3 minute read

Manufacturing Day 2022: Looking to the Future

Manufacturing Day 2022: Looking to the Future

iMpact Utah

National Manufacturing Day, an annual event that takes place on the first Friday of every October, is an occasion during which manufacturers open their doors, showcase the potential of modern manufacturing, and foster interest in manufacturing careers.

But why the need to generate interest in manufacturing? There is, after all, ample opportunity for high-paying jobs—according to the Bureau of Economic Analysis and Bureau of Labor Statistics, the average annual income of U.S. manufacturing employees in 2020 was $92,832. Moreover, there are 4 million manufacturing jobs that need to be filled between now and 2030 according to The Manufacturing Institute and Deloitte.

Despite these promising figures, more than half of those jobs could be left unfilled due to skill gaps, misperceptions about modern manufacturing, and the retirement of baby boomers.

How can the manufacturing industry grow its labor force and prepare them for work with advanced technologies? We can begin by exploring future trends in manufacturing and the exciting, high-paying career paths they will foster.

Digital Transformation

Potential Careers: Robot Teaming Coordinator, Digital Offering Manager

By utilizing 4.0 digital technologies like AI and machine learning, augmented reality, and the IIOT, Digital Twin Engineers can help manufacturers handle marketplace disruptions, like the ones experienced during the pandemic. For many companies in 2020, access to labor and workspace was significantly reduced. Those who were best equipped to weather the disruptions had the digital infrastructure needed to keep their operations running. That infrastructure includes 5G networks, robotics, computers, and machine learning—all parts of the digital transformation we’re seeing in the manufacturing sector.

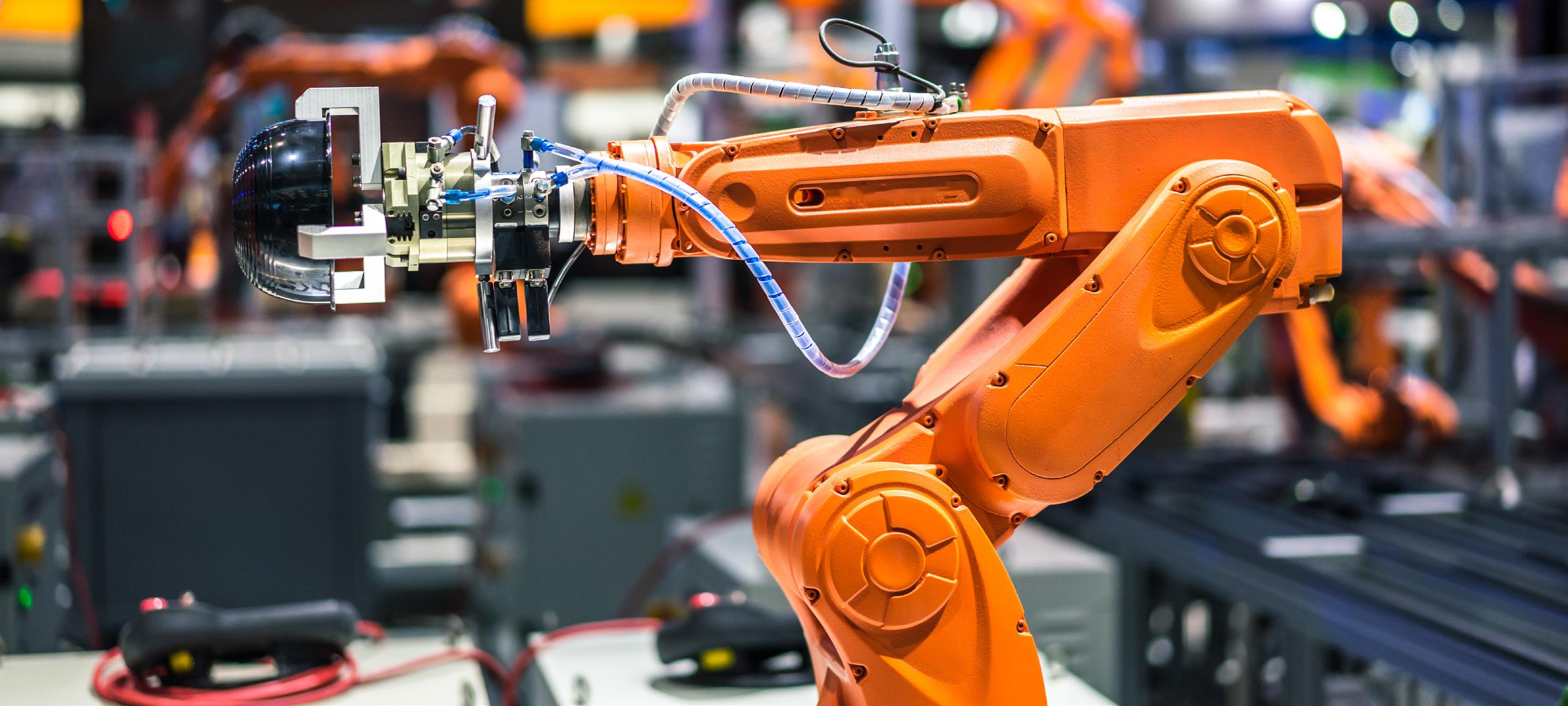

Automation

Potential Careers: Smart QA Manager, Drone Data Coordinator, Smart Scheduler

As technology continues to advance, the cost of automation is decreasing, allowing more manufacturers to leverage the power of automation to increase productivity, precision, and efficiency. As manufacturers look to the future, they should consider prioritizing automation to stay competitive. Of course, not all processes should be automated-that decision should be driven by data and your company's specific goals.

Industrial Internet of Things (IIOT) & Digital Twins

Potential Careers: Digital Twin Engineer, Smart Factory Manager, Predictive Supply Network Analyst

Much of the power behind automation is driven by IIOT and digital twins. The IIOT is made up of interconnected devices within industrial/manufacturing settings that are used to collect data on how things are performing. With this data, manufacturers can better maintain their machines, reduce machine downtime, and leverage predictive maintenance.

A digital twin is a virtual representation of a real-world process or system. Using AI and machine learning, digital twins can be used for system simulations, integration, testing, monitoring, and maintenance. With a digital twin, manufacturers can digitally reproduce machinery, factory layouts, products, and entire supply chains, making it an incredible aid to lean companies.

Visualizing a future in which our businesses are transformed by technology opens up promising career paths that will need skilled workers. Manufacturing Day and the whole month of October is an opportunity to inspire students and reach out to educators by offering workshop tours or internships. Be sure to use the #MFGDay22 #CreatorsWanted hashtags to share your manufacturing story on social media.

If you’re ready to transform your company and grow your team, visit www.impactutah.org to learn more.