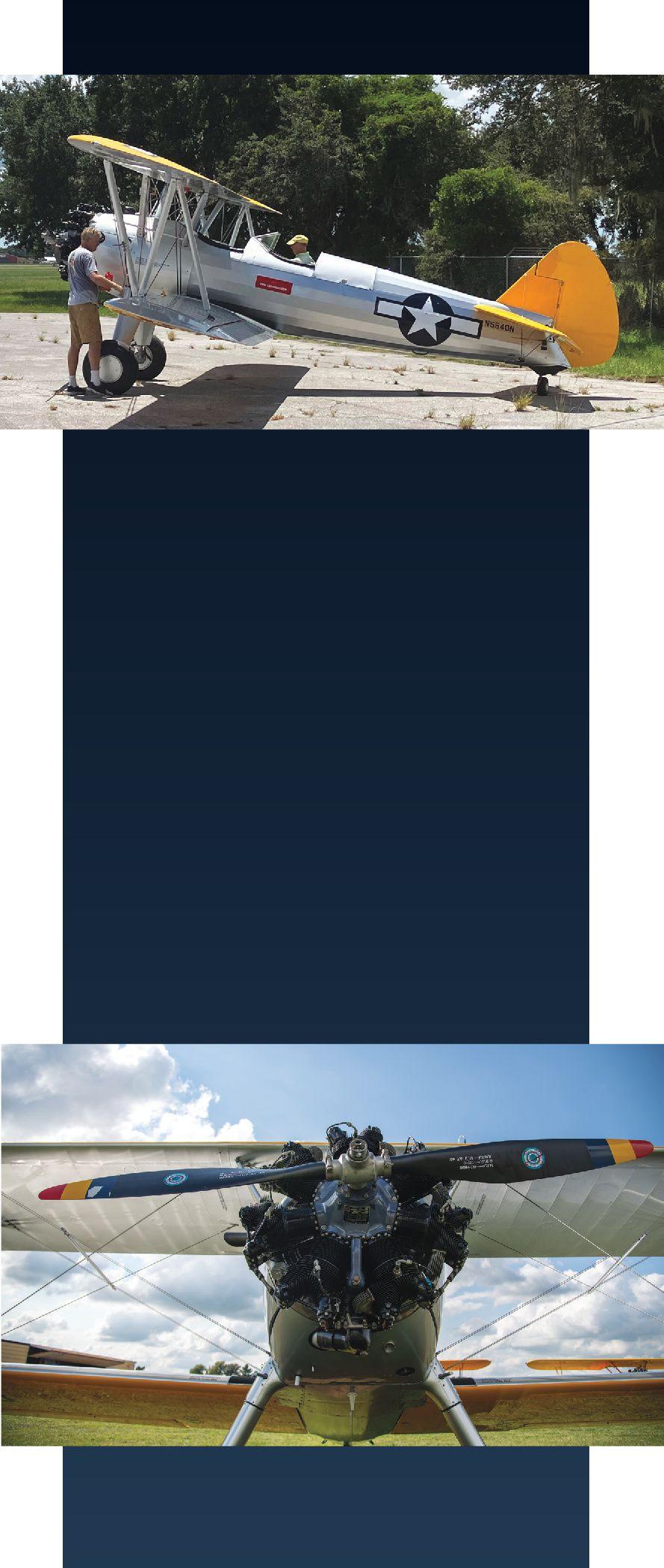

When it came time to choose the final paint scheme, Jim had already decided that one a long time ago.

“Jim had seen Fred Wright’s yellow and silver Stearman at Galesburg, 10 years ago, or longer,” Rob said. “He saw that airplane there and did some research, and that was actually a legitimate paint scheme. It wasn’t just in somebody’s head. And it was a unique paint scheme that you didn’t see very often. So he decided on that when he saw that airplane. And he stuck to his guns, because the world has enough blue and yellow ones. The world has enough yellow Stearmans. It’s like these oddball colors that are unique and military and it’s historically accurate. That makes it kind of fun.”

Rob didn’t have to look far to find a qualified painter to attack the yellow and silver scheme.

“I have a guy at our airport; his name is Neal Butterworth. He owns Heart of Florida Aviation,” he said. “I took the airplane through all the STC steps of Poly Fiber. You have to put Poly-Tone on it. And then once you do that, you can put some more modern coatings on it that looks better than the factory urethane paint. And you get to a certain point where originality crosses a boundary. You want it to be original, but were they glossy in World War II? No, but do you want it to show well? Yes. Do you kind of look the other way with the paint? Yes, for a lot of the customers.”

Jim wanted his Stearman to be glossy. Neal shoots PPG paint. He likes it, and he knows how to spray it. So that’s the paint that Jim and Neal chose to put on this airplane. With the Stearman, all the fabric parts were painted white Poly-Tone.

“You do that because when you’re going to be painting yellow, if you put yellow over silver, the yellow’s going to come out dull. It’s going to not be a true yellow,” Rob said. “The silver color of the Poly-Spray will alter the final yellow color, which you don’t want. So you spray two coats of white Poly-Tone on the fabric surfaces and give it a good base. And you want it all white.

“So when you spray yellow on it, you’ll use actually less yellow than you would if you were spraying over silver,” he said. “And it’s going to make the color pop. So we just do that with the whole airplane. Even the silver that went on the fuselage; I painted all that white. You have to use the PolyBrush, and you got to use the Poly-Spray, then you got to use the Poly-Tone. You have to do that to satisfy the STC or it’s illegal. But over the Poly-Tone, you can spray the urethane paint.

“So everything has to be in yellow,” Rob said. “Now, when you start doing the metal panels, on Stearmans, the inside of the airplane’s all OD [olive drab] green. So you paint the panel, you prime the panel with green epoxy primer, and then you have to mask off the inside and spray the outside white. And then it goes in for final paint. So it’s a lot of labor. So when you start dealing with Stearmans, I mean, the owner has to understand the steps and the process and the amount of work and time it takes, because you can’t rush that stuff. And it’s expensive. It gets to be expensive. But you get an airplane that looks like Jim’s at the end, and that makes it all worthwhile.”

When the Stearman came back from the paint shop and Rob started putting the center section on it and then the engine on it, it started taking up more room in his hangar.

“And then the tail goes on it,” Rob said. “And then at that point, the wings were in the wing rack all painted, and the star and the bars are on it, and then it’s like, ‘Wow, it’s kind of starting to get exciting, because this thing’s about three months away from flying.’

“The cool part I thought is, when I put it all together, then it went back over to the paint shop, and then they put all the stencils on it. Neal put the insignias on both sides of the fuselage. When it came back, I would just go out there, sit in front of it, and stare at it, because it was shiny, in your face, and it was a beautiful plane. In addition, it was like, ‘Wow, this thing’s come a long ways.’ It was born in that hangar, which was kind of cool.”

The BC400 Alternator system is now FAA-approved for Piper J-5C, PA-11, PA-12, PA-14, PA-16, PA-18, PA-20, and PA-22 aircraft. Includes brackets for Wide- or Narrow-deck engines ... with NO change of oil cooler location required!

Take Me Home

Rob pushed hard to finish that Stearman so it could fly on August 28, 2022. That date to most people is insignificant. For some, it’s just another day. But for this airplane, it was a special anniversary.

“On the 28th of August 1943, this airplane flew for the first time,” Rob said. “When I found that out, I was like, ‘We’re going to push for this date.’ And it turned out that was a good weather day, the airplane was ready to fly, and Jim flew his restored Stearman for the first time. A few days later, Jim asked me and my girlfriend, Jill, to fly the airplane ‘home’ to the Stearman gathering in Galesburg. When we left for Galesburg, it had two and a half hours on it, which was great.”

Jim flew his yellow and blue Stearman from Punta Gorda to Winter Haven.

“We met him at the gas pump and we left, and I ran that thing hard all the way up there, because the engine needed to be broken in,” Rob said. “It’s redlined at 2075. So I would run it at 1900 rpm, then I’d run it at 1950, then I’d bring it back to 1875, 1850. So you’d run it in different power ranges, because the different power settings are going to give you different cylinder pressure, and you want the rings pushed up against the side of the cylinder so they’re rubbing and they’re breaking in.”

At Galesburg 2022, Jim’s Stearman received a lot of looks and attention.

“I was so relieved, because after all that work and all the time Jim had put into creating this historic time capsule, it won the Yellow Peril Award,” Rob said. “So it is bittersweet as a mechanic. I learned a lot on this project, because I had to, because it was challenging at times. And everything had to be perfect on his plane, because the airplane was built for a specific reason. It was built to kind of do what it did at Galesburg. It was built to win an award there. And he pulled out all the stops for this plane to be done, and it did it, which was great. I have a saying I remind Jill of a lot: ‘The best two days are when it comes in and when it flies away.’ It is true.

“Before doing restorations, I was always under the impression that ‘I don’t want to work on somebody else’s plane and build it, because you get attached to it and then it leaves you,’” he said. “And then you’re like, ‘Man, but it’s mine; it’s not yours.’ But I don’t feel that way. Because I learned a lot on this Stearman, and look forward to the next one.”